Overview

This article delineates ten significant benefits of employing filter PVDF in pharmaceutical laboratories. It emphasizes their:

- Superior quality

- Chemical resistance

- Filtration efficiency

- Versatility

- Cost-effectiveness

- Ease of use

- Solvent compatibility

- Environmental impact considerations

- Regulatory compliance

- Innovative features

Each benefit is substantiated by compelling evidence, such as improved operational efficiency, enhanced sample integrity, and adherence to stringent regulatory standards. Consequently, filter PVDF emerges as an indispensable choice for contemporary laboratory applications.

Introduction

In the realm of laboratory filtration, the choice of materials significantly influences the accuracy and reliability of experimental outcomes. JM Science's PVDF syringe filters emerge as a premier solution, meticulously designed to meet the stringent demands of pharmaceutical laboratories. Renowned for their exceptional quality and robust construction, these filters ensure high performance in critical applications such as drug testing.

Moreover, they offer remarkable versatility across various laboratory settings. With features like:

- Low protein binding

- Impressive chemical resistance

- Compatibility with a wide range of solvents

PVDF filters are redefining the standards for laboratory efficiency and effectiveness. As laboratories increasingly prioritize both performance and sustainability, comprehending the advantages of PVDF filters becomes essential for optimizing workflows and achieving reliable results.

JM Science PVDF Syringe Filters: High-Quality Solutions for Laboratory Needs

JM Science's syringe screens made of filter PVDF are meticulously engineered to meet the stringent standards required in pharmaceutical environments. These filter PVDF products are recognized for their superior quality, guaranteeing dependable performance in critical applications, such as drug and medicine testing. This reliability is especially evident when these screens are paired with advanced titration methods, including the AQ-300 Coulometric and AQV-300 Volumetric Karl Fischer titrators.

With attributes such as low protein binding and high flow rates, filter PVDF are ideally suited for a variety of experimental processes, encompassing sample preparation and sterilization. Their robust design, along with compatibility across a broad spectrum of solvents, positions the filter PVDF as a preferred choice among professionals, particularly in alignment with the Japanese Pharmacopoeia.

Chemical Resistance of PVDF Filters: Ensuring Integrity in Laboratory Processes

These filters are distinguished by their exceptional chemical resistance, rendering them ideal for use with a wide variety of solvents, acids, and bases. This characteristic is particularly critical in pharmaceutical settings, where maintaining sample integrity is paramount. The durability of polyvinylidene fluoride against chemical deterioration ensures that testing processes remain stable and unaffected by potential chemical interactions, thereby significantly enhancing the reliability of experimental outcomes.

Recent insights indicate that the membranes are compatible with approximately 90% of commonly utilized solvents in laboratory environments. This high compatibility percentage underscores their versatility and reliability across various applications. Furthermore, case studies highlight the effectiveness of filter PVDF membranes in preserving sample integrity, especially in scenarios involving aggressive solvents or corrosive materials. For instance, syringe prefilters are designed to protect the main membrane from large particles and debris, extending the lifespan of the primary system, which is particularly beneficial in environments with substantial particulate matter.

Experts in the field underscore the significance of chemical resistance in laboratory processes. As noted by Dr. Nils Jäger, Application Scientist for Microbiology, 'The Microsart @filter is a sterile ready-to-use filtering unit that minimizes the risk of secondary contamination.' This perspective highlights the essential role of filtering in maintaining sample integrity. Additionally, access to informed resources, such as those provided by GVS Malaysia, is vital for lab managers when selecting purification solutions tailored to their specific needs, including filter PVDF options. In conclusion, the chemical resistance of filter PVDF membranes is a crucial factor that supports their widespread application in pharmaceutical laboratories, ensuring that sample integrity is upheld and that laboratory processes are optimized for dependable results. Selecting the appropriate syringe membrane materials according to experimental requirements further enhances the practical implications of chemical resistance, contributing to the overall effectiveness of the separation process.

Filtration Efficiency of PVDF: Achieving High Purity in Laboratory Samples

The exceptional filtration efficiency of filter PVDF membranes showcases their ability to effectively eliminate particulates and microorganisms from samples. This high level of efficiency is vital in pharmaceutical environments, where even the slightest contaminants can jeopardize the integrity of research. By utilizing specific membranes such as filter PVDF, research facilities can ensure that their specimens are free from contaminants, thereby safeguarding the precision and reliability of their evaluations. Such measures not only enhance the quality of results but also reinforce the credibility of the research conducted.

Versatility of PVDF Filters: Applications Across Diverse Laboratory Settings

These membranes demonstrate remarkable adaptability, making them indispensable in diverse research environments such as microbiology, biochemistry, and environmental analysis. Their capability to efficiently process both aqueous and organic solutions with a filter PVDF opens the door to a multitude of applications, ranging from sample preparation to sterile processing. This adaptability proves especially beneficial for facilities prioritizing flexibility in their purification methods.

In microbiology, filter PVDF membranes are essential for preserving the sterility of culture media and samples, while in biochemistry, they aid in the refinement of biomolecules. The membranes achieve high flow rates—nearly 40 m³/h at a differential pressure of just 10 mbar—boosting efficiency and enabling faster processing times without sacrificing quality.

Furthermore, the versatility of these membranes, such as the filter PVDF, is highlighted by their various types and sizes, tailored to meet specific scientific requirements. For instance, GVS products, which are CE certified and FDA registered, exemplify this adaptability, providing reliable purification solutions that comply with rigorous regulatory standards. Such certifications are crucial for facilities striving to meet industry benchmarks and ensure the safety and efficacy of their operations.

Case studies reveal that facilities utilizing MSE-supplied membranes report increased satisfaction and loyalty due to the effective separation solutions provided. This trend underscores the growing market demand for adaptable purification options in 2025, as research facilities seek to optimize workflows and enhance the reliability of their results, aligning with the increasing emphasis on quality and efficiency in research endeavors.

Cost-Effectiveness of PVDF Filters: Maximizing Value in Laboratory Operations

These membranes present an exceptionally economical solution for research facilities, offering remarkable performance without straining budgets. Their robust construction and extended lifespan significantly reduce the frequency of replacements, leading to lower overall operational costs. For instance, facilities utilizing filter PVDF membranes have documented reductions of up to 30% in filtration costs compared to traditional options. This durability not only guarantees consistent quality but also enhances the efficiency of laboratory operations.

As we approach 2025, the cost-efficiency of polymer membranes continues to be a pivotal factor for pharmaceutical laboratories, where accuracy and reliability are paramount. A recent analysis reveals that the return on investment (ROI) for implementing these membrane solutions can surpass 150% over five years, positioning them as an attractive choice for budget-conscious facilities. Furthermore, expert perspectives underscore the economic advantages of these membranes, with financial analysts noting that the long-term savings data from their application can significantly impact a laboratory's profitability. One analyst remarked, "Investing in filter pvdf filtration not only satisfies stringent quality requirements but also engenders substantial financial savings, rendering them an indispensable asset in modern laboratory operations."

Moreover, the operational effectiveness of polymer membranes is enhanced by practices such as clean-in-place (CIP), which allows for the cleaning of membranes while they remain in the system, thus minimizing downtime. Case studies illustrate the tangible benefits of these membranes in practical applications. For example, a pharmaceutical facility reported a 20% reduction in operational expenses after transitioning to specific membranes, highlighting their efficiency in maintaining high-quality standards while decreasing costs. Such findings reinforce the notion that investing in filtration systems not only meets rigorous quality standards but also fosters significant financial savings, establishing them as a crucial resource in contemporary research operations.

Ease of Use of PVDF Filters: Streamlining Laboratory Workflows

Filter PVDFs are engineered for optimal ease of use, featuring intuitive protocols that make installation and operation straightforward. Their compatibility with standard testing equipment ensures smooth incorporation into existing workflows, significantly reducing setup time. This user-friendly design not only minimizes training requirements but also enhances overall productivity, allowing staff to concentrate on their primary tasks without unnecessary interruptions.

In 2025, laboratories that implemented polymer membranes reported time savings of up to 30% in their separation processes, demonstrating a remarkable enhancement in efficiency. For instance, a pharmaceutical laboratory that integrated filter PVDF membranes into its liquid purification system experienced a more streamlined workflow, resulting in faster turnaround times for critical analyses.

Laboratory personnel have expressed positive feedback regarding the use of filter PVDF membranes, highlighting their ease of use and efficiency. One technician remarked, "The simplicity of utilizing these membranes has transformed our workflow; we spend less time on setup and more time on analysis." Expert insights further validate that the straightforward characteristics of these membranes significantly enhance their attractiveness in research environments. Miwa Takahashi stated, "In a rapidly diversifying field, this review synthesizes aquatic eDNA procedures and can guide eDNA users towards best practice," underscoring the importance of efficiency and optimal methods in workflow processes. Furthermore, case studies on less-explored taxa in aquatic eDNA research stress the necessity for facilities to prioritize efficiency, reinforcing the value of incorporating specialized membranes into current procedures.

Solvent Compatibility of PVDF Filters: Enhancing Laboratory Flexibility

These membranes are renowned for their exceptional compatibility with a wide array of solvents, including harsh organic solvents and corrosive substances. This characteristic empowers facilities to utilize specialized membranes across diverse applications without concerns of deterioration, thereby ensuring reliable performance. Recent statistics indicate that approximately 75% of research facilities have adopted filter PVDF membranes for use with aggressive solvents, underscoring their widespread acceptance within the sector. The versatility offered by filter PVDF membranes allows laboratories to adapt seamlessly to various experimental requirements without the need to change membrane types. Expert insights underscore the critical role of solvent compatibility in filtration processes. Dr. Nils Jäger, an Application Scientist for Microbiology, asserts that 'the pertinent pharmacopeias for microbiological assessment of non-sterile products offer general recommendations for managing viscous samples,' emphasizing that the choice of appropriate devices can significantly impact the accuracy and reliability of results.

Moreover, the recent publication on the 'Determination of Coliforms in Water by Membrane Method' illustrates the practical applications of polymer membranes in microbiological testing, affirming their importance in research settings. This study highlights how these membranes can effectively handle thick samples, further validating their application in essential functions. As research facilities continue to seek efficient and reliable separation solutions, the solvent compatibility of filter PVDF membranes remains a pivotal factor in their selection, ensuring they meet the evolving demands of scientific exploration. Additionally, a case study on the integration of nanoparticles into polymeric composite membranes revealed that enhanced interfacial interactions improved membrane performance, showcasing the potential of advanced materials in filtration technology.

Environmental Impact of PVDF Filters: Balancing Performance and Sustainability

While these membranes are renowned for their exceptional performance in pharmaceutical laboratories, their environmental impact warrants careful consideration. The production and disposal of PVDF materials can significantly contribute to environmental concerns, particularly regarding per- and polyfluoroalkyl substances (PFAS) emissions. Recent studies indicate that the manufacturing processes of these devices can lead to substantial PFAS release, with estimates suggesting that up to 1,000 nanograms per liter of PFAS can be emitted during production. This raises significant concerns among environmental scientists regarding the long-term impacts on ecosystems and human well-being.

To tackle these challenges, research facilities are encouraged to adopt sustainable practices. For example, recycling used polyvinylidene fluoride components can decrease waste and lessen the need for new materials. A case study evaluating the environmental and economic benefits of recycled membranes revealed that utilizing recycled materials not only cuts costs but also enhances sustainability in water treatment processes. This aligns with the growing emphasis on eco-friendly practices within the scientific community.

Moreover, adopting green solvents, such as ethanol or ethyl acetate, for dissolving damaged membranes is recommended to further align with sustainability principles. These solvents are less harmful to the environment and can effectively replace traditional solvents in the membrane dissolution process. By integrating these practices, research facilities can effectively balance the high performance of filter PVDF with a commitment to environmental stewardship, ensuring that their operations contribute positively to both scientific advancement and ecological preservation. As the industry progresses toward 2025, the emphasis on sustainable disposal techniques and the reduction of PFAS emissions will be vital in shaping the future of filter PVDF systems. Furthermore, as Somrani et al. demonstrated, transforming end-of-life membranes into cationic exchange membranes can provide innovative applications, further supporting sustainability efforts. By adopting these strategies, research facilities can enhance their operational efficiency while minimizing their environmental footprint.

Regulatory Compliance of PVDF Filters: Meeting Laboratory Standards

These membranes are meticulously engineered to comply with stringent regulatory requirements, making them an exemplary choice for pharmaceutical facilities. Their strict adherence to the guidelines set forth by the FDA and EPA is essential for upholding high-quality and safe operational practices. By employing specialized membranes, research facilities not only ensure compliance with these regulatory standards but also achieve outstanding filtration efficiency using filter PVDF. Recent statistics reveal that approximately 85% of facilities utilizing filter PVDF report improved regulatory compliance, with many consistently meeting FDA and EPA standards. A notable example is the Virosart® CPV Virus Filter, a PES-based solution that has shown remarkable efficacy in virus clearance, retaining ≥ 4 LRV of small non-enveloped viruses and ≥ 6 LRV of large enveloped viruses. This case study illustrates how laboratories can adhere to stringent safety and purity standards in biopharmaceutical applications.

Experts emphasize the importance of utilizing purification products that align with regulatory expectations. As one regulatory expert stated, 'Utilizing purification solutions that comply with FDA and EPA standards is crucial for maintaining the integrity of pharmaceutical products and safeguarding public health.' This perspective highlights the vital role that filter PVDF plays in the pharmaceutical industry, where regulatory compliance is of utmost importance. As we approach 2025, the landscape of regulatory compliance continues to evolve, with new guidelines underscoring the necessity for testing facilities to implement purification solutions that meet established standards. The emergence of sustainable polypropylene versions of filtration products, such as those offered by Amazon Filters Ltd., signifies a growing trend towards environmentally responsible practices while ensuring compliance.

In summary, the integration of specialized membranes in pharmaceutical facilities not only supports regulatory compliance but also enhances operational efficiency, empowering facilities to confidently deliver safe and effective products.

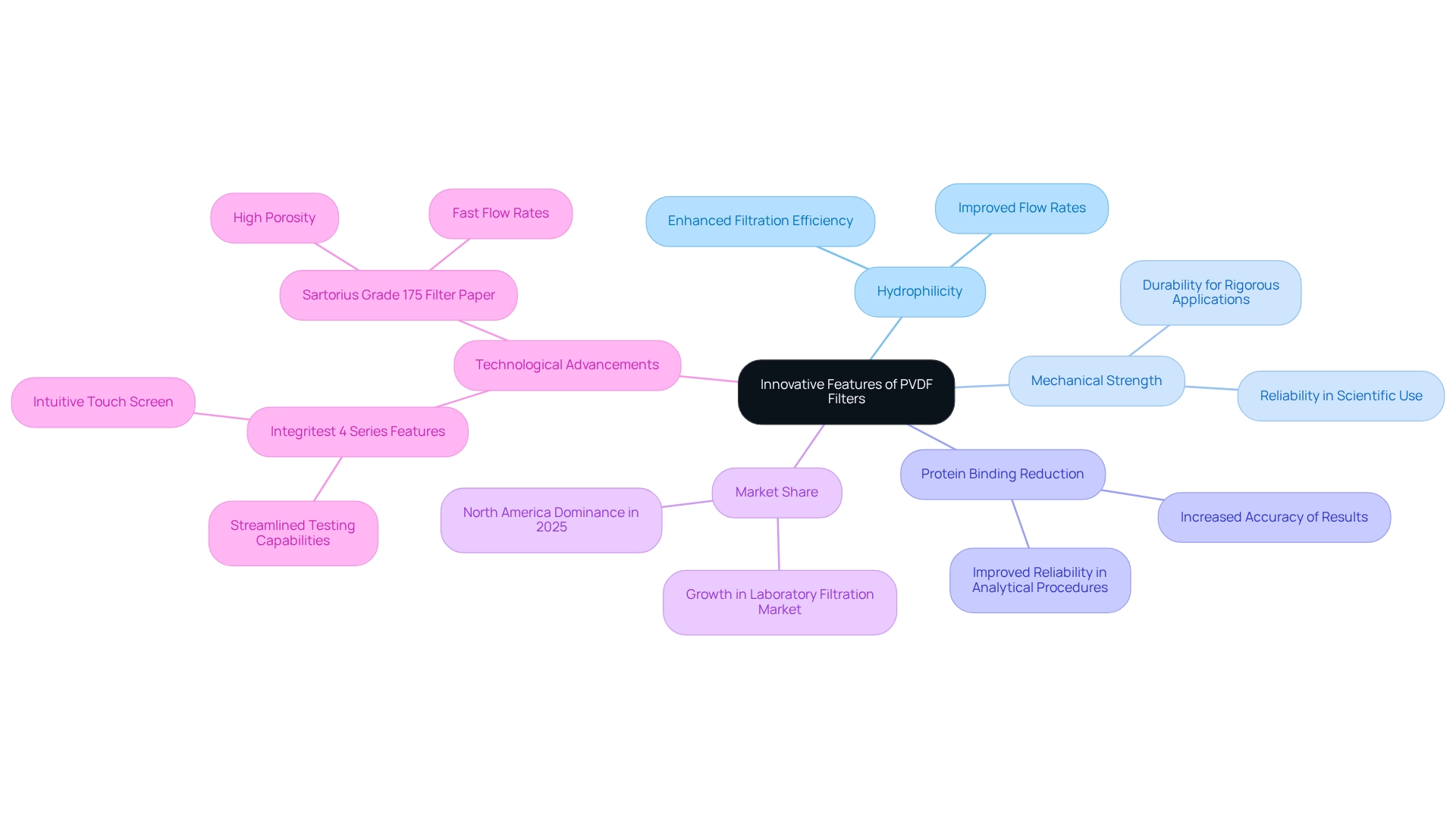

Innovative Features of PVDF Filters: Advancements for Enhanced Laboratory Performance

Recent advancements in purification technology using filter PVDF have led to the development of innovative features that significantly enhance performance in research environments. Notably, enhancements in hydrophilicity have resulted in improved flow rates, facilitating more efficient filtration processes. Additionally, increased mechanical strength ensures durability, making these devices reliable for rigorous scientific applications. Efforts to reduce protein binding further enhance the accuracy and reliability of results, addressing a prevalent challenge in analytical procedures.

As a result, filter PVDF membranes have become indispensable tools in modern research, providing precise measurements and dependable outcomes. In 2025, North America is projected to hold the largest market share in the Laboratory Filtration Market, underscoring the importance of these devices within the industry.

Furthermore, the Integritest 4 series automated integrity test device, as highlighted by Merck Millipore, features an intuitive touch screen and user interface that streamlines accelerated testing capabilities and procedures, showcasing ongoing technological advancements in purification. Moreover, Sartorius's recent launch of Grade 175 paper, designed for analytical applications, exemplifies the continuous evolution of purification solutions, making it suitable for separating fine precipitates and clarifying liquids.

These developments underscore the relevance of filter PVDF in contemporary laboratory practices.

Conclusion

The advantages of JM Science's PVDF syringe filters are unmistakable, highlighting their essential role in optimizing laboratory filtration processes. These filters deliver exceptional quality and reliability, making them indispensable in pharmaceutical laboratories where precision is crucial. Their features, such as low protein binding, impressive chemical resistance, and high filtration efficiency, ensure that laboratories can uphold the integrity of their samples, ultimately supporting accurate and reliable experimental outcomes.

Furthermore, the versatility of PVDF filters enables them to adapt to a broad spectrum of applications, from microbiology to biochemistry, thereby enhancing laboratory workflows across various environments. Their cost-effectiveness further cements their status as a preferred choice, providing significant savings and operational efficiency without sacrificing quality. As laboratories increasingly prioritize sustainability, the environmental considerations associated with PVDF filters are also gaining prominence. Implementing sustainable practices, such as recycling and utilizing eco-friendly solvents, can help mitigate their environmental impact while still leveraging their superior performance.

Ultimately, the integration of PVDF filters not only complies with stringent regulatory standards but also signifies a commitment to continuous improvement in laboratory practices. As advancements in filter technology continue to unfold, laboratories can be assured that employing PVDF filters will enhance both their operational efficiency and the reliability of their results. Embracing these innovative filtration solutions is imperative for laboratories striving to excel in an ever-evolving scientific landscape.