Overview

Selecting the appropriate infrared spectroscopy machine is crucial for laboratory success. Key criteria to consider include:

- Sensitivity

- Resolution

- Wavelength range

- Sample type

- Budget

- User-friendliness

Understanding these factors is vital, as they directly influence the effectiveness of your analytical capabilities. Furthermore, familiarity with the types of machines available and the purchasing process enhances your ability to choose an instrument that meets your specific laboratory needs. By prioritizing these considerations, you can ensure that your selection process is both informed and effective.

Introduction

The realm of infrared spectroscopy serves as a gateway to unveiling the intricate details of molecular structures, playing a crucial role across diverse fields, from pharmaceuticals to environmental science. As the market for infrared spectroscopy machines continues to grow, it becomes essential for researchers and laboratory managers to understand how to select the appropriate instrument.

What key factors can influence the decision in choosing the optimal infrared spectroscopy machine? How can one effectively navigate the complexities of this purchasing process?

This guide explores the essential steps and considerations necessary to ensure that the selected equipment aligns with specific analytical needs while optimizing both performance and budget.

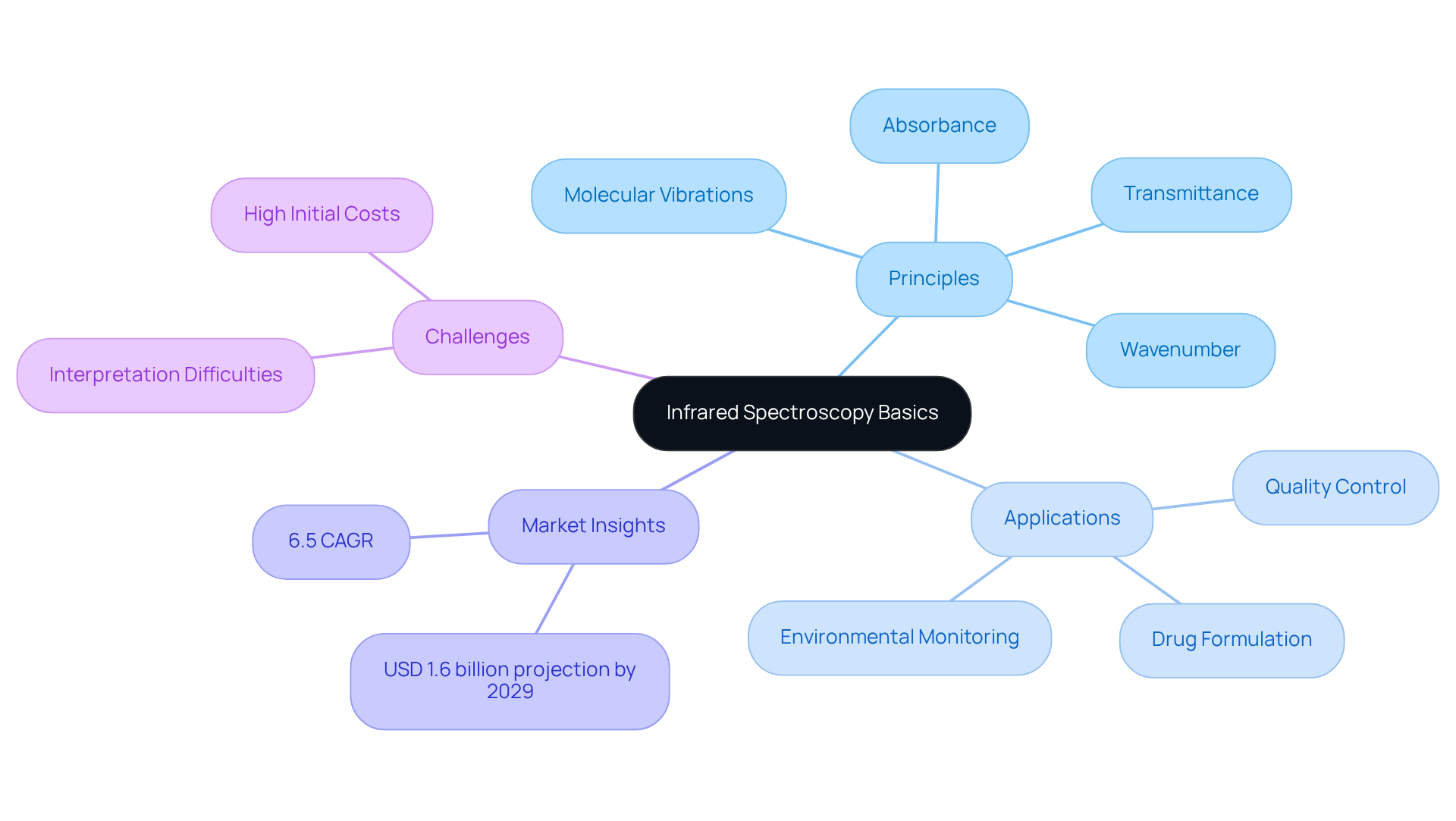

Understand the Basics of Infrared Spectroscopy

This analytical method serves as a powerful technique that scrutinizes the interaction of thermal radiation with substances, primarily by using an infrared spectroscopy machine to evaluate the absorption of thermal light by molecules. This absorption induces molecular vibrations at specific frequencies, facilitating the identification of functional groups in organic compounds and the characterization of various materials. In experimental settings, approximately 60% of research facilities utilize thermal analysis for material characterization, underscoring its critical role in chemical examination. The global infrared spectroscopy machine analysis market is projected to reach USD 1.6 billion by 2029, with a compound annual growth rate (CAGR) of 6.5%, reflecting the growing reliance on the infrared spectroscopy machine technology across diverse sectors.

Understanding the is essential for selecting the appropriate infrared spectroscopy machine for your laboratory. Key concepts include the types of molecular vibrations—stretching and bending—as well as pivotal terms like wavenumber, transmittance, and absorbance, which are frequently referenced during the selection process. The thermal spectrum itself is an indispensable tool for interpreting molecular structures and behaviors, making it crucial in fields such as pharmaceuticals and environmental monitoring, especially with the use of an infrared spectroscopy machine.

The practical applications of thermal light measurement are extensive, particularly in chemical examination. For instance, it plays a vital role in drug formulation and quality control, where accurate identification of active pharmaceutical ingredients is imperative. However, challenges can arise in the evaluation process, such as the interpretation of thermal spectra for complex samples analyzed with an infrared spectroscopy machine, complicating the evaluation process. As emphasized by experts in the field, "A comprehensive grasp of thermal analysis methods is crucial for any scientist engaged in material examination, as it offers insights that are frequently unreachable through alternative approaches." This statement underscores the method's importance in advancing research and ensuring compliance with regulatory standards. Leading players in the infrared analysis market, including Thermo Fisher Scientific and Agilent Technologies, continue to innovate the infrared spectroscopy machine, enhancing its functionalities and applications as an essential analytical instrument.

Explore Different Types of Infrared Spectroscopy Machines

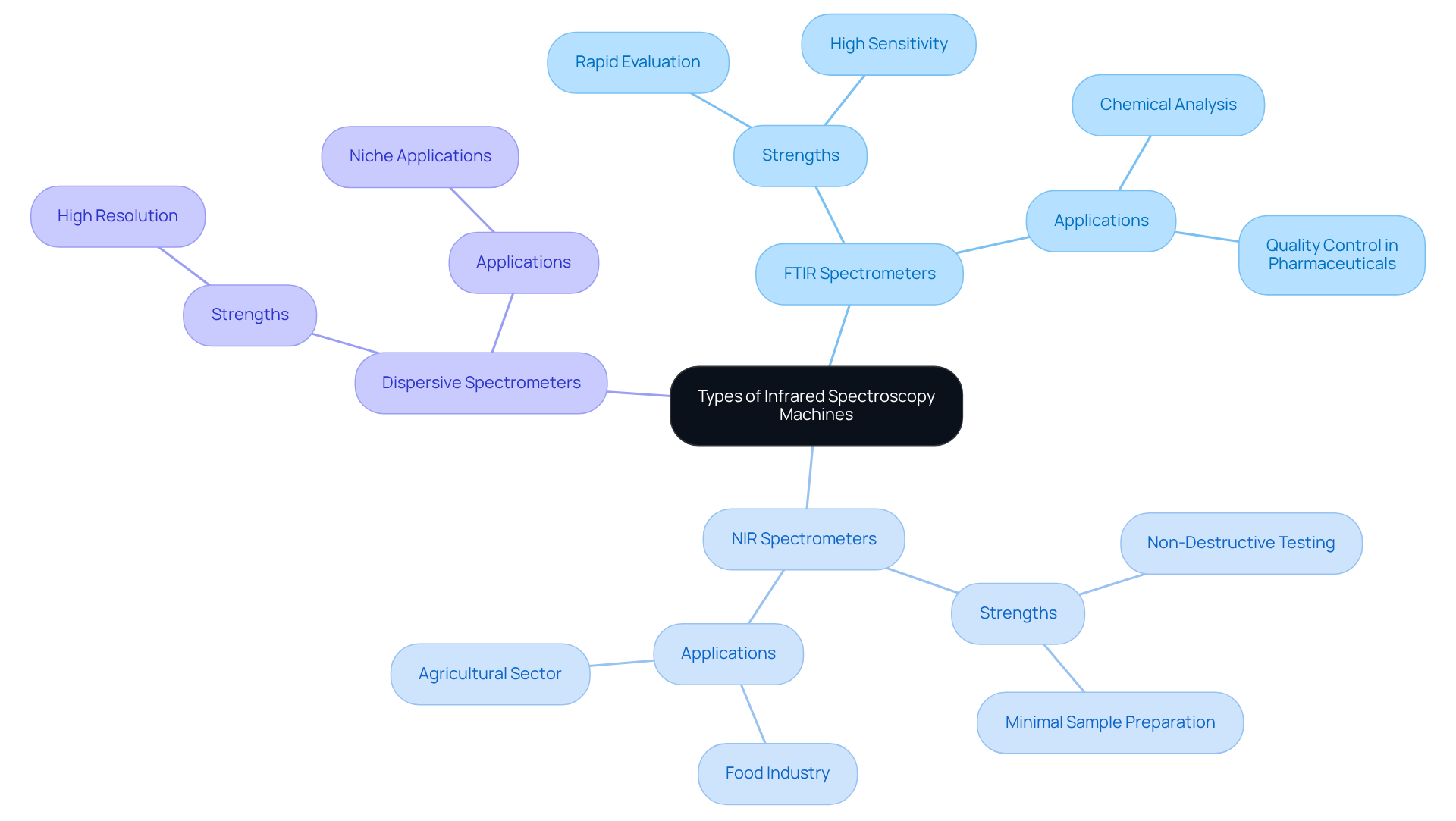

Infrared spectroscopy machines are mainly categorized into three types:

- Fourier Transform Infrared (FTIR) spectrometers

- Near-Infrared (NIR) spectrometers

- Dispersive spectrometers

FTIR spectrometers are renowned for their rapid evaluation and high sensitivity, making them ideal for various applications, including chemical analysis and quality control in pharmaceuticals. Conversely, [NIR spectrometers excel in non-destructive testing](https://verifiedmarketreports.com/product/ir-spectroscopy-equipment-market), allowing for the analysis of samples without extensive preparation, which is particularly advantageous in the food and agricultural sectors. Although dispersive spectrometers are less common today, they retain their value in niche applications that require high resolution.

Understanding the strengths and applications of these instruments is crucial for selecting the most suitable infrared spectroscopy machine for your analytical needs. Industry leaders emphasize that the decision between FTIR and NIR spectrometers often depends on specific application requirements, with FTIR preferred for detailed molecular characterization and NIR favored for rapid, non-invasive assessments.

As the infrared analysis market continues to evolve, advancements in technology are enhancing the capabilities and accessibility of the infrared spectroscopy machine, further facilitating its integration into various laboratory settings. However, the initial investment required for advanced IR analysis devices can pose a financial challenge for smaller institutions.

The global IR analysis market is projected to reach an estimated USD 1.8 billion by 2025, driven by increasing demand from pharmaceutical and biotechnology companies. This context highlights the importance of understanding the competitive landscape and key players in the market, such as Thermo Fisher Scientific and Agilent Technologies, to make informed decisions.

Evaluate Key Selection Criteria for Your Laboratory Needs

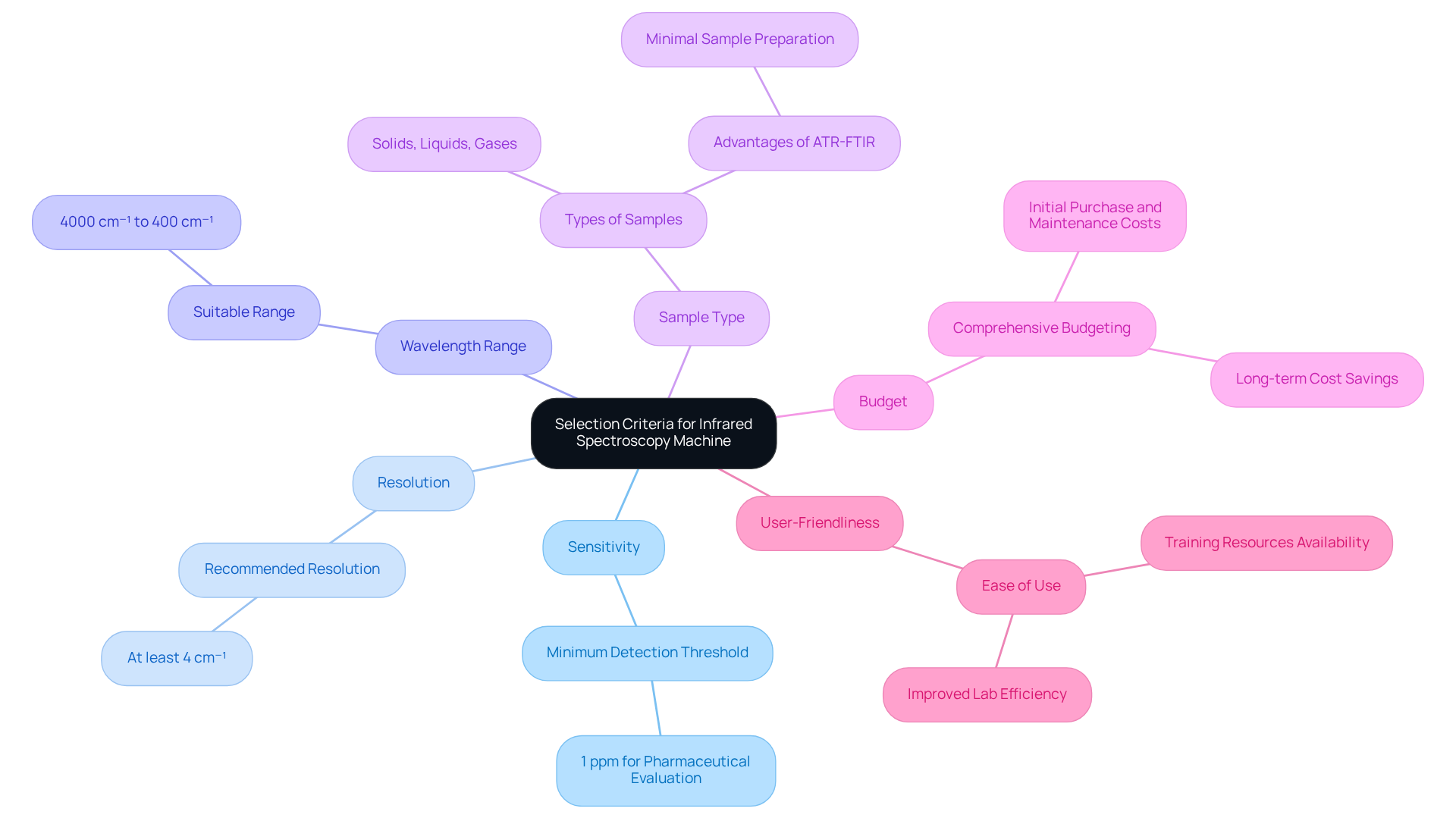

Several key criteria must be considered when selecting an infrared spectroscopy machine to ensure optimal performance and suitability for your laboratory's needs.

- Sensitivity: Establish the minimum concentration of analytes required for detection. High sensitivity is crucial for trace examination, especially in pharmaceutical applications where even tiny amounts can be important. Research shows that a sensitivity threshold of 1 ppm (parts per million) is often essential for effective pharmaceutical evaluation.

- Resolution: Evaluate the spectral resolution necessary for your specific applications. Improved resolution allows for better distinction between closely located spectral features, which is essential for precise identification and evaluation of complex samples. Laboratory managers often recommend a resolution of at least 4 cm⁻¹ for reliable results in most applications.

- Wavelength Range: Confirm that the machine encompasses the required wavelength range for your samples. Various substances demonstrate at different wavelengths, rendering this a crucial factor for effective evaluation. An infrared spectroscopy machine that covers the range from 4000 cm⁻¹ to 400 cm⁻¹ is typically suitable for analyzing most organic compounds.

- Sample Type: Assess whether your analyses will involve solids, liquids, or gases, as this will influence the choice of spectrometer. ATR-FTIR spectroscopy is particularly advantageous for solid and semi-solid samples due to its minimal sample preparation requirements. As noted by a facility manager, 'The simplicity of use with ATR-FTIR has greatly enhanced our workflow for solid samples.'

- Budget: Define a comprehensive budget that accounts not only for the initial purchase price but also for ongoing maintenance and operational costs. While a high-performance spectrometer may have a higher upfront cost, its reliability and lower maintenance needs can lead to cost savings in the long run. This holistic approach ensures that financial considerations do not compromise the quality of your analytical capabilities.

- User-Friendliness: Consider the ease of use and the availability of training resources. A user-friendly machine can significantly improve efficiency in the lab, enabling staff to concentrate on analysis instead of resolving equipment issues. A facility manager recently stated, 'Investing in user-friendly equipment has decreased our training time and enhanced productivity.'

By carefully assessing these criteria, you can effectively narrow your choices and select a spectrometer that matches your laboratory's specific needs, ultimately enhancing your analytical capabilities.

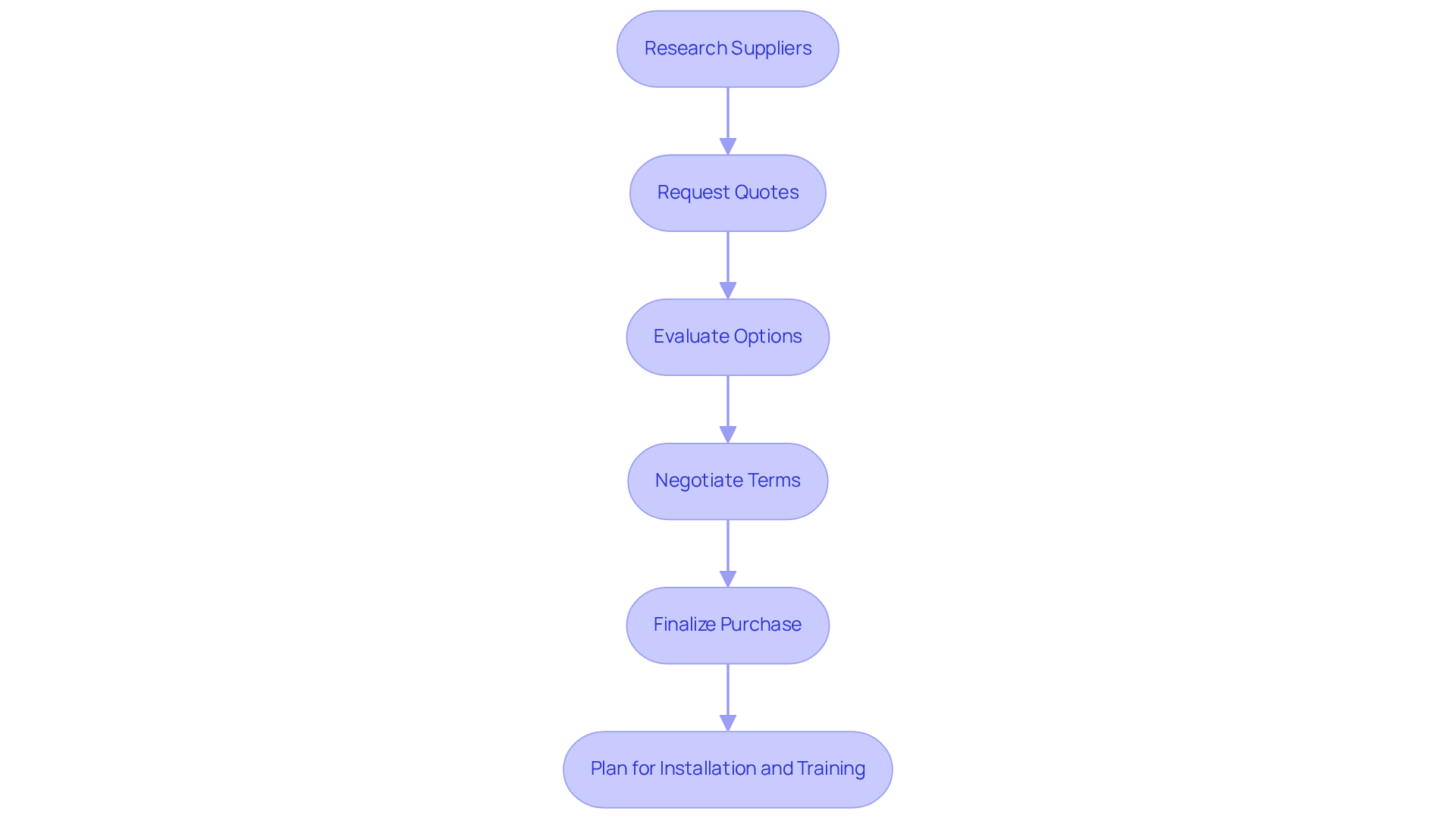

Navigate the Purchasing Process for Infrared Spectroscopy Machines

To successfully navigate the purchasing process for an infrared spectroscopy machine, follow these steps:

- Research Suppliers: Identify trustworthy providers and producers of thermal analysis machines. Look for those with a strong track record in customer service and support. Considering the anticipated expansion of the infrared analysis market, which is predicted to rise from USD 1.25 billion in 2025 to USD 1.6 billion by 2029, choosing a dependable supplier is essential.

- Request Quotes: Contact multiple suppliers to request quotes. Ensure that you provide them with your specific requirements to receive accurate pricing. This step is vital, especially considering the , which can pose challenges to market penetration.

- Evaluate Options: Compare the features, warranties, and support services offered by different suppliers. Consider the total cost of ownership, including maintenance and consumables. Procurement experts frequently highlight the significance of assessing suppliers according to their capacity to fulfill particular requirements and offer continuous assistance.

- Negotiate Terms: Don’t hesitate to negotiate pricing and terms. Discuss potential discounts for bulk purchases or long-term service agreements. Given the competitive landscape, securing favorable terms can significantly impact your budget and operational efficiency.

- Finalize Purchase: Once you have selected a supplier, finalize the purchase agreement. Ensure that all terms are clearly outlined, including delivery timelines and installation support. On average, facilities may take several weeks to finalize purchases, so setting clear expectations with suppliers is essential.

- Plan for Installation and Training: Coordinate with the supplier for installation and training sessions to ensure that your team is well-prepared to use the new equipment effectively. Real-world examples of successful installations can provide insights into best practices and potential challenges.

By following these steps, you can streamline the purchasing process and ensure that you obtain the right infrared spectroscopy machine for your laboratory.

Conclusion

Selecting the appropriate infrared spectroscopy machine is a crucial endeavor that necessitates a thorough understanding of both the technology and its applications. This guide underscores the importance of aligning equipment choices with the specific analytical needs of a laboratory, thereby ensuring optimal performance and cost-effectiveness.

Key considerations are highlighted throughout the article, including the various types of infrared spectroscopy machines:

- FTIR

- NIR

- Dispersive spectrometers

Each presents unique advantages for different applications. Essential selection criteria, such as sensitivity, resolution, wavelength range, sample type, budget, and user-friendliness, are discussed to facilitate informed decision-making. Moreover, navigating the purchasing process through diligent research, careful evaluation, effective negotiation, and meticulous planning for installation guarantees that laboratories efficiently acquire the right equipment.

In conclusion, the selection of an infrared spectroscopy machine transcends mere purchasing; it represents a strategic investment capable of significantly enhancing analytical capabilities. By comprehending the complexities of infrared spectroscopy and adhering to best practices in equipment selection and procurement, laboratories position themselves to excel in their research endeavors. Embracing this technology not only fosters innovation but also propels advancements across various scientific fields, reinforcing the indispensable role of infrared spectroscopy in contemporary analysis.