Overview

To ensure the precision of pipettes in laboratory settings, four key practices are paramount:

- Regular calibration

- Effective pipetting techniques

- Routine maintenance and testing

- Comprehensive staff training

These practices are not merely recommendations; they are essential components that collectively enhance the accuracy and reliability of liquid handling. By implementing these measures, laboratories can prevent contamination and ensure compliance with industry standards. Ultimately, this commitment to precision leads to more dependable experimental results, reinforcing the integrity of scientific research.

Introduction

In the intricate realm of laboratory work, precision reigns supreme, and the significance of pipettes is undeniable. These indispensable tools, utilized for liquid handling, play a pivotal role in determining the accuracy of experimental outcomes. However, without meticulous calibration and proper technique, even the most advanced pipettes can introduce errors, resulting in misleading results.

This article explores the essential components of pipette calibration, effective pipetting techniques, routine maintenance, and the critical importance of staff training. By comprehensively understanding and implementing these best practices, laboratories can ensure their results are not only reliable but also uphold the highest standards of scientific integrity.

Understand the Importance of Pipette Calibration

Pipette adjustment is paramount for ensuring precision in liquid handling within laboratory environments. Routine adjustment inspections are essential to verify that dispensers release accurate volumes, with recommendations suggesting adjustments at least once a year or more frequently for instruments in regular use. This process typically involves comparing the dispensed volume against a known standard, such as distilled water, which possesses a well-defined density. This practice not only ensures compliance with industry standards but also significantly enhances the reliability of experimental data. Recent studies indicate that unadjusted dispensers can introduce a variance of up to 10% in results, underscoring the necessity of rigorous adjustment protocols to uphold data integrity.

Furthermore, adherence to ISO8655-2 standards provides specific guidelines for calibrating piston pipettes, ensuring that metrological requirements and permissible errors are clearly defined, which is vital for maintaining high measurement accuracy across various laboratory devices. It is also crucial to distinguish between ; while ISO17025 focuses on documenting internal processes, ISO8655-2 outlines best practices for measurement accuracy.

Efficient data management plays a critical role in the adjustment process. As Kristen Emata states, "Qualer asset management software provides you with excellent data management that makes calibrating with us all the more simple and convenient."

To guarantee efficient instrument adjustment, laboratories should adhere to the following steps:

- Verify the pipette's accuracy against a known standard.

- Record the adjustment results meticulously.

- Arrange regular adjustment intervals according to usage frequency.

- Train staff on proper calibration techniques.

By applying these methods, facilities can significantly enhance their measurement precision and data dependability.

Implement Effective Pipetting Techniques

To achieve optimal results in laboratory settings, personnel must adopt effective pipetting techniques that enhance the precision of pipette. Pre-wetting the pipette tip is crucial; this practice helps equalize temperature and minimizes the risk of liquid adhering to the tip. Additionally, using the correct angle is essential: hold the instrument vertically during aspiration and at a 45-degree angle during dispensing to ensure accurate liquid transfer.

Controlling the speed of aspiration and dispensing also plays a vital role. Slow and steady movements prevent bubble formation and guarantee complete liquid transfer. Furthermore, avoiding excessive immersion is important; the tip should only be immersed just below the liquid's surface to prevent contamination and ensure the precision of .

By implementing these techniques, laboratory personnel can significantly reduce variability in results and enhance the reproducibility of experiments. Adhering to these practices is not just recommended; it is imperative for achieving consistent and reliable outcomes in scientific research.

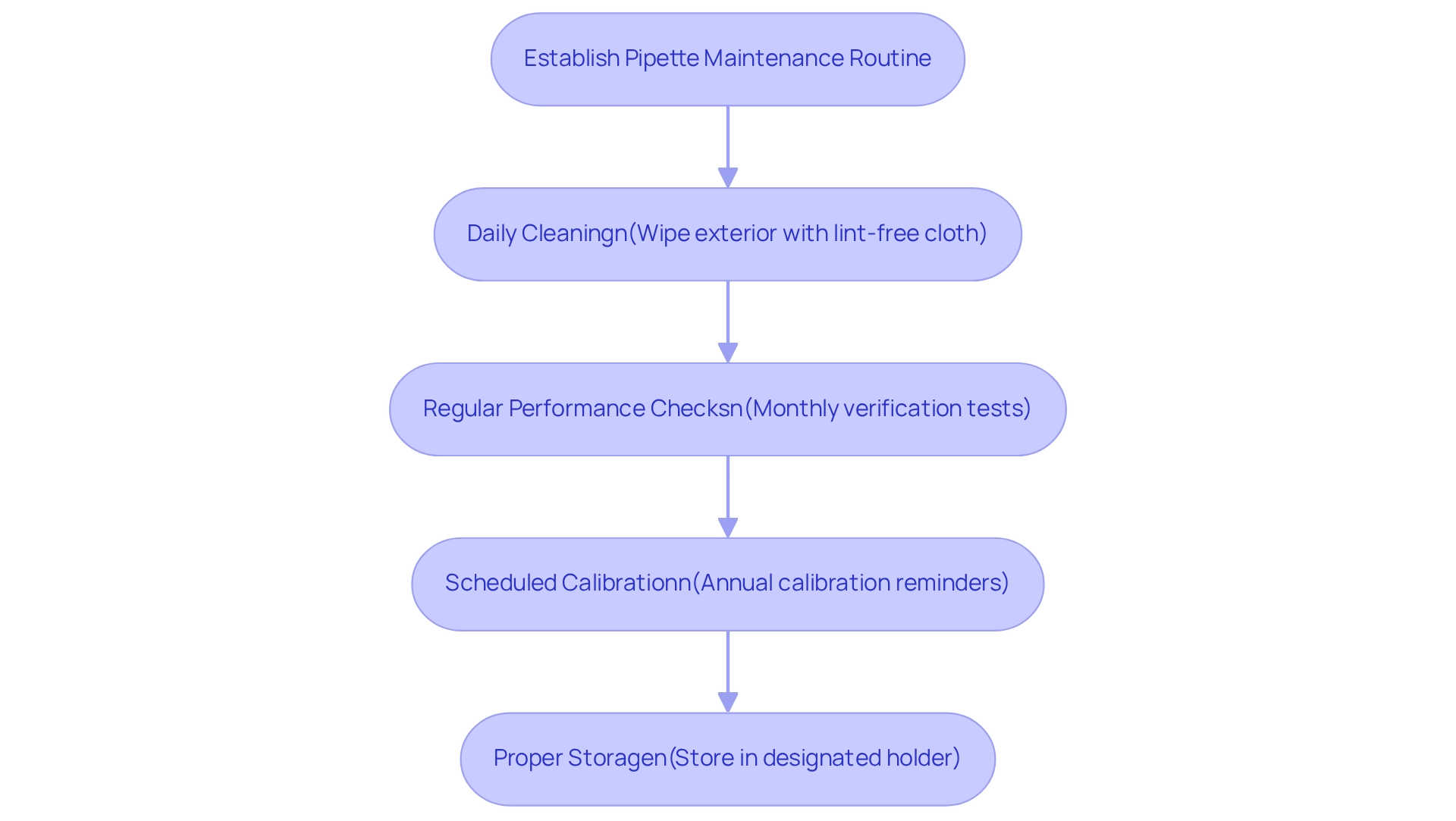

Establish a Routine for Pipette Maintenance and Testing

Establishing a maintenance and testing schedule for the device is imperative to ensure consistent performance. This routine encompasses several critical tasks:

- Daily cleaning: Regularly wipe the exterior of the pipette with a lint-free cloth and an appropriate cleaning solution to prevent contamination.

- Regular performance checks: Implement monthly performance verification tests to assess the accuracy and precision of pipette functions.

- Scheduled calibration: Set calendar reminders for calibration checks based on usage frequency, ensuring that all instruments are calibrated at least annually to maintain the precision of pipette use.

- Proper storage: Store liquid handling devices in a designated holder when not in use to prevent damage and contamination.

By adhering to these maintenance practices, facilities can ensure that their pipettes remain in optimal condition, thereby enhancing the precision of pipette results.

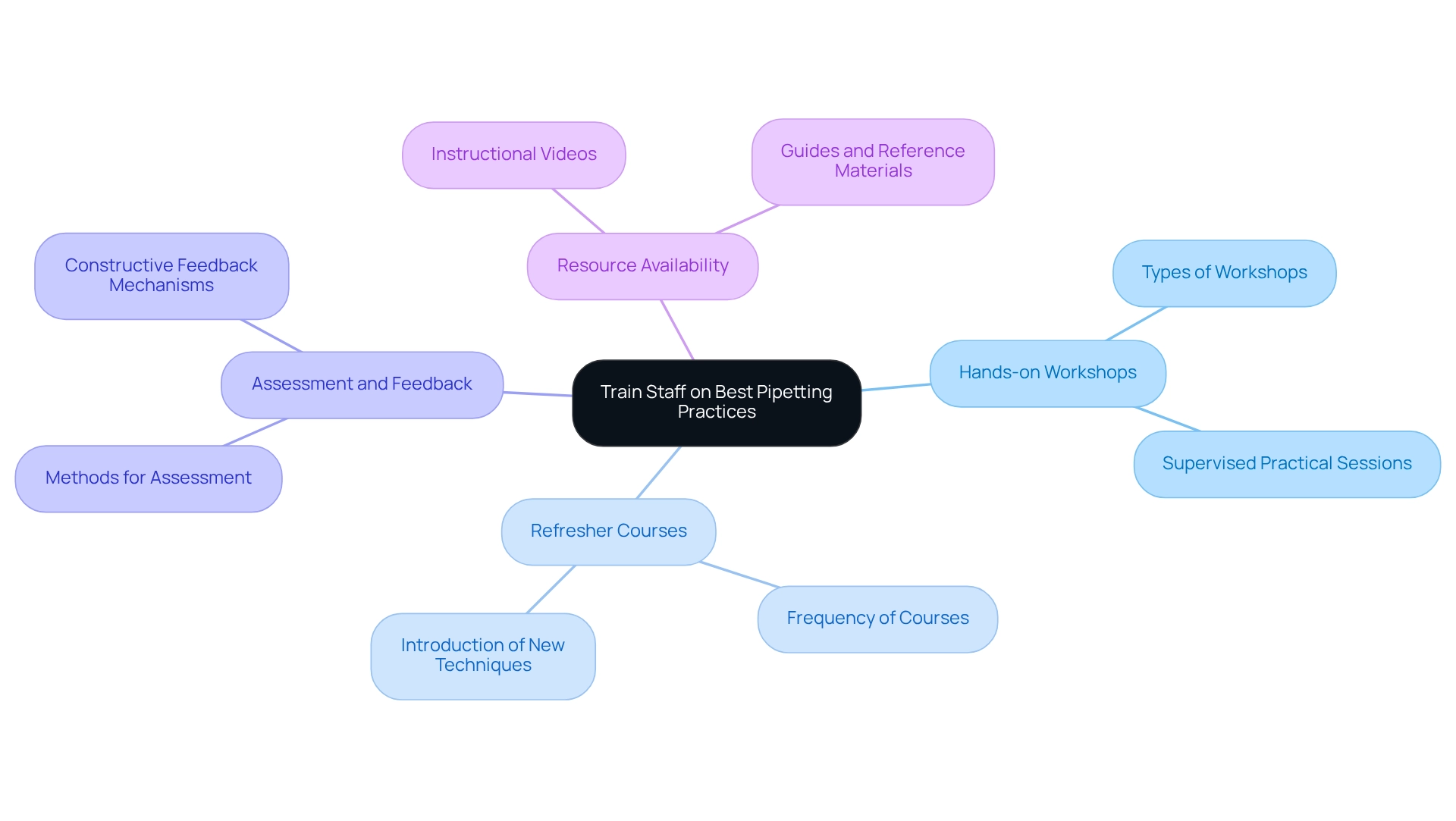

Train Staff on Best Pipetting Practices

Educating personnel on optimal pipetting techniques is essential for upholding high standards in laboratory work. Effective training programs must encompass hands-on workshops, where staff can engage in practical sessions under supervision, allowing for immediate feedback and correction of errors.

Regular refresher courses should be scheduled to reinforce best practices and introduce new techniques or equipment. Furthermore, an assessment and feedback system is crucial for evaluating pipetting skills and providing constructive feedback, ensuring continuous improvement.

Lastly, resource availability is vital; making instructional materials such as videos and guides readily accessible for staff to reference as needed enhances their learning experience. By investing in staff training, laboratories can significantly enhance the precision of pipette operations in their pipetting processes. This investment leads to more reliable experimental results, fostering an environment of excellence and ensuring the precision of pipette in scientific research.

Conclusion

Ensuring the accuracy and reliability of laboratory results hinges on the effective use of pipettes, making calibration, technique, maintenance, and training paramount. Regular calibration is essential, with recommendations suggesting at least annual checks to verify that pipettes dispense the correct volumes. Adhering to established standards such as ISO8655-2 not only enhances compliance but also reinforces the integrity of experimental data. Effective data management during the calibration process further strengthens these efforts, ensuring that laboratories can trust their measurements.

Implementing proper pipetting techniques is equally important. Simple practices like pre-wetting tips, maintaining the correct angles, and controlling aspiration speed can significantly minimize variability and improve reproducibility. Regular maintenance routines, including daily cleaning and scheduled performance checks, help sustain pipette performance, ensuring that laboratories can consistently rely on their tools.

Lastly, investing in staff training is crucial for cultivating a culture of precision in laboratory environments. Through hands-on workshops, refresher courses, and accessible resources, personnel can refine their skills and stay updated on best practices. This commitment to training not only enhances individual performance but also contributes to the overall quality of laboratory work.

In summary, by embracing robust calibration practices, employing effective pipetting techniques, maintaining equipment diligently, and prioritizing staff training, laboratories can uphold the highest standards of scientific integrity. These collective efforts are vital in achieving reliable results that advance research and innovation.