Overview

The article delineates ten significant benefits of liquid handling automation for pharmaceutical laboratories, underscoring enhanced efficiency, accuracy, and cost savings. These advantages are substantiated by evidence drawn from various case studies and expert testimonials, which collectively demonstrate that automation effectively minimizes human error, streamlines workflows, and ultimately results in more reliable and reproducible experimental outcomes in pharmaceutical research.

Introduction

Liquid handling automation is transforming the landscape of pharmaceutical laboratories, delivering precision and efficiency that traditional methods cannot match. By streamlining repetitive tasks and minimizing human error, these advanced systems not only enhance the accuracy of experimental results but also drive significant cost savings and operational improvements. As the demand for high-quality research intensifies, laboratories must consider how to harness the full potential of liquid handling automation to remain competitive and meet the evolving challenges of pharmaceutical development.

JM Science Liquid Handling Automation: Precision and Reliability

JM Science Inc. provides advanced liquid handling automation solutions that ensure accuracy and reliability in pharmaceutical laboratories. Their systems are meticulously designed to minimize variability in fluid dispensing, which is crucial for maintaining the integrity of experimental results. By utilizing high-performance chromatography (HPLC) components alongside other specialized instruments, JM Science significantly enhances the precision of fluid management processes. This makes their solutions indispensable for both research institutions and pharmaceutical companies, underscoring the importance of high-quality scientific instruments in laboratory settings.

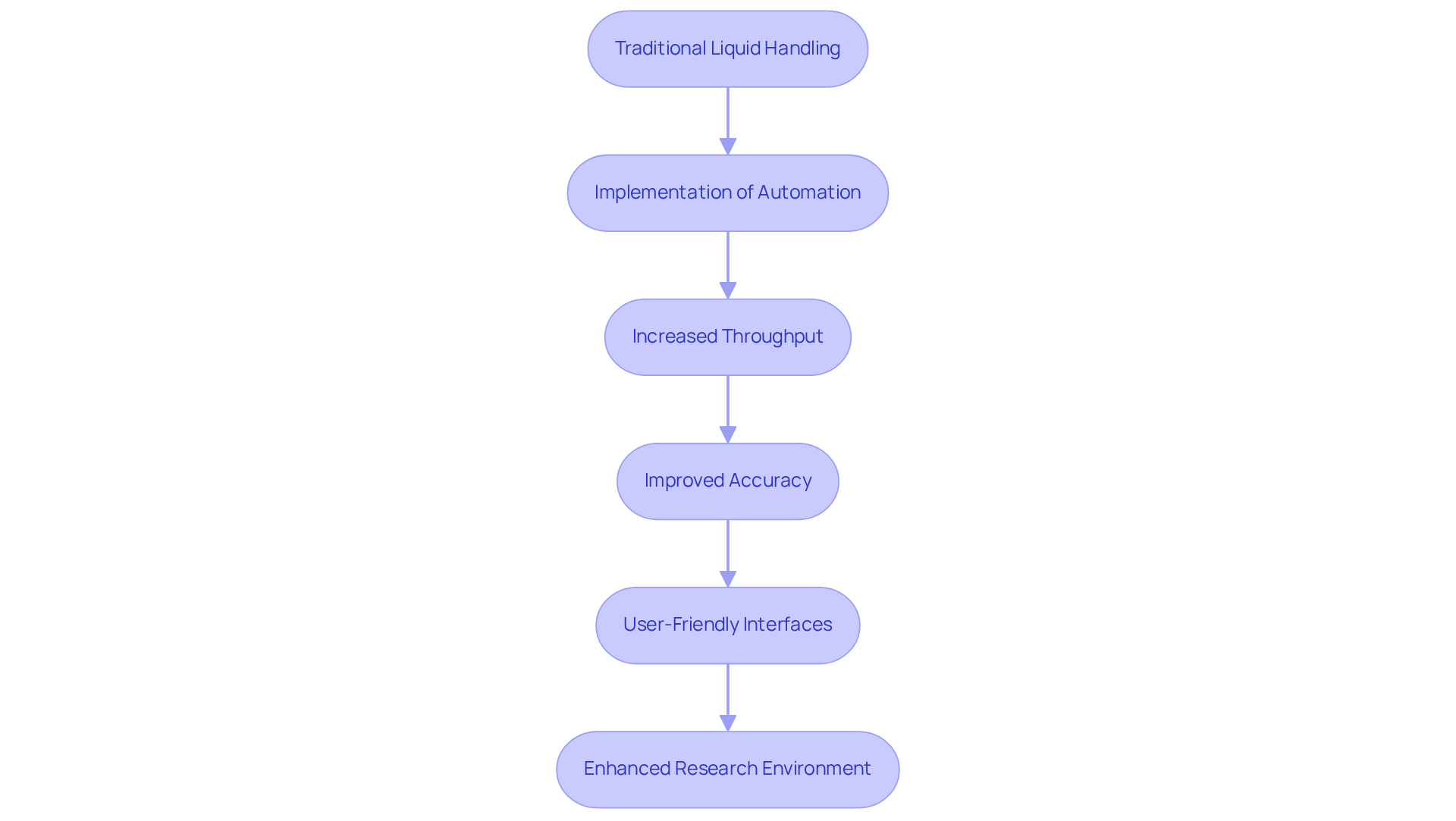

Increased Efficiency: Streamlining Laboratory Processes

Liquid handling automation through automated devices revolutionizes laboratory processes by significantly reducing the time spent on repetitive tasks such as pipetting and sample preparation. These sophisticated systems operate continuously, dramatically enhancing throughput and enabling laboratories to manage a greater volume of samples with efficiency. For example, the Agilent Bravo Automated Liquid Handling Platform can achieve an average cycle time of approximately 10 seconds for microplate transfers, allowing for simultaneous processing of multiple samples. This acceleration not only streamlines workflows but also empowers researchers to focus on more intricate analytical tasks.

Laboratory managers have observed that the implementation of liquid handling automation has optimized their operations, with many reporting an average throughput increase of up to 50% in their workflows. By utilizing liquid handling automation for routine activities, laboratories can improve accuracy and consistency, thereby minimizing the risk of human error. Furthermore, advancements in automation software have significantly enhanced the precision of liquid handling automation, ensuring reliable results across various applications. User-friendly interfaces in these systems facilitate the management of multiple instruments and assays, making them accessible to technicians with diverse levels of expertise. This transition towards automation not only boosts operational efficiency but also cultivates a more productive research environment, ultimately propelling progress in pharmaceutical development.

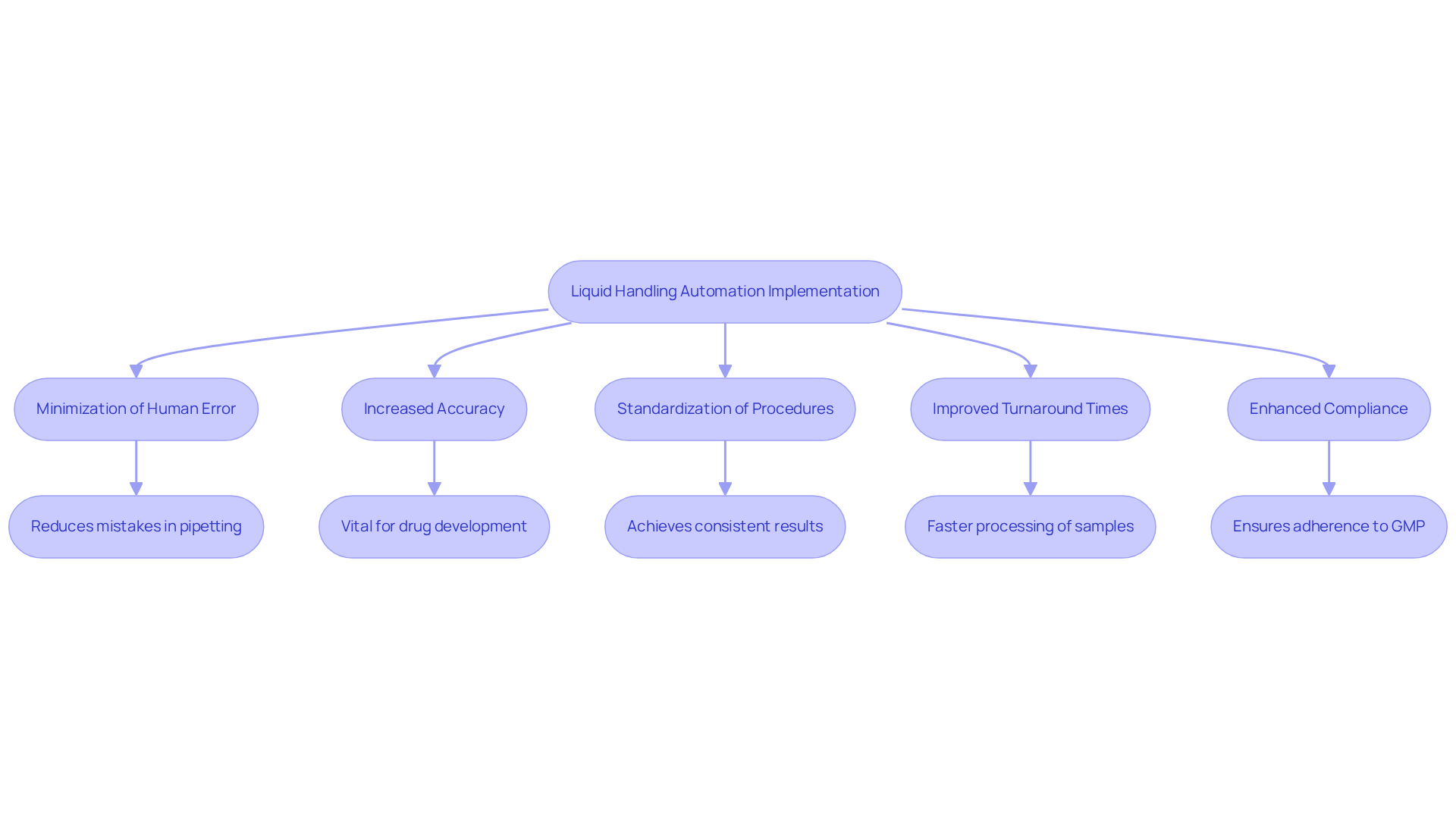

Minimized Human Error: Enhancing Accuracy in Experiments

One of the most significant advantages of liquid handling automation is its capability to significantly minimize human error. Automated systems in liquid handling automation are meticulously programmed to execute tasks with exceptional precision, thereby minimizing the risk of mistakes that can arise during manual pipetting. This accuracy is vital in pharmaceutical settings, where even slight inaccuracies can result in significant consequences in drug development and testing.

By standardizing liquid handling automation procedures, research facilities can achieve more consistent and reliable results. The adoption of automated solutions, particularly liquid handling automation, has demonstrated enhancements in turnaround times and a decrease in processing mistakes, as indicated by the experiences of facilities employing advanced technologies such as the Freedom EVO workstation.

Prof Haferlach noted, "No matter how good your workflows and staff are, mistakes happen. Liquid handling automation will always be more reproducible, generating better quality results than manual procedures, with far less risk of processing errors."

Such innovations not only streamline workflows but also enable researchers to concentrate on more complex tasks, thereby promoting a more efficient and productive work environment. Furthermore, automation plays a vital role in ensuring compliance with Good Manufacturing Practices (GMP), ultimately enhancing the quality assurance process in pharmaceutical operations.

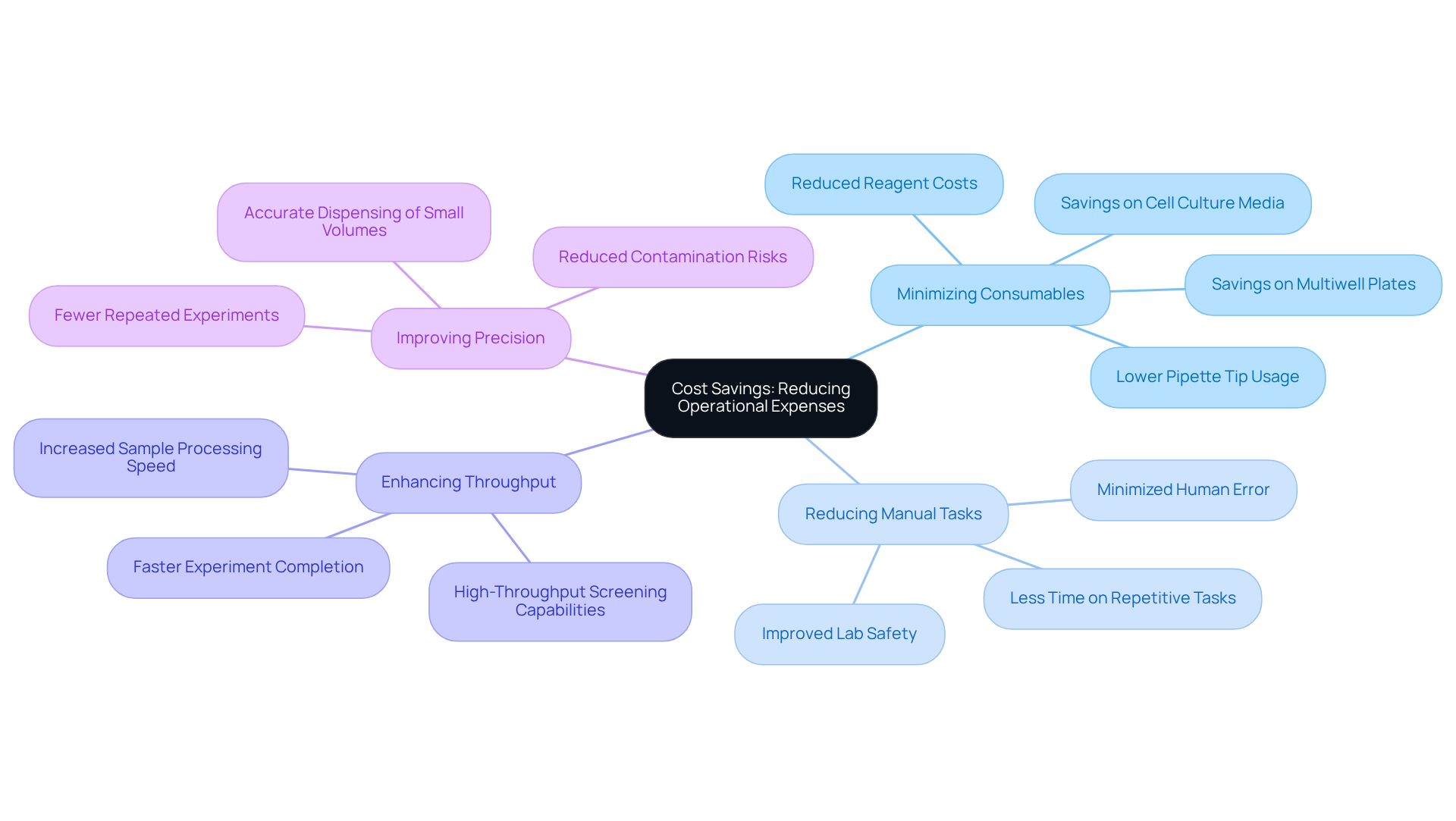

Cost Savings: Reducing Operational Expenses

Introducing liquid handling automation systems presents an opportunity for substantial cost reductions within pharmaceutical research facilities. By minimizing reliance on consumables such as pipette tips and reagents, alongside reducing the time allocated to manual tasks, laboratories can significantly lower their operational expenses with liquid handling automation.

Furthermore, the enhanced throughput and efficiency associated with liquid handling automation systems can expedite project completion, thereby amplifying cost-effectiveness. Liquid handling automation through automated fluid management systems executes dispensing tasks with remarkable precision, which diminishes the need for repeated experiments. This precision translates directly into savings on essential supplies, including multiwell plates and cell culture media.

Additionally, these frameworks improve liquid handling automation, which mitigates human errors and contamination—critical factors in research environments—thereby streamlining procedures and ensuring more reliable outcomes.

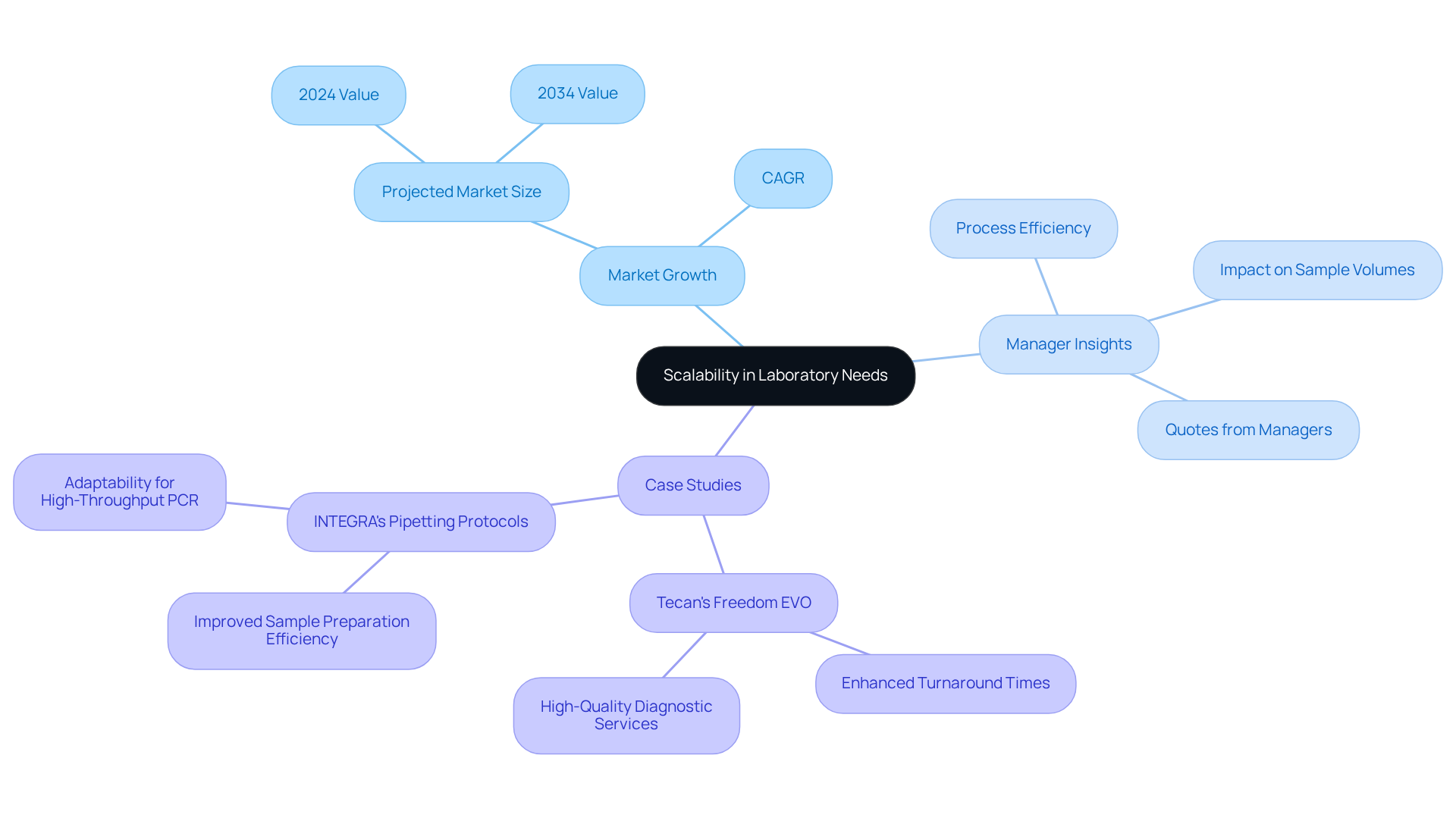

Scalability: Adapting to Growing Laboratory Needs

Automated fluid management solutions, specifically liquid handling automation, are essential for research facilities experiencing expansion, providing the necessary scalability to accommodate increasing sample volumes and evolving experimental procedures. These systems offer easy expansion and modification, enabling facilities to maintain operational efficiency without incurring significant additional costs for new equipment. The global automated fluid management market, projected to reach approximately USD 1061.29 million in 2024, is expected to grow at a CAGR of 8.60%, nearing USD 2421.77 million by 2034. This growth is propelled by heightened research activities in life sciences and drug development, which demand more efficient workflows.

Laboratory managers have observed the transformative effects of automation on their operations. A manager from Sullivan Nicolaides Pathology emphasized the need to adapt to rising sample volumes, noting that automation not only streamlines processes but also improves accuracy and reproducibility. For example, during the COVID-19 pandemic, facilities rapidly adopted liquid handling automation to boost testing capabilities, illustrating the technology's effectiveness in meeting urgent demands.

Case studies further demonstrate this adaptability. In one instance, a research facility implemented Tecan's Freedom EVO solutions, enabling unattended overnight processing. This alleviated personnel from repetitive tasks, allowing them to focus on more complex research activities. This implementation not only enhanced turnaround times but also contributed to sustained productivity and ensured high-quality outcomes. Similarly, INTEGRA's automated pipetting protocols significantly improved sample preparation efficiency for high-throughput PCR testing, showcasing how liquid handling automation can be customized to meet the growing demands of research facilities.

As laboratories continue to expand, the integration of liquid handling automation will be vital for sustaining productivity and ensuring high-quality results.

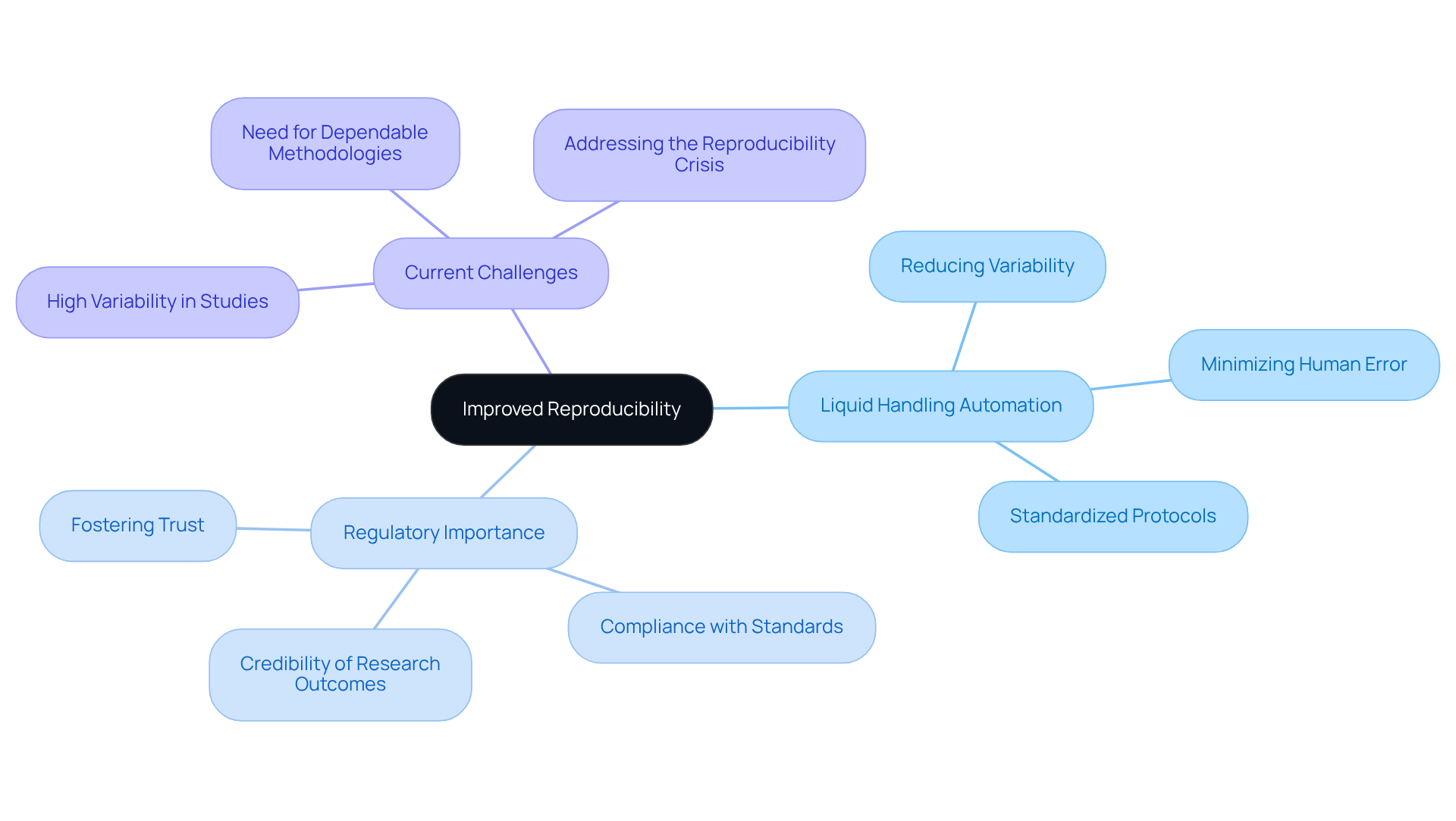

Improved Reproducibility: Consistent Results Across Experiments

Liquid handling automation technologies are essential for enhancing the consistency of experimental outcomes in pharmaceutical laboratories. By implementing uniform fluid management procedures, these systems ensure that every experiment is conducted under identical conditions, significantly reducing variability. This consistency is crucial in pharmaceutical research, where reproducibility is not only necessary for validating findings but also for adhering to stringent regulatory standards.

Regulatory experts assert that consistent results are fundamental to the credibility of research outcomes, fostering trust in the generated data. Research indicates that laboratories employing automated fluid management experience fewer inconsistencies in their results, leading to more reliable data that can withstand scrutiny during regulatory assessments.

Moreover, it is alarming that over 50% of preclinical animal studies lack reproducibility, highlighting the urgent need for dependable methodologies in research. By minimizing human errors and ensuring precise fluid management, these technologies demonstrate how automation can elevate the quality of experimental procedures, ultimately supporting the advancement of pharmaceutical development.

To enhance your laboratory's reproducibility, consider integrating automated fluid distribution technologies into your workflows.

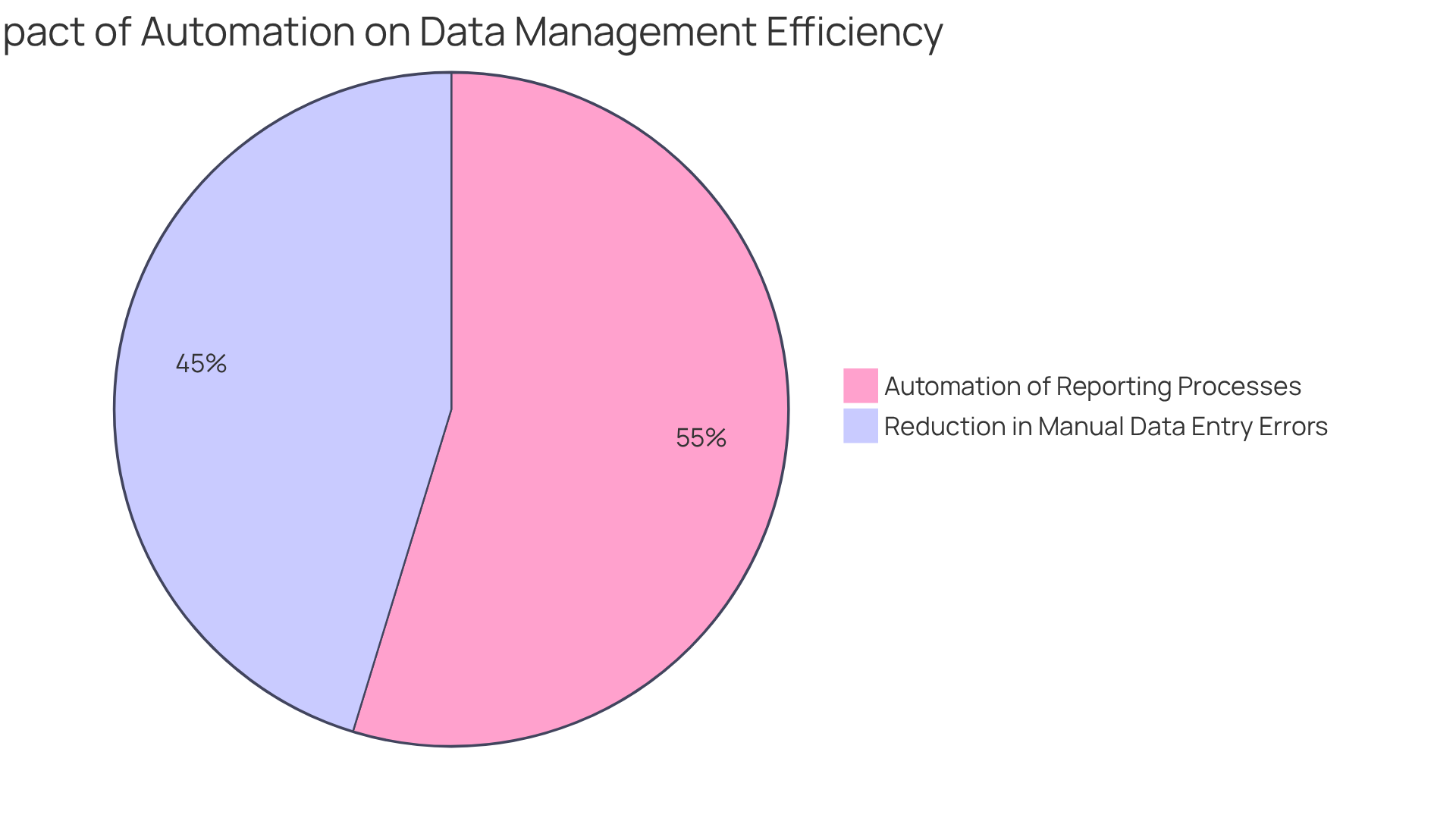

Enhanced Data Management: Streamlining Compliance and Reporting

Liquid handling automation systems significantly enhance data management by seamlessly integrating with information management systems (LIMS) and other software solutions. This integration streamlines compliance and reporting processes, ensuring that all data is accurately captured and readily accessible. By automating data entry and management, research facilities can minimize the risk of errors, which is essential for meeting stringent regulatory requirements.

Organizations that have implemented LIMS integration report a marked improvement in compliance, with many noting a reduction in manual data entry errors by up to 48%. As highlighted in Work Insight Reports, "BPM tools successfully automate tasks, particularly reducing manual errors by 48%." Furthermore, 58% of organizations automate reporting and planning processes to enhance decision-making, enabling facilities to respond more swiftly to regulatory changes and improve overall operational efficiency.

Consequently, facilities utilizing liquid handling automation achieve substantial enhancements in their compliance and reporting capabilities, ultimately fostering a more reliable and effective research environment.

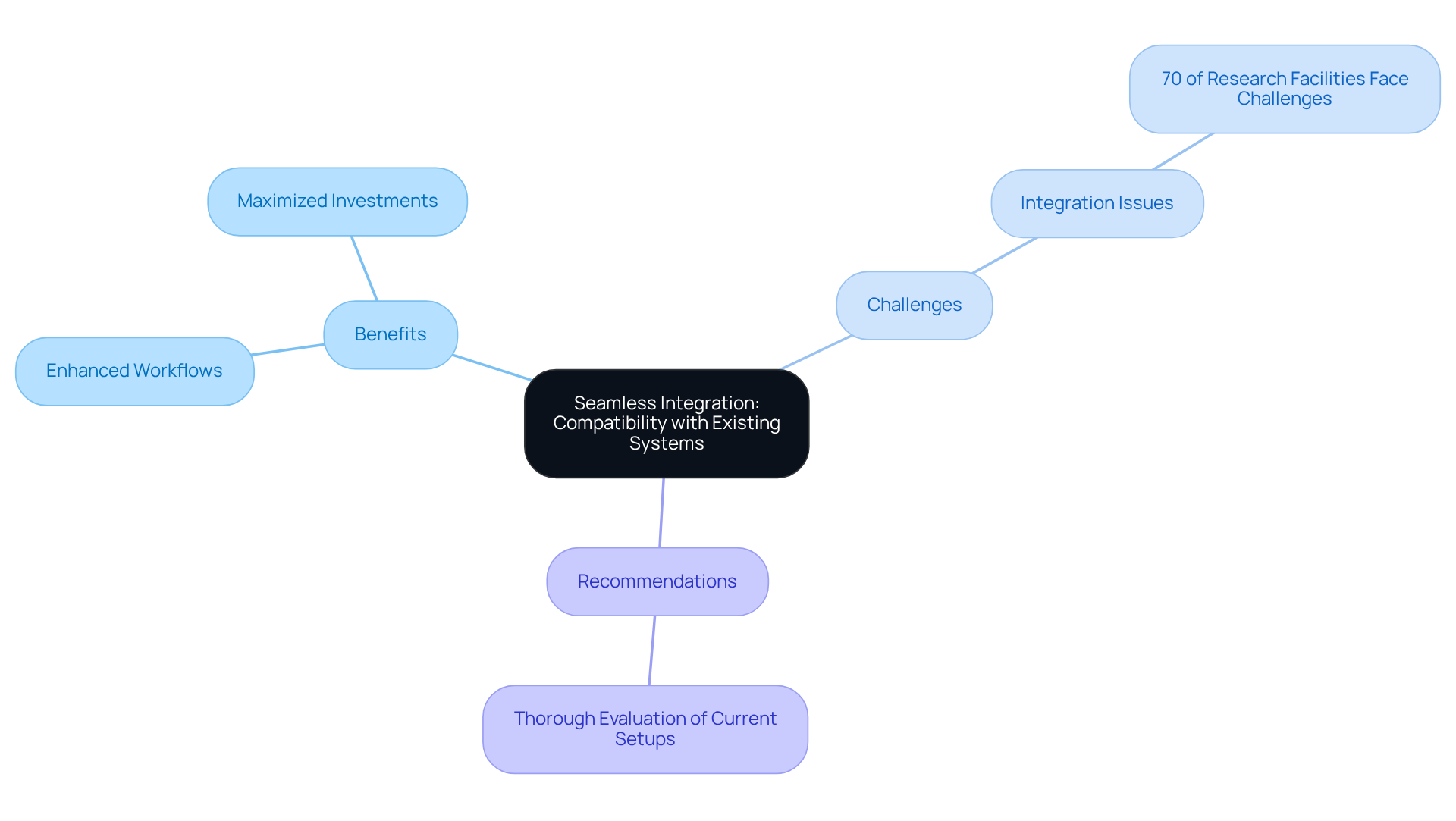

Seamless Integration: Compatibility with Existing Systems

Liquid handling automation systems are engineered for seamless integration with existing equipment and software, thereby facilitating enhanced workflows without necessitating complete system overhauls. This compatibility is crucial, as it empowers facilities to incorporate new automation technologies alongside their current instruments, ultimately maximizing their investments.

A recent study revealed that 70% of research facilities faced integration challenges when adopting automation, underscoring the necessity for solutions that streamline these processes. Laboratory directors assert that successful automation not only boosts productivity but also preserves existing workflows, resulting in a smoother transition to advanced technologies.

For instance, one director noted, "The integration of liquid handling automation with our existing protocols has greatly enhanced our resource utilization and outcomes in pharmaceutical research." By aligning automation technologies with established workflows, facilities can effectively mitigate integration challenges and enhance operational efficiency.

To further refine the integration process, facilities should conduct a thorough evaluation of their current setups, identifying specific areas where automation can deliver the most substantial benefits.

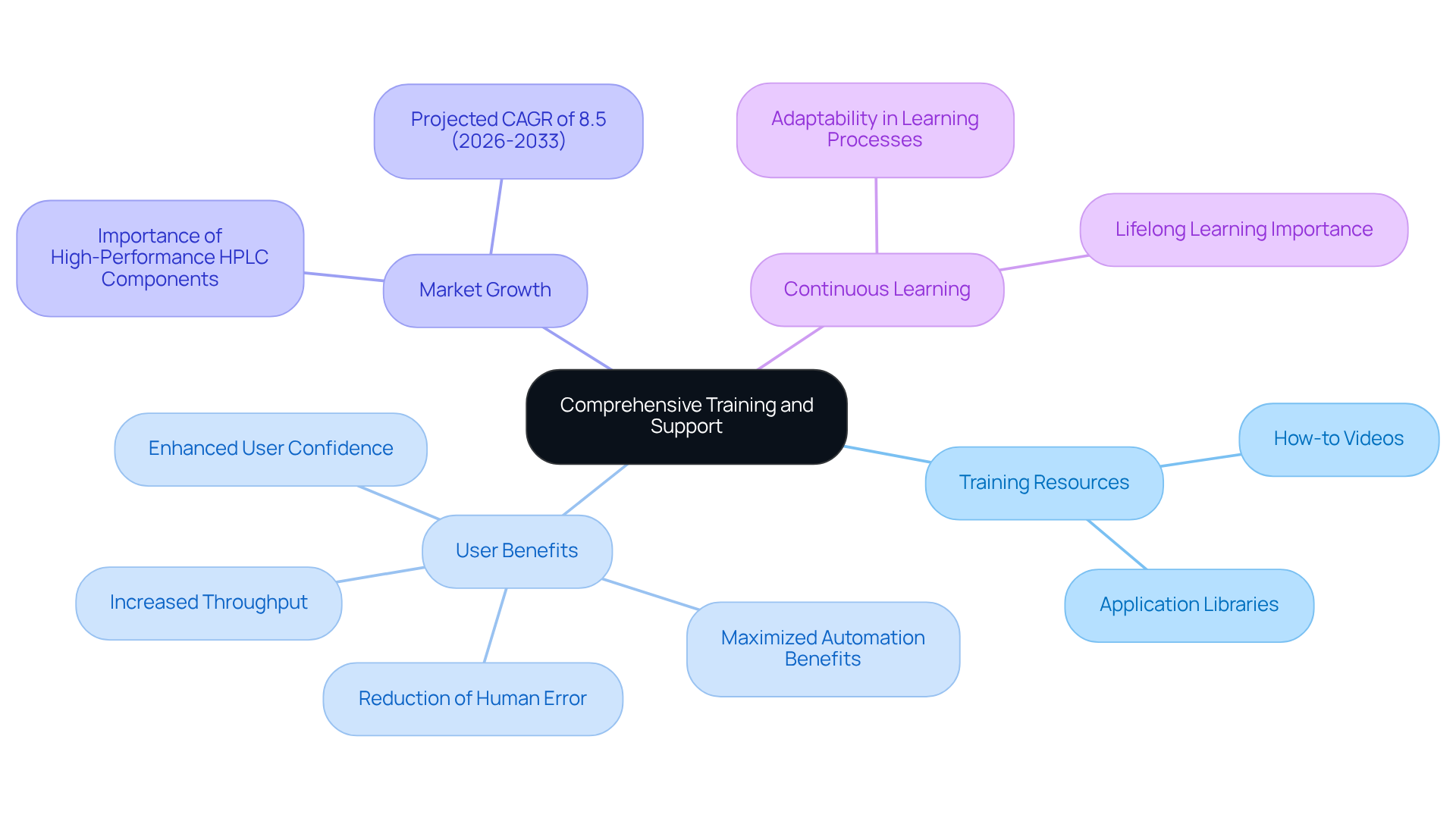

Comprehensive Training and Support: Ensuring Successful Implementation

The successful execution of liquid handling automation solutions hinges on comprehensive training and support. JM Science offers an extensive array of resources, including how-to videos and application libraries, aimed at empowering personnel to master new technologies. This training not only enhances user confidence but also maximizes the benefits of automation, ensuring that systems are leveraged to their full potential.

Facilities that have embraced liquid handling automation report significant improvements in workflow efficiency and precision, resulting in a reduction of human error and an increase in throughput. A case study highlighting the integration of AI and ML in automation underscores these advancements, demonstrating how they enhance workflow efficiency and accuracy while minimizing human error and boosting throughput.

As the automation equipment market is projected to grow at a CAGR of 8.5% from 2026 to 2033, JM Science's commitment to providing exceptional pricing on high-performance HPLC components and effective training becomes increasingly vital. By equipping users with essential skills and knowledge, JM Science plays a crucial role in enhancing operational efficiency and fostering innovation within pharmaceutical labs.

As training specialist Jim Kwik aptly states, "If knowledge is power, then learning is a superpower," highlighting the significance of continuous learning in harnessing automation technologies.

Future Trends: Innovations Shaping Liquid Handling Automation

The field of liquid handling automation is continuously evolving, with innovations like AI integration, miniaturization, and enhanced robotics significantly shaping its future. These advancements are not merely incremental; they promise to substantially enhance efficiency, accuracy, and scalability in experimental procedures. As laboratories increasingly adopt liquid handling automation along with other cutting-edge technologies, they will be better positioned to meet the rigorous demands of modern pharmaceutical research and development. Embracing these innovations is not just an option; it is essential for staying competitive in an ever-evolving landscape.

Conclusion

Liquid handling automation signifies a transformative advancement in the efficiency and accuracy of pharmaceutical laboratories. By integrating advanced technologies, these systems not only streamline workflows but also enhance precision, reduce human error, and improve overall reproducibility in experimental results. The importance of adopting such automation cannot be overstated; it empowers laboratories to uphold high standards in drug development and research.

Key insights from the discussion underscore the multifaceted advantages of liquid handling automation. These include:

- Increased efficiency through the reduction of manual tasks

- Minimized errors that lead to more reliable outcomes

- Significant cost savings achieved by optimizing resource utilization

Furthermore, the scalability of these systems enables laboratories to adjust to growing demands without compromising quality, while enhanced data management capabilities ensure compliance with regulatory standards.

As the landscape of pharmaceutical research evolves, embracing liquid handling automation becomes essential for laboratories striving to remain competitive. The potential for future innovations, such as AI integration and advanced robotics, promises to further revolutionize experimental conduct, ensuring that laboratories can meet the rigorous demands of modern science. Investing in these technologies today will not only enhance operational efficiency but also pave the way for groundbreaking advancements in pharmaceutical development.