Overview

Automated liquid handlers present significant advantages for pharmaceutical laboratories, including:

- Enhanced efficiency

- Improved accuracy

- Reduced contamination risks

- Substantial cost savings

These systems automate repetitive tasks, thereby minimizing human error and facilitating high-throughput capabilities. The result is increased productivity and innovation within drug development processes, underscoring the essential role of high-quality scientific instruments in laboratory settings. By adopting these advanced technologies, labs can streamline operations and drive forward the pace of research and development.

Introduction

Automated liquid handlers are revolutionizing the landscape of pharmaceutical laboratories. They offer a transformative approach to laboratory workflows that minimizes manual tasks and maximizes efficiency. These advanced systems not only enhance throughput and accuracy but also significantly reduce the risk of human error. In the high-stakes world of drug development, this makes them indispensable. As laboratories increasingly adopt automation, a pressing question arises: how can they fully leverage these technologies to meet regulatory demands while fostering innovation and productivity in their research endeavors?

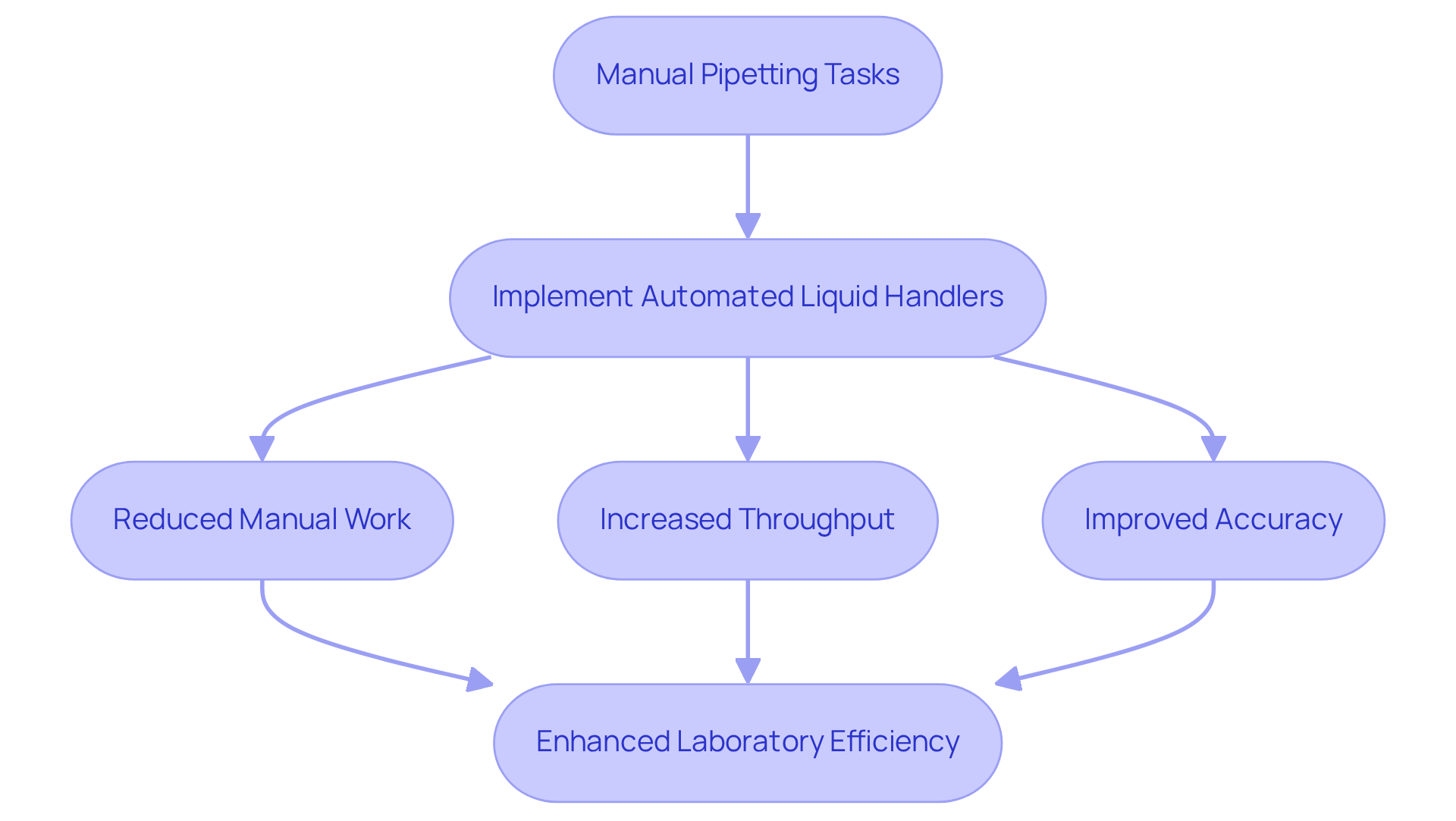

JM Science Automated Liquid Handlers: Enhanced Efficiency in Laboratory Operations

Automated liquid handlers from JM Science are meticulously engineered to transform workflows in scientific environments by minimizing manual pipetting tasks. These sophisticated technologies significantly boost throughput, empowering pharmaceutical laboratories to achieve more consistent and reliable results—an essential requirement in drug development. The AQ-300 Coulometric and AQV-300 Volumetric Karl Fischer Titrators are specifically tailored for precise moisture content analysis in drugs and medicines, ensuring compliance with the Japanese Pharmacopoeia. By automating repetitive processes, laboratories can redirect resources to focus on intricate analyses that necessitate human expertise, thereby enhancing overall efficiency.

This strategic shift not only accelerates research timelines but also contributes to elevated productivity levels. Automated liquid handlers have been shown to enhance throughput by as much as 50%, facilitating swift testing and analysis of compounds. Furthermore, case studies indicate that laboratories utilizing automated liquid handlers from JM Science report a significant reduction in human error, leading to more reproducible outcomes. As research managers have noted, the integration of these technologies has revolutionized their operations, enabling them to meet the escalating demands of pharmaceutical research while maintaining high standards of precision and accuracy.

Improved Accuracy and Reproducibility: Precision in Every Sample

Automated liquid handlers are essential in enhancing the precision and reproducibility of experiments within pharmaceutical laboratories. By significantly reducing human involvement, these systems minimize the variability often associated with manual pipetting. Each sample is processed with remarkable precision, guaranteeing consistent results across multiple trials. This reliability is vital for regulatory compliance and fosters trust in research findings, particularly in drug development, where reproducibility directly affects clinical outcomes.

Research indicates that robotic pipetting devices can achieve a minimum coefficient of variation as low as 0.20%, underscoring their capability to deliver accurate and uniform volumes of fluid. Furthermore, the integration of advanced technologies, such as robotic systems equipped with multiple pipetting heads, facilitates the execution of intricate protocols, thereby enhancing experimental designs and workflows.

As emphasized by researchers, the significance of precision in experiments cannot be overstated, as it directly influences data quality and the success of drug discovery initiatives. With the global biotech sector projected to reach $465.9 billion by 2024, the implementation of automated liquid handlers is not merely advantageous but essential for maintaining a competitive edge and ensuring the reliability of pharmaceutical research.

However, it is crucial to evaluate both precision and accuracy when assessing liquid handlers, as an overreliance on precision may adversely affect data quality. Additionally, mechanized systems can efficiently manage a substantial volume of samples simultaneously, significantly boosting throughput—an essential factor for laboratories processing high sample quantities.

As Nila Lê noted, robotic pipetting offers laboratories numerous benefits that enhance throughput, accuracy, and overall workflow efficiency.

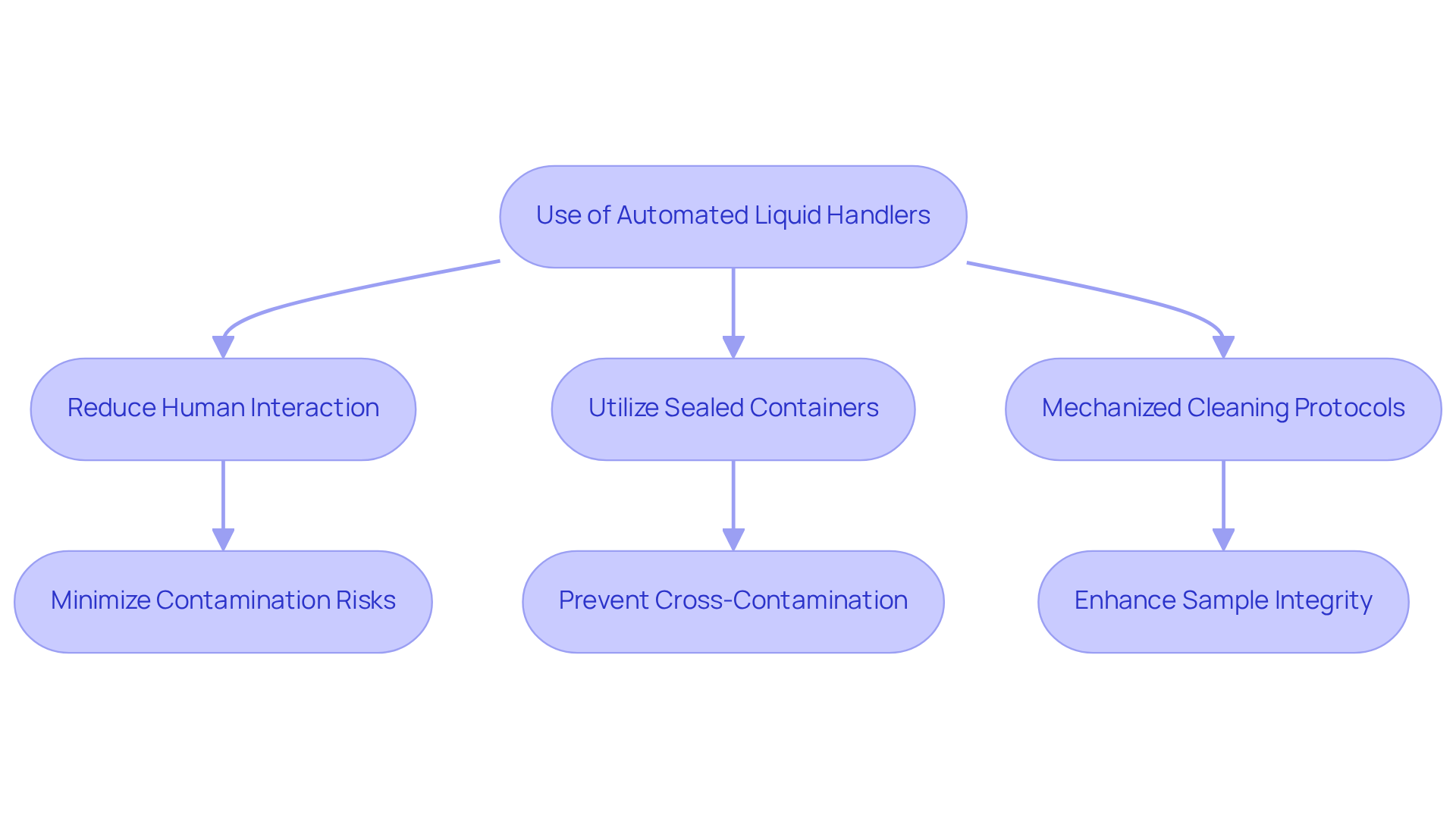

Reduction of Contamination Risks: Ensuring Sample Integrity

Automated liquid handlers play a crucial role in mitigating contamination risks by significantly reducing human interaction with samples. Operating within regulated environments, these systems utilize sealed containers and mechanized cleaning protocols to effectively prevent cross-contamination. This is particularly crucial in pharmaceutical settings, where even minor contamination can lead to substantial errors in research outcomes.

By preserving the integrity of samples, automated processes enhance the overall reliability of test results. Laboratory safety experts emphasize that minimizing human intervention is vital for maintaining sample purity, as operator actions can introduce variability and contamination risks. Research demonstrates that automated liquid handlers can significantly bolster sample integrity, underscoring their effectiveness in pharmaceutical research.

Furthermore, the implementation of automated liquid handlers not only safeguards sample quality but also streamlines workflows, allowing researchers to focus on critical tasks without the persistent worry of contamination. This transition towards automation is increasingly recognized as a necessary advancement in scientific practices, especially in light of stringent regulatory standards and the escalating complexity of pharmaceutical research.

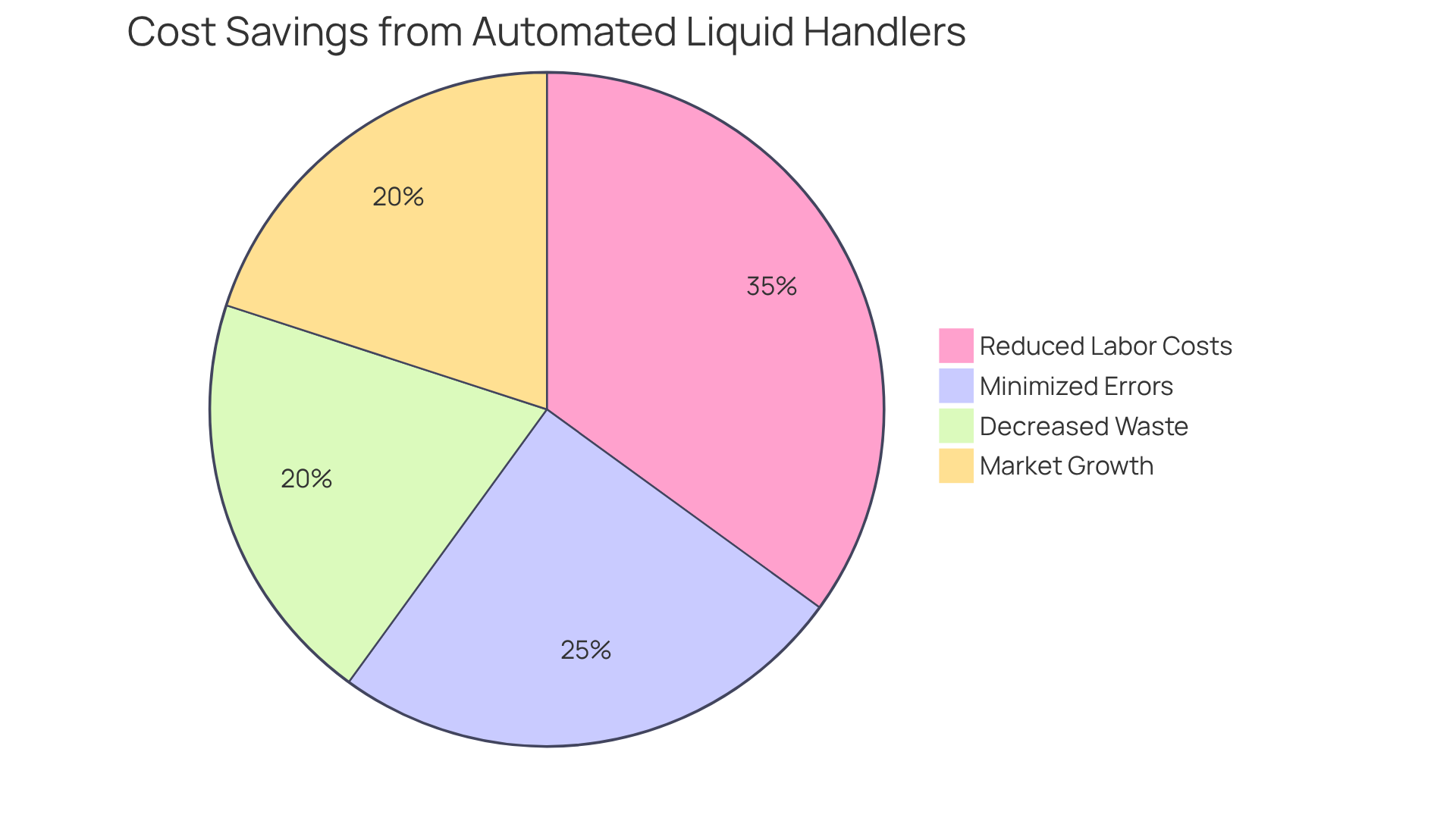

Cost Savings: Maximizing Budget Efficiency in Research

The implementation of automated liquid handlers can yield significant cost savings for pharmaceutical facilities. These automated liquid handlers not only reduce reliance on manual labor but also minimize errors, leading to lower operational costs. By ensuring accurate dispensing, automation decreases the consumption of reagents and consumables, effectively reducing waste and optimizing laboratory budgets.

For instance, robotic liquid handlers can eliminate the need for pipette tips entirely, further cutting down on plastic waste and associated expenses. Ultimately, the initial investment in automated liquid handlers is frequently recovered through these savings, making them a financially sound choice for research facilities.

Financial analysts have noted that the return on investment (ROI) for automation can be substantial, with numerous organizations reporting enhanced efficiency and decreased operational costs as key advantages.

As the market for automated liquid handlers continues to expand, with forecasts indicating a compound annual growth rate of 10.4% from 2025 to 2034, this growth exemplifies the increasing acceptance of automation technologies in research facilities, underscoring the economic benefits of implementing these systems.

Improved Ergonomics and Safety: Protecting Laboratory Staff

Automated liquid handlers greatly improve ergonomics and safety in workspaces by reducing the physical strain that comes with manual pipetting. In research environments, repetitive strain injuries (RSIs) are prevalent, often stemming from the continuous motion required in traditional pipetting tasks. The use of automated liquid handlers in automating these processes not only safeguards personnel from potential injuries but also boosts overall productivity.

Furthermore, these mechanized systems are equipped with advanced safety features, such as non-contact dispensing technologies, which minimize exposure to hazardous materials, thereby providing additional protection for lab personnel. Research indicates that the incorporation of automation in fluid management can lower injury rates; for instance, studies suggest that ergonomic enhancements can lead to a substantial reduction in RSIs among research personnel.

Occupational health specialists, including Dr. Holger Armbruster, emphasize that mitigating physical strain through automation is vital for sustaining a healthy workforce, enabling researchers to concentrate on complex tasks rather than repetitive motions.

In summary, the shift towards automated liquid handlers represents a significant advancement in safety and ergonomics within research settings, with the market projected to expand at a CAGR of 10.4% from 2025 to 2034, reflecting the growing acceptance of these technologies.

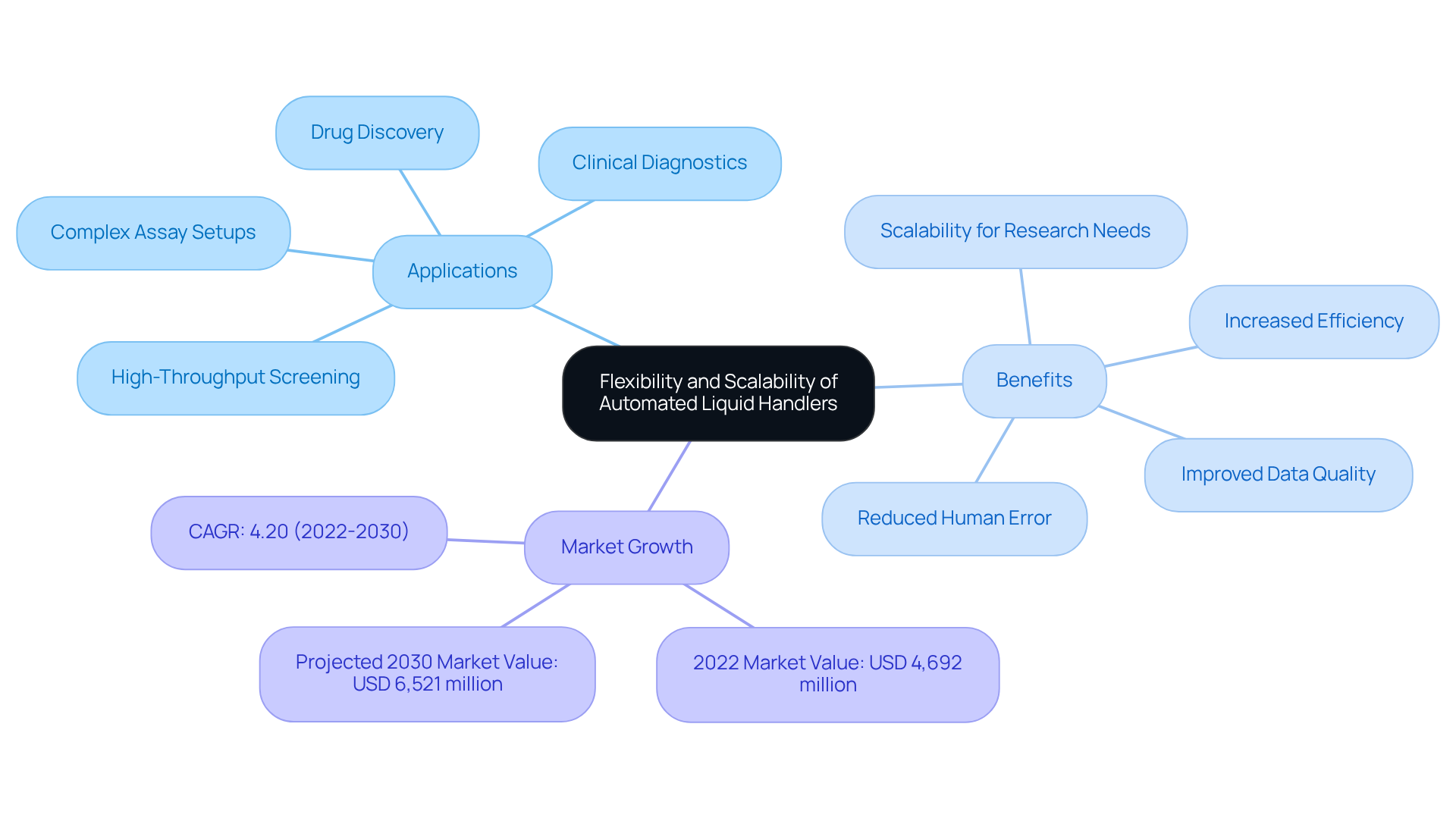

Flexibility and Scalability: Adapting to Diverse Research Demands

Automated liquid handlers demonstrate exceptional flexibility and scalability, allowing laboratories to seamlessly adapt to a wide variety of research demands. These systems can be programmed for various protocols, making them ideal for applications that span from high-throughput screening to complex assay setups. For instance, a modular self-operating protocol allows researchers to prepare 96 samples for tryptic digestion in under an hour, underscoring the efficiency and versatility of these systems in proteomic analysis.

As research needs evolve, laboratories have the capability to scale their automation solutions effortlessly. This adaptability is crucial in pharmaceutical settings, where precision and efficiency are of utmost importance. Laboratory supervisors have noted that the integration of mechanical processes not only enhances workflow efficiency but also significantly reduces human errors, thereby improving data quality. Nathan J Hillson from Agile BioFoundry emphasizes that "mechanized solutions will be necessary to reduce human error, conserve time and resources, and enhance the data quality." Studies reveal that automated sample preparation methods can achieve a median protein variance of merely 18% to 22% CV, with expected results showing less than 15% CV of relative protein abundance, highlighting the reliability of these systems.

The scalability of automation in pharmaceutical environments is further illustrated by the increasing complexity of life science research projects. Automated liquid handlers can be tailored to accommodate various sample sizes and types, ensuring that research facilities remain adaptable to emerging challenges. This flexibility is essential for advancing drug discovery and clinical diagnostics, where the ability to swiftly adjust protocols can result in significant breakthroughs in research outcomes. Moreover, the global automated liquid handlers market was valued at USD 4,692 million in 2022 and is projected to reach USD 6,521 million by 2030, emphasizing the rising demand for high-throughput screening and automation solutions.

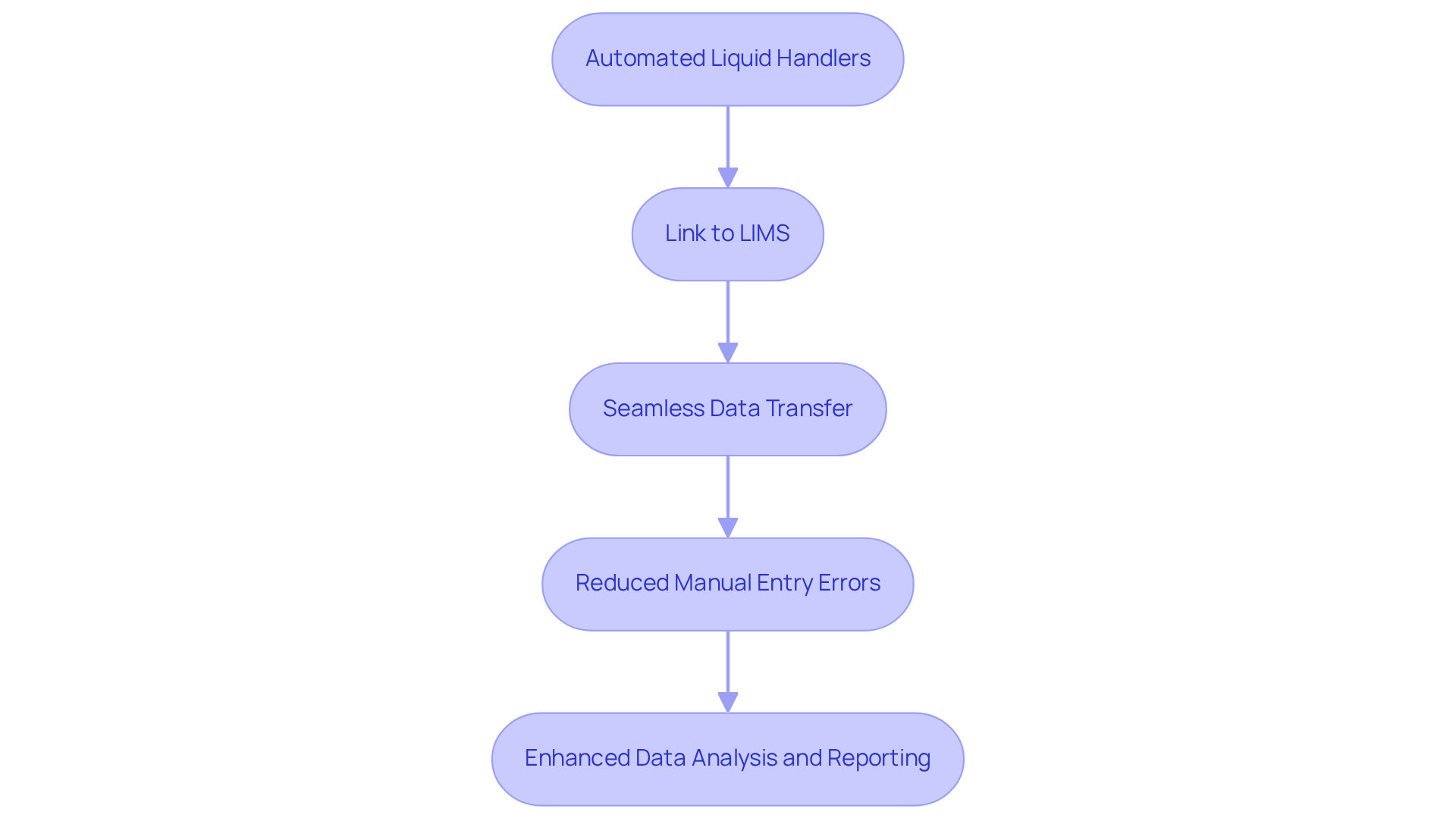

Data Management and Integration: Streamlining Laboratory Processes

The role of automated liquid handlers is crucial in enhancing data management and integration within scientific workflows. By linking these systems to information management systems (LIMS), laboratories can facilitate seamless data transfer and analysis. The use of automated liquid handlers in this automation not only streamlines data collection but also significantly reduces the risk of errors associated with manual data entry. Consequently, research facilities can ensure that their findings are precise and readily accessible for thorough analysis and reporting. The adoption of such advanced technologies is essential for maintaining the integrity and efficiency of scientific research.

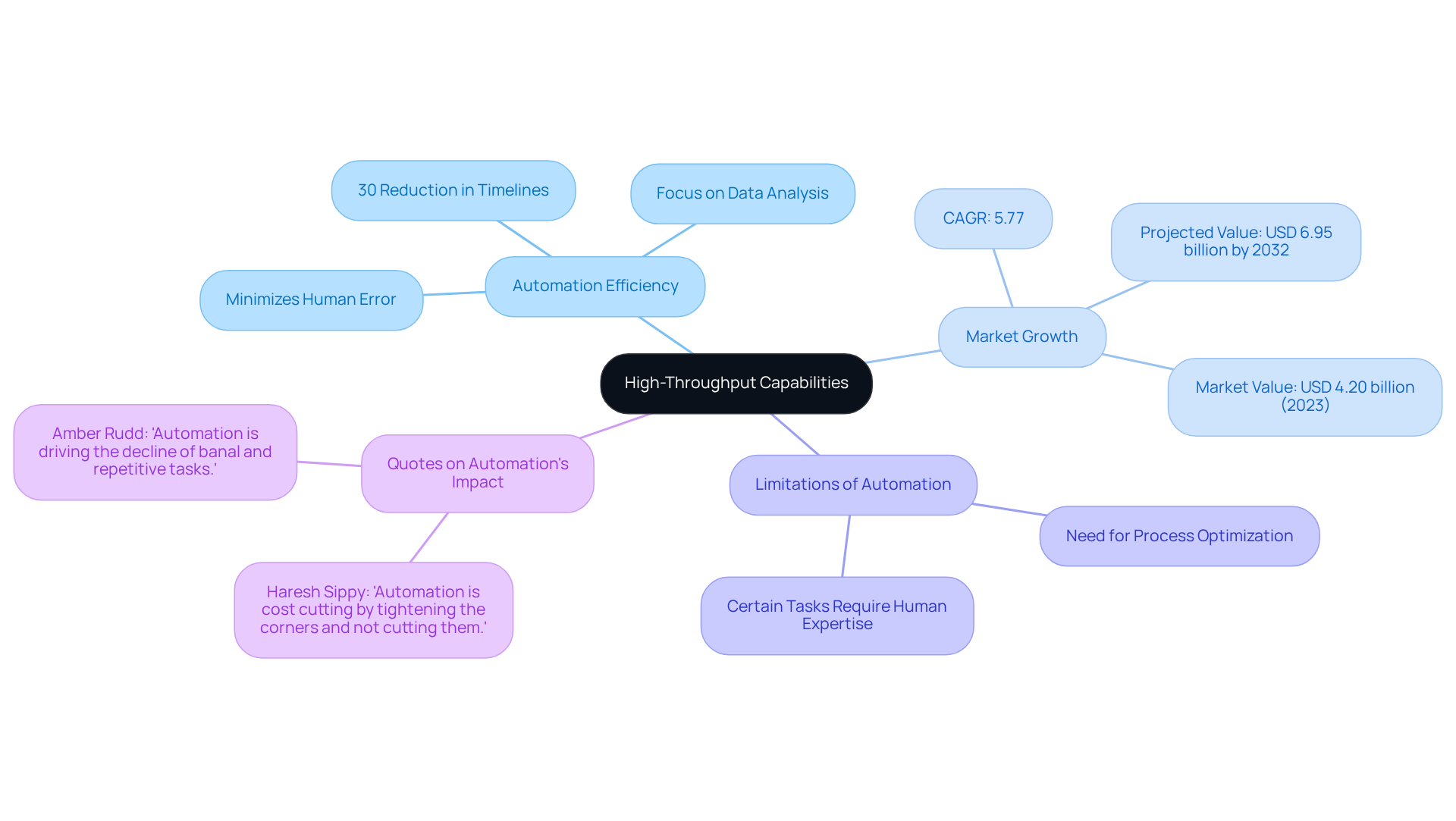

High-Throughput Capabilities: Accelerating Research Timelines

High-throughput applications are empowered by automated liquid handlers, enabling facilities to efficiently process substantial volumes of samples. This efficiency is paramount in drug discovery and development, where timely results can dramatically influence project outcomes. By automating repetitive tasks, research facilities can significantly reduce the time required for experiments, allowing scientists to focus more on data analysis and interpretation. Notably, studies suggest that automation can shorten research timelines by as much as 30%, facilitating quicker decision-making during critical phases of drug development.

Furthermore, industry specialists have noted that integrating mechanized systems not only enhances throughput but also minimizes human error, leading to more reliable results. As Amber Rudd aptly stated, "Automation is driving the decline of banal and repetitive tasks," highlighting the vital role of automation in elevating laboratory efficiency.

Additionally, the Liquid Handling System Market, valued at USD 4.20 billion in 2023, is anticipated to reach USD 6.95 billion by 2032, reflecting a CAGR of 5.77%. This growth underscores the increasing significance of automation within the industry. However, optimizing processes prior to implementing automation is crucial, as emphasized by CFB Bots, to ensure superior outcomes.

While mechanized fluid handling technologies are becoming indispensable in pharmaceutical laboratories, it is essential to recognize their limitations, as certain tasks still require human expertise and involvement. Ultimately, the adoption of automated liquid handlers is propelling advancements in research and accelerating the journey from concept to market.

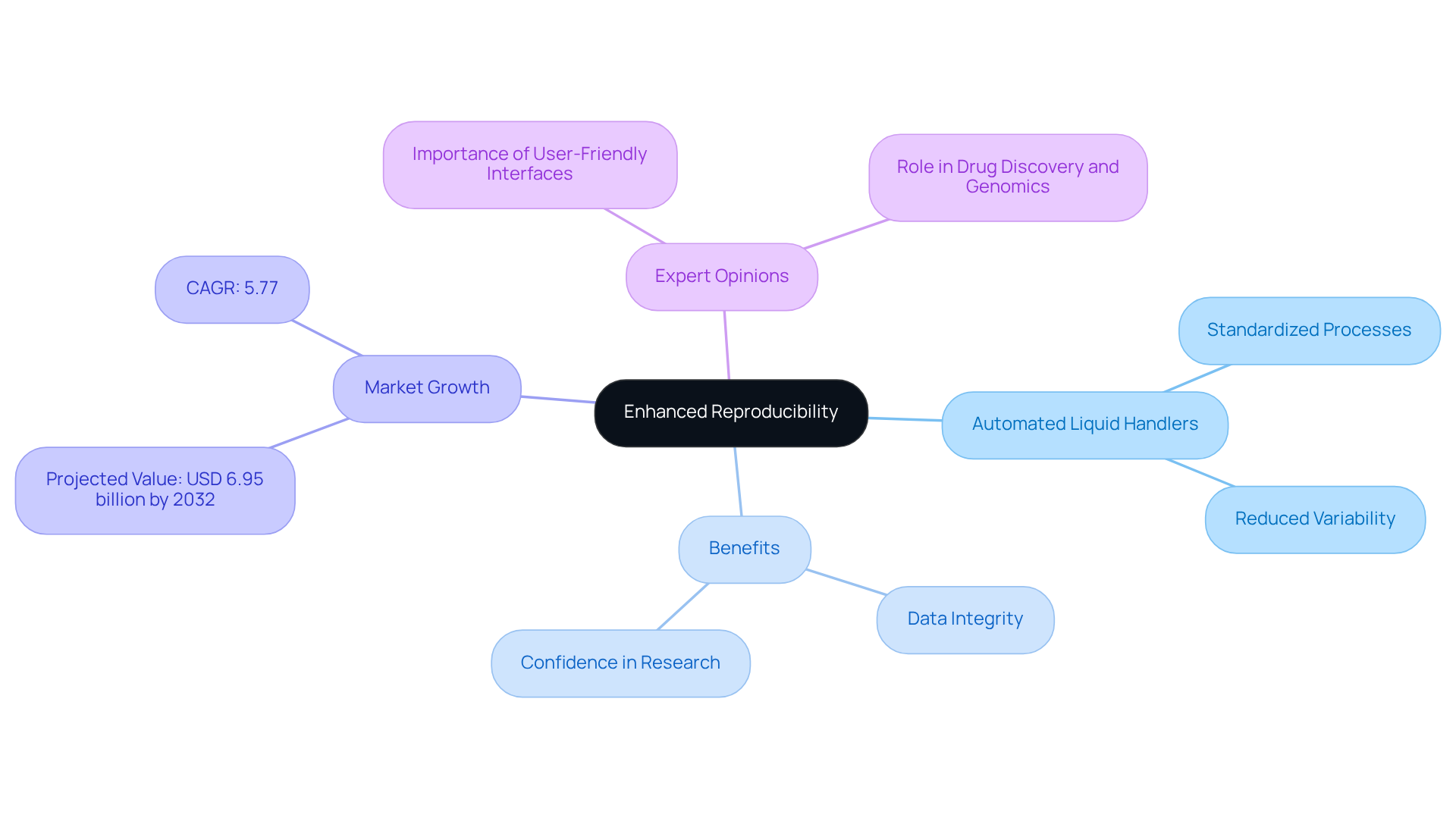

Enhanced Reproducibility: Consistency Across Experiments

Automated liquid handlers greatly improve reproducibility by standardizing the liquid handling processes utilized in experiments. This consistency is vital for validating research findings and ensuring reliable replication of results. By minimizing variability caused by human operators, these devices maintain the integrity of experimental data, which is essential for fostering confidence in research results and enabling thorough peer review.

For instance, the introduction of automated liquid handlers, like the I.DOT Liquid Handler with a dead volume of only 1 μL, enables researchers to utilize fewer reagents while demonstrating improvements in precision and effectiveness. Moreover, research indicates that standardized fluid handling procedures can lead to a substantial enhancement in the reproducibility of outcomes.

The fluid management market is projected to expand considerably, anticipated to reach USD 6.95 billion by 2032, growing at a CAGR of 5.77%. This trend underscores the increasing demand for precision in pharmaceutical research, which can be achieved through the use of automated liquid handlers.

Researchers assert that consistency in experimental data is not merely advantageous but essential for advancing scientific knowledge and ensuring the credibility of findings in high-stakes environments. As noted by Akash Anand, Head of Business Development & Strategy, 'The Liquid Handling Market is expanding due to the rising demand for automated liquid handlers in drug discovery, genomics research, and clinical applications.

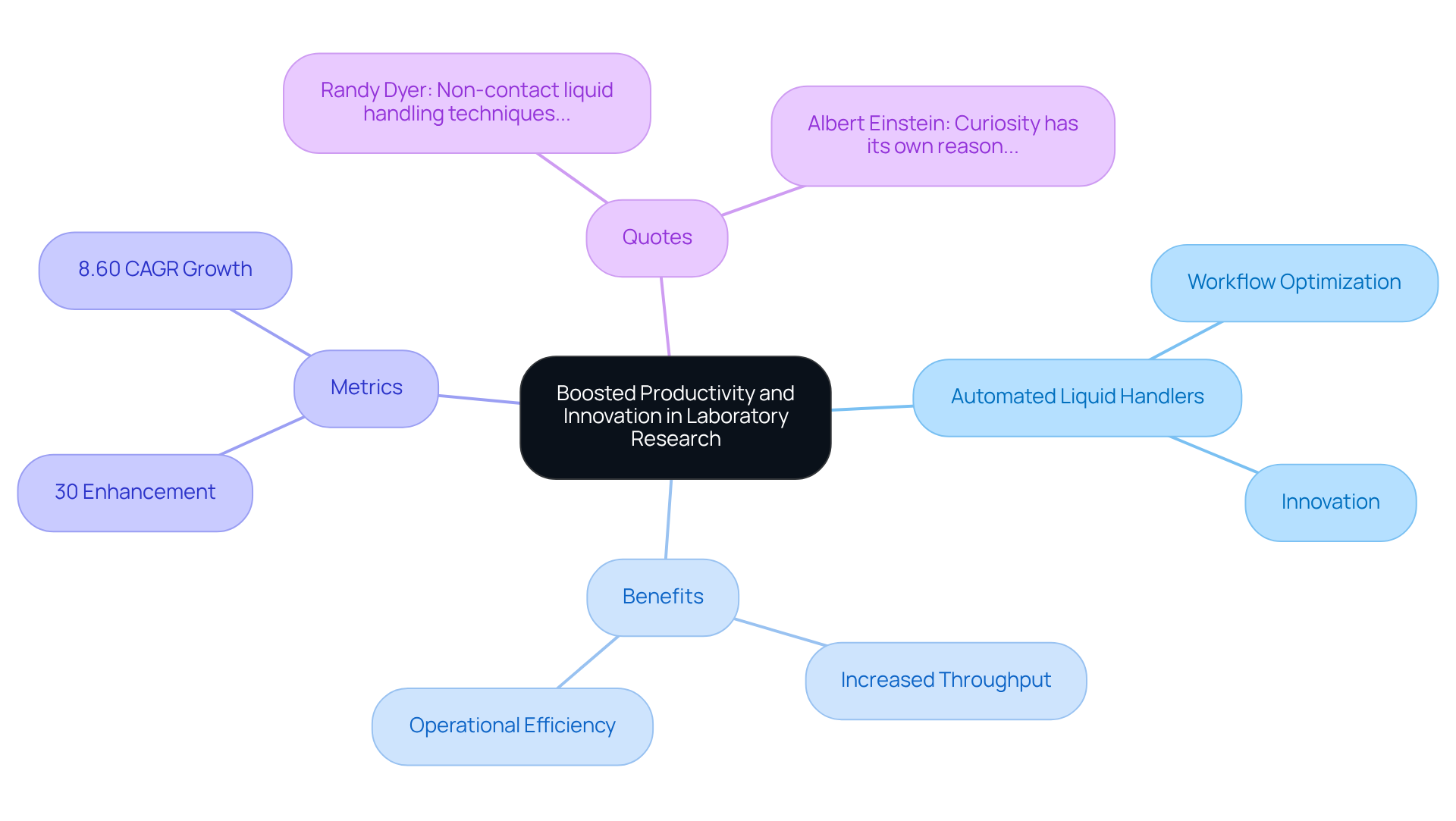

Boosted Productivity and Innovation: Transforming Laboratory Research

The revolution in productivity within research environments is being driven by automated liquid handlers, which foster a culture of innovation. By utilizing automated liquid handlers to optimize workflows and minimize the time spent on repetitive tasks, these solutions empower researchers to focus on innovative problem-solving and experimental design. This shift not only boosts laboratory output but also nurtures an environment where new ideas can flourish, resulting in significant advancements in pharmaceutical research.

Research indicates that implementing automated liquid handlers can enhance throughput by up to 30%, facilitating more effective drug discovery processes. Furthermore, the automated liquid handlers market is projected to grow at a CAGR of 8.60% from 2025 to 2034, underscoring the increasing importance of these technologies in the industry.

As pharmaceutical companies progressively adopt innovations such as automated liquid handlers, they not only enhance operational efficiency but also pave the way for groundbreaking discoveries that can transform healthcare. The integration of automated liquid handlers in laboratories exemplifies how innovation can be accelerated, ultimately propelling the future of pharmaceutical research.

As Randy Dyer notes, 'Non-contact liquid handling techniques are allowing scientists to obtain accurate data with fewer steps and much less sample and reagent,' which highlights the efficiency gains associated with these advancements.

Conclusion

Automated liquid handlers represent a transformative force in pharmaceutical laboratories, enhancing efficiency, accuracy, and safety while significantly reducing the potential for human error. By automating repetitive tasks, these systems not only streamline workflows but also enable researchers to concentrate on more complex analyses that require human expertise. This shift ultimately drives advancements in drug development and clinical research.

The key benefits include:

- Improved accuracy and reproducibility, essential for regulatory compliance and the reliability of research findings.

- Reduction of contamination risks through minimized human interaction ensures sample integrity.

- Cost savings from decreased operational expenses and optimized reagent use underscore the financial advantages of implementing these automated systems.

- Flexibility and scalability of automated liquid handlers allow laboratories to adapt to diverse research demands, solidifying their role in the future of pharmaceutical research.

In light of these insights, the adoption of automated liquid handlers is not merely an enhancement; it is a necessity for laboratories striving to maintain a competitive edge in the fast-evolving biotech landscape. As the market for these technologies continues to grow, embracing automation will be crucial for fostering innovation, improving productivity, and ultimately transforming the landscape of pharmaceutical research. The journey toward more efficient and reliable laboratory practices is underway, and the integration of automated liquid handlers will lead this evolution.