Overview

The article highlights the significant benefits of auto titration for pharmaceutical laboratories, capturing attention with its emphasis on:

- Enhanced accuracy

- Reduced human error

- Time savings

- Cost-effectiveness

- Scalability

These advantages are not merely theoretical; evidence demonstrates that automated titration systems markedly improve measurement precision, streamline workflows, and lower operational costs. Such improvements are critical, as they ultimately lead to better compliance with industry standards and enhanced patient outcomes. By adopting automated solutions, laboratories can ensure a higher level of efficiency and reliability in their operations, paving the way for advancements in pharmaceutical quality and safety.

Introduction

The pharmaceutical industry is increasingly leaning on automation to enhance laboratory efficiency and accuracy. Auto titration systems emerge as a pivotal advancement in this realm. These sophisticated devices not only streamline moisture analysis but also ensure compliance with stringent regulatory standards, ultimately safeguarding product integrity.

However, as laboratories embrace these technologies, a critical question arises: how can facilities fully leverage the benefits of automated titration while minimizing the challenges associated with implementation and training?

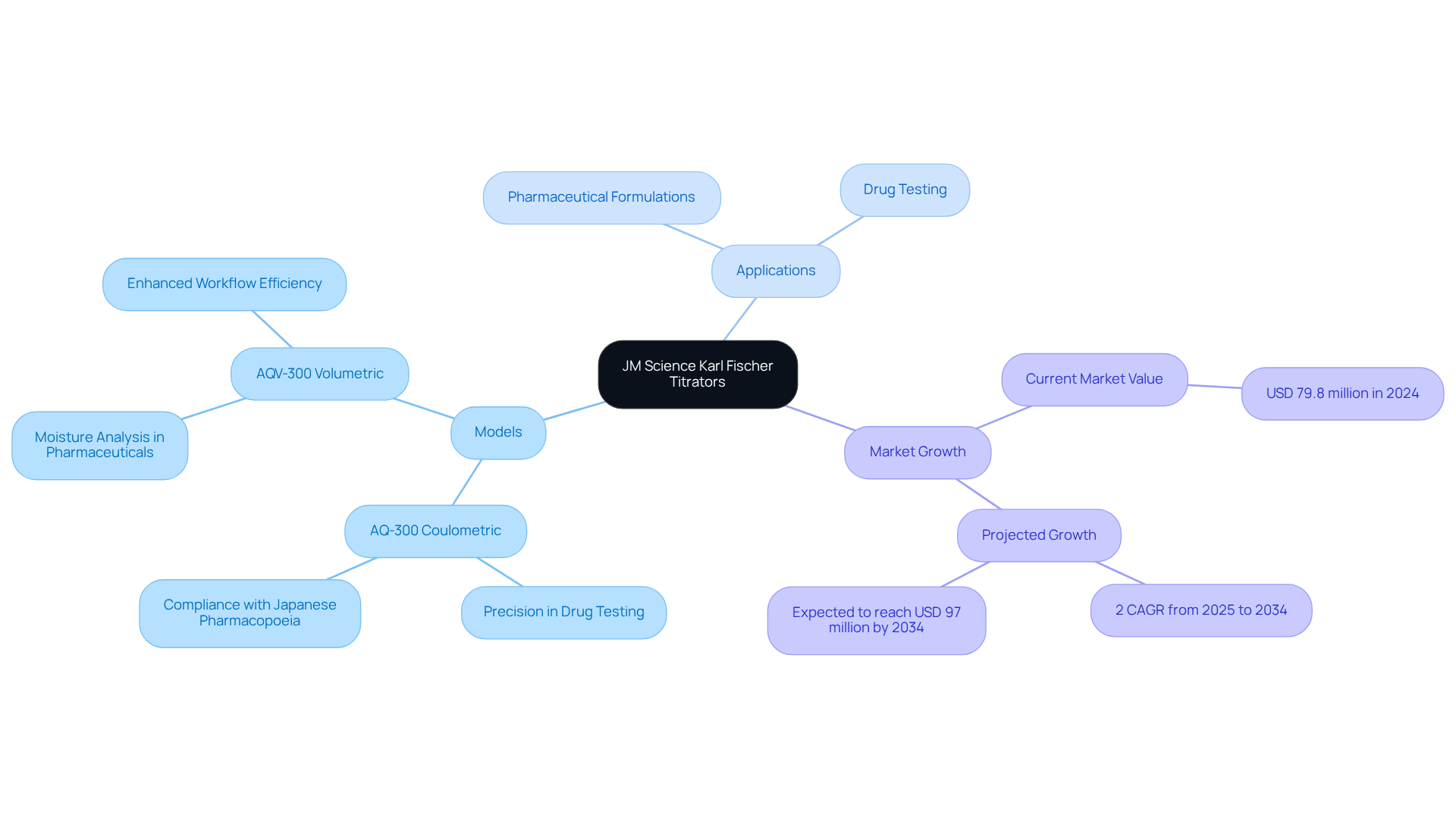

JM Science Karl Fischer Titrators: Precision in Moisture Analysis

JM Science's Karl Fischer titrators, specifically the AQ-300 Coulometric and AQV-300 Volumetric models, are meticulously engineered for precise moisture analysis—an essential component in pharmaceutical formulations. By employing the Karl Fischer method, these auto titration devices are celebrated for their exceptional accuracy in determining water content, which is crucial for upholding the integrity of drug products. Notably, the AQ-300 Coulometric Karl Fischer Titrator is recognized for its application in drug and medicine testing, ensuring adherence to the Japanese Pharmacopoeia with its auto titration capabilities.

In 2024, the U.S. Karl Fischer titrators industry generated USD 79.8 million and is projected to experience a growth rate of 2% CAGR from 2025 to 2034, ultimately reaching USD 97 million by 2034. Recent technological advancements in moisture analysis, highlighted by the launch of the EVA Volumetric Karl Fischer Titrator by Mettler Toledo, have significantly enhanced the capabilities of these instruments. This progress empowers facilities to effectively meet stringent regulatory standards.

By employing these sophisticated measurement setups, facilities can not only ensure compliance with industry standards but also enhance product reliability and safety, leading to improved patient outcomes. The accurate determination of water content is paramount for understanding the performance of drug substances and products, directly influencing drug content accuracy.

Increased Efficiency: Streamline Processes with Automated Titration Systems

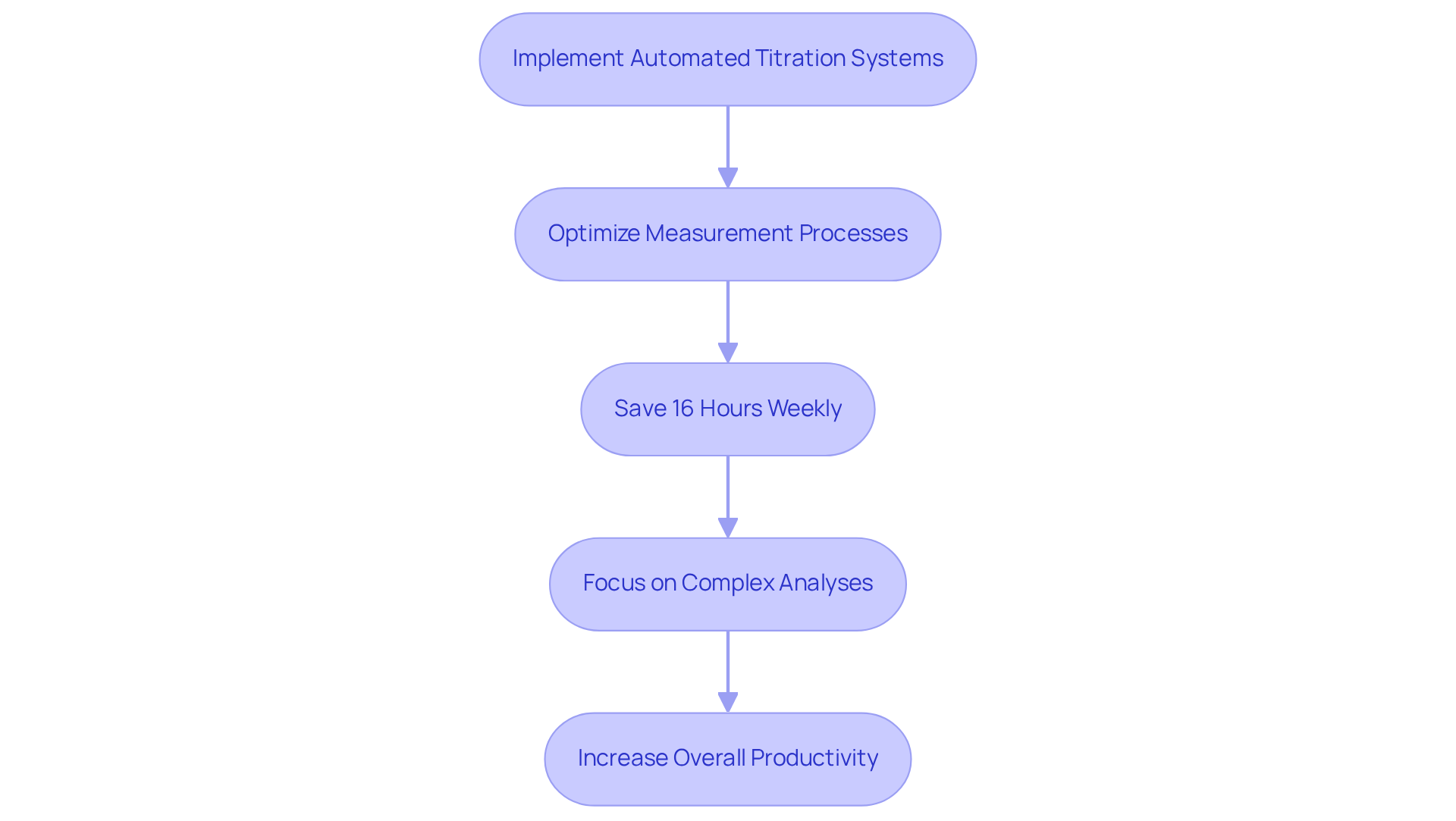

Automated dosing systems significantly enhance laboratory efficiency by optimizing measurement processes. JM Science Inc.'s premium analyzers, including Karl Fischer models and potentiometric devices, are engineered to perform multiple analyses simultaneously, which drastically reduces evaluation time.

For example, automation can save approximately 16 hours weekly through data transfer automation, enabling personnel to concentrate on more complex analyses. This strategic shift not only elevates overall productivity but also increases throughput in pharmaceutical labs, allowing them to meet the stringent timelines that are critical for life-saving product development.

Lab managers have observed that automation has revolutionized their workflows, with one remarking, 'The time savings are substantial.' By automating routine tasks with JM Science's advanced measurement solutions, research facilities can achieve a more efficient operation, ultimately leading to improved outcomes in research and development.

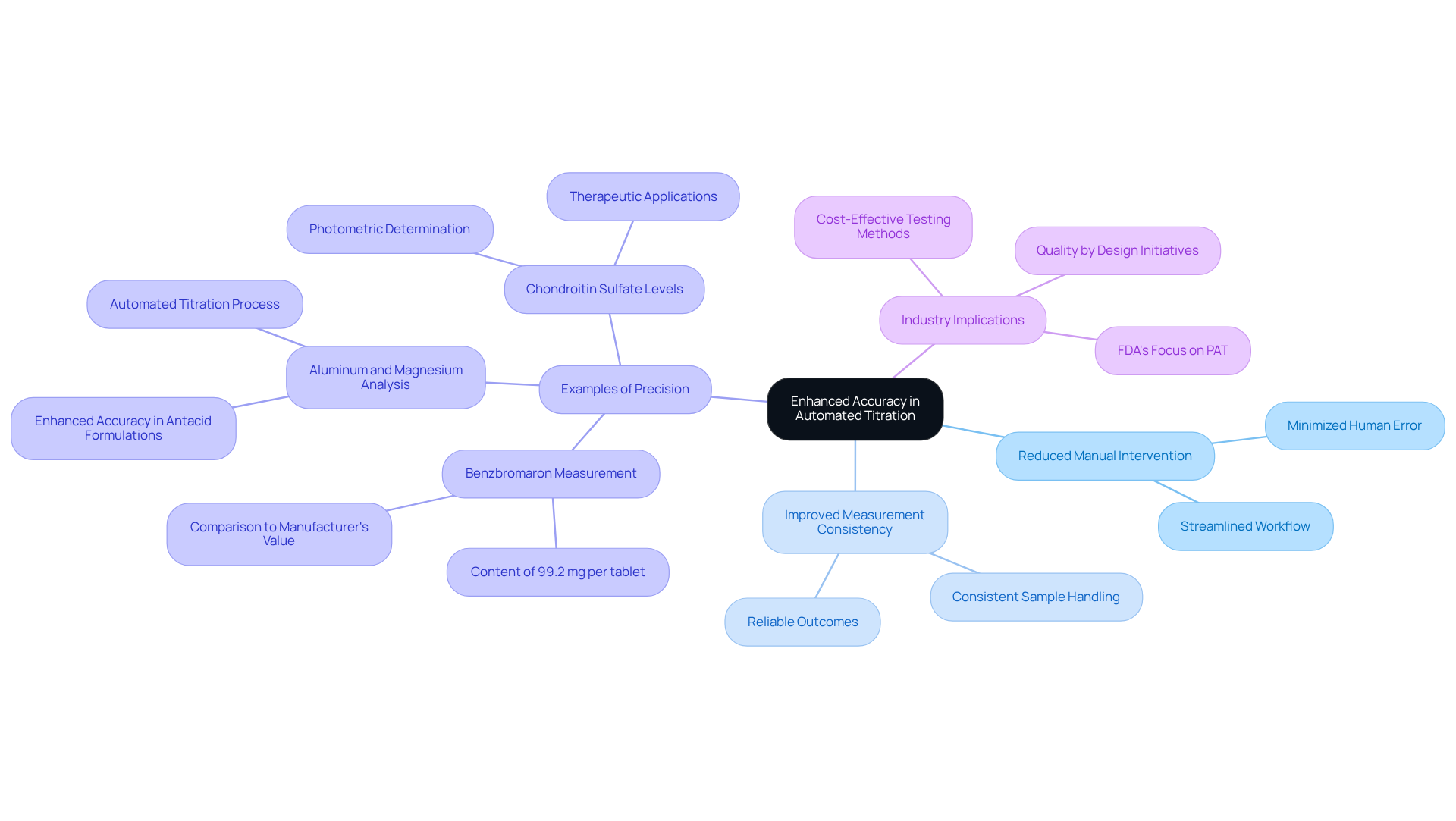

Enhanced Accuracy: Achieve Reliable Results with Automated Titration

Automated measurement devices from JM Science Inc. are meticulously designed to enhance accuracy, a critical factor in pharmaceutical laboratories. By significantly reducing manual intervention, these systems mitigate variability and guarantee consistent results. This precision is essential, as even minor discrepancies in measurements can lead to serious implications for product safety and efficacy. For instance, mechanized potentiometric analysis has been shown to improve precision and effectiveness in evaluating active pharmaceutical ingredients (APIs) like benzbromaron, achieving a content of 99.2 mg per tablet, closely aligning with the manufacturer's declared value of 100 mg. This method not only simplifies the analysis procedure but also reduces the likelihood of human errors, a common concern in manual techniques.

Moreover, the transition to automated processes fosters enhanced consistency in measurement outcomes. Automated systems have exhibited superior performance in complex analyses, such as determining aluminum and magnesium in antacid formulations, where traditional methods may struggle. The FDA's focus on process analytical technology (PAT) highlights the industry's movement towards more efficient and cost-effective testing methods, reinforcing the significance of automation in attaining precise measurements.

Kerri-Ann Blake, a product specialist at JM Science, notes that potentiometric analysis has emerged as a formidable method for assessing active ingredients and excipients in pharmaceuticals. She emphasizes that each sample is treated consistently, thereby improving the precision of determinations. This consistency streamlines processes and delivers reliable outcomes, positioning auto titration as an essential tool in modern pharmaceutical laboratories. Furthermore, JM Science's offerings include HPLC solutions and Karl Fischer reagents, which enhance the mechanized measuring devices and boost overall laboratory efficiency. The accurate assessment of chondroitin sulfate levels through mechanized techniques illustrates the effectiveness of these methods in therapeutic applications. Additionally, the direct method for evaluating zirconium concentration in pharmaceutical formulations bolsters the reliability of automated analysis techniques. Ultimately, the integration of these advanced technologies not only improves measurement accuracy but also contributes to enhanced efficiency and safety in pharmaceutical testing.

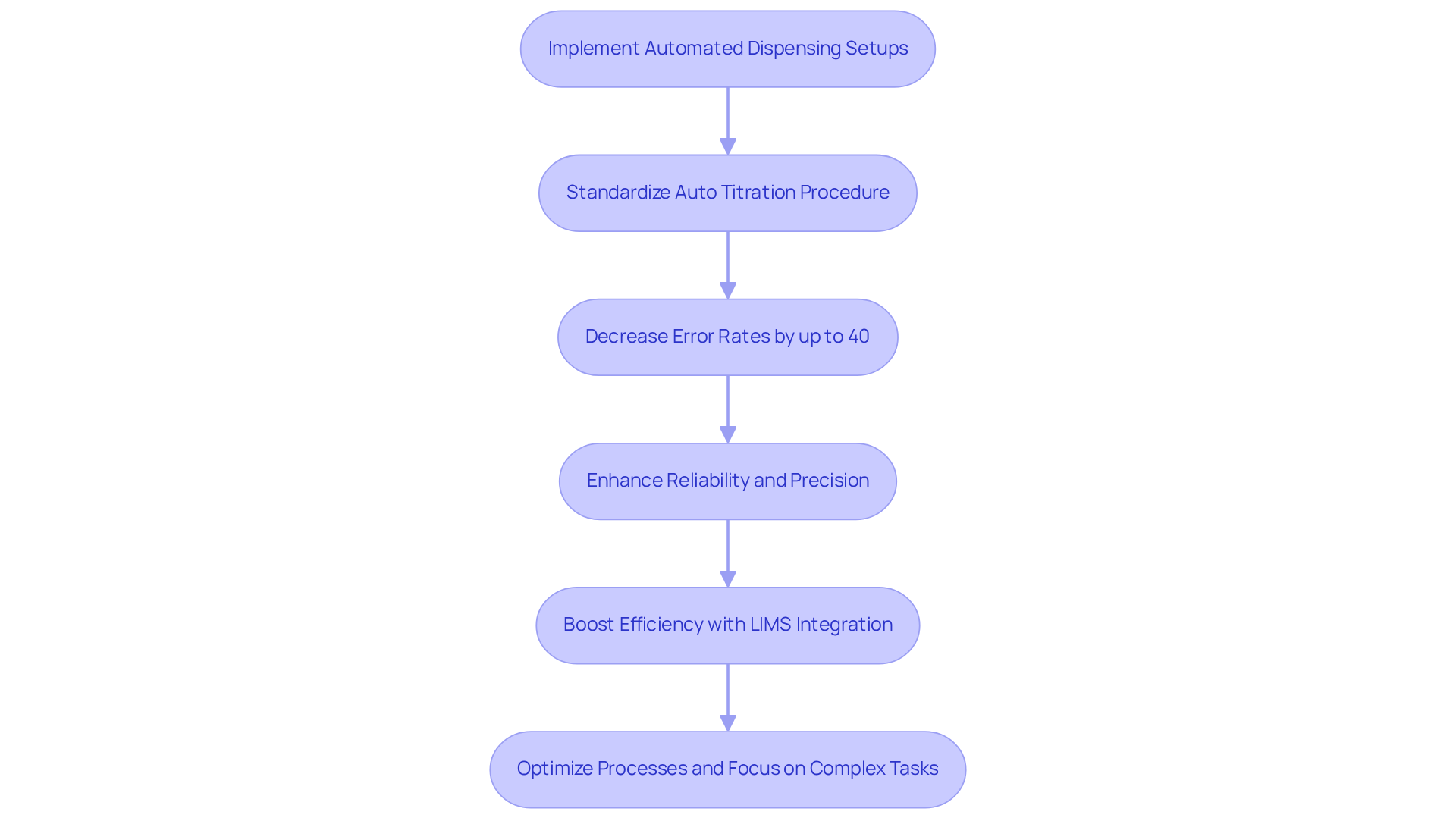

Reduced Human Error: Minimize Mistakes with Automated Systems

Automated dispensing setups significantly reduce human errors, a common issue in manual processes due to miscalculations and varying techniques. By standardizing the auto titration procedure, these systems ensure that each operation is conducted under uniform conditions, thereby enhancing both the reliability and precision of results. JM Science Inc.'s premium titrators, including Karl Fischer titrators and potentiometric titrators, are engineered to deliver high precision in chemical analysis, making them particularly suitable for pharmaceutical laboratories.

Research indicates that automated technologies can decrease error rates by up to 40%, providing consistently reliable outcomes that are crucial in pharmaceutical settings. Furthermore, the integration of information management platforms (LIMS) boosts efficiency through data integration and real-time monitoring, further streamlining laboratory workflows.

Laboratory professionals have observed that automation not only optimizes processes but also enables technicians to concentrate on more complex tasks, enhancing overall productivity. As Ane Bordagaray noted, 'Both methods are precise, accurate, easy to use and fast, making them suitable for quality control processes and real-time monitoring.'

This shift towards automation, particularly through auto titration, not only elevates the precision of chemical analysis but also aligns with the industry's demand for higher quality standards in testing practices. Additionally, it contributes to environmental sustainability by minimizing reagent consumption and waste.

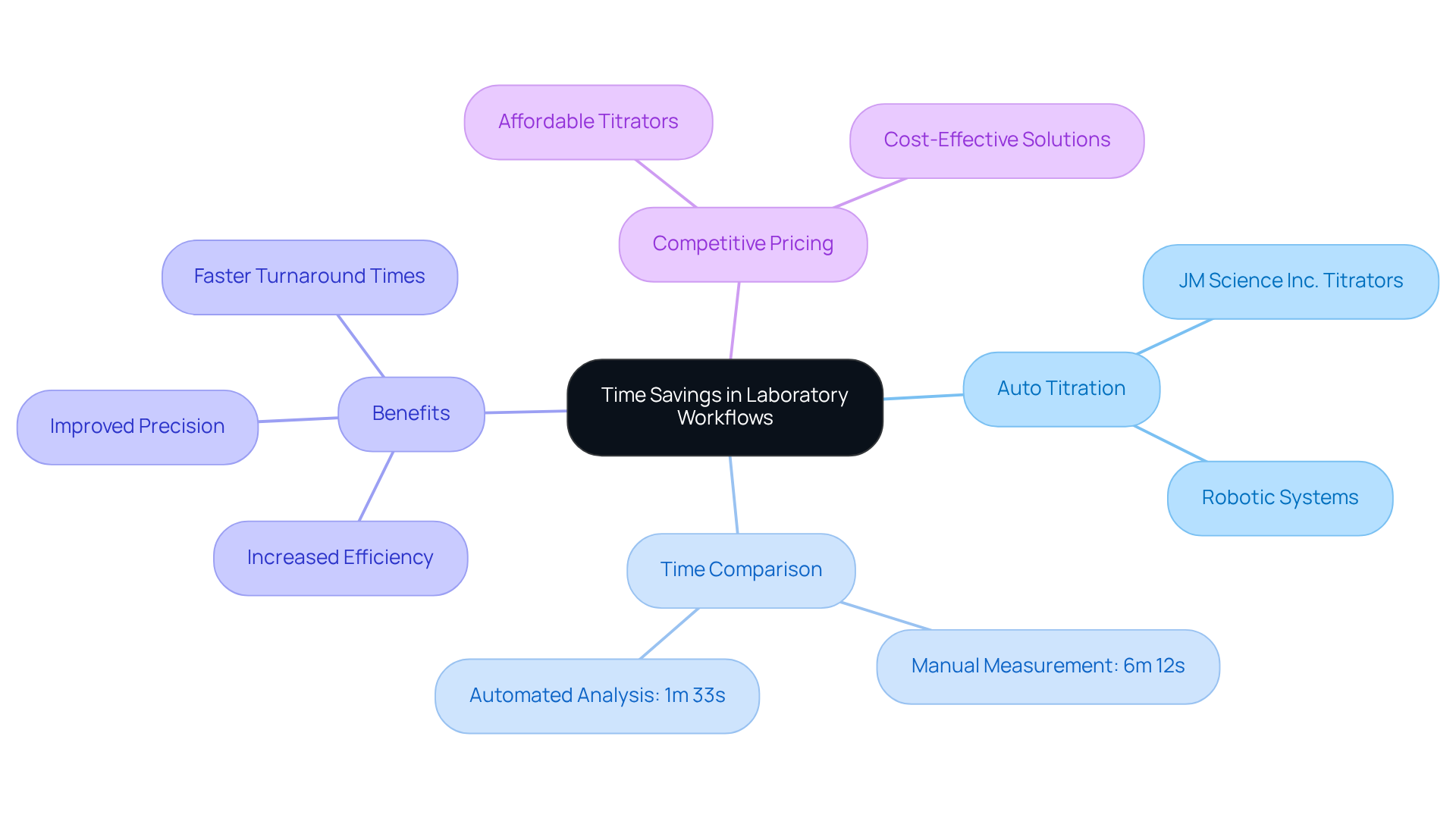

Time Savings: Accelerate Laboratory Workflows with Automation

Auto titration in automated dosing setups significantly enhances laboratory workflows by drastically reducing the time needed for measurement processes. JM Science Inc.'s premium titrators are engineered for auto titration, allowing them to conduct multiple analyses simultaneously and automate repetitive tasks, resulting in quicker turnaround times for results.

For instance, while manual measurement averages 6 minutes and 12 seconds per analysis, JM Science's robotic systems streamline this process, allowing a lab analyst's involvement to be reduced to approximately 1 minute and 33 seconds per mechanized analysis. This level of efficiency is essential in pharmaceutical labs, where timely data is crucial for informed decision-making and project advancement.

Furthermore, JM Science offers competitive pricing on their titrators, HPLC solutions, and Karl Fischer reagents, making them an attractive option for facilities aiming to enhance their operations. By integrating auto titration into their workflows, facilities can not only improve precision—minimizing subjective errors associated with manual measurement—but also accelerate processes, ultimately enhancing efficiency and adaptability in a fast-paced environment.

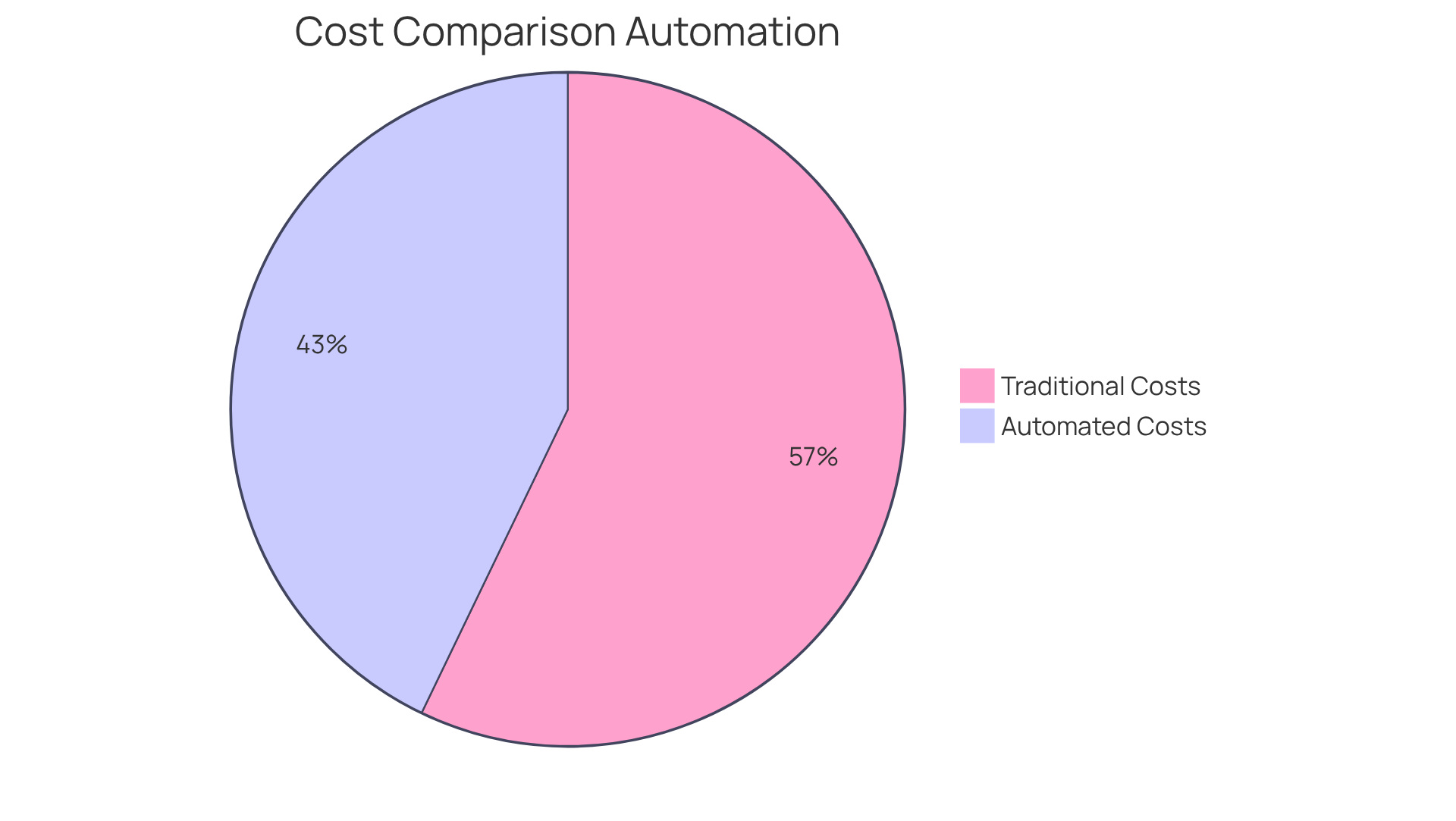

Cost-Effectiveness: Lower Operational Costs with Automated Titration

Introducing automated dosing solutions can lead to substantial cost reductions for pharmaceutical facilities. By significantly minimizing the time spent on manual measurements and reducing the risk of errors—such as those caused by parallax when reading meniscus levels—these systems utilize auto titration to effectively lower operational costs. JM Science Inc.'s premium titrators, including their advanced electronic burets, enhance precision by a factor of 20, achieving a resolution of 10,000-100,000 steps. This allows for precision levels down to 0.5 μL for a 50 mL motor-driven buret, directly impacting the financial bottom line by decreasing the need for costly rework due to inaccuracies.

Moreover, automation empowers laboratories to process samples more efficiently, enabling better resource allocation. This increased throughput not only boosts productivity but also contributes to a reduction in labor costs associated with auto titration processes. In fact, businesses that integrate automation report an average reduction of 25% in labor costs per unit, leading to enhanced profitability.

Real-world examples underscore these benefits:

- The Munich Leukemia Laboratory, which automated its cytogenetics protocols, now manages over 60,000 samples annually with improved turnaround times and reduced operational costs.

Such advancements highlight the financial impact of automation in pharmaceutical labs, positioning it as a strategic investment for enhancing overall financial performance. Furthermore, JM Science offers a variety of products, including HPLC solutions and Karl Fischer reagents, further assisting facilities in achieving operational efficiency.

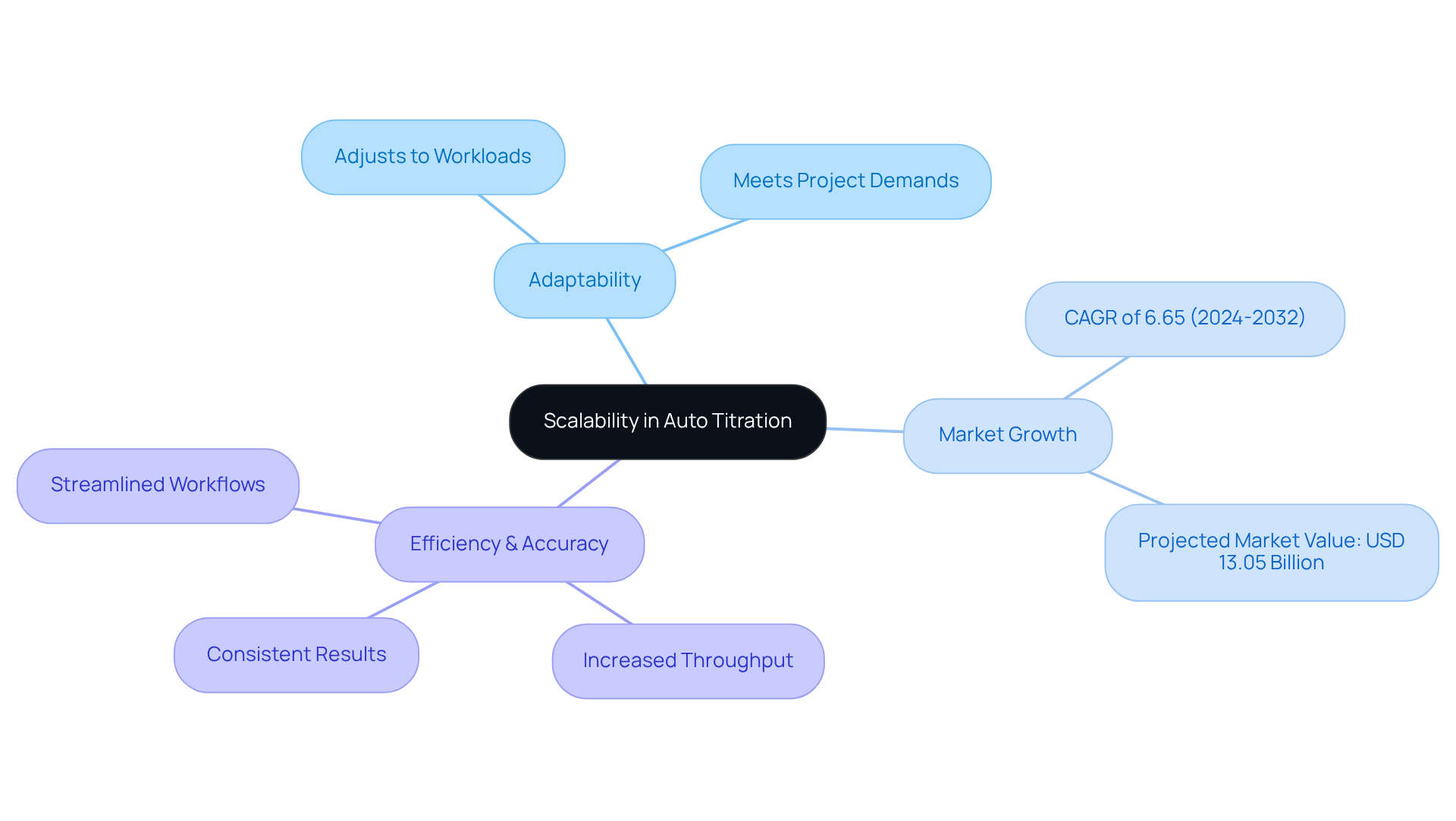

Scalability: Adapt Automated Titration to Changing Laboratory Needs

Auto titration setups present exceptional scalability, empowering pharmaceutical laboratories to seamlessly adapt to evolving requirements. As research facilities expand their operations or shift focus to meet new project demands, these systems can be readily configured to handle diverse workloads. This adaptability is vital, particularly in an environment where the volume of samples and the complexity of experiments are increasing.

Notably, the automation market for scientific research is anticipated to grow at a compound annual growth rate (CAGR) of 6.65% from 2024 to 2032, underscoring the rising demand for efficient and precise analytical solutions. By leveraging automated processes like auto titration, laboratories can maintain consistent efficiency and accuracy, regardless of the challenges encountered. This capability not only enhances productivity but also equips research facilities to respond swiftly to the dynamic landscape of pharmaceutical research and development.

Seamless Integration: Combine Automated Titration with Existing Lab Equipment

Automated dosing setups are meticulously engineered for seamless integration with existing laboratory equipment, empowering pharmaceutical facilities to enhance their operations without extensive modifications. JM Science Inc. offers a comprehensive range of high-quality titrators, Karl Fischer reagents, and HPLC solutions that can be effortlessly incorporated into workflows, preserving established methodologies while significantly boosting efficiency.

Numerous laboratories have successfully integrated JM Science's mechanized dosing apparatus with their current analytical balances and spectrophotometers, resulting in heightened precision and reliability in their processes. Lab managers have observed that this integration not only streamlines workflows but also markedly reduces manual errors, yielding more consistent results.

Furthermore, evidence indicates that dispensing devices from JM Science can be readily adapted for various research environments, making them a versatile choice for enhancing analytical capabilities. By embracing these advanced frameworks, research facilities can refine their procedures, ensuring compliance with stringent quality control standards while maintaining high output and rapid turnaround times.

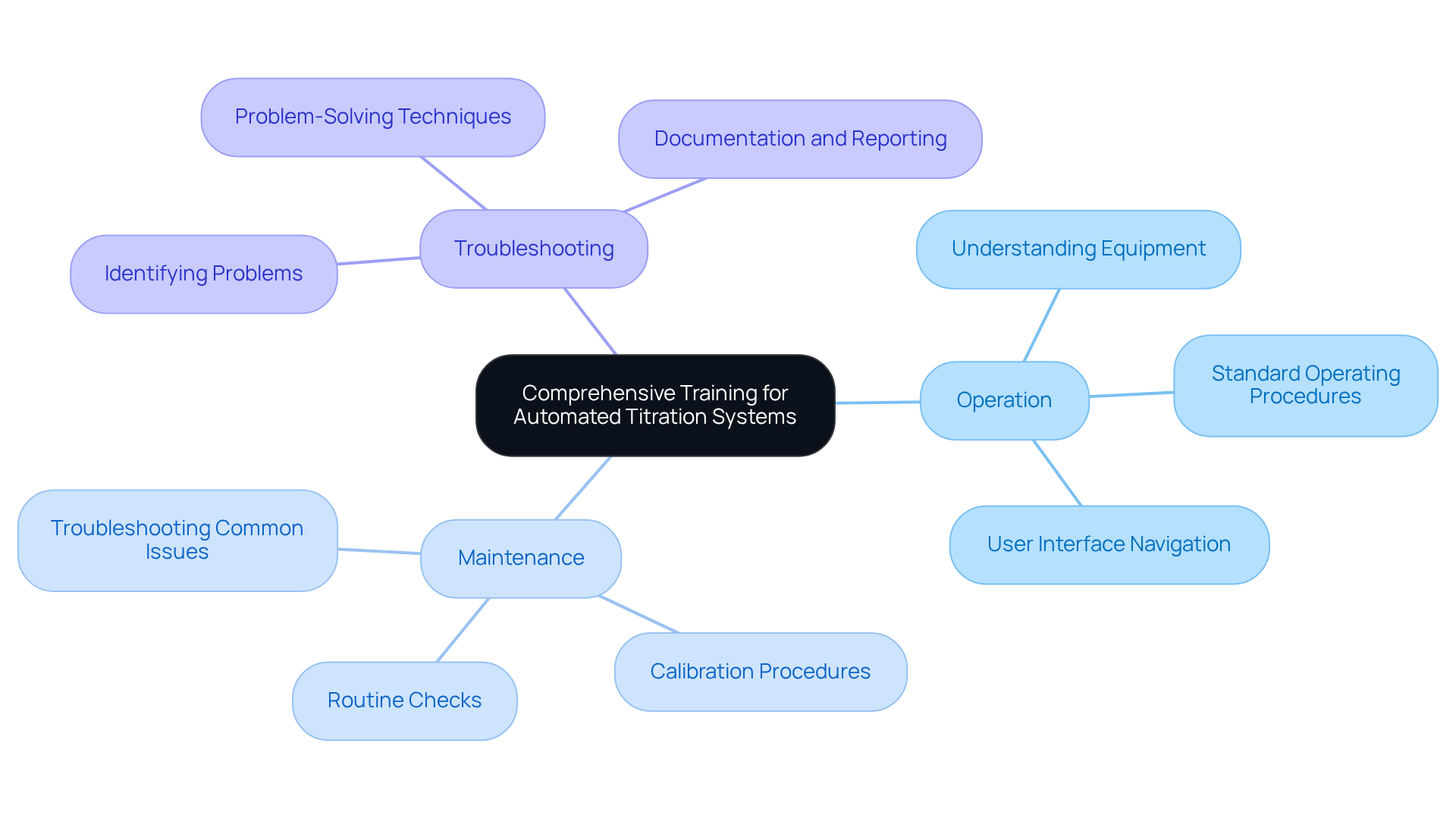

Comprehensive Training: Ensure Effective Use of Automated Titration Systems

To fully harness the advantages of mechanized titration setups, comprehensive training for staff is essential. Training programs must cover operation, maintenance, and troubleshooting, ensuring that users can effectively leverage this technology. By investing in such training, laboratories not only enhance user confidence but also optimize the performance of their technological setups. This strategic investment is crucial for maximizing the benefits of high-quality scientific instruments in laboratory environments.

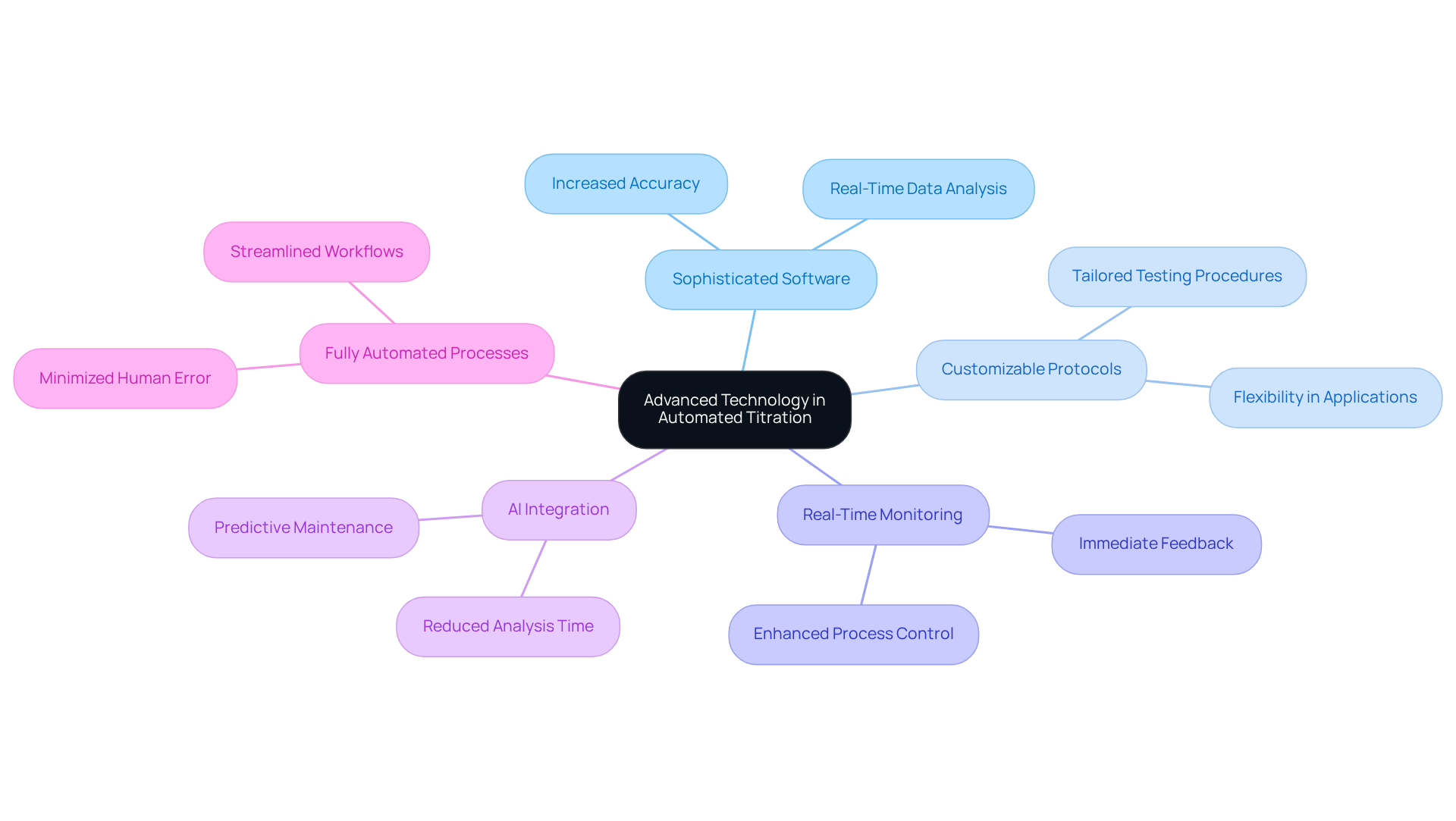

Innovative Features: Leverage Advanced Technology in Automated Titration

Contemporary robotic measuring devices are equipped with advanced technologies that significantly enhance their functionality. Features such as sophisticated software for data analysis, customizable protocols, and real-time monitoring capabilities have become standard. For example, AI-integrated technologies can reduce analysis time by up to 20% and improve accuracy by 15%, making these devices indispensable in pharmaceutical laboratories where precision is paramount.

The AQ-300 Coulometric Karl Fischer Titrator and the AQV-300 Volumetric Karl Fischer Titrator from JM Science exemplify the tools essential for drug and medicine testing, ensuring compliance with the Japanese Pharmacopoeia.

Furthermore, the implementation of fully automated processes, including auto titration and management of sample preparation and result assessment, is revolutionizing laboratory workflows, significantly minimizing human error and chemical exposure. However, the high initial costs of these systems can present challenges for smaller enterprises.

As the pharmaceutical industry increasingly prioritizes quality control and regulatory compliance, the adoption of these advanced technologies, including JM Science's premium scientific instruments like HPLC solutions, is crucial for sustaining competitive analytical capabilities.

Conclusion

The advantages of auto titration in pharmaceutical laboratories are substantial. These systems not only enhance precision and efficiency but also significantly reduce human error. By integrating advanced technologies, such as JM Science's Karl Fischer titrators, labs can achieve reliable moisture analysis, which is crucial for maintaining the integrity of pharmaceutical products. The streamlined processes afforded by automation ensure that laboratories remain compliant with rigorous industry standards while also improving overall productivity.

Key points throughout the article highlight the transformative impact of automated titration systems:

- Increased efficiency and accuracy

- Cost-effectiveness and scalability

These technologies are reshaping laboratory workflows. The ability to minimize manual intervention and human error leads to more consistent results, which is vital in the high-stakes environment of pharmaceutical testing. Additionally, the seamless integration of these systems with existing lab equipment allows for enhanced operational capabilities without the need for extensive overhauls.

Ultimately, embracing automated titration is not just a matter of keeping pace with industry advancements; it is a strategic decision that can lead to improved patient outcomes and greater laboratory efficiency. As the pharmaceutical landscape continues to evolve, investing in these innovative solutions will be essential for laboratories aiming to optimize their processes and maintain a competitive edge.