Overview

To effectively optimize a monolithic HPLC column, three critical steps must be followed:

- Proper column preparation

- Optimizing injection volume

- Adjusting the flow rate for ideal separation efficiency

These steps are essential for enhancing analytical performance. By implementing optimal practices, one can prevent overloading and maintain consistent results during analyses. This approach not only improves the reliability of the outcomes but also underscores the significance of high-quality scientific instruments in laboratory settings.

Introduction

In the realm of high-performance liquid chromatography (HPLC), the emergence of monolithic columns signifies a pivotal advancement poised to transform laboratory practices.

Constructed from a single piece of porous material, these columns provide remarkable advantages, including:

- High permeability

- Enhanced efficiency

- Simplified maintenance

As a result, they have become the preferred choice for researchers and analysts.

With the escalating demand for rapid and precise analyses, it is crucial to comprehend the advantages and selection criteria for these innovative columns.

This article explores the distinct features of monolithic HPLC columns, evaluates essential factors for their selection, and outlines practical steps for optimization, ensuring that laboratories can fully leverage their potential for improved analytical performance.

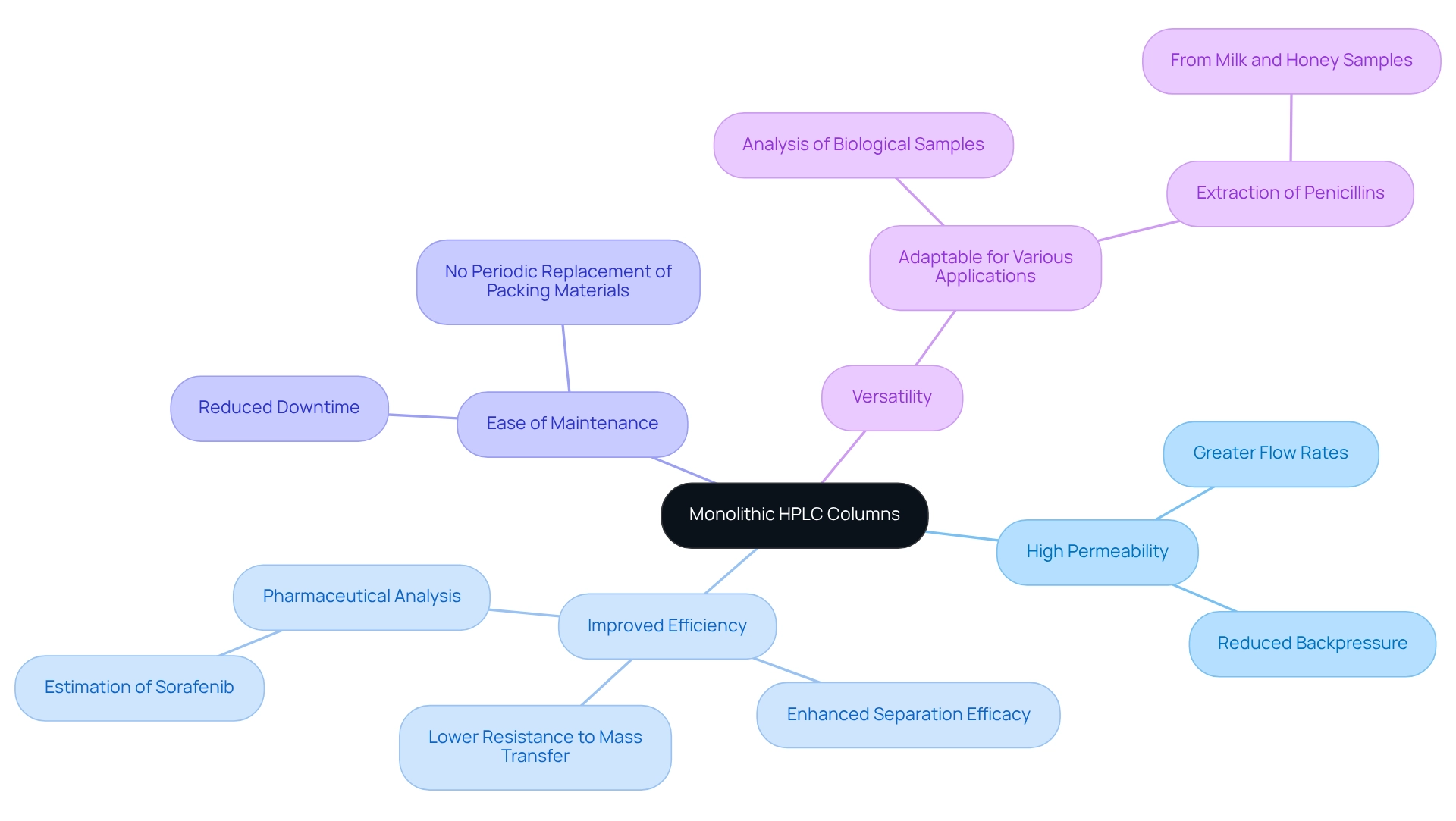

Understand Monolithic HPLC Columns and Their Advantages

Monolithic HPLC columns, made from a single piece of porous material, provide distinct advantages over traditional packed units, which is driving their increasing adoption in laboratory settings. One of the primary benefits is high permeability. The continuous design of these unified supports in a monolithic HPLC column allows for greater flow rates, significantly reducing backpressure and enabling faster separations—an essential factor for high-throughput analyses.

Moreover, these supports exhibit improved efficiency. They typically present lower resistance to mass transfer, resulting in enhanced separation efficacy. This feature is particularly advantageous in pharmaceutical analysis, where precision is critical. As noted by Eswarudu Munnangi, a sensitive, rapid, precise, and accurate high-performance liquid chromatographic technique utilizing a monolithic HPLC column was developed for estimating Sorafenib in tablet dosage form, underscoring the effectiveness of such methods in pharmaceutical applications.

Unlike conventional systems that necessitate periodic replacement of packing materials, these solid structures are easier to maintain and handle, thereby reducing downtime in laboratory operations. Their versatility further enhances their appeal; monolithic HPLC columns with solid structures can be adapted for a variety of applications, including the analysis of biological samples and pharmaceuticals, making them indispensable tools in diverse research environments.

The advantages of monolithic HPLC columns in solid high-performance liquid chromatography systems are further emphasized by recent advancements in the field, particularly those propelled by JM Science's commitment to evolving product offerings. JM Science Inc. provides a range of premium liquid chromatography devices, including solid options, designed to meet the dynamic needs of laboratories. For instance, a recent study highlighted the effective application of a material-based approach for extracting penicillins from milk and honey samples, illustrating their practical utility in real-world scenarios.

As laboratories continue to seek innovative solutions, recognizing these advantages is vital for enhancing the application of monolithic HPLC columns in high-efficiency liquid chromatography processes.

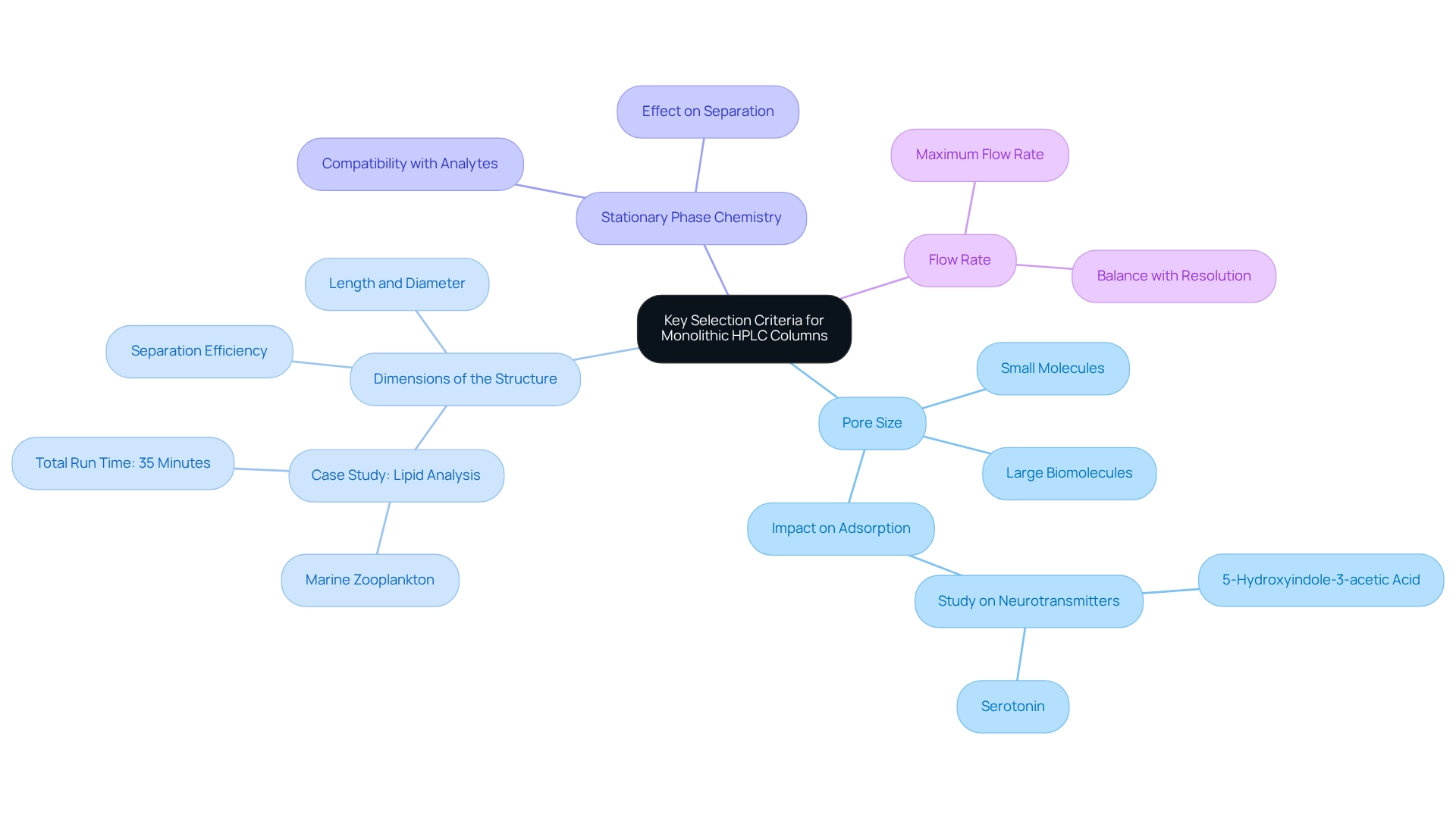

Evaluate Key Selection Criteria for Monolithic HPLC Columns

When selecting a monolithic HPLC column, several key criteria must be considered to ensure optimal performance:

- Pore Size: The choice of pore size is crucial and should align with the analytes being analyzed. Smaller pores are ideal for small molecules, while larger pores are necessary for accommodating larger biomolecules. The effect of pore size on the performance of the system is considerable, as variations can affect adsorption characteristics. For instance, a study on neurotransmitters demonstrated that the developed on-chip MNP structure effectively analyzed 5-hydroxyindole-3-acetic acid and serotonin, showcasing the importance of selecting the appropriate pore size.

- Dimensions of the Structure: The length and diameter of the support play a vital role in separation efficiency and flow rate. Longer structures generally improve resolution but may increase analysis time. An enhanced HPLC technique for lipid analysis in marine zooplankton effectively separated a wide range of lipids in a single run of only 35 minutes, demonstrating the practical implications of optimizing dimensions.

- Stationary Phase Chemistry: Ensuring that the stationary phase is compatible with the chemical properties of the analytes is essential. This compatibility is key to achieving optimal separation and can significantly affect the overall analysis outcome.

- Flow Rate: Assessing the maximum flow rate that the structure can manage without compromising performance is essential. While higher flow rates can expedite analyses, they may also negatively impact resolution, necessitating a careful balance.

As Fabrice Gritti observed, "These variations appear to be linked to the differences in the total porosities of these structures, which vary by 3% from #31 to #34, the one with higher porosity exhibiting the stronger adsorption." By thoroughly evaluating these criteria, you can choose a monolithic HPLC column that meets your analytical needs, ultimately enhancing the efficiency and precision of your laboratory's results. Furthermore, keeping informed about developments in high-performance liquid chromatography technology, as JM Science consistently does, is vital for ensuring peak performance in your analyses.

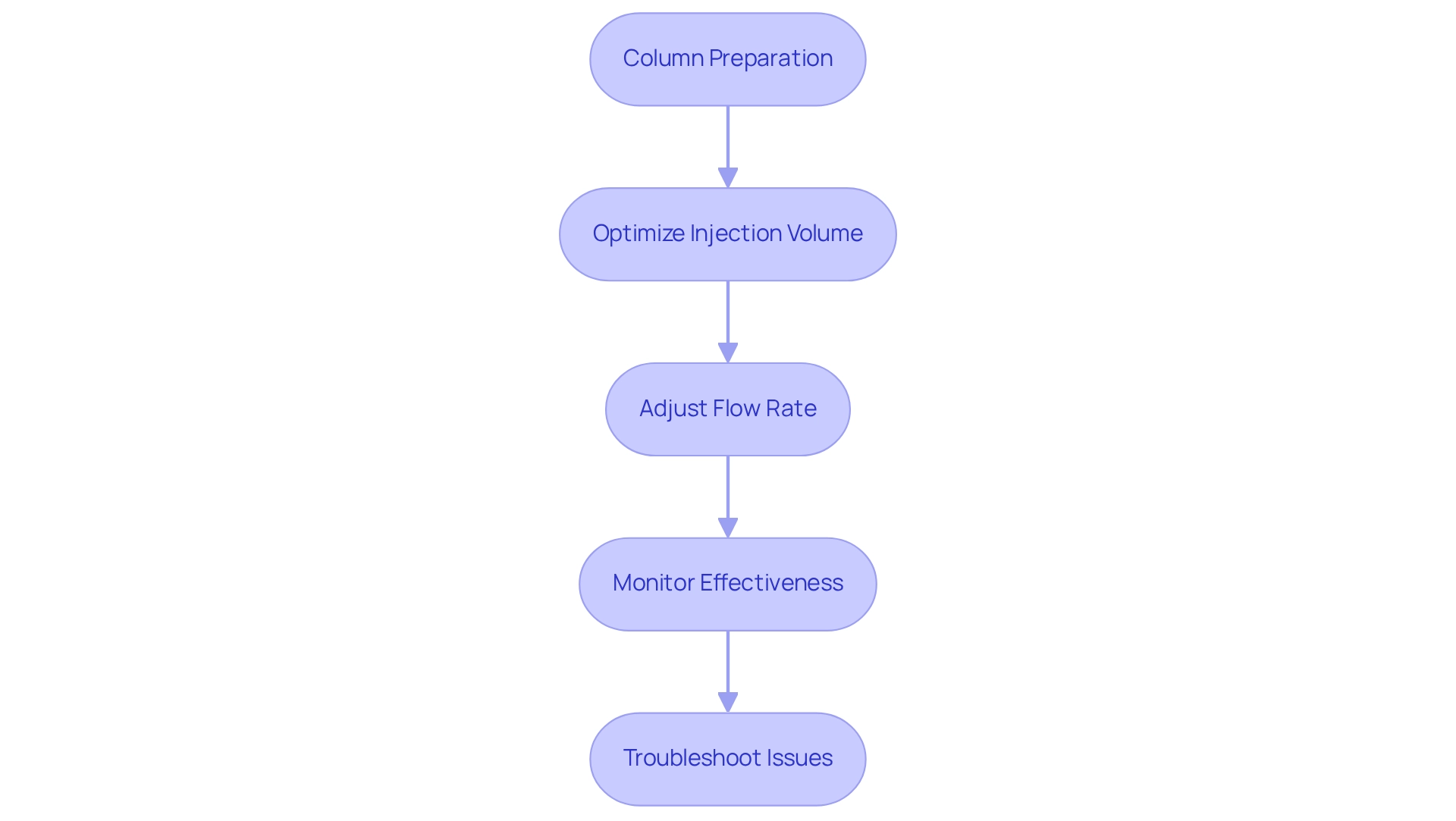

Implement and Optimize Your Monolithic HPLC Column for Best Results

To effectively implement and optimize your monolithic HPLC column, it is essential to adhere to the following steps:

-

Column Preparation: Begin by conditioning the apparatus through rinsing it with the mobile phase. This process is crucial for eliminating contaminants and equilibrating the stationary phase, which is vital for achieving reliable results.

-

Optimize Injection Volume: It is advisable to utilize an injection volume that does not exceed 1-2% of the total volume. For example, for a column with a 3 mm I.D. and a length ranging from 50 to 150 mm, the optimal injection volume varies from 2.5 to 14.8 µL. This practice prevents overloading and ensures accurate analytical outcomes.

-

Adjust Flow Rate: Start with a moderate flow rate and gradually increase it while closely monitoring separation efficiency. Achieving a balance between speed and resolution is essential for optimal results. As Dr. Egidijus Machtejevas, Sr. Technical Advisor, Analytical Chromatography Workflows, states, "Be prepared for the need to accept a compromise between detection limit and resolution."

-

Monitor Effectiveness: Regular evaluations are imperative. Analyze standard samples and compare retention times and peak shapes to ensure consistent results. This ongoing assessment helps maintain the integrity of your analyses. For instance, sensitivity tests conducted to ascertain the limit of detection (LOD) for various analytes demonstrated that supports with lower LOD values were more effective for analyte detection, underscoring the importance of enhancing support efficiency.

-

Troubleshoot Issues: If challenges arise, such as poor resolution or elevated backpressure, consider adjusting the mobile phase composition or flow rate. Additionally, inspect the system for potential blockages that could hinder efficiency.

By diligently following these steps, you can optimize your monolithic HPLC column, which will significantly enhance analytical performance and contribute to advancements in research and healthcare.

Conclusion

The exploration of monolithic HPLC columns highlights their substantial advantages, including high permeability, enhanced efficiency, and simplified maintenance. These attributes not only accelerate analyses and improve accuracy but also streamline laboratory operations, establishing them as a preferred choice for researchers across various disciplines. Their versatility enables application in numerous scenarios, from pharmaceutical analysis to environmental testing, thereby underscoring their significance in contemporary laboratory practices.

Selecting the appropriate monolithic HPLC column necessitates careful evaluation of key criteria such as:

- Pore size

- Column dimensions

- Stationary phase chemistry

- Flow rate

By aligning these factors with specific analytical requirements, laboratories can ensure optimal performance and achieve dependable results. Staying abreast of technological advancements in HPLC will further augment the efficacy of these innovative columns.

Implementing and optimizing monolithic HPLC columns entails a systematic approach, which includes:

- Proper conditioning

- Meticulous adjustment of injection volumes and flow rates

- Regular performance monitoring

Promptly addressing challenges through troubleshooting can significantly alleviate issues that may arise during analyses. By adhering to these guidelines, laboratories can fully harness the potential of monolithic columns, ultimately enhancing analytical performance and propelling advancements in research and healthcare.