Overview

This article presents a systematic approach for implementing process analytics in pharmaceutical labs, highlighting the critical need to evaluate current procedures, define clear objectives, select suitable tools, train staff effectively, and continuously monitor performance. Such a structured methodology is vital for enhancing efficiency, ensuring compliance, and improving product quality.

Case studies illustrate significant cost savings and improved outcomes achieved when these steps are executed effectively. By adopting this approach, laboratories can not only optimize their processes but also foster a culture of continuous improvement and excellence.

Introduction

In the rapidly evolving landscape of pharmaceutical manufacturing, the role of process analytics stands as a cornerstone for success. Laboratories face the dual challenge of meeting stringent regulatory standards while ensuring product quality. In this context, the ability to monitor and analyze manufacturing processes in real time has become critical.

By employing advanced analytics, organizations can:

- Identify inefficiencies

- Minimize waste

- Enhance decision-making capabilities that drive operational excellence

With innovative tools and technologies at their disposal, pharmaceutical labs are positioned to revolutionize their manufacturing approach, ultimately improving compliance and product integrity while adeptly navigating the complexities of the industry.

Define Process Analytics and Its Importance in Pharmaceutical Labs

Procedure evaluation entails a methodical approach to overseeing and examining drug manufacturing operations, ensuring peak performance and compliance with regulatory guidelines. In 2025, the significance of process analytics in drug laboratories is paramount, as it facilitates real-time observation of critical quality attributes (CQAs) and critical process parameters (CPPs), essential for guaranteeing product quality and safety. By leveraging advanced analytics, laboratories can swiftly identify inefficiencies, minimize waste, and boost overall productivity.

The integration of cloud information warehouses and lakes has revolutionized information management, providing centralized storage and computing capabilities for real-time data analysis. This technological advancement empowers drug companies to substantially enhance their decision-making capabilities. According to Accenture’s Healthcare Analytics Benchmark Survey, pharmaceutical organizations that have effectively integrated their data silos experience markedly accelerated decision-making capabilities. Furthermore, Novartis has reported a return on investment exceeding 300% from its real-world evidence analytics initiative, underscoring the financial benefits of efficient process analytics. Current trends indicate an increasing reliance on innovative tools such as light-induced fluorescence spectroscopy and near-infrared spectroscopy (NIRS) for monitoring powder composition during the process analytics of tableting. These analytical technology (PAT) tools not only improve product quality but also ensure compliance with industry standards. Additionally, the airflow rate during the coating process is a critical factor influencing granule size and coating efficiency, highlighting the importance of monitoring specific operational variables.

In the realm of drug and medicine testing, the utilization of Karl Fischer titration with Hiranuma Aquacounter AQV-300 volumetric and AQ-300 coulometric titrators is vital for ensuring compliance with the Japanese Pharmacopoeia. These titrators deliver precise moisture content analysis, crucial for maintaining the integrity and efficacy of medicinal products. Moreover, case studies demonstrate the effectiveness of techniques like X-Ray Fluorescence (XRF) for elemental analysis, which offers high sensitivity and selectivity for real-time monitoring of product quality. Such capabilities are essential for upholding compliance during evaluations and examinations, further emphasizing the importance of process analytics in drug manufacturing. In conclusion, the execution of process analytics is indispensable for drug laboratories, promoting advancements in efficiency, compliance, and product quality while adapting to the evolving landscape of the industry.

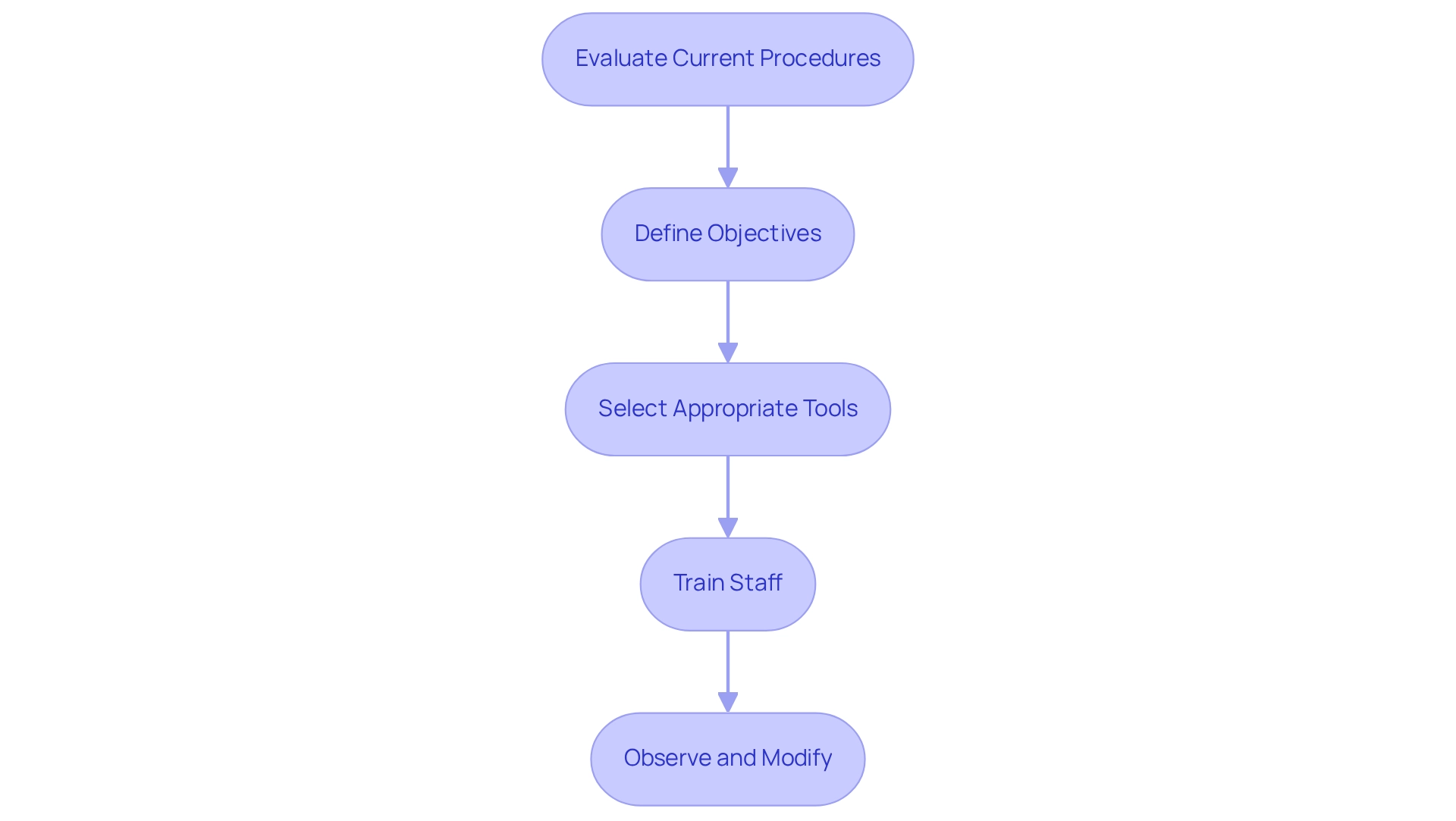

Outline Steps for Implementing Process Analytics

Introducing workflow analysis in pharmaceutical laboratories involves several crucial steps:

-

Evaluate Current Procedures: Begin by reviewing existing workflows to identify areas for incorporating procedure analysis. This includes mapping current procedures and pinpointing inefficiencies that could benefit from process analytics.

-

Define Objectives: Clearly outline the goals for implementing process analysis. Objectives may include enhancing product quality, reducing cycle times, or improving compliance with regulatory standards by utilizing process analytics, leading to significant operational efficiencies. For instance, pharmaceutical companies utilizing process analytics for compliance monitoring report 40% fewer regulatory findings and 60% faster response times to potential compliance issues.

-

Select Appropriate Tools: Choose analytical tools and technologies that align with your defined objectives. This may involve selecting software for process analytics, sensors for real-time monitoring, and systems for seamless data integration, ensuring that the tools enhance overall lab performance.

-

Train Staff: Provide extensive instruction for laboratory personnel on the new tools and methods. This training should cover both the technical features of the tools and the strategic significance of procedure evaluation in achieving laboratory objectives. Businesses with more information-literate staff are more likely to thrive in an analytics-driven environment, making information literacy an essential aspect of the training process.

-

Observe and Modify: Following implementation, continuously track the performance of the system for analysis. Be prepared to make adjustments based on feedback and analysis to enhance results. Organizations that regard process analytics as a fundamental skill can utilize healthcare information for better patient outcomes and operational effectiveness.

By adhering to these steps, pharmaceutical laboratories can efficiently apply process analytics in their workflow analysis, resulting in improved efficiency and reduced expenses. For example, firms employing process analytics in their development pipelines have realized a 45% decrease in late-stage development expenses, highlighting the financial advantages of precision medicine. Furthermore, the typical savings of $12 million per Phase III trial at AstraZeneca emphasizes the financial benefits of embracing workflow evaluation.

Identify Tools and Technologies for Process Analytics

The effectiveness of process analytics in pharmaceutical labs relies on a diverse array of essential tools and technologies that significantly enhance data management and operational efficiency.

- Data Analytics Software: Leading programs such as JMP and Thermo Fisher's Lab Data Management Software play a pivotal role in analyzing extensive datasets. These tools furnish crucial insights into workflow performance and quality control, empowering labs to make informed decisions.

- Real-Time Monitoring Systems: Technologies like near-infrared spectroscopy and Raman spectroscopy facilitate continuous monitoring of critical quality attributes throughout production. Such systems are indispensable for maintaining compliance and ensuring product integrity by providing real-time information on manufacturing operations.

- Integration Platforms: Solutions that amalgamate data from various sources are vital for delivering a comprehensive view of the manufacturing operation. This integration bolsters better decision-making and enhances operational transparency, aligning with the industry's shift towards data-driven strategies.

- Statistical Process Control (SPC) Tools: SPC tools employ statistical techniques to oversee and regulate operations, ensuring they remain within defined limits. This proactive approach aids in identifying variations early, thereby reducing the risk of non-compliance.

- Training and Support Resources: Access to comprehensive training materials and vendor support is crucial for maximizing the effectiveness of these tools. Continuous education ensures that laboratory personnel are well-equipped to leverage technology for optimal results.

The adoption of these tools not only streamlines operations but also aligns with the industry's transition towards data-driven decision-making, particularly through process analytics, as evidenced by the substantial cost savings reported in clinical trials. For instance, AstraZeneca has achieved an average savings of $12 million per Phase III trial by refining their evaluation and analysis methods. As noted by Sarah Lee in Deloitte’s Healthcare Analytics Impact Report, drug companies utilizing data analysis for clinical trial enhancement have reduced development expenses by 15-25%. Furthermore, as the biologics market continues to expand, with an anticipated compound annual growth rate of 15% until 2027, the demand for innovative solutions in workflow analysis will only increase. This underscores the significance of these technologies in drug manufacturing, particularly in addressing the complexities associated with monoclonal antibodies and the semiconductor-like methods that are transforming the industry.

Troubleshoot Common Challenges in Process Analytics Implementation

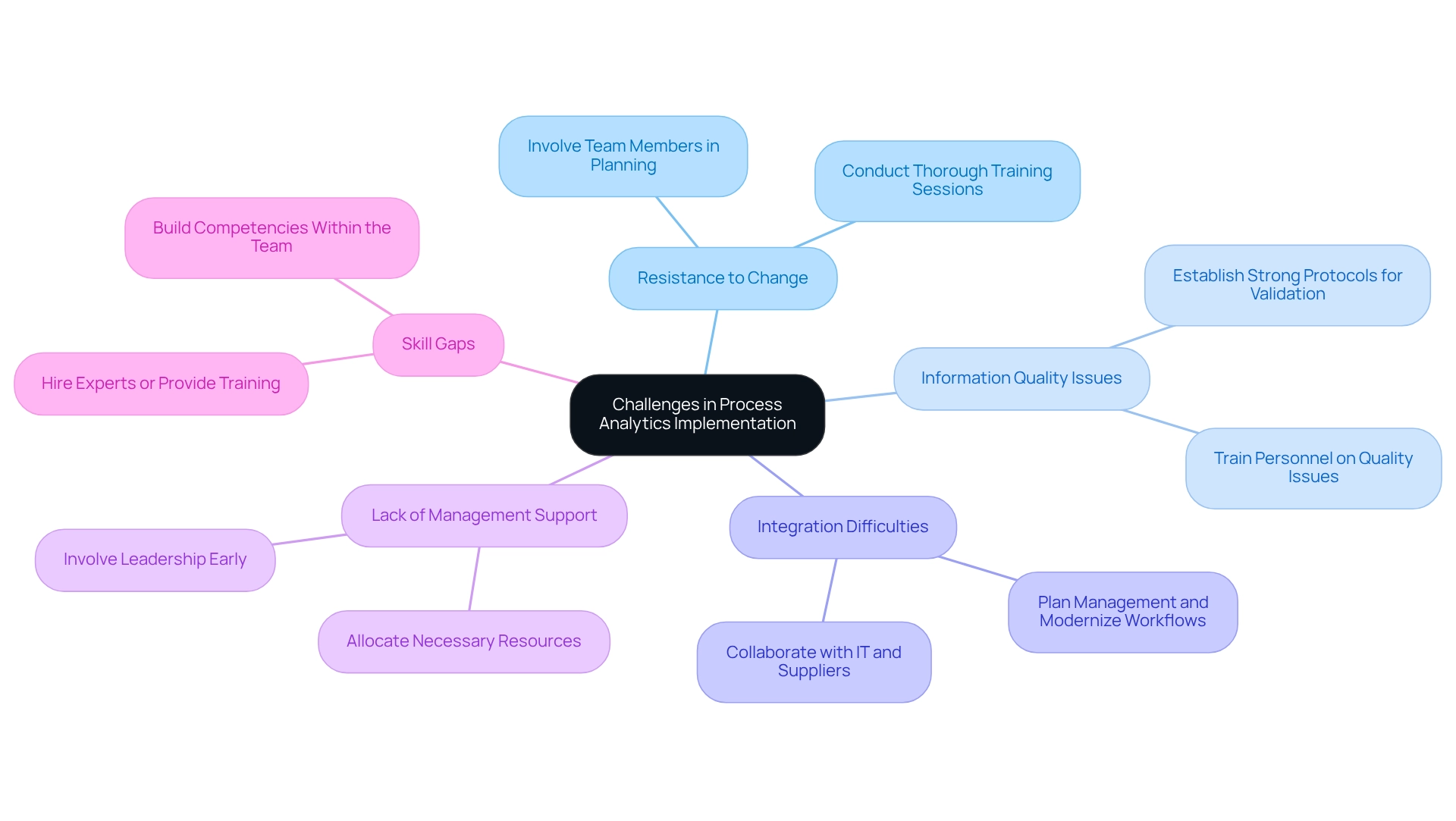

Introducing workflow analysis in pharmaceutical laboratories presents several challenges that must be addressed effectively. Among these challenges are common issues that can significantly impact the success of implementation, along with strategies to overcome them.

- Resistance to Change: Staff may resist adopting new processes due to uncertainty or fear of the unknown. Involving team members in the planning stages fosters a sense of ownership, which can counteract resistance. Conducting thorough training sessions demonstrates the advantages of process evaluation, addressing concerns and promoting acceptance.

- Information Quality Issues: The integrity of analytics efforts can be severely undermined by incorrect or incomplete information. Establishing strong protocols for information validation is essential. Notably, Fortune 500 firms have reduced validation expenses by 50% by proactively tackling these concerns. Ensuring that all information sources are trustworthy and training personnel to identify and address quality issues is crucial, as the responsibility for quality is a collective effort throughout the organization.

- Integration Difficulties: Integrating new tools with existing systems can pose significant challenges. Close collaboration with IT divisions and suppliers is necessary to ensure compatibility and facilitate smooth information flow. Strategically planned management and modernized workflows enable pharmaceutical companies to transform data pools into revenue-generating assets. This proactive approach minimizes disruptions and enhances overall efficiency.

- Lack of Management Support: It is vital for leadership to recognize the importance of workflow analysis and allocate the necessary resources for effective execution. Involving leadership early on secures their backing and ensures that the initiative is prioritized within the organization. The EMA has issued warnings and imposed penalties after inspections revealed inadequate documentation and discrepancies in quality control measures, highlighting the critical nature of management involvement in ensuring compliance and quality.

- Skill Gaps: If staff members lack the necessary skills to implement and utilize new data analysis tools effectively, consider hiring experts or providing targeted training programs. Building the required competencies within the team is essential for successfully adopting process analytics. The responsibility for data quality falls on everyone within an organization, underscoring the need for a collective effort to manage and improve data quality across all levels of a business.

By addressing these challenges head-on, pharmaceutical labs can significantly enhance their analytical capabilities, ultimately leading to improved outcomes in research and healthcare.

Conclusion

The implementation of process analytics in pharmaceutical labs transcends mere trend; it stands as an essential strategy for enhancing efficiency, ensuring compliance, and maintaining product quality within a competitive landscape. By systematically monitoring and analyzing manufacturing processes, organizations can identify inefficiencies and minimize waste, thereby achieving significant operational improvements.

Key steps for successful implementation encompass:

- Assessing current workflows

- Defining clear objectives

- Selecting appropriate tools

- Training staff

- Continuously monitoring performance

Leveraging advanced technologies such as real-time monitoring systems and robust data integration platforms empowers pharmaceutical labs to enhance decision-making capabilities and realize remarkable returns on investment.

While challenges may arise during the implementation of process analytics—such as resistance to change or data quality issues—proactive strategies can effectively mitigate these hurdles. Engaging staff in the planning process, ensuring reliable data sources, and securing management support are crucial for fostering a culture that embraces analytics.

Ultimately, the adoption of process analytics signifies a transformative opportunity for pharmaceutical labs. As the industry evolves, organizations that prioritize data-driven decision-making will not only enhance their operational capabilities but also position themselves for long-term success in delivering high-quality pharmaceutical products. Embracing this analytical approach is pivotal for navigating the complexities of pharmaceutical manufacturing and achieving excellence in compliance and product integrity.