Overview

Automated pipetting presents considerable advantages for pharmaceutical laboratories, including:

- Enhanced accuracy

- Increased throughput

- Cost efficiency

- Improved ergonomics

These mechanized liquid handling systems significantly reduce human error, streamline workflows, and lower operational costs. As a result, they foster a more productive and reliable laboratory environment, which is essential for drug development and compliance with regulatory standards. The integration of such advanced technology not only meets the demands of modern pharmaceutical research but also sets a new standard for operational excellence.

Introduction

Automated pipetting has emerged as a game-changer in pharmaceutical laboratories, where precision and efficiency are paramount. By minimizing human error and streamlining workflows, these advanced systems not only enhance the accuracy of liquid handling but also significantly boost productivity. As the demand for rapid and reliable results grows, the question remains: how can pharmaceutical labs fully leverage the benefits of automated pipetting to stay ahead in an increasingly competitive landscape?

JM Science Automated Pipetting Solutions: Enhancing Precision in Pharmaceutical Labs

JM Science Inc. delivers a comprehensive suite of mechanized liquid handling solutions, specifically engineered to enhance accuracy in pharmaceutical laboratories. These systems are meticulously crafted to minimize human error and ensure consistent liquid handling, a critical factor in drug development and testing processes. Notably, the integration of mechanized liquid handling with advanced titration techniques, including the Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 Coulometric Karl Fischer Titrators, significantly elevates the precision of moisture content analysis in pharmaceuticals, thereby ensuring compliance with the Japanese Pharmacopoeia.

By leveraging cutting-edge technology, JM Science's robotic liquid handling solutions yield precise and reliable outcomes, which are essential for meeting the rigorous regulatory standards of the pharmaceutical industry. Furthermore, the rising prevalence of chronic illnesses has led to an increased demand for reliable diagnostic methods, underscoring the critical role of within pharmaceutical laboratories.

Improved Accuracy: Reducing Human Error in Liquid Handling

Automated pipetting is essential for enhancing accuracy in laboratory settings by eliminating the variability associated with manual pipetting. These advanced systems employ that consistently deliver the correct volume, significantly reducing the likelihood of human error.

In the realm of pharmaceutical laboratories, where even the slightest inaccuracies can lead to significant consequences for research outcomes and product development, this enhancement is vital. Research indicates that robotic technologies can effectively reduce common laboratory errors, such as transcription mistakes and mislabeling, which often stem from fatigue and inadequate training.

By ensuring reliable and repeatable results, automated pipetting not only enhances the dependability of experimental findings but also fosters a culture of accuracy and compliance within the laboratory environment. As pharmaceutical lab managers increasingly recognize the critical importance of precision in liquid handling, the adoption of automated pipetting solutions becomes essential for safeguarding the integrity of scientific research and advancing drug development initiatives.

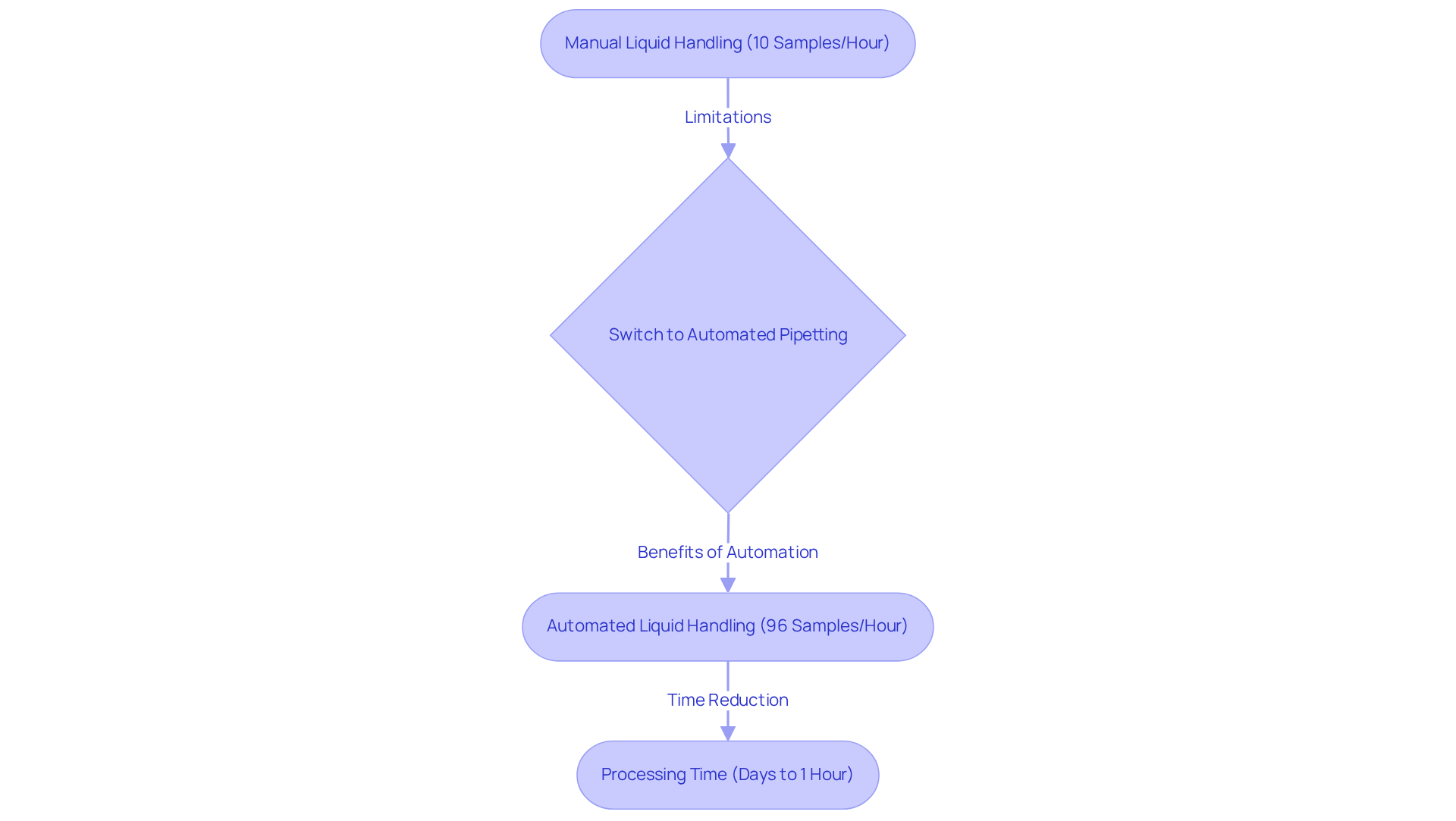

Increased Throughput: Streamlining Laboratory Workflows

Automated pipetting devices significantly enhance laboratory productivity by allowing the processing of a greater number of samples in a fraction of the time required for manual techniques. These systems automate repetitive tasks, allowing researchers to concentrate on more complex analyses and decision-making processes. For instance, while manual liquid handling may allow for the management of only 10 samples per hour, machine systems can efficiently handle up to 96 samples simultaneously. This capability is essential for pharmaceutical laboratories that face stringent time constraints and the necessity of managing extensive datasets.

associated with mechanization are striking; machine-driven workflows for RNA extraction can reduce processing times from several days to approximately 1 hour. Such efficiency not only accelerates research timelines but also diminishes the risk of human error, leading to more reliable results. Lab supervisors have noted that automation fosters streamlined workflows, enhancing overall productivity and enabling teams to focus on high-value tasks rather than labor-intensive processes.

Furthermore, the integration of automated systems has been demonstrated to improve data quality and consistency, which is vital in pharmaceutical research. As one lab supervisor articulated, 'Automated pipetting and automation enable us to enhance throughput and develop ready-to-run workflows, which can be especially beneficial for repetitive liquid handling tasks.' This perspective reflects a broader trend within the industry, where laboratories are increasingly adopting automation to optimize their operations and elevate their research capabilities.

Cost Efficiency: Lowering Operational Expenses with Automation

Implementing automated pipetting can significantly reduce operational expenses for pharmaceutical labs. By minimizing reliance on manual labor and decreasing the likelihood of errors that necessitate costly rework, automated pipetting systems significantly contribute to . Mechanization can result in a 30-50% decrease in operational expenses, optimizing workflows and improving accuracy.

Furthermore, the efficiency achieved through mechanization accelerates project turnaround times, enabling labs to allocate resources more effectively and enhance overall productivity. Financial analysts observe that organizations employing automated pipetting in laboratory environments frequently experience a significant reduction in operational costs, enabling them to focus on strategic initiatives that foster innovation and advancement in pharmaceutical research.

A study by Salesforce indicates that:

- 74% of employees utilizing automated tools reported increased speed in their work processes, further illustrating the influence of such tools on efficiency and cost savings.

- 51% of IT leaders believe that automation initiatives can reduce overall costs by 10% to 50%, reinforcing the argument for adopting automated solutions in pharmaceutical labs.

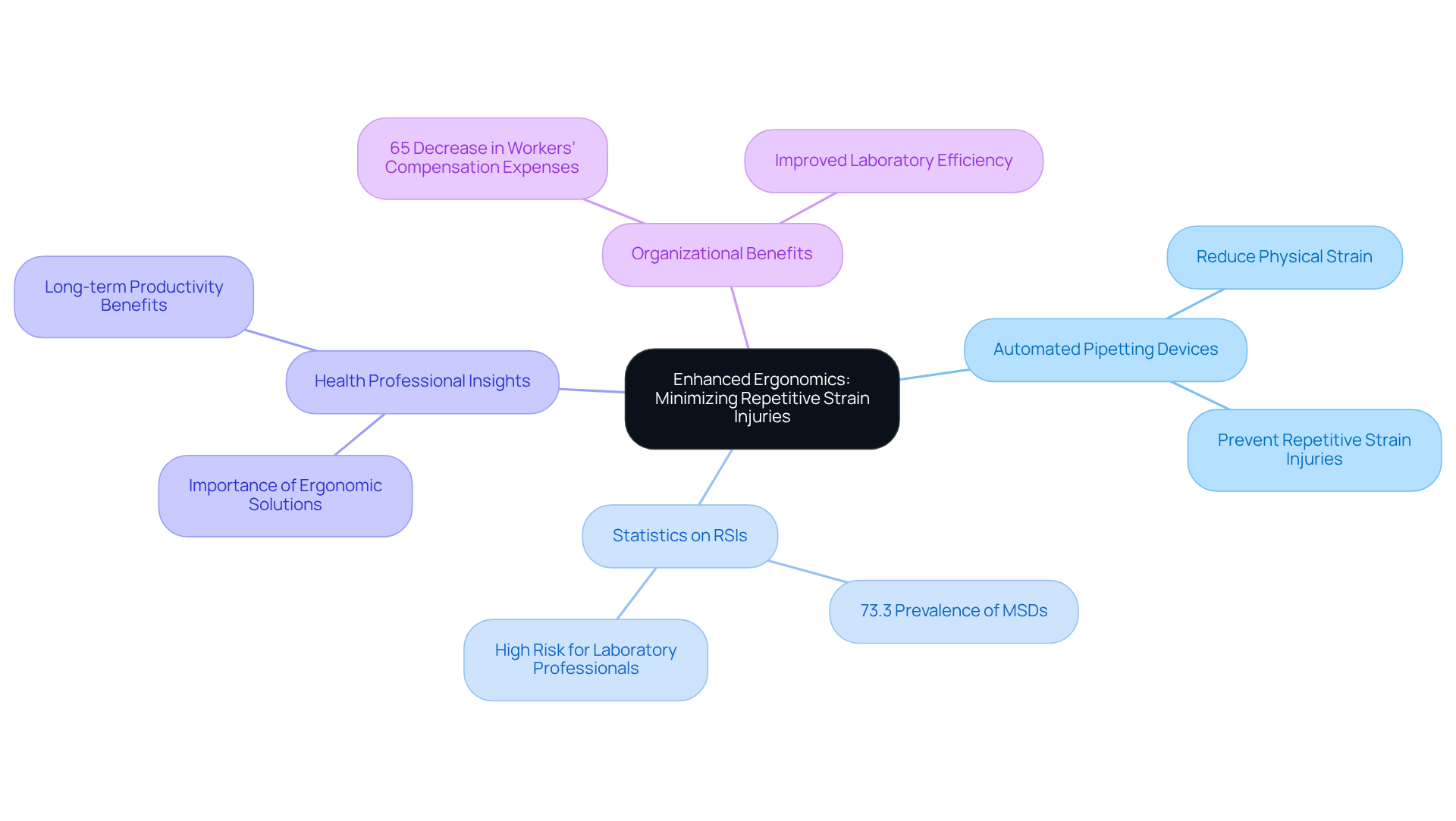

Enhanced Ergonomics: Minimizing Repetitive Strain Injuries

Automated pipetting devices are essential for enhancing laboratory ergonomics, as they significantly reduce the physical strain associated with repetitive manual liquid transfer tasks. These sophisticated systems diminish the necessity for continuous hand movements and awkward postures, which often lead to repetitive strain injuries (RSIs) among laboratory personnel.

For example, studies indicate that the prevalence of musculoskeletal disorders (MSDs) among medical laboratory professionals can reach as high as 73.3%, highlighting the critical need for ergonomic solutions. By addressing these ergonomic risks, automated pipetting not only fosters a healthier work environment but also significantly enhances overall productivity.

Health professionals, such as Anne Tennier from the Canadian Centre for Occupational Health and Safety, assert that emphasizing ergonomic solutions is vital for maintaining long-term productivity in laboratory settings. Moreover, organizations that have adopted automated pipetting in their liquid handling processes report notable reductions in RSIs, with some clients experiencing a remarkable 65% decrease in workers’ compensation expenses. This underscores the efficacy of these systems in creating a .

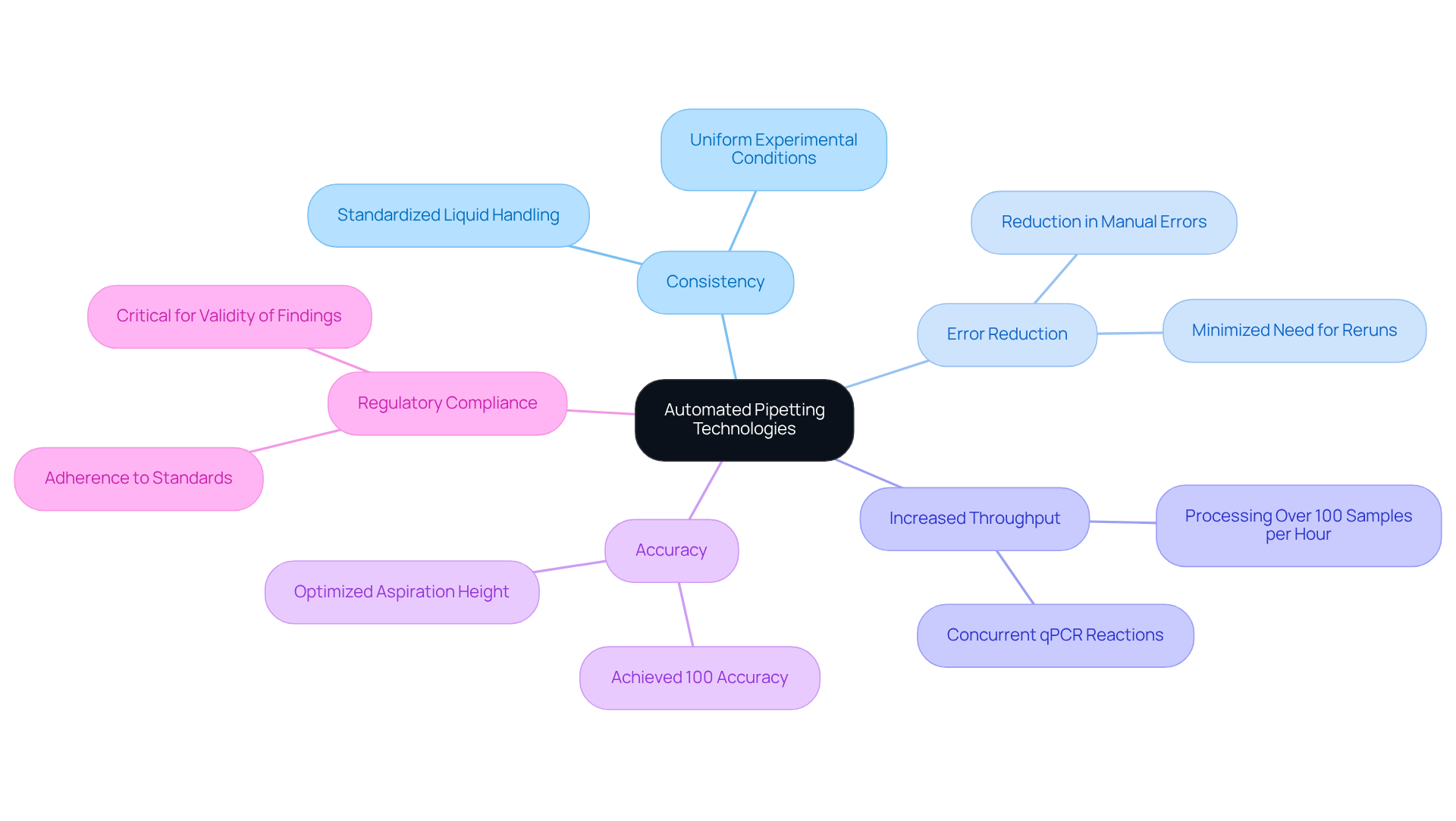

Consistent Results: Ensuring Reliable Experimental Outcomes

Automated pipetting technologies provide a level of consistency that manual techniques struggle to match. By standardizing liquid handling procedures, these systems ensure that experiments are conducted under uniform conditions, which is essential for producing reliable and reproducible results.

In the realm of pharmaceutical research, where even minor variations can jeopardize the validity of findings and regulatory compliance, this consistency becomes critical. Researchers relying on automated pipetting report a substantial reduction in manual pipetting errors, which can lead to costly and time-consuming repeat experiments.

Moreover, studies demonstrate that automation can significantly enhance throughput, enabling laboratories to process over 100 samples per hour while preserving accuracy. Automated systems can execute multiple qPCR reactions concurrently, greatly expediting research timelines and reducing the likelihood of human error.

The D-ONE liquid handling module's further guarantees precise results by optimizing aspiration height. As highlighted by New Hampshire Public Health Laboratories, the automated pipetting process achieved 100 percent accuracy, underscoring the reliability of mechanization in pharmaceutical research.

Additionally, consistent liquid handling diminishes the need for reruns, as evidenced by case studies focused on improving PCR experiment quality, ultimately elevating the overall quality of experimental outcomes. Industry experts emphasize that achieving consistent results through automated pipetting is vital for advancing pharmaceutical research and ensuring adherence to stringent regulatory standards.

Versatility: Adapting to Diverse Liquid Handling Needs

Automated pipetting devices exemplify versatility, adeptly managing a wide array of fluids and volumes. This flexibility empowers pharmaceutical laboratories to leverage automated pipetting systems across various applications, such as high-throughput screening and meticulous sample preparation. Lab managers have noted that the ability to customize liquid handling protocols markedly enhances the functionality of these systems, allowing them to meet specific experimental requirements.

In the realm of drug discovery, for instance, automated pipetting streamlines workflows by facilitating rapid sample processing, which is a crucial factor for maintaining efficiency in research. Furthermore, the integration of proves advantageous in domains like genomics and proteomics, where precision and consistency are paramount.

Data indicates that these systems can handle sub-microliter volumes with remarkable accuracy, thereby reducing variability and improving overall data quality. As pharmaceutical laboratories increasingly embrace mechanization, the role of automated pipetting solutions becomes ever more critical in advancing research and development initiatives.

Integration: Enhancing Lab Efficiency with Advanced Technologies

Integrating other laboratory technologies, such as data management software and robotic systems, with automated pipetting systems significantly enhances overall lab efficiency. This integration enables seamless data transfer and , allowing researchers to concentrate on analysis rather than manual data entry.

By fostering a connected laboratory environment, pharmaceutical labs can optimize operations and boost productivity. Research indicates that mechanization can reduce manual steps by as much as 80% in specimen transport throughout all testing stages. Furthermore, industry leaders assert that 42% of business leaders believe workflow automation saves time and permits focus on strategic tasks.

This makes automation technologies essential for laboratories striving to uphold high standards of patient care while addressing staffing challenges and expanding testing menus.

Comprehensive Support: Training for Effective Automation Implementation

To fully harness the advantages of , comprehensive training for laboratory personnel is imperative. JM Science offers specialized training programs tailored to equip users with the essential knowledge and skills necessary for the proficient operation of these advanced systems.

Research demonstrates that engaging in training programs significantly boosts user proficiency, resulting in enhanced efficiency and a marked reduction in errors during liquid handling. Notably, McKinsey research reveals that nearly 50% of current work tasks could be automated with existing technology, underscoring the critical role of mechanization in laboratory settings.

By investing in such training, laboratories can ensure their staff is adept at utilizing automated pipetting technologies, which ultimately elevates productivity and precision in their operations. As Takehisa Yamamoto notes, "Our data showed that involvement in the training program and the degree of experience with liquid handling significantly enhanced accuracy."

Effective training stands as a cornerstone of successful automation implementation, particularly in automated pipetting, empowering labs to maximize the benefits of their investments in technology while addressing challenges such as employee resistance and initial setup costs.

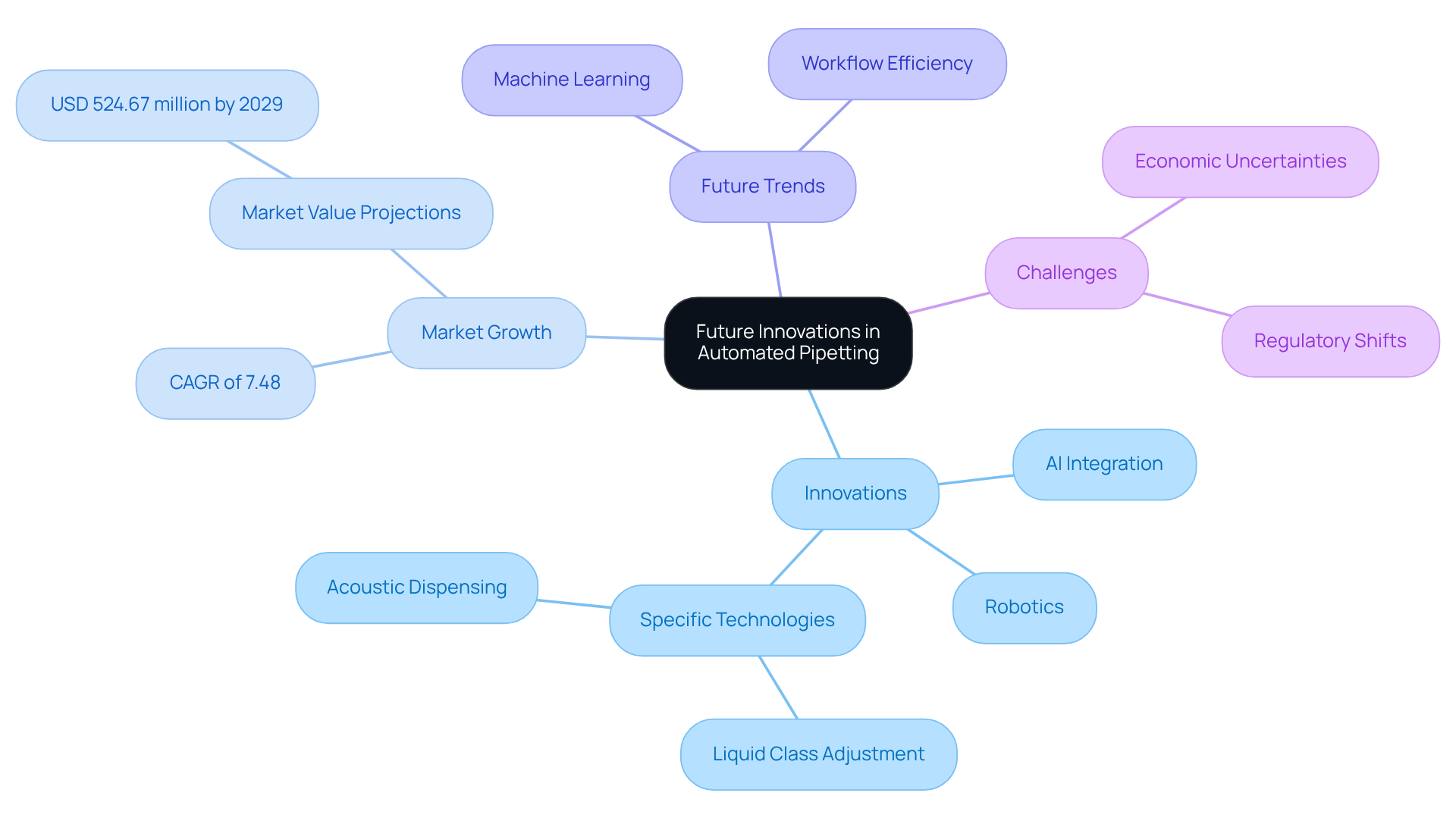

Future Innovations: The Evolving Landscape of Automated Pipetting

The mechanized liquid handling field is rapidly advancing, driven by innovations that significantly enhance efficiency, precision, and user experience. Notable advancements include the integration of sophisticated robotics and artificial intelligence, which are transforming traditional liquid handling techniques into highly automated procedures. For instance, are increasingly being adopted in pharmaceutical laboratories, enabling the management of large sample volumes with minimal human intervention, thereby reducing the risk of manual errors.

Statistics indicate that the global liquid handling robots market is projected to grow at a compound annual growth rate (CAGR) of 7.48% from 2023 to 2029, underscoring a substantial shift towards mechanization in laboratory settings. As laboratories strive for enhanced throughput and accuracy, the incorporation of automated pipetting in liquid handling processes is becoming commonplace, with many organizations recognizing the need for advanced solutions to meet their operational demands.

Looking ahead to 2025, trends in laboratory mechanization are expected to focus on optimizing workflow efficiency and integrating intelligent technologies. This encompasses the use of machine learning algorithms to refine liquid handling processes and enhance accuracy in sample preparation. By adopting these innovations, pharmaceutical laboratories can not only bolster their research capabilities but also secure a competitive advantage in an increasingly challenging industry.

Nonetheless, the automated liquid handling market faces challenges such as economic uncertainties and regulatory shifts that could impact growth. Furthermore, the competitive landscape is evolving, with significant mergers and acquisitions influencing market dynamics. For example, companies like Waters have broadened their capabilities through strategic acquisitions, thereby enhancing their technology portfolios in laboratory automation.

Industry leaders reiterate the significance of these advancements. As a technology leader stated, 'The incorporation of AI and robotics in liquid handling setups is not merely a trend; it's essential for laboratories seeking to enhance efficiency and precision.' Additionally, specific technologies such as Liquid Class Adjustment and Acoustic Dispensing are revolutionizing liquid management, making mechanized setups more adaptable and efficient.

By remaining vigilant about these trends and challenges, pharmaceutical laboratories can strategically position themselves to take advantage of automated pipetting.

Conclusion

Automated pipetting is a transformative force in pharmaceutical laboratories, redefining precision and efficiency in liquid handling. By minimizing human error and streamlining workflows, these advanced systems enhance result accuracy and significantly improve productivity. As the pharmaceutical industry faces escalating demands for rapid and reliable outcomes, embracing automated pipetting becomes essential for maintaining a competitive edge.

The article underscores several key benefits of automated pipetting:

- Improved accuracy through the reduction of human error

- Increased throughput enabling the processing of more samples in less time

- Substantial cost efficiencies that lower operational expenses

Furthermore, ergonomic advantages mitigate the risk of repetitive strain injuries among laboratory personnel, while the consistency of results ensures reliable experimental outcomes. The versatility of these systems allows laboratories to adapt to various liquid handling needs, thereby enhancing overall operational efficiency.

As pharmaceutical laboratories continue to evolve, integrating advanced technologies and providing comprehensive training for personnel will be crucial in maximizing the benefits of automated pipetting. By remaining attuned to innovations and trends in automation, labs can bolster their research capabilities and position themselves for success in a rapidly changing landscape. Embracing these advancements is not merely a trend; it is an essential strategy for driving innovation and excellence in pharmaceutical research.