Overview

This article serves as a comprehensive guide for selecting the appropriate centrifugal tubes for laboratory applications. It highlights essential criteria such as:

- Substance compatibility

- Size

- Maximum relative centrifugal force (RCF) ratings

- Sealing mechanisms

- Sterility requirements

Careful selection is emphasized as crucial for ensuring reliable experimental results and maintaining sample integrity. By following these guidelines, researchers can enhance their laboratory practices and uphold the quality of their work.

Introduction

Centrifugal tubes are indispensable instruments in laboratory environments, playing a crucial role in the isolation of materials via centrifugation. The careful selection of these tubes can significantly impact experimental results, making it essential for researchers to navigate the extensive array of options available. As laboratories increasingly prioritize precision and reliability, the pressing question arises: how can one guarantee that the selected centrifugal tubes fulfill the specific requirements of their applications? This guide explores the essential steps and considerations necessary for choosing the appropriate centrifugal tubes, empowering professionals with the insights needed to enhance the integrity of their research.

Understand the Role of Centrifugal Tubes in Laboratory Applications

Centrifugal tubes are indispensable instruments in laboratory environments, primarily utilized for isolating materials based on density through centrifugation. Available in various forms and sizes, these cylinders are typically constructed from materials such as polypropylene or glass, selected according to the specific requirements of the substances being processed. In fields like clinical diagnostics, molecular biology, and biochemistry, the choice of centrifugal tubes can significantly impact the quality of results.

For example, using inappropriate materials for piping can trigger chemical reactions that jeopardize specimen integrity, leading to inaccurate outcomes. Laboratory professionals emphasize the critical nature of selecting the right centrifugal tubes, asserting that appropriate material selection not only enhances the reliability of results but also safeguards the integrity of sensitive samples.

By acknowledging the vital role of these containers, researchers can make informed decisions that ensure precise and dependable results in their experiments.

Identify Key Selection Criteria for Centrifugal Tubes

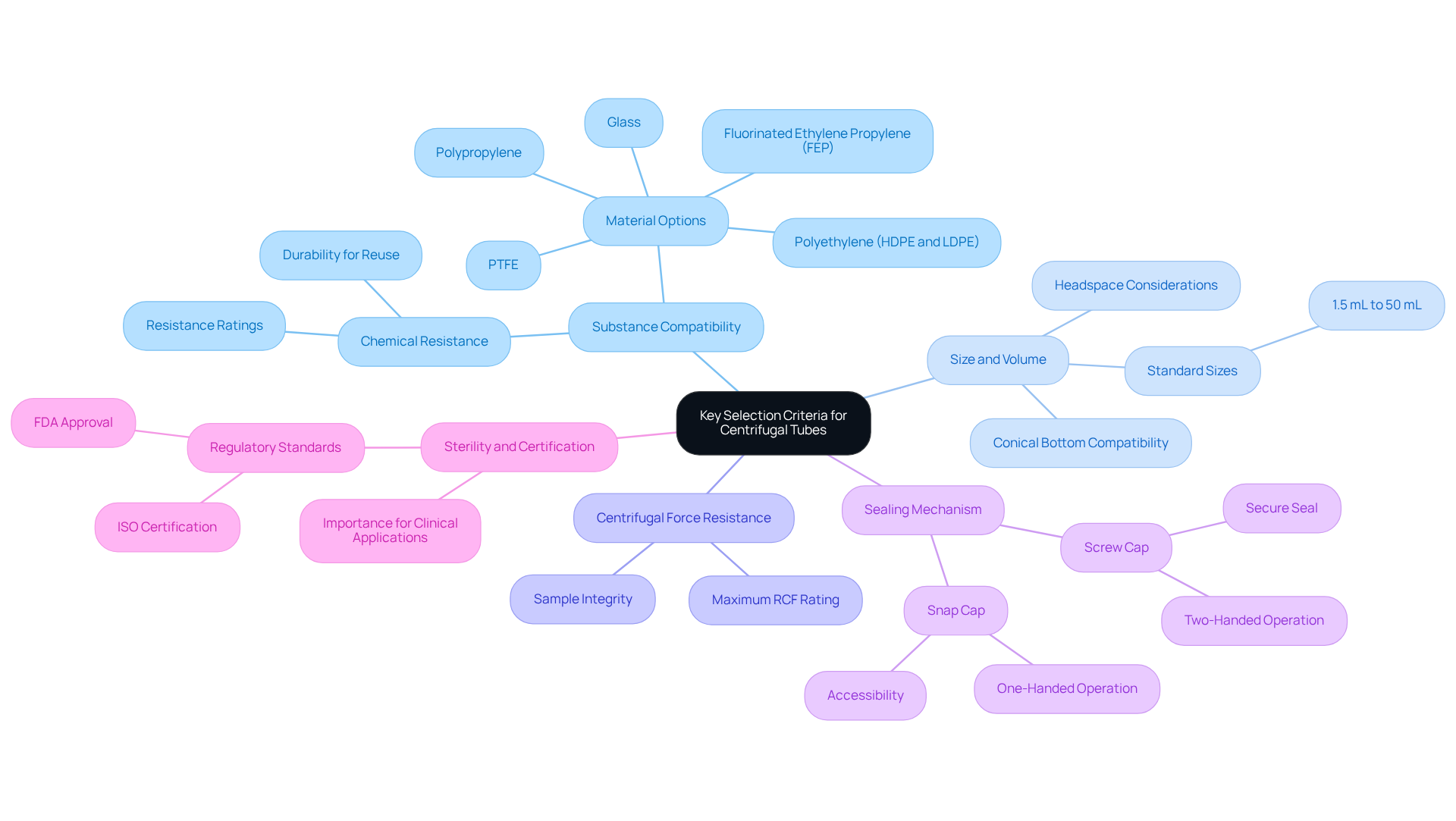

Several key criteria must be considered when selecting centrifugal tubes to ensure optimal performance and reliability in laboratory settings.

-

Substance Compatibility is paramount; it is essential to select pipes constructed from materials that are chemically resistant to the samples being processed. Common materials include polypropylene, which offers resistance comparable to polyethylene and superior resistance to specific chemicals for general use, and glass for applications requiring high clarity. Notably, only pipes made from fluorinated ethylene propylene (FEP) and glass are resilient enough for reuse, guaranteeing longevity in laboratory environments.

-

Next, consider Size and Volume. Ensure the size of the centrifugal tubes accommodates the sample volume while leaving adequate headspace to prevent spillage during centrifugation. Standard sizes of centrifugal tubes typically range from 1.5 mL to 50 mL, with conical bottom containers being crucial for compatibility with microcentrifuges, as only these centrifugal tubes fit into microcentrifuges.

-

Centrifugal tubes play a critical role in centrifugal force resistance. Verify the maximum relative centrifugal force (RCF) rating of the container to ensure it can withstand the forces generated during centrifugation without breaking. This is essential for maintaining sample integrity and preventing contamination.

-

The Sealing Mechanism also warrants attention. Depending on the application, consider whether a screw cap or snap cap is more suitable. Screw cap containers provide a secure seal but require both hands for manipulation, while snap cap containers allow for one-handed use, enhancing accessibility and convenience.

-

Finally, Sterility and Certification are vital for clinical applications. It is crucial to ensure that the containers are sterile and comply with relevant regulatory standards, such as FDA approval or ISO certification. This guarantees that the materials used do not compromise the quality or safety of the specimen.

Follow a Step-by-Step Process to Select the Appropriate Centrifugal Tubes

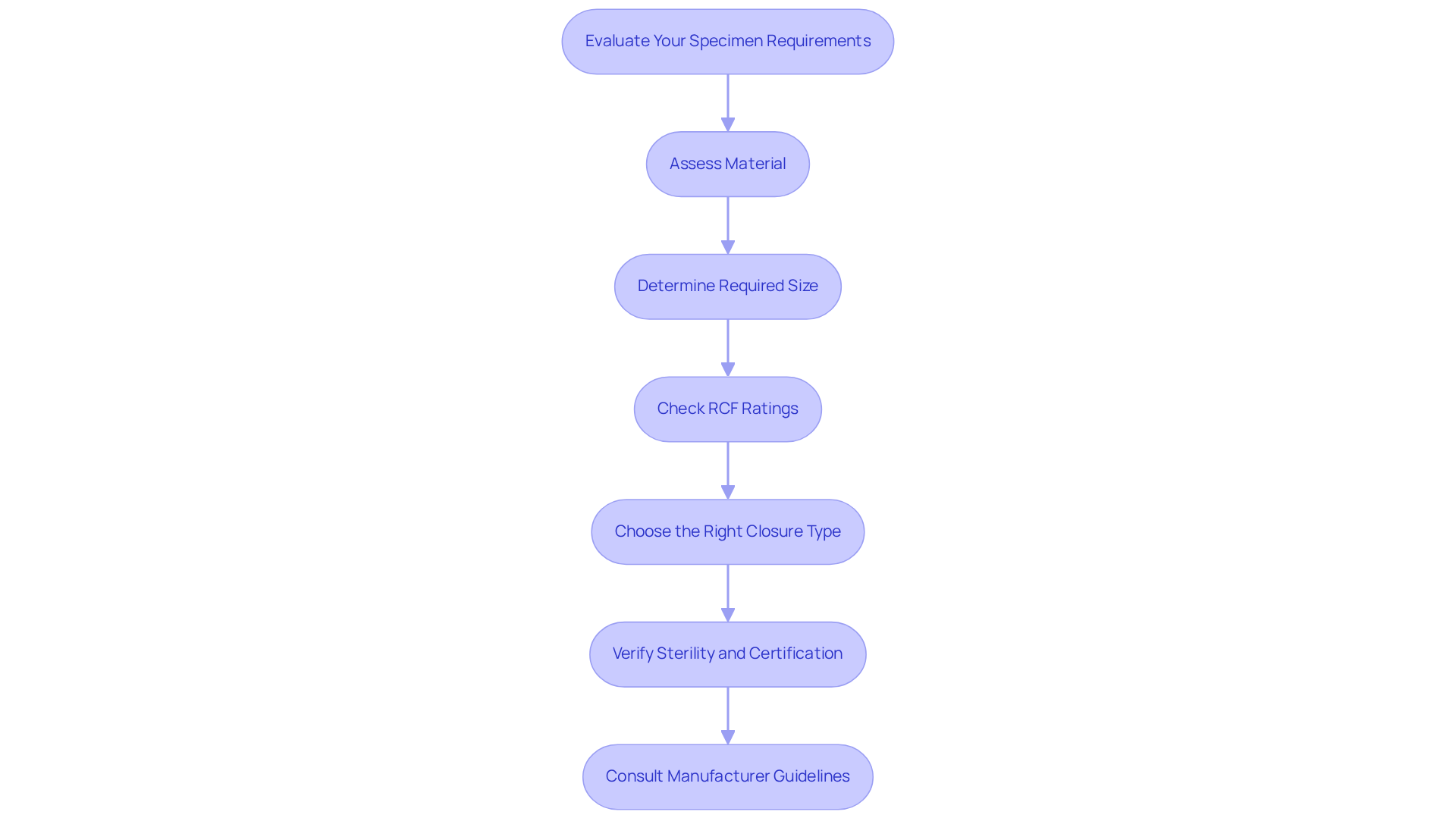

To select the appropriate centrifugal tubes, follow these essential steps:

-

Evaluate Your Specimen Requirements: Begin by determining the types of specimens you will process. Consider their volume, chemical nature, and specific handling needs to ensure compatibility with your chosen tubes.

-

Assess Material: It is crucial to select a material that is suitable for your specimens. For example, polypropylene or polyallomer tubes are ideal for handling organic solvents, ensuring durability and reliability in your processes.

-

Determine Required Size: Choose a cylinder dimension that accommodates your specimen volume while providing adequate headspace. For instance, a 15 mL container is appropriate for a 10 mL sample volume, allowing for sufficient space during centrifugation.

-

Check RCF Ratings: Review the specifications of your selected cylinders to ensure they can withstand the necessary centrifugal forces, as indicated by the manufacturer. RCF ratings are vital for confirming that the centrifugal tubes can withstand the applied forces without failure, thereby safeguarding your samples.

-

Choose the Right Closure Type: Decide between screw caps and snap caps based on your application needs. Generally, screw caps provide a more secure seal for volatile samples, minimizing the risk of contamination or loss.

-

Verify Sterility and Certification: If sterile conditions are required for your specimens, ensure that the containers are certified sterile and comply with relevant regulatory standards. This step is critical for maintaining the integrity of your samples.

-

Consult Manufacturer Guidelines: Finally, always refer to the manufacturer's recommendations for specific instructions regarding the use and limitations of the products you are considering. Adhering to these guidelines will enhance the reliability and effectiveness of your laboratory processes.

Access Resources and Troubleshooting Tips for Centrifugal Tube Selection

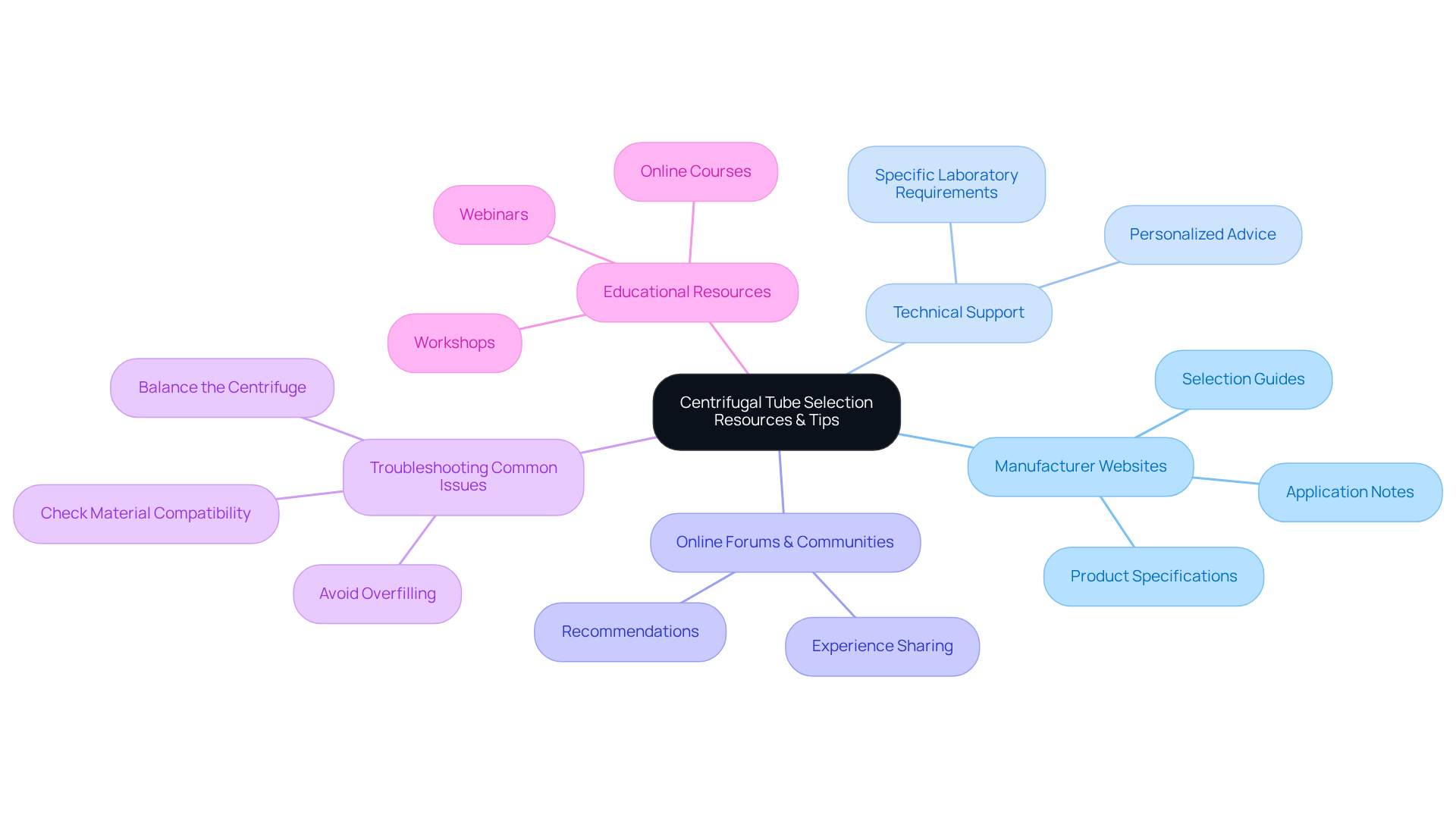

To assist in the selection of centrifugal tubes, it is essential to consider several key resources and troubleshooting tips that can significantly enhance the decision-making process regarding these tubes.

-

Manufacturer Websites: Many manufacturers offer comprehensive product specifications, selection guides, and application notes. Centrifugal tubes are invaluable resources for making informed decisions tailored to your laboratory's needs.

-

Technical Support: Do not hesitate to contact the technical support teams of manufacturers. They can provide personalized advice based on your specific laboratory requirements, ensuring you choose the right products.

-

Online Forums and Communities: Engaging with online scientific communities or forums allows laboratory professionals to share their experiences and recommendations regarding the selection of containers. This collective knowledge can guide you in making the best choices.

-

Troubleshooting Common Issues: When encountering problems such as tube breakage or sample contamination, consider the following strategies:

- Ensure that tubes are not overfilled, as this can lead to spillage during centrifugation.

- Verify compatibility between the tube material and the sample to prevent adverse chemical reactions.

- Always balance the centrifuge correctly by loading containers symmetrically to avoid imbalances that could damage the equipment.

-

Educational Resources: Seek out webinars, workshops, or online courses that focus on laboratory best practices, including centrifugation techniques and tube selection. These educational opportunities can further enhance your understanding and skills in this critical area.

Conclusion

Selecting the appropriate centrifugal tubes is a critical aspect of laboratory work that significantly influences the accuracy and reliability of experimental results. Understanding the specific applications and requirements of these tubes enables laboratory professionals to choose the right materials and designs that align with their needs, ultimately safeguarding specimen integrity.

Essential criteria for selecting centrifugal tubes include:

- Substance compatibility

- Size

- Maximum relative centrifugal force (RCF) ratings

- Sealing mechanisms

- Sterility standards

By following a systematic approach—evaluating specimen requirements, assessing material suitability, and consulting manufacturer guidelines—laboratory professionals can streamline the selection process and mitigate potential issues during centrifugation.

The importance of careful selection cannot be overstated. Prioritizing informed decision-making and utilizing available resources, such as manufacturer support and online communities, enhances operational efficiency and maintains the highest standards of scientific integrity. Embracing these best practices fosters reliable results and contributes to the overall advancement of research and diagnostics across various scientific fields.