Overview

The article examines a range of robotic liquid handling solutions that significantly enhance efficiency in pharmaceutical laboratories. It underscores the pivotal role of advanced systems, such as those developed by JM Science, Hamilton Robotics, and Thermo Fisher Scientific, in improving accuracy and reducing human error. These innovations streamline workflows, thereby expediting drug discovery processes and ensuring adherence to stringent industry standards. By adopting such technologies, laboratories can not only optimize their operations but also maintain compliance with evolving regulatory requirements.

Introduction

The pharmaceutical landscape is undergoing a significant transformation, propelled by the urgent demand for efficiency and precision in research and drug development. Robotic liquid handling solutions have emerged as pivotal innovations, empowering laboratories to streamline workflows, minimize human error, and enhance reproducibility in essential processes. Yet, with a plethora of systems available, how can laboratories discern which robotic solutions align best with their specific requirements? This article explores ten groundbreaking robotic liquid handling systems that are redefining efficiency within pharmaceutical labs, examining their features, benefits, and the unique challenges they address.

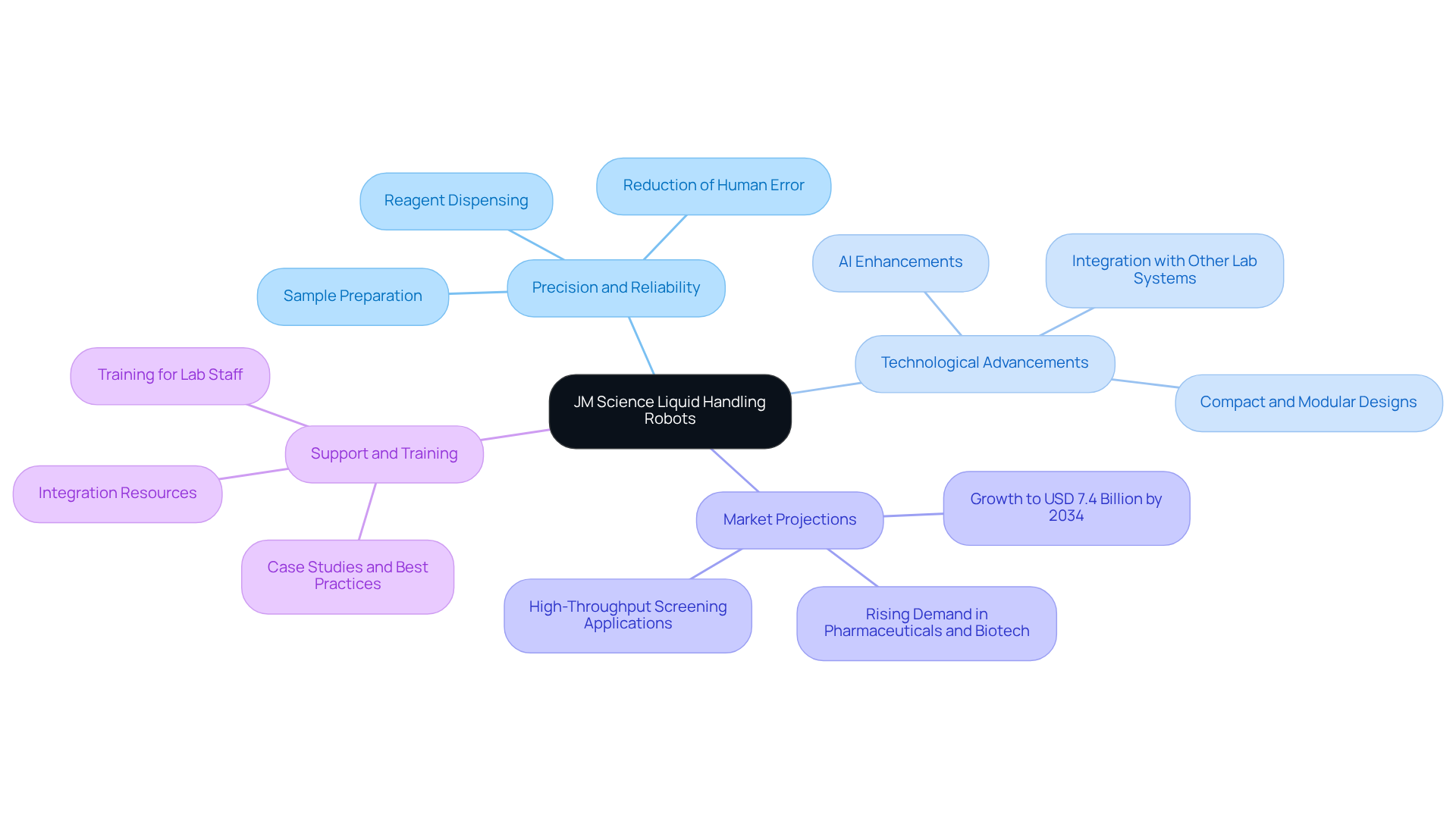

JM Science Liquid Handling Robots: Precision and Reliability in Pharmaceutical Labs

JM Science offers a sophisticated array of fluid management robots tailored for pharmaceutical applications, ensuring the accuracy and reliability essential for critical tasks such as sample preparation and reagent dispensing. These cutting-edge systems, such as robotic liquid handling, are engineered to reduce human error and enhance reproducibility, rendering them indispensable in high-stakes environments like drug development. For instance, automated fluid handlers are increasingly utilized in high-throughput screening, allowing researchers to process thousands of samples swiftly and accurately, significantly accelerating the drug discovery process.

Recent advancements in liquid handling technology feature the incorporation of artificial intelligence, which bolsters decision-making during experiments and enhances overall accuracy. This innovation is vital as the pharmaceutical industry confronts escalating regulatory demands for safety, compelling companies to embrace robotic liquid handling solutions that optimize workflows and minimize errors.

Furthermore, JM Science provides extensive support and training resources, ensuring that facilities can seamlessly integrate these robotic solutions into their existing workflows. Case studies illustrate that automated systems not only enhance workflow efficiency but also facilitate faster, more reliable disease diagnosis in clinical environments, ultimately improving patient care. With the market for automated fluid management technologies projected to reach approximately USD 7.4 billion by 2034, the commitment to accuracy and reliability in pharmaceutical fluid processes remains a pivotal element of innovation and efficiency in research facilities.

Hamilton Robotics: Advanced Liquid Handling Systems for High-Throughput Screening

Hamilton Robotics stands at the forefront of providing advanced robotic liquid handling systems, specifically designed for high-throughput screening—a critical element in contemporary drug discovery. These platforms enhance efficiency through robotic liquid handling to automate repetitive tasks, allowing researchers to focus on more complex analyses. The adaptability of Hamilton systems is a hallmark feature, enabling customization for robotic liquid handling to meet various research workflows and fulfilling the specific needs of drug development.

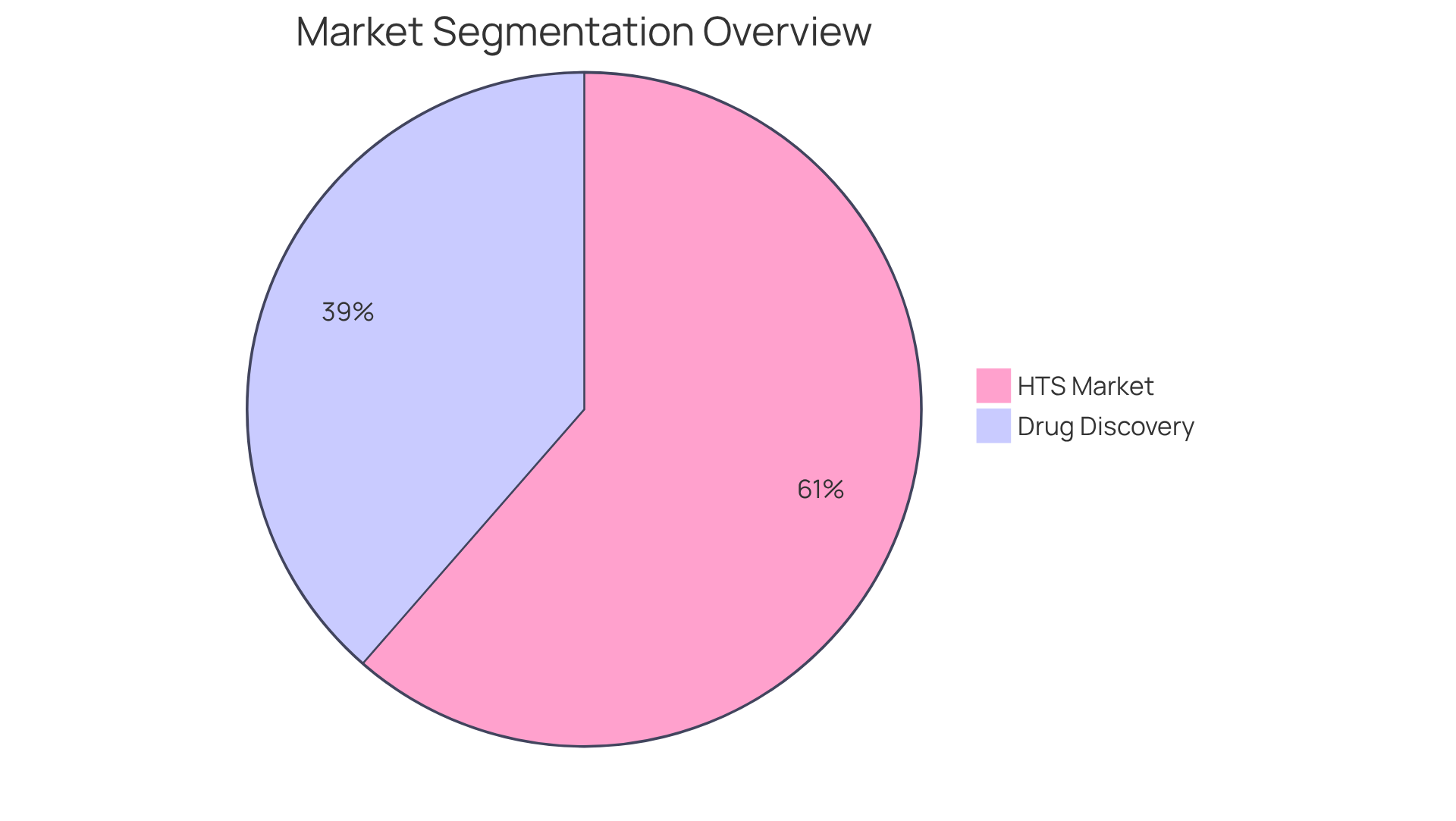

This precision and speed are essential for laboratories striving to accelerate drug discovery processes, particularly in a landscape where the global high-throughput screening market is projected to expand from USD 22.1 billion in 2022 to over USD 49.8 billion by 2032. Furthermore, the drug discovery segment alone is expected to exceed USD 31.3 billion by 2032. Real-world applications, such as the integration of Hamilton's Microlab STAR into automated workflows at Oxford Biomedica, exemplify how these systems enhance operational capabilities in laboratories, ultimately facilitating more efficient and reliable drug development.

The U.S. Food and Drug Administration (FDA) endorses high-throughput screening as a vital tool for modern drug development, further underscoring the importance of these technologies in advancing medical research.

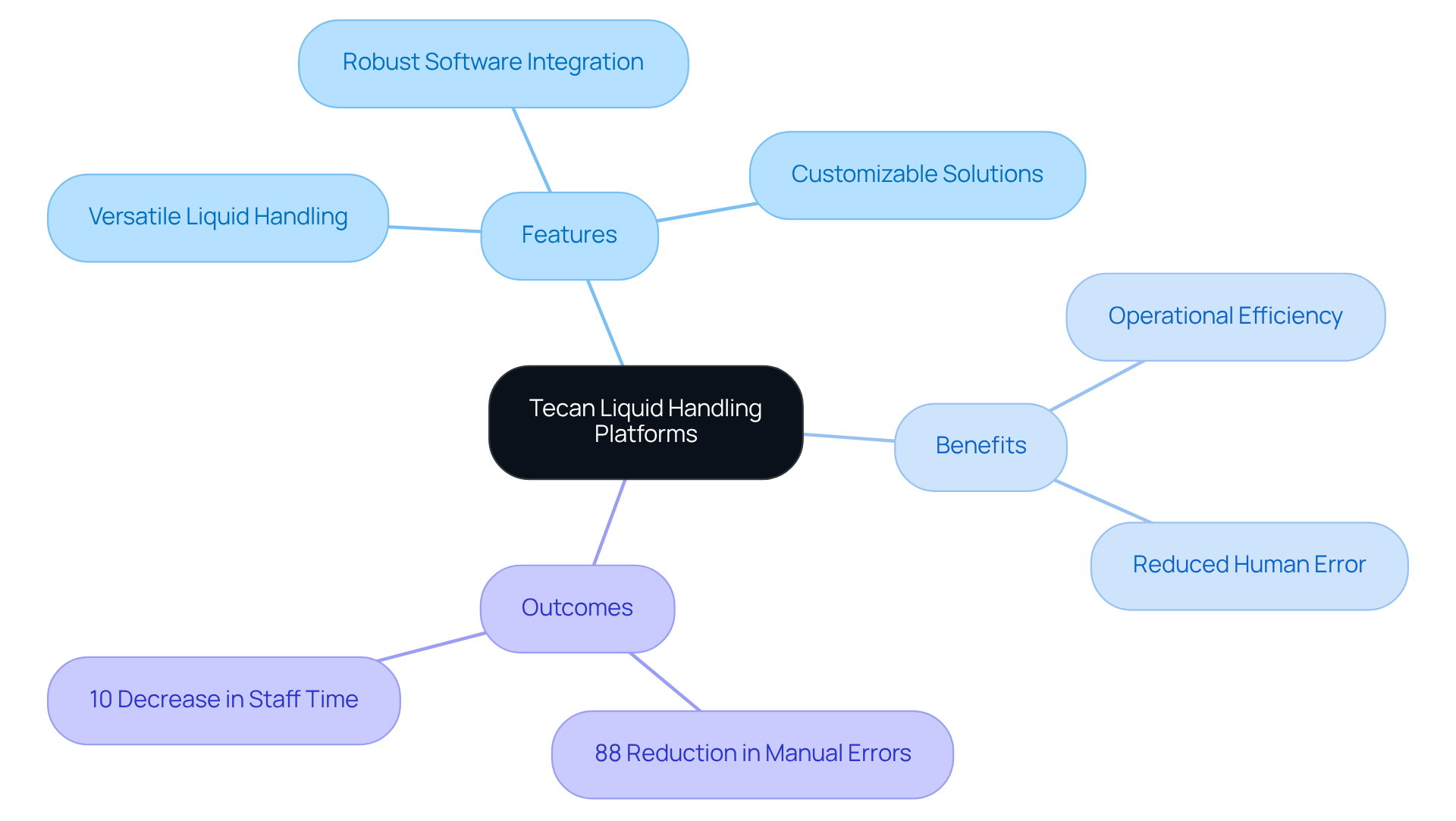

Tecan: Versatile Liquid Handling Platforms for Automated Laboratory Processes

Tecan presents highly versatile liquid handling systems, expertly designed to meet the diverse demands of automated research processes. Capable of performing a spectrum of tasks—from simple pipetting to complex multi-step workflows—these systems are indispensable for laboratories striving to enhance operational efficiency.

The robust software integration of Tecan platforms facilitates seamless connectivity with other testing instruments, optimizing data management and analysis. This capability not only accelerates workflows but also significantly reduces human error, ensuring consistent and reliable results across various applications in pharmaceutical research.

Notably, facilities that have embraced automation, including Tecan's systems, report an impressive 88% reduction in manual errors and a 10% decrease in staff time per specimen analyzed. As the demand for high throughput and operational efficiency in research facilities escalates, Tecan's solutions emerge as a strategic choice for organizations aiming to optimize their processes.

To fully leverage these advantages, lab managers in the drug industry should consider integrating Tecan's customizable fluid transfer solutions into their workflows.

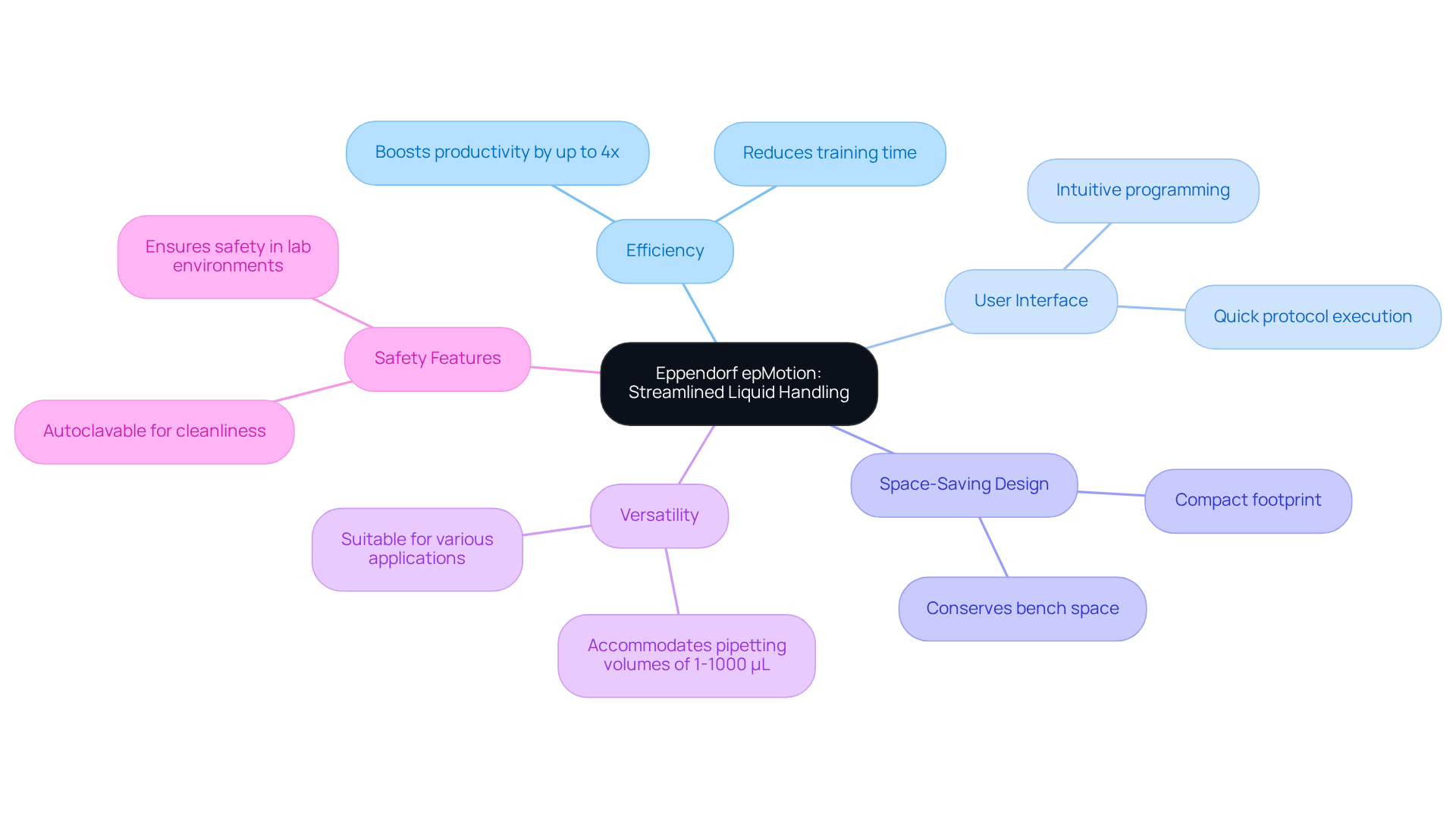

Eppendorf epMotion: Streamlined Liquid Handling for Enhanced Laboratory Efficiency

The Eppendorf epMotion series revolutionizes liquid handling tasks, significantly boosting efficiency in laboratory environments. With its intuitive interface and straightforward programming, users can quickly establish and execute complex protocols, thereby reducing the necessity for extensive training. This user-centric design proves particularly beneficial in the fast-paced pharmaceutical sector, where timely execution is paramount.

Additionally, the epMotion's compact footprint conserves valuable bench space without compromising exceptional performance. Research shows that these instruments can enhance productivity by up to four times compared to traditional 1-channel dispensing systems. The epMotion series accommodates pipetting volume ranges of 1-50 µL, 20-300 µL, and 40-1000 µL, making it versatile for a variety of applications.

Furthermore, its autoclavable feature ensures cleanliness and safety in the lab, further establishing its value as an essential asset in modern research facilities. As Dr. Josef Lott, product manager for automation at Eppendorf, asserts, 'We have developed a liquid handler that makes the implementation of automation in laboratory workflows easier than ever before, and we are confident that the new epMotion will become an invaluable tool in your laboratory.

Agilent Technologies: Robotic Solutions for Automated Sample Preparation

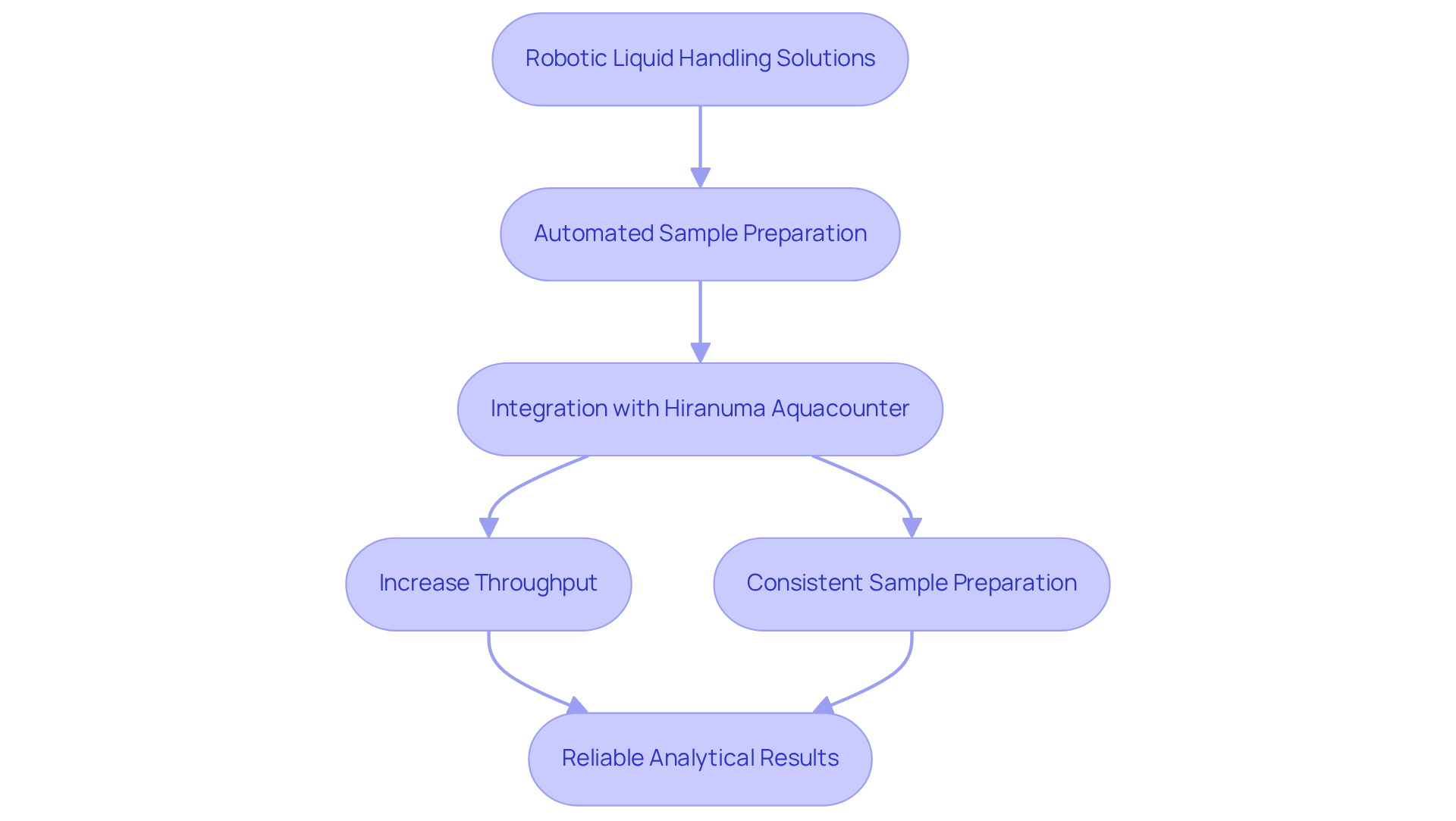

Agilent Technologies presents advanced robotic liquid handling solutions specifically designed for automated sample preparation, which is a crucial element in pharmaceutical research. These systems enhance the accuracy and reproducibility of sample management, significantly mitigating the risks of contamination and human error.

The integration of Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 Coulometric Karl Fischer titrators serves as a prime example of how robotic liquid handling can optimize drug and medicine testing in accordance with the Japanese Pharmacopoeia. By employing these titration techniques, laboratories can increase throughput and ensure consistent sample preparation, which is vital for achieving reliable analytical results.

Agilent's steadfast commitment to innovation places its solutions at the forefront of laboratory technology, empowering researchers to attain optimal outcomes in their investigations.

BioTek Instruments: Automated Liquid Handling for Precision in Assays

BioTek Instruments stands at the forefront of robotic liquid handling solutions, emphasizing precision in assay development. Their systems are meticulously engineered to minimize variability in sample preparation, a critical factor for achieving accurate and reproducible results. By leveraging advanced technologies such as fluid level detection and precise dispensing systems, BioTek empowers researchers to place their trust in the integrity of their data. This level of precision is particularly vital in drug laboratories, where assay validation serves as a cornerstone of the drug development process.

Research has consistently demonstrated that standardized fluid management procedures significantly enhance assay accuracy. This approach reduces inter-operator variability, ensuring dependable results that are essential in high-stakes environments. Moreover, the integration of robotic liquid handling platforms has proven to streamline workflows, facilitating more efficient sample processing while upholding stringent accuracy standards.

The unwavering commitment to accuracy in assay development not only supports regulatory compliance but also fosters innovation in medical research. Ultimately, this dedication contributes to the advancement of healthcare solutions, reinforcing the importance of high-quality scientific instruments in laboratory settings.

Labcyte Echo: Acoustic Liquid Handling for High-Precision Applications

Labcyte Echo utilizes advanced acoustic fluid management technology for robotic liquid handling to achieve precise transfers, thereby eliminating the need for traditional pipetting methods. This innovative system for robotic liquid handling significantly minimizes sample loss and reduces contamination risks, making it exceptionally well-suited for high-precision applications in medical research. For example, the Echo 525 Liquid Handler can pool 384 samples in merely 18 minutes—a task that would typically consume over 100 hours using conventional techniques—underscoring its remarkable efficiency. This capability is vital when dealing with valuable or limited samples, as it facilitates accurate dispensing with minimal waste.

Moreover, studies indicate that the Echo system, utilizing robotic liquid handling, can decrease reagent costs per sample from approximately $40 to just $0.35, yielding a reduction of 50x to 100x. This demonstrates its potential for substantial cost savings. The Echo 525 also excels in transferring ultra-small droplets of 2.5 nL, enhancing its accuracy in fluid management. By integrating robotic liquid handling technology, facilities can enhance their fluid management capabilities while adhering to stringent accuracy standards, ultimately driving progress in drug research.

As highlighted by AstraZeneca, the introduction of the Echo acoustic reformatter has transformed the compound management process, further emphasizing the impact of this technology within the field.

PerkinElmer: Robotic Liquid Handling for Streamlined Drug Discovery

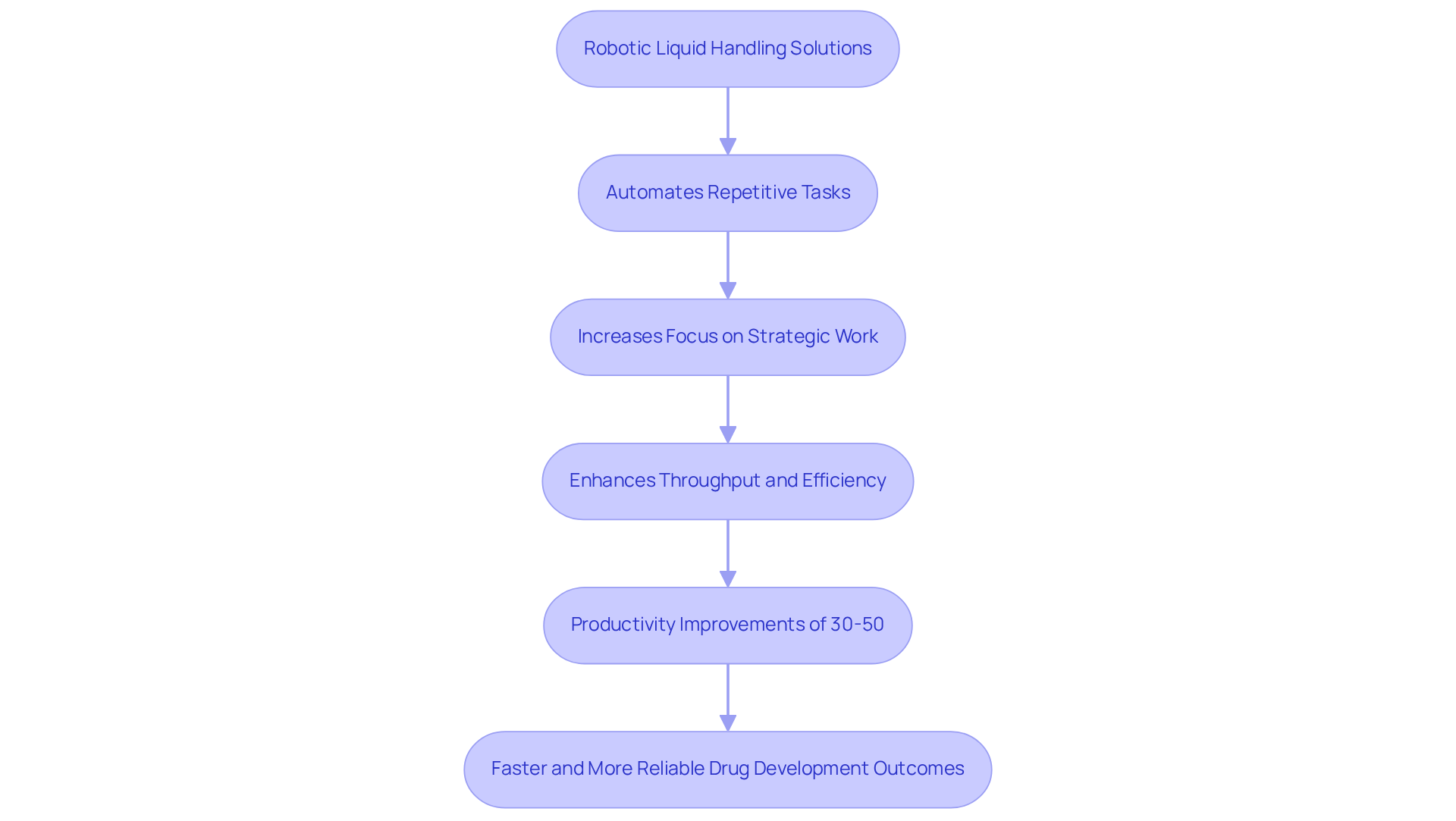

PerkinElmer's robotic liquid handling solutions play a pivotal role in optimizing drug discovery processes within pharmaceutical laboratories. By automating repetitive tasks, these systems empower researchers to focus on the more strategic aspects of their work. The integration of advanced robotics and robotic liquid handling with sophisticated software not only enhances throughput but also significantly boosts efficiency, thereby accelerating the overall pace of drug development.

With automation driving productivity improvements of 30-50%, PerkinElmer's solutions for robotic liquid handling enable laboratories to achieve higher output while minimizing human error, ultimately leading to faster and more reliable drug development outcomes. As the global AI-driven pharma manufacturing automation market is projected to reach $8 billion by 2030, the significance of such innovations cannot be overstated.

Lab managers are urged to evaluate their current processes for potential automation opportunities to remain competitive in this rapidly evolving landscape.

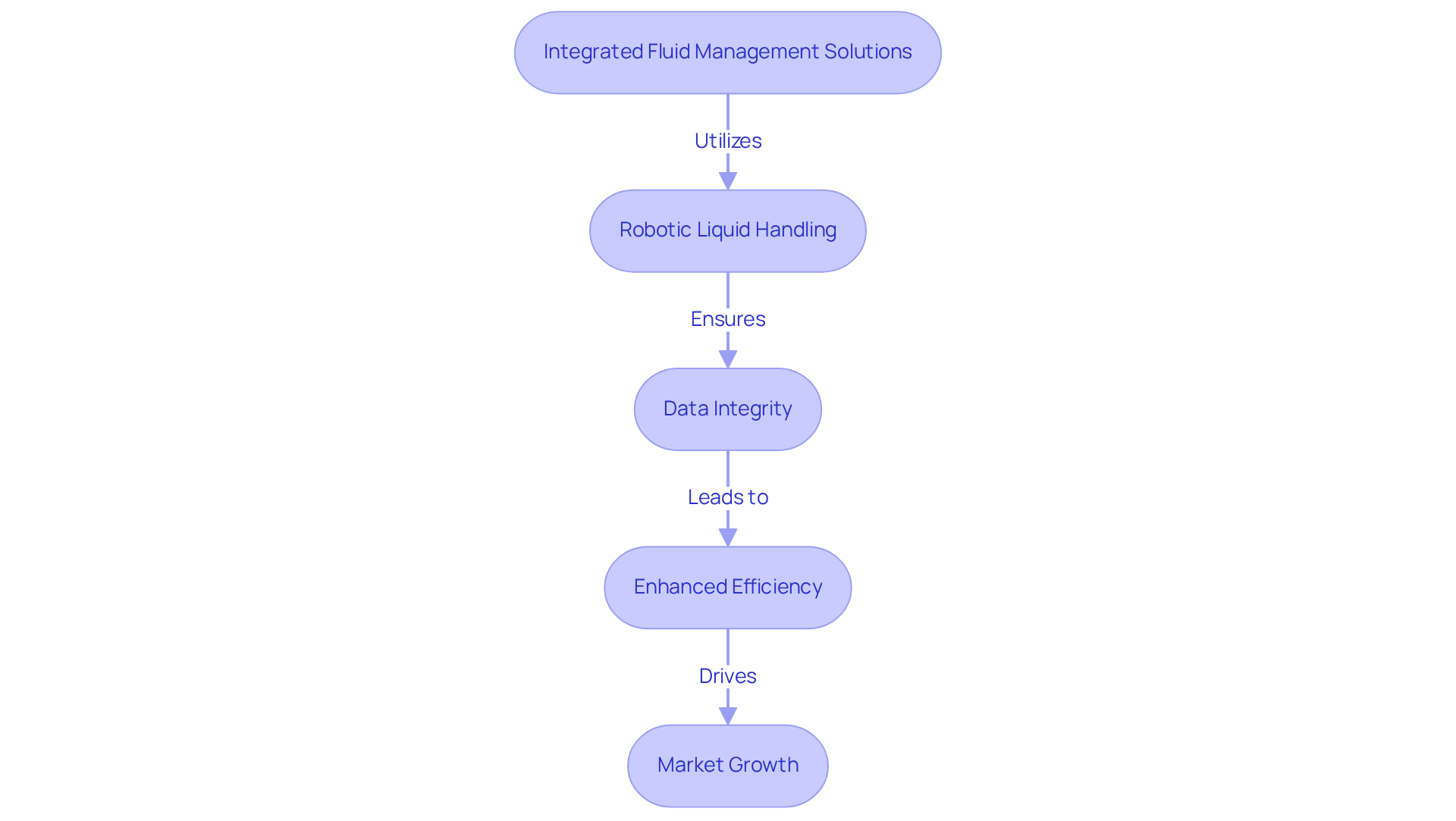

Sartorius: Integrated Liquid Handling Solutions for Biopharmaceutical Development

Sartorius delivers integrated fluid management solutions specifically designed for biopharmaceutical development, ensuring seamless compatibility with diverse research instruments. This integration is essential for preserving data integrity throughout the research process, a critical factor in the highly regulated biopharmaceutical sector.

By using robotic liquid handling to automate fluid management tasks, Sartorius significantly reduces manual errors, enhancing overall laboratory efficiency. For example, their advanced robotic liquid handling systems optimize workflows, allowing researchers to concentrate on critical analyses instead of repetitive tasks. This unified approach not only expedites research timelines but also meets the stringent demands of biopharmaceutical research, where precision and reliability are non-negotiable.

Furthermore, the automated fluid management systems market is projected to grow at a CAGR of 9.82% from 2023 to 2029, underscoring the increasing importance of automation in research facilities. Nevertheless, challenges such as the high costs associated with automated systems may hinder adoption in smaller research labs, emphasizing the need for cost-effective solutions.

Leveraging insights from industry leaders like Sartorius can offer valuable guidance for laboratories navigating these complexities.

Thermo Fisher Scientific: Comprehensive Liquid Handling Solutions for Pharmaceutical Research

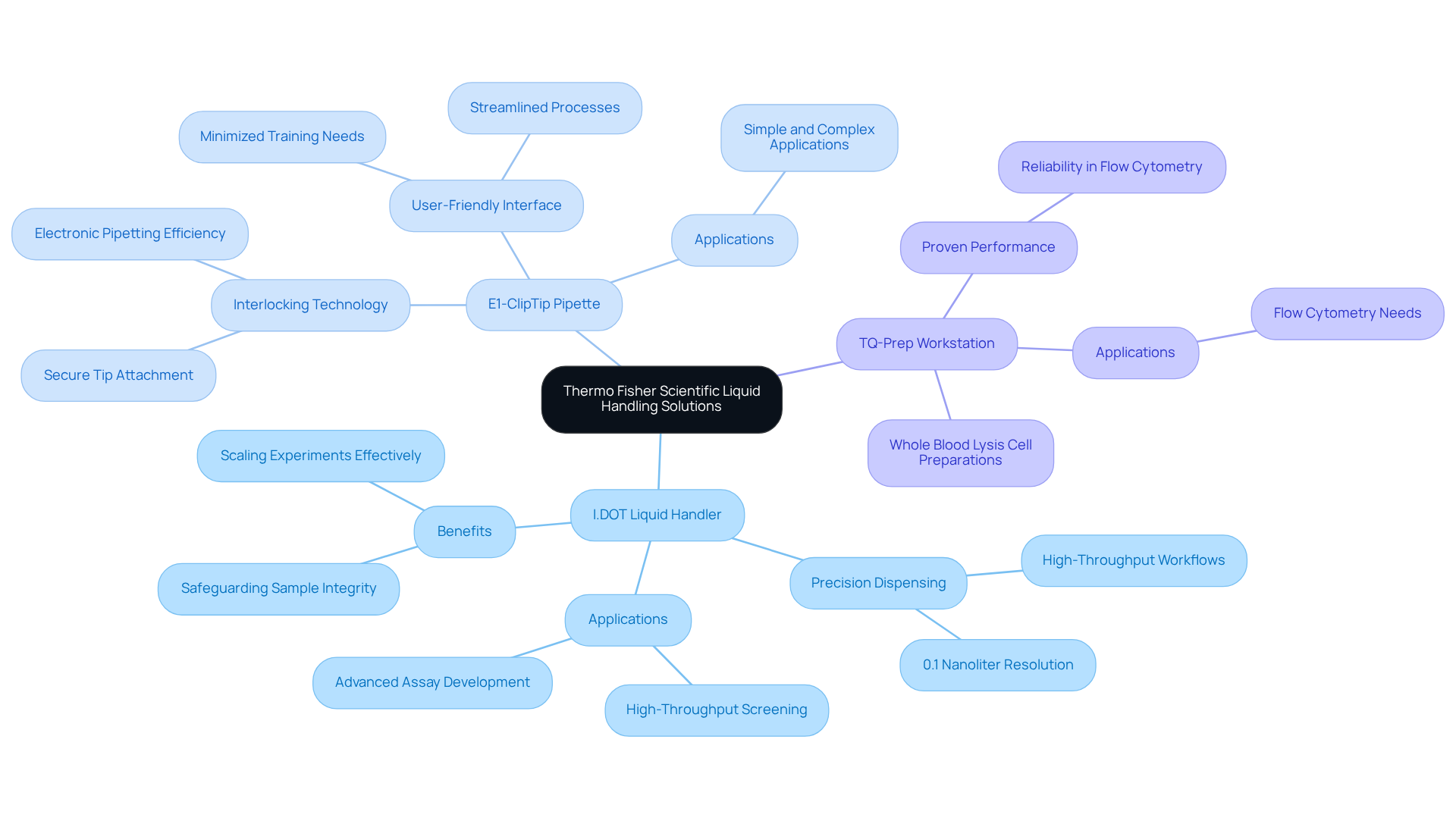

Thermo Fisher Scientific presents an extensive array of fluid management solutions tailored for drug research, encompassing applications that range from straightforward fluid transfers to intricate multi-step procedures. By emphasizing robotic liquid handling and precision, these systems significantly enhance laboratory efficiency and accuracy. For example, the I.DOT Liquid Handler boasts an impressive resolution of 0.1 nanoliters, facilitating precise nanoliter-scale dispensing that supports higher throughput workflows without necessitating multiple instruments. This capability proves particularly advantageous for complex protocols, such as high-throughput screening and advanced assay development, enabling laboratories to scale experiments effectively while safeguarding sample integrity.

Furthermore, Thermo Fisher's dedication to innovation is exemplified by their advanced automated pipetting instruments, now accessible to small and medium-sized laboratories. These compact designs integrate seamlessly into existing setups, minimizing disruption and simplifying workflow transfers. The E1-ClipTip pipette, featuring interlocking technology for secure tip attachment, showcases how automation can streamline processes, diminish manual errors, and enhance productivity.

As pharmaceutical laboratories increasingly embrace robotic liquid handling systems, they can expect improved data quality and reduced operational costs. The integration of robotic liquid handling not only accelerates research timelines but also enables scientists to focus on critical tasks, ultimately driving advancements in drug development and patient care. As Nila Lê observed, "Automated liquid handlers are changing cancer research by boosting efficiency, reducing errors, and accelerating breakthroughs in drug discovery." Additionally, the TQ-Prep Workstation is distinguished for its proven performance in whole blood lysis cell preparations, further illustrating the diverse applications of Thermo Fisher's products.

Conclusion

Robotic liquid handling solutions are revolutionizing pharmaceutical laboratories by significantly enhancing precision, efficiency, and reliability in critical processes. The integration of advanced robotics in liquid handling not only mitigates human error but also accelerates workflows—an essential factor in the fast-paced realm of drug discovery and development.

Insights from leading providers such as JM Science, Hamilton Robotics, and Tecan illustrate the diverse capabilities and applications of these automated systems. From high-throughput screening to streamlined sample preparation, each solution presents unique benefits tailored to the specific needs of pharmaceutical research. This increasing reliance on robotic technologies reflects a broader trend toward automation in the industry, driven by the imperative for accuracy and compliance with stringent regulatory standards.

As pharmaceutical labs continue to progress, the adoption of robotic liquid handling solutions will be vital for sustaining a competitive edge. The advancements in this domain promise not only to enhance operational efficiencies but also to pave the way for groundbreaking innovations in drug development. Laboratories are urged to evaluate their current workflows and consider the integration of these advanced systems to optimize processes, reduce costs, and ultimately improve patient outcomes. The future of pharmaceutical research is rooted in automation, and the time to act is now.