Overview

The article titled "7 Benefits of Using a Centrifugal Unit in Your Lab" highlights the significant advantages that centrifugal units offer in laboratory settings. These benefits encompass:

- Improved efficiency in sample separation and purification

- Enhanced accuracy and reliability of results

- Versatility to adapt to diverse applications

Such capabilities are underscored by evidence demonstrating increased productivity and cost savings within research environments. By integrating these units into laboratory practices, researchers can optimize their workflows and achieve superior outcomes.

Introduction

Centrifugal units have emerged as indispensable tools in contemporary laboratories, fundamentally transforming how researchers conduct sample separation and purification. Their capacity to efficiently segregate components based on density not only improves experimental accuracy but also optimizes workflows across diverse scientific disciplines.

As laboratories increasingly pursue enhanced efficiency and reliability, one pivotal question arises: how can the integration of centrifugal units reshape research practices and drive substantial advancements in scientific inquiry?

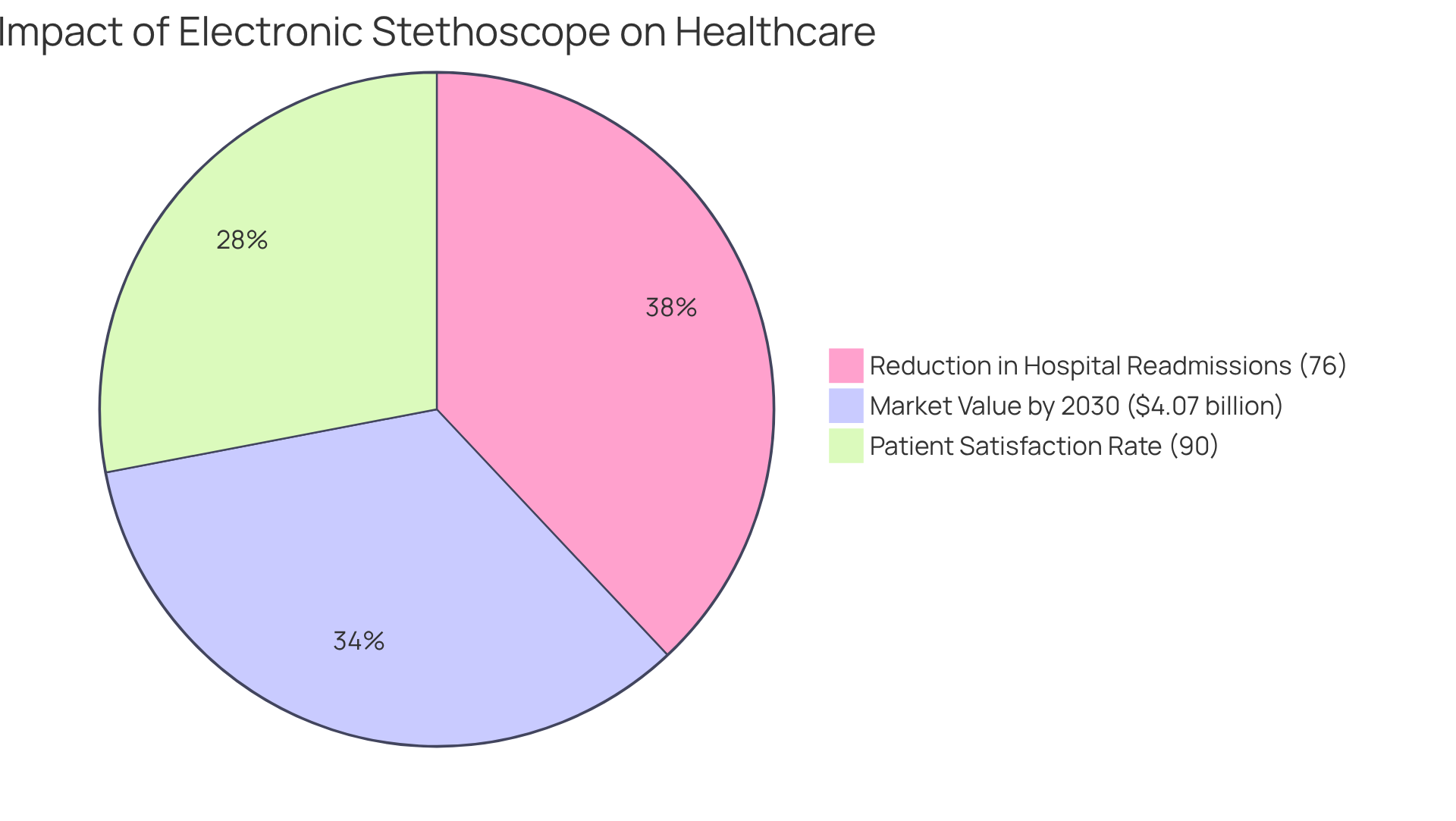

JM Science Electronic Stethoscope: Enhance Remote Patient Monitoring

The JM Science electronic stethoscope is meticulously engineered to enhance remote patient monitoring, allowing healthcare professionals to evaluate patients' heart and lung sounds from a distance. This capability is vital in telemedicine, where timely and accurate assessments can significantly influence patient outcomes. By leveraging advanced audio technology, the stethoscope ensures superior sound transmission, facilitating precise diagnostics without the need for physical presence. This innovation not only elevates patient care but also streamlines workflows in busy medical environments, establishing it as an indispensable tool for contemporary healthcare practices.

With the rise of remote patient monitoring projected to reach a market value of $4.07 billion by 2030, and its demonstrated ability to reduce hospital readmissions by up to 76%, the electronic stethoscope is pivotal in empowering healthcare providers to deliver effective care. Furthermore, it contributes to maintaining patient satisfaction rates exceeding 90%, as reported by the University of Pittsburgh Medical Center. As telemedicine continues to evolve, the integration of such advanced tools will be essential in shaping the future of healthcare delivery.

JM Science Karl Fischer Titrators: Achieve Accurate Moisture Analysis

Karl Fischer titrators from JM Science, including the AQV-300 Volumetric and AQ-300 Coulometric models, are essential tools for achieving precise moisture analysis across a variety of samples, particularly within the pharmaceutical sector. These titrators utilize a well-established methodology that accurately quantifies water content, a critical factor for pharmaceutical formulations and food products.

In 2025, the significance of moisture analysis in pharmaceuticals is underscored by stringent regulatory requirements, including compliance with the Japanese Pharmacopoeia, rendering these titrators indispensable for quality assurance. Recent advancements in titration technology, such as the integration of IoT and cloud-based systems for real-time monitoring, have notably enhanced the accuracy and efficiency of moisture measurements. This progress allows facilities to streamline their quality control processes effectively.

By employing JM Science's Karl Fischer titrators, facilities can ensure adherence to regulatory standards while simultaneously enhancing the overall quality of their products. The user-friendly design and reliability of these titrators solidify their status as the preferred choice for facilities committed to maintaining high-quality control standards.

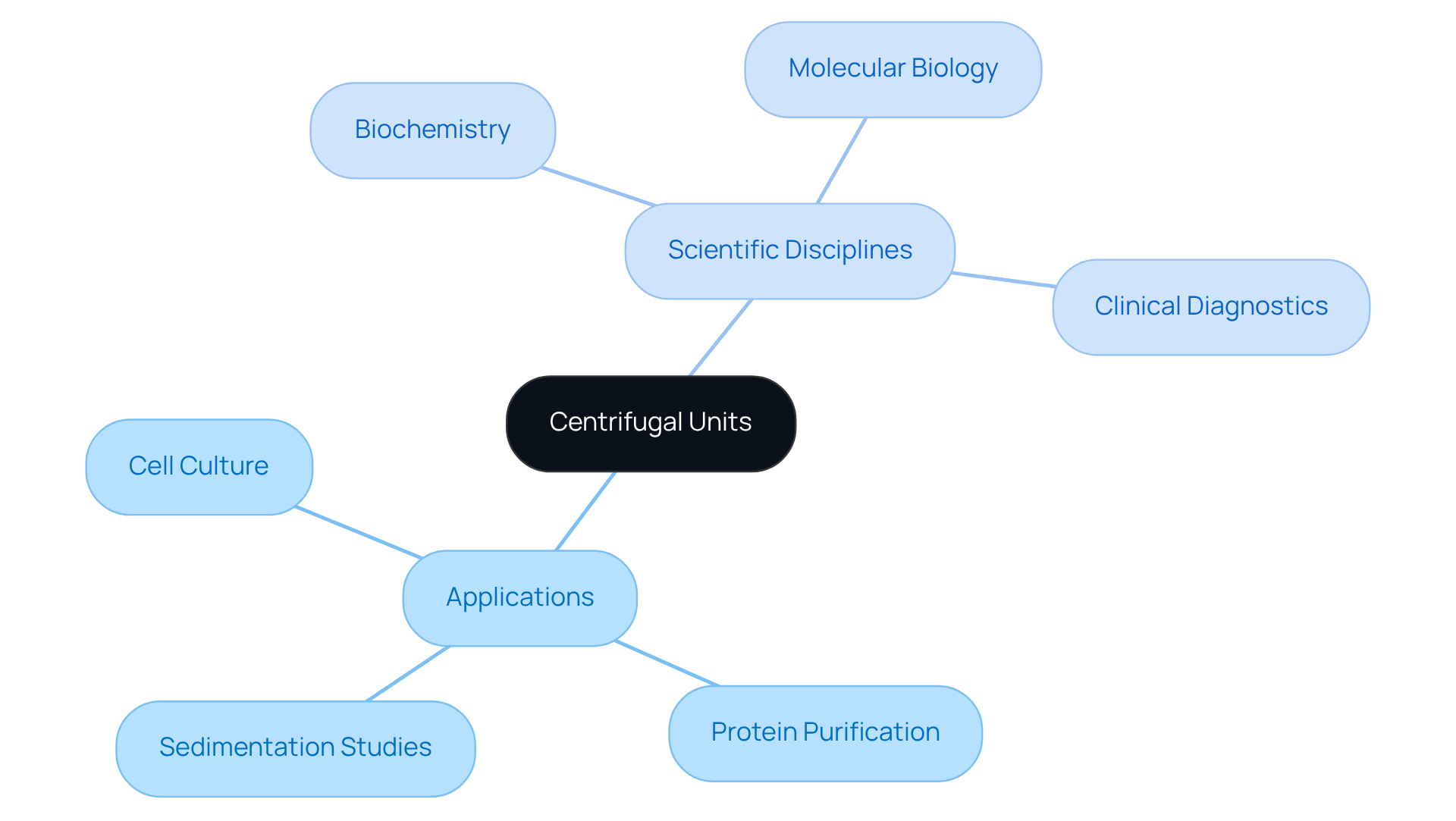

Centrifugal Units: Versatile Solutions for Separation and Purification

Centrifugal units are indispensable instruments in research facilities, crucial for the separation and purification of samples. By harnessing rotational force, the centrifugal unit proficiently segregates components based on their density, making it essential for a variety of applications, including:

- Cell culture

- Protein purification

- Sedimentation studies

Their versatility spans multiple scientific disciplines, such as:

- Biochemistry

- Molecular biology

- Clinical diagnostics

For example, research indicates that optimizing centrifugation conditions—such as centrifugation at 3000xg for 5 minutes without compromising the integrity of analytes—can significantly reduce turnaround times, yielding improvements of up to five minutes in intra-laboratory workflows. Furthermore, the ability to achieve greater yields—up to four times more when comparing horizontal centrifugation with fixed-angle centrifugation—demonstrates the effectiveness of centrifugal units in enhancing experimental processes. Additionally, centrifugation is pivotal in testing for infectious diseases by concentrating viruses and bacteria from samples. By integrating these devices into their workflows, researchers can substantially improve the efficiency of their separation methods, thereby advancing their scientific investigations and outcomes. Lab managers are strongly encouraged to routinely evaluate and refine their centrifugation protocols based on the latest findings to maximize both efficiency and accuracy.

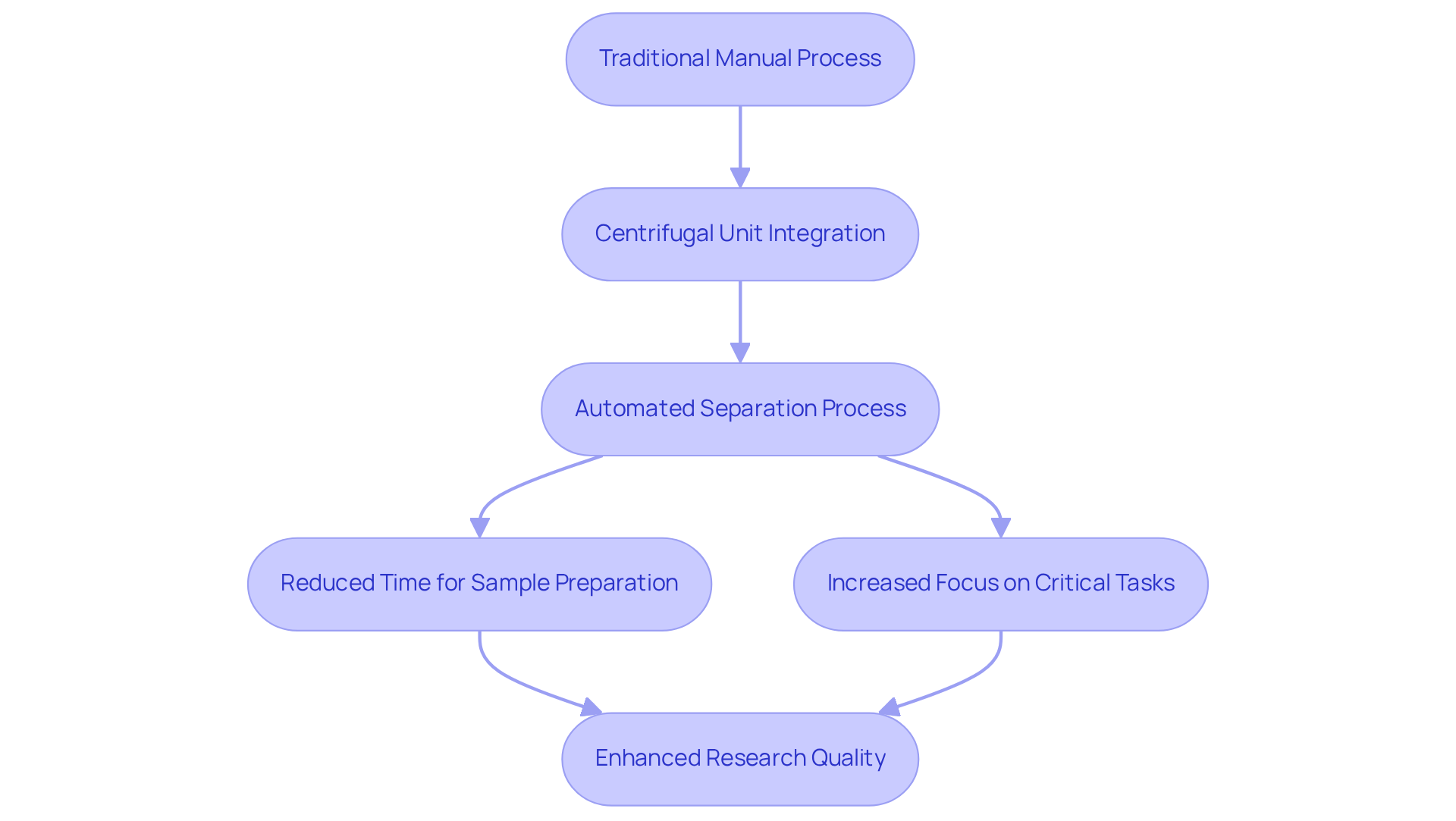

Centrifugal Units: Save Time with Streamlined Laboratory Workflows

The centrifugal unit plays a pivotal role in enhancing laboratory workflows by automating the separation process, which has traditionally required manual intervention. This automation significantly reduces the time spent on sample preparation and analysis, enabling researchers to focus on critical tasks such as data interpretation and experimental design. Furthermore, the rapid processing capabilities of these spinning devices facilitate quicker turnaround times for results, a crucial factor in high-throughput environments where efficiency is paramount. In essence, integrating centrifugal units into laboratory practices not only streamlines operations but also elevates the overall quality of research outcomes.

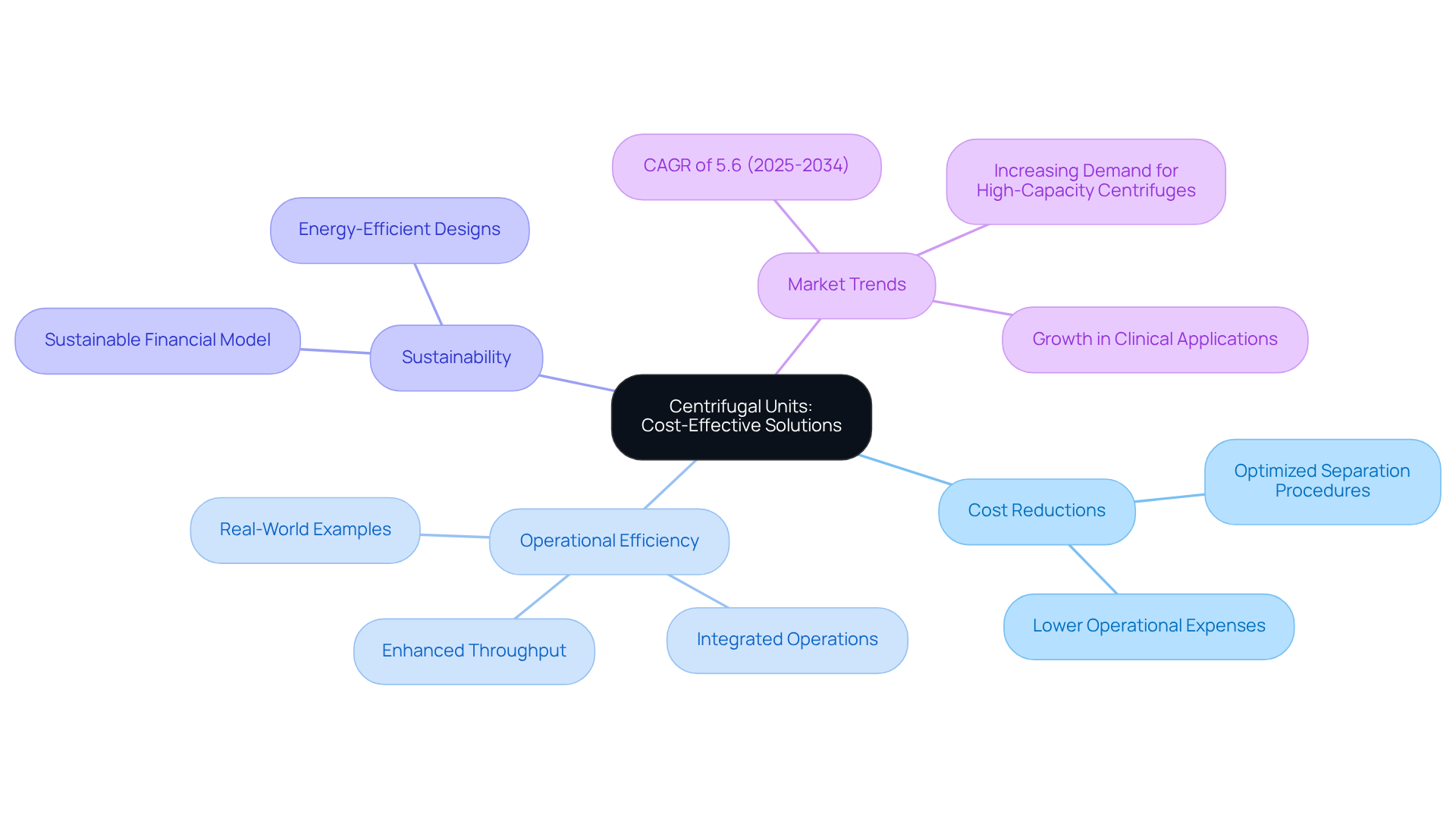

Centrifugal Units: Cost-Effective Solutions for Laboratory Operations

Investing in a centrifugal unit presents a compelling opportunity for research facilities to achieve substantial cost reductions by optimizing separation procedures. These advanced components significantly diminish reliance on various separation methods, thereby facilitating a more integrated and efficient operation of the centrifugal unit.

The centrifugal unit in modern spinning devices is designed with innovative features that enhance efficiency and throughput in research environments, resulting in considerable long-term savings. By lowering operational expenses while simultaneously boosting output, facilities can allocate resources more effectively, ultimately enhancing overall productivity and profitability.

Laboratory directors have noted that the transition to spinning technology, particularly the implementation of a centrifugal unit, not only elevates operational efficiency but also fosters a more sustainable financial model, marking it as a wise investment for the future.

Furthermore, the global centrifuge market is projected to experience a CAGR of 5.6% from 2025 to 2034, underscoring the increasing demand for high-capacity and high-speed centrifugation in both research and clinical settings.

Real-world examples illustrate how facilities that have adopted spinning technology and utilized a centrifugal unit have realized improved operational efficiency, further solidifying the financial benefits of this strategic investment.

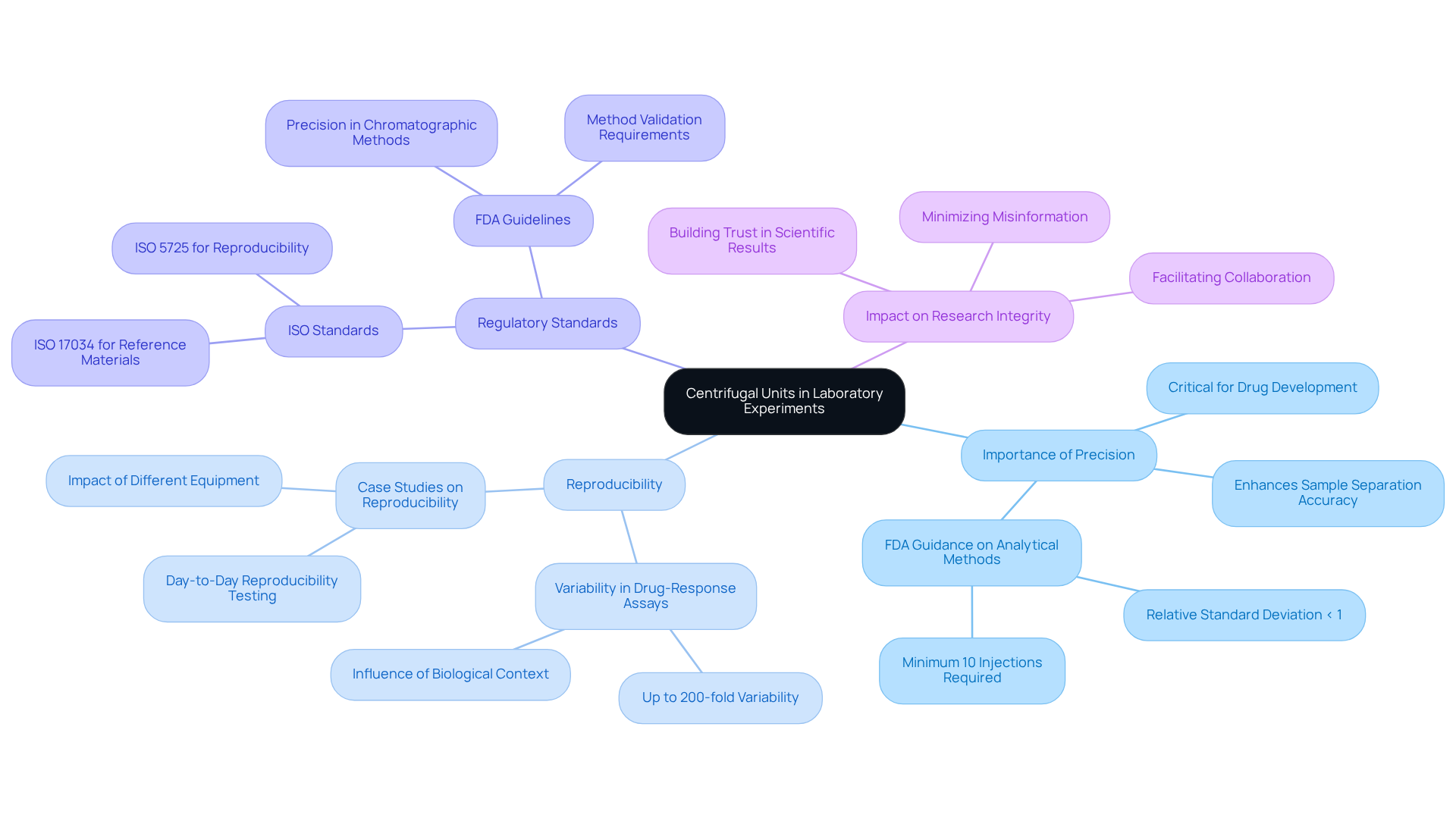

Centrifugal Units: Ensure Reliable Results in Laboratory Experiments

Centrifugal units are essential for delivering consistent and dependable outcomes in experimental procedures, significantly enhancing the accuracy of sample separation. This precision is particularly vital in pharmaceutical research, where even minor variability can drastically affect drug development and regulatory approval processes. By employing spinning technology, research facilities can markedly improve the reproducibility of their experiments, thereby bolstering the credibility of their research results. For example, studies from the NIH LINCS Program Consortium reveal that reproducibility in drug-response assays can fluctuate by as much as 200-fold among different research centers, highlighting the critical need for precise methodologies.

Moreover, FDA guidance underscores that analytical methods must exhibit a relative standard deviation of less than 1% for repeatability, further emphasizing the importance of precision in achieving reliable results. As research facilities increasingly adopt centrifugal units, they enhance their experimental precision and contribute to the overall integrity of scientific inquiry, fostering greater confidence in the results that inform public health and safety. Integrating reproducibility into the uncertainty budget is also paramount for ensuring that facilities maintain high standards of reliability and transparency in their methodologies.

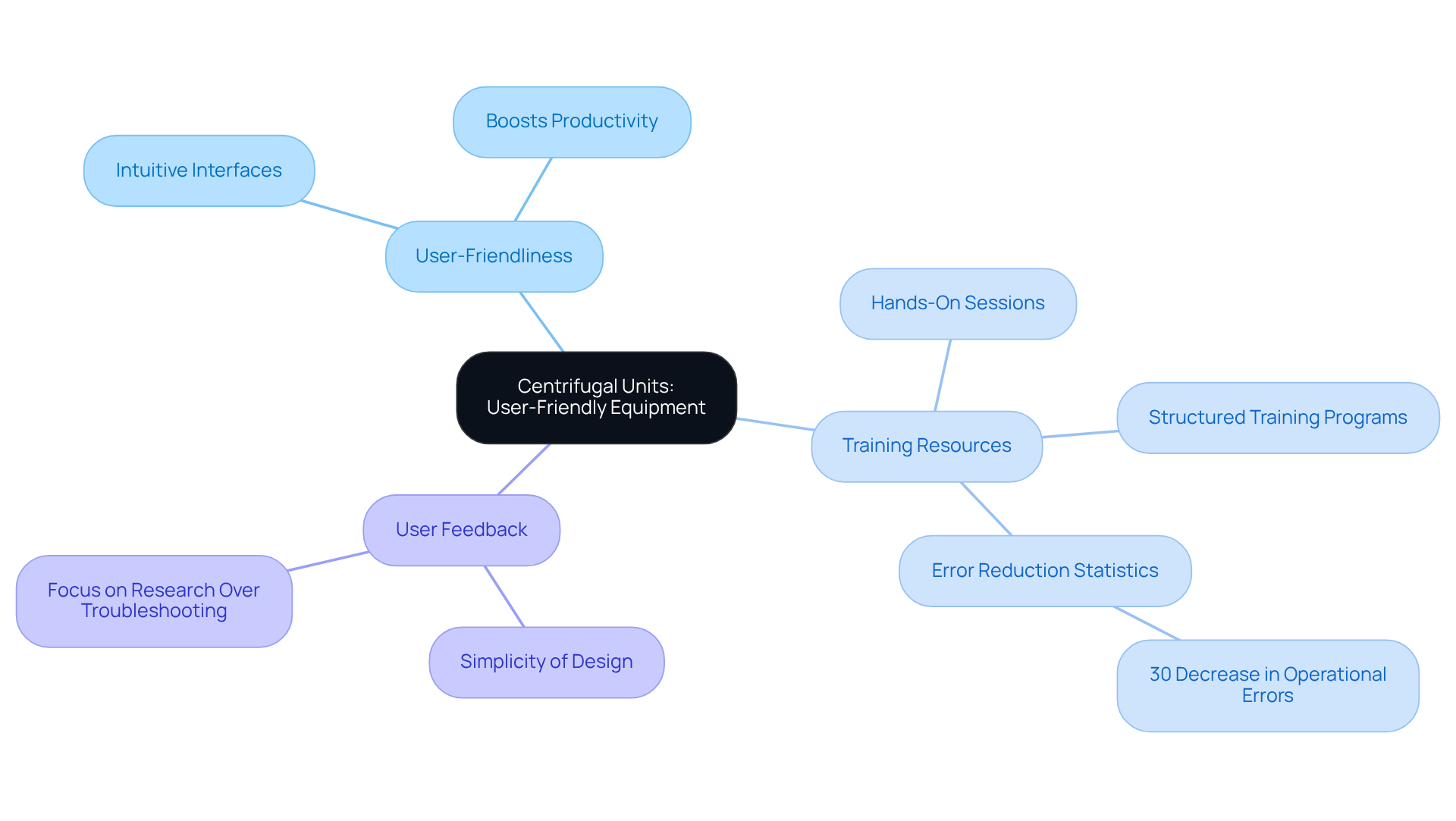

Centrifugal Units: User-Friendly Equipment for All Skill Levels

Contemporary centrifugal units are engineered for user-friendliness, ensuring accessibility for staff across varying skill levels. With intuitive interfaces and straightforward operational protocols, new users can swiftly master the equipment, significantly boosting productivity and reducing operational errors.

Training resources are vital in this context; for instance, numerous research facilities have instituted structured training programs that encompass hands-on sessions and detailed manuals. Notably, statistics reveal that effective training can result in a 30% decrease in operational errors, highlighting the importance of investing in staff education.

Input from laboratory personnel consistently underscores the simplicity of these devices, with many noting that the clear design allows them to focus more on their research rather than troubleshooting equipment issues. By prioritizing education and support, research facilities can cultivate a collaborative environment where all personnel are empowered to utilize the centrifugal unit effectively, ultimately enhancing research outcomes.

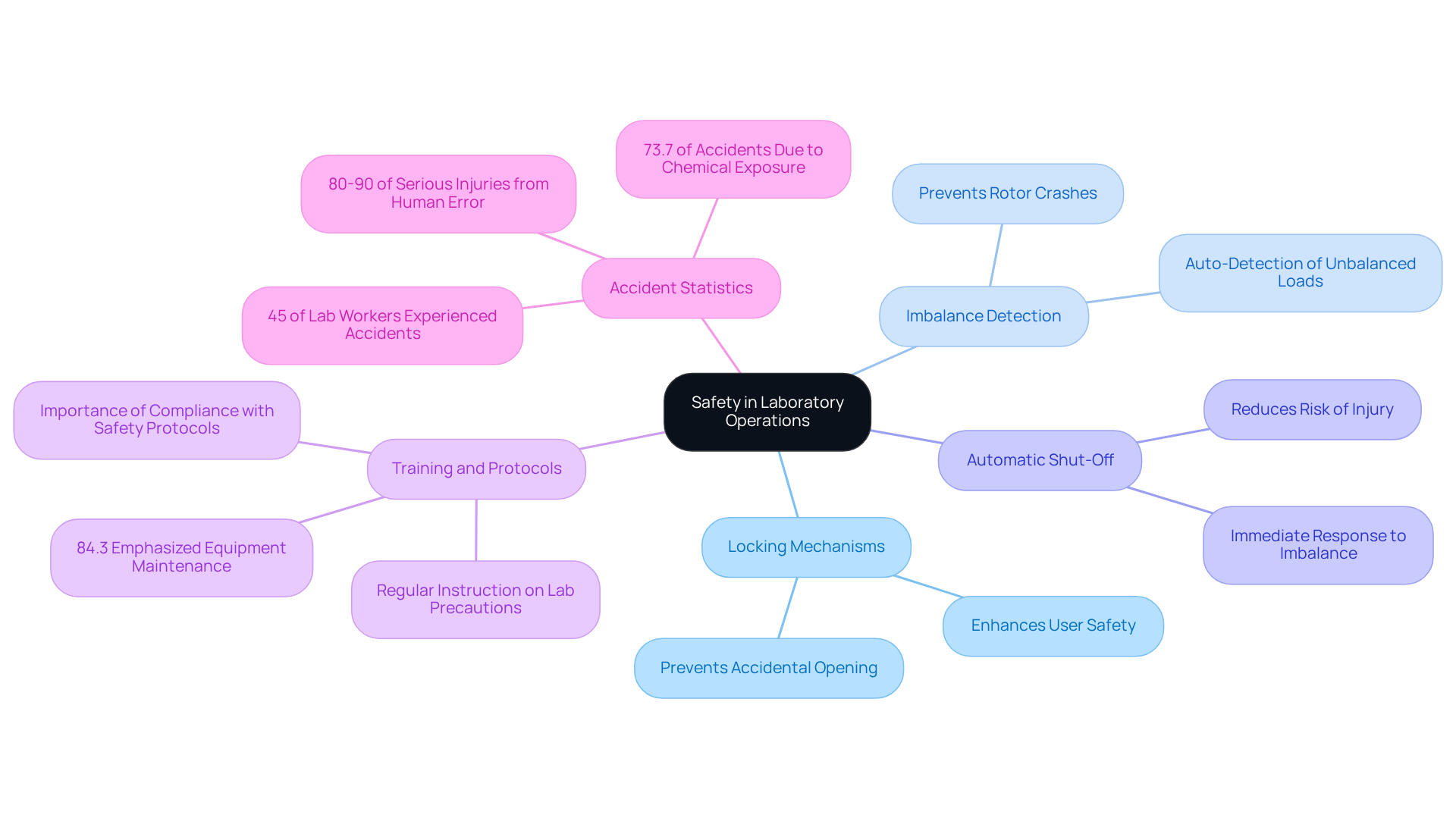

Centrifugal Units: Prioritize Safety in Laboratory Operations

Safety stands as a fundamental concern in laboratory operations, with spinning devices engineered to enhance safe usage through various features. These devices typically incorporate:

- Locking mechanisms

- Imbalance detection systems

- Automatic shut-off functions

All of which collectively work to prevent accidents during operation. For instance, many modern centrifuges are equipped with auto-imbalance detection that can decelerate or shut off if an excessively unbalanced load is detected. This capability significantly reduces the risk of rotor crashes and potential injuries.

The significance of adhering to protocols when utilizing a centrifugal unit cannot be overstated. Regular instruction on lab precautions is vital, as research indicates that a considerable portion of lab incidents stems from insufficient training and awareness of protocols. In fact, 84.3% of participants in a recent study underscored the necessity of regular upkeep of equipment, including centrifuges, to ensure optimal performance and security. This statistic highlights that maintenance is not merely a routine task but a crucial precaution that can avert accidents.

Real-world instances illustrate the beneficial impact of spinning technology on research environment security. For example, a study revealed that 45% of research facility workers encountered accidents primarily due to chemical exposure, underscoring the need for effective protective measures. By implementing strict protocols and utilizing advanced spinning machines, facilities can significantly mitigate risks associated with sample handling, thereby safeguarding staff and enhancing overall operational security. Moreover, it is essential to recognize that 80-90 percent of serious workplace injuries arise from human errors, emphasizing the necessity for ongoing training and compliance with established protocols.

In summary, the integration of safety features in centrifugal units, coupled with a commitment to adhering to established safety protocols, is crucial for ensuring a secure research environment. This proactive approach not only protects research staff but also bolsters the integrity of scientific inquiry.

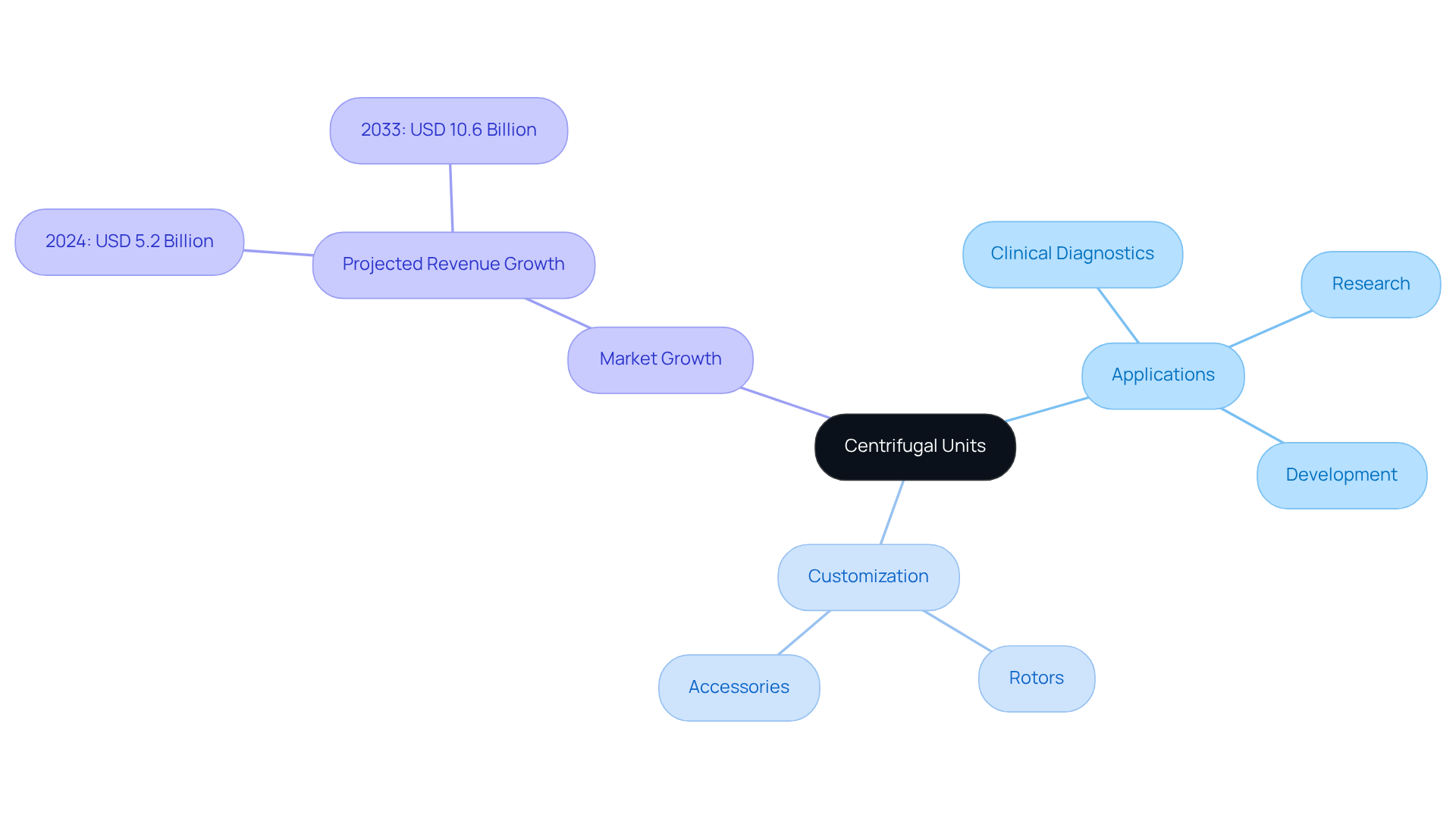

Centrifugal Units: Adaptable Tools for Diverse Laboratory Applications

The centrifugal unit serves as an adaptable tool that is essential for a myriad of applications in clinical diagnostics, research, and development. Their ability to accommodate various sample types and volumes makes them indispensable across diverse scientific disciplines. Laboratories can customize their centrifugal unit with an array of rotors and accessories, enabling specific modifications that cater to distinct experimental requirements. This customization not only enhances operational flexibility but also allows research facilities to swiftly adapt to evolving research demands, thereby optimizing workflows and improving overall efficiency.

As the scientific equipment market expands, with projected revenue growth from USD 5.2 billion in 2024 to USD 10.6 billion by 2033, the importance of flexible instruments like the centrifugal unit becomes increasingly evident. Their integration into research environments exemplifies a commitment to precision and adaptability—qualities that are crucial for advancing scientific inquiry. By investing in such high-quality instruments, laboratories position themselves at the forefront of innovation, ready to tackle the challenges of modern research.

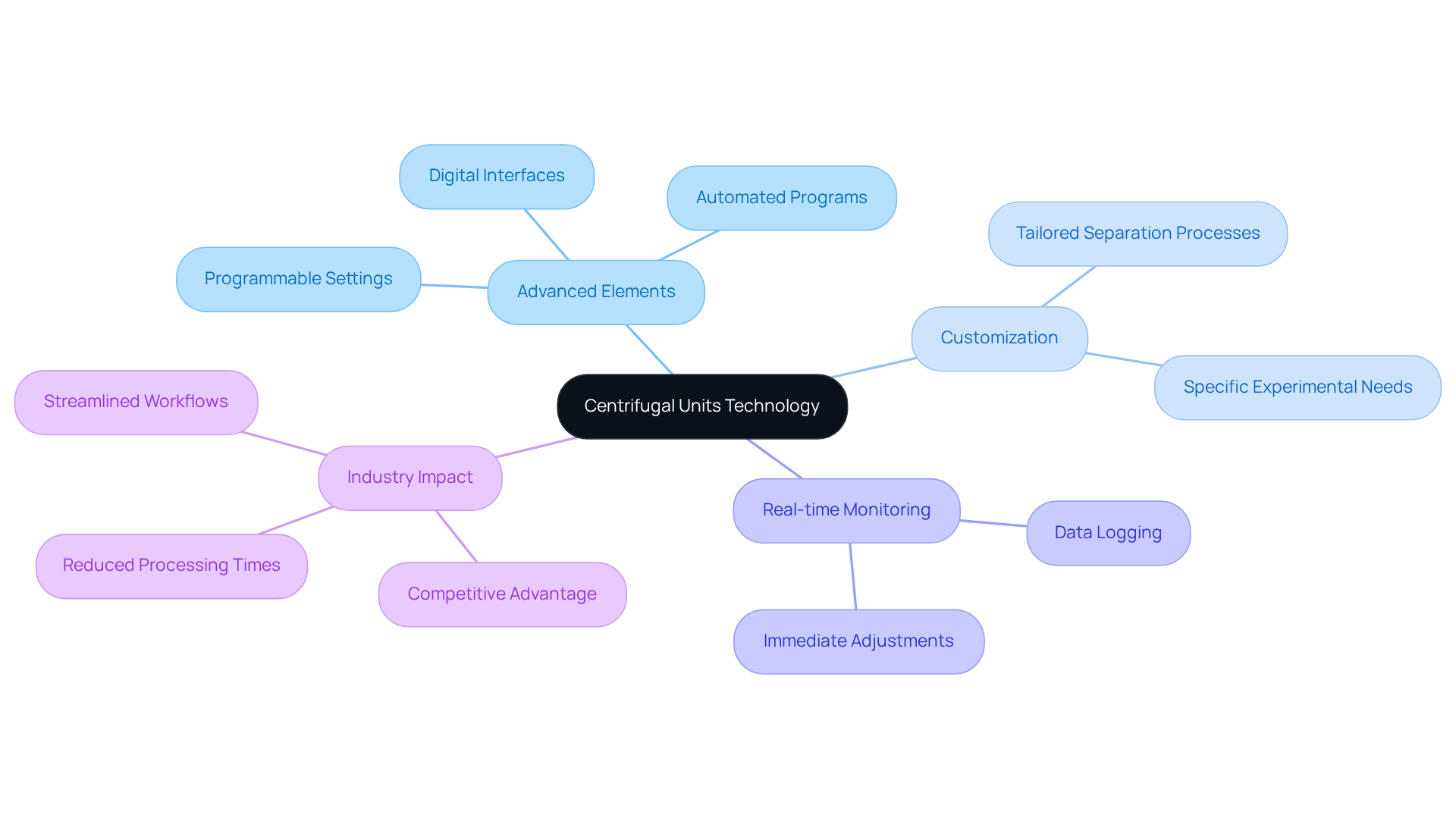

Centrifugal Units: Leverage Advanced Technology for Enhanced Performance

Contemporary centrifugal units are at the forefront of technological innovation, featuring advanced elements that significantly enhance their performance and efficiency. By leveraging programmable settings, research facilities can customize their separation processes to meet specific experimental needs, resulting in improved accuracy and reliability of results.

Furthermore, real-time monitoring capabilities elevate performance metrics, enabling immediate adjustments and data logging, which aids in compliance with regulatory standards. According to Thermo Fisher Scientific, the integration of digital interfaces and automated programs has been shown to reduce sample processing times by up to 25%, illustrating the tangible benefits of adopting cutting-edge centrifugal unit technology.

Industry specialists highlight that these innovations not only streamline workflows but also empower facilities to maintain a competitive advantage in research. By embracing these advancements, laboratories can ensure the highest quality of their research outputs and respond effectively to the evolving demands of the scientific community.

Conclusion

Centrifugal units emerge as indispensable tools within laboratory environments, providing numerous advantages that enhance both research efficiency and accuracy. Their capacity to automate sample separation processes not only conserves time but also bolsters the reliability of experimental results. By integrating these sophisticated devices into laboratory workflows, researchers can optimize their operations, ensuring they remain leaders in scientific innovation.

The discussion emphasizes several pivotal benefits of centrifugal units, including:

- Their versatility across diverse scientific fields

- Cost-effectiveness

- User-friendly design

From enabling precise moisture analysis in pharmaceuticals to streamlining workflows in clinical diagnostics, these units are crucial for achieving superior outcomes. Furthermore, the inclusion of safety features enhances operational security, making them suitable for personnel at all skill levels.

As research facilities continue to adapt, the prioritization of centrifugal unit adoption becomes increasingly critical. Investing in these advanced instruments not only fosters efficiency and accuracy but also positions laboratories to respond swiftly to evolving demands in the scientific landscape. By embracing the capabilities of centrifugal units, laboratories will undoubtedly experience enhanced research outcomes, paving the way for future advancements in laboratory practices.