Overview

This article highlights the critical benefits of using sterile syringe filters in laboratory environments. These filters play an essential role in ensuring contamination-free results, enhancing workflow efficiency, and promoting sustainability. By preventing microbial intrusion, they streamline processes and significantly reduce waste. This underscores their vital importance in maintaining the accuracy and reliability of scientific research across various applications. In summary, the implementation of sterile syringe filters is not merely a choice but a necessity for laboratories aiming for excellence in their scientific endeavors.

Introduction

Sterile syringe filters serve as more than mere laboratory tools; they are vital protectors of sample integrity and experimental accuracy. By effectively preventing contamination, these filters play a crucial role in ensuring that research results are both reliable and valid, particularly in high-stakes environments such as pharmaceuticals and clinical testing.

Given the vast array of filtration options available, how can laboratories guarantee they are selecting the right solution to protect their results and enhance workflow efficiency? This article explores the seven key benefits of using sterile syringe filters, highlighting their indispensable role in contemporary laboratory practices.

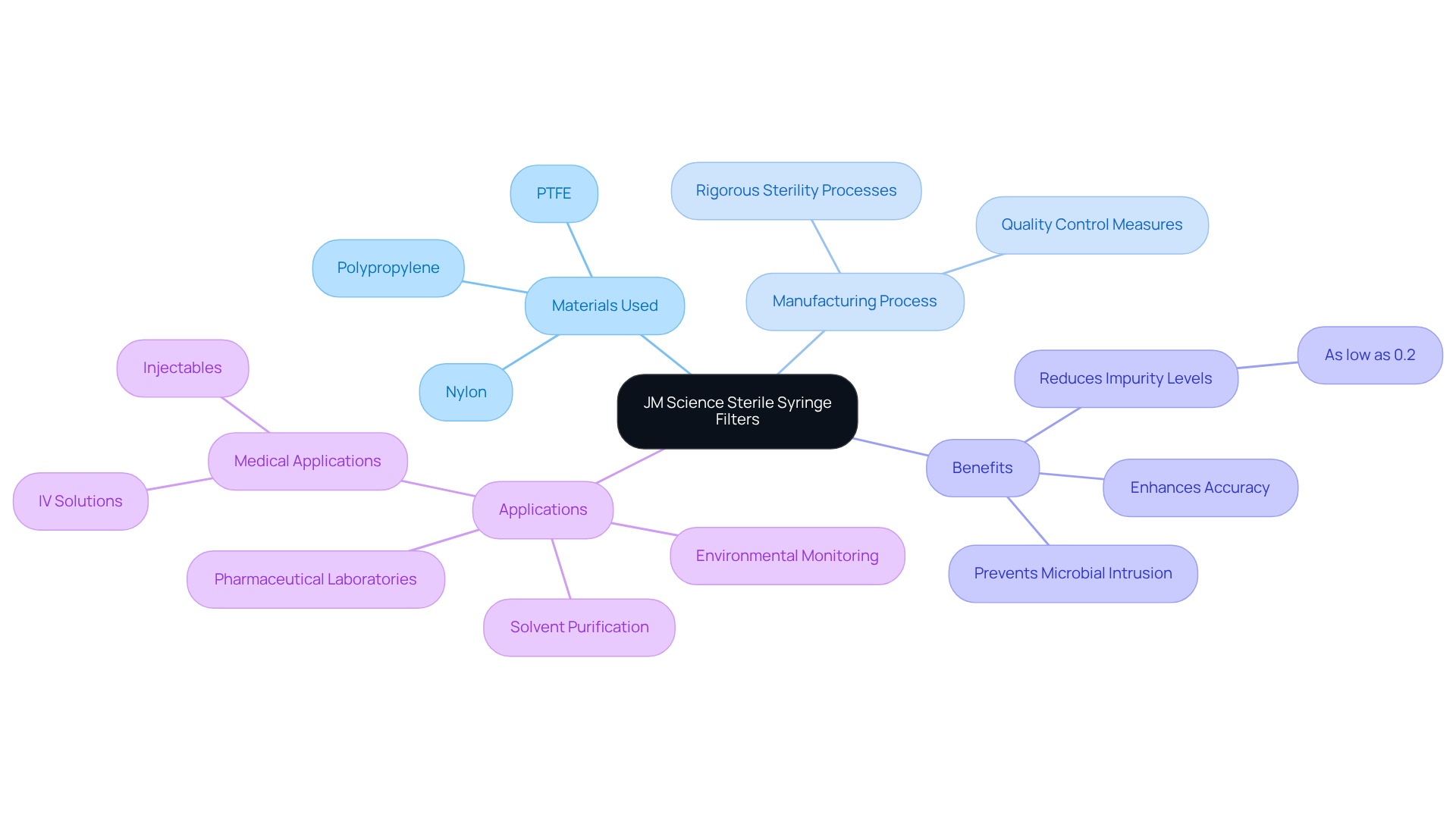

JM Science Sterile Syringe Filters: Ensuring Contamination-Free Results

JM Science's sterile syringe filter membranes are meticulously engineered for optimal purification, ensuring that samples remain uncontaminated. Utilizing high-quality materials such as polypropylene, nylon, and PTFE, these devices are manufactured through rigorous processes that guarantee sterility. This makes them indispensable for sensitive applications in pharmaceutical and medical laboratories. Their ability to prevent microbial intrusion is vital for maintaining the integrity of experimental results, particularly in high-stakes environments where precision is paramount.

Laboratory supervisors have noted that the reliability of these devices significantly enhances the accuracy of assessments, thereby reducing impurity levels. Indeed, research indicates that the proper use of sterile needle screens can lower impurity rates to as little as 0.2%, as highlighted by van Grafhorst et al., underscoring their critical role in safeguarding against contaminants in medical laboratories.

By integrating these advanced filtration solutions, such as a sterile syringe filter, JM Science ensures that research facilities can achieve contamination-free results, ultimately supporting advancements in research and healthcare. Furthermore, selecting the appropriate medical device for filtration is crucial for minimizing impurities and improving precision, as demonstrated in numerous case studies. These devices also fulfill significant roles in applications such as solvent purification and environmental monitoring, showcasing their versatility across various research environments.

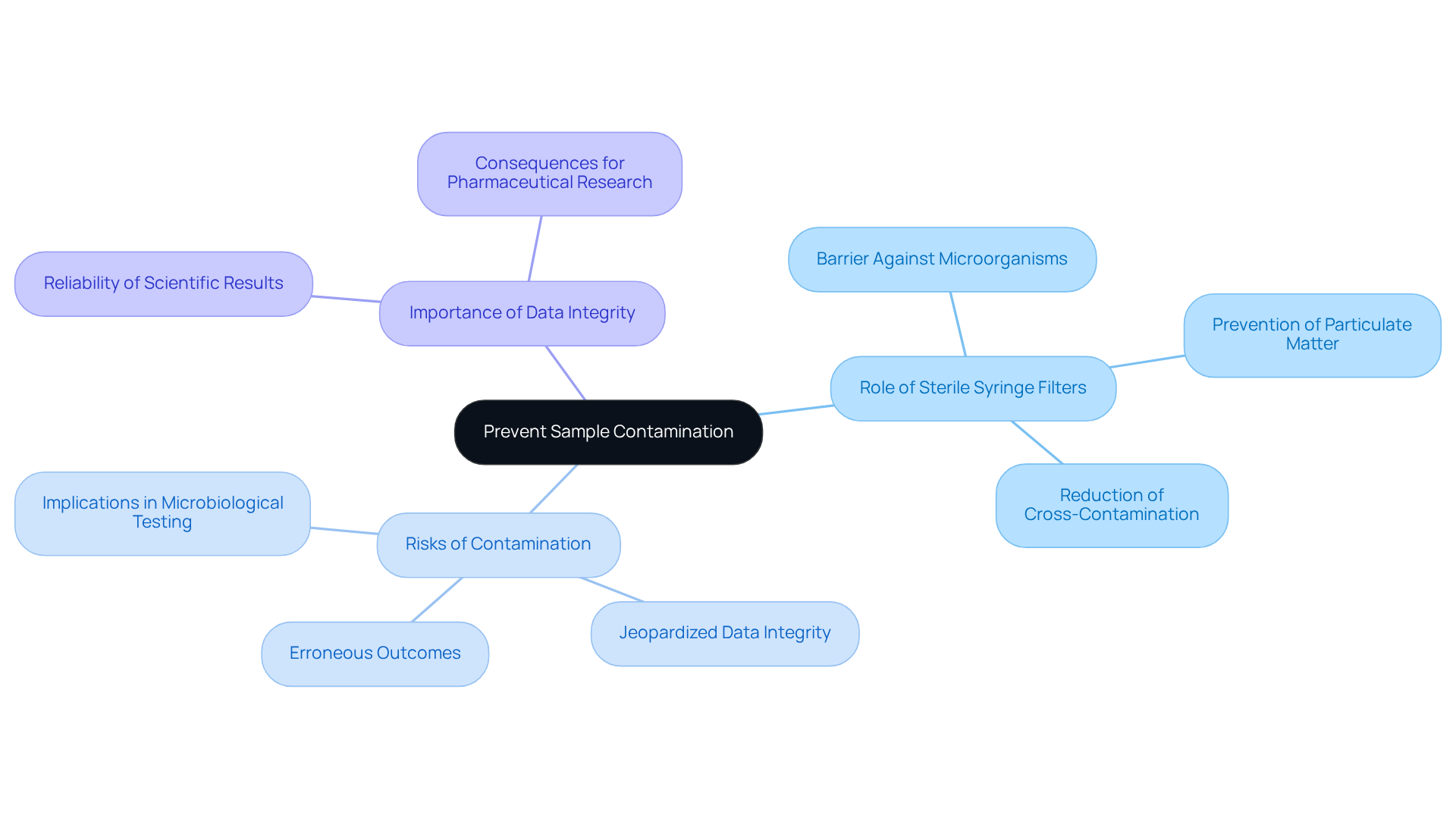

Prevent Sample Contamination: The Key Role of Sterile Syringe Filters

Sterile syringe filters are essential in safeguarding against sample pollution, acting as a formidable barrier against microorganisms and particulate matter. By utilizing these screens, research facilities significantly reduce the risk of cross-contamination during sample preparation and analysis. This is particularly critical in microbiological testing and pharmaceutical research, where even the slightest contamination can result in erroneous outcomes and jeopardize data integrity. Therefore, the implementation of high-quality sterile syringe filters is not merely advisable; it is imperative for maintaining the reliability and accuracy of scientific results.

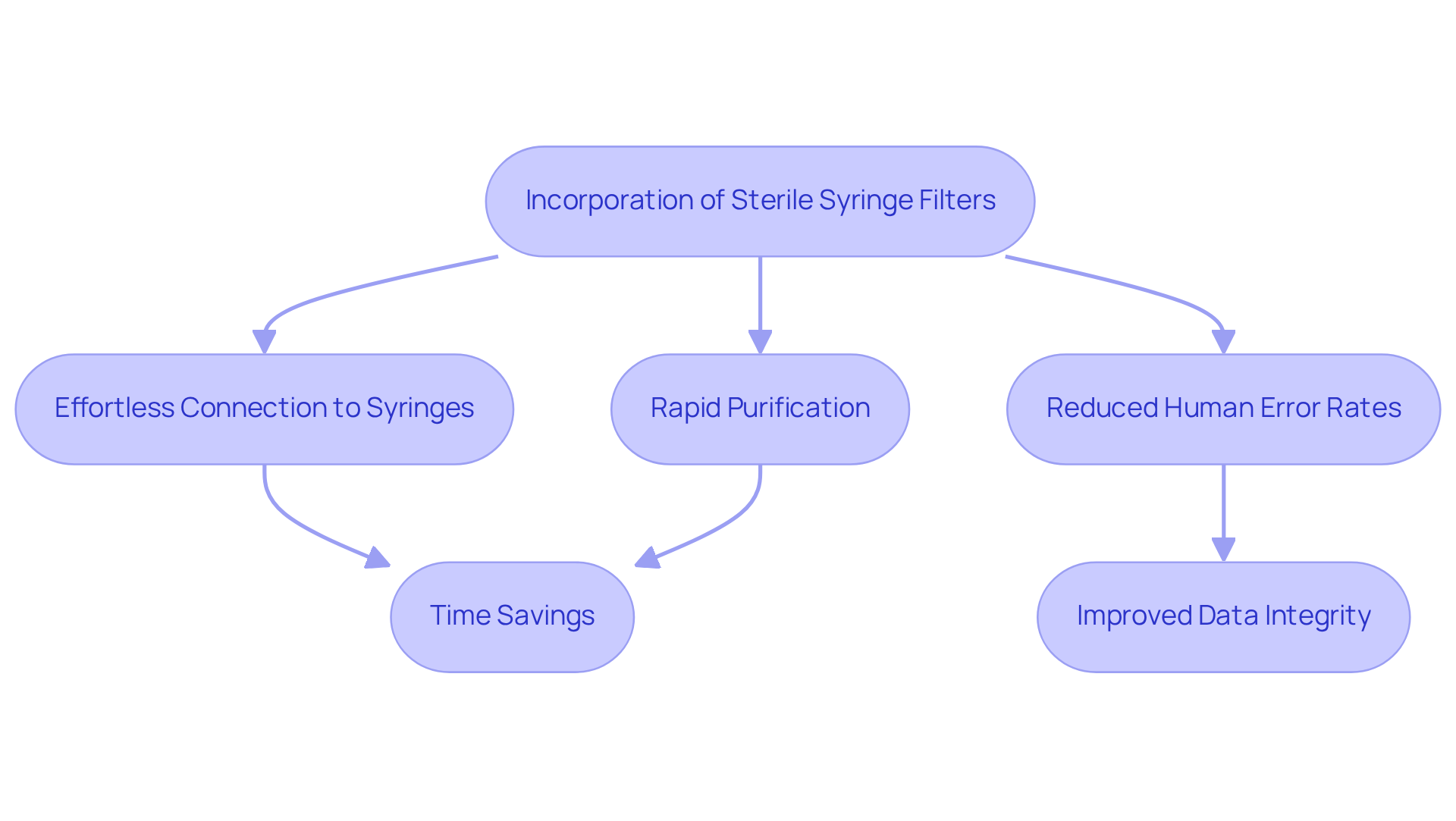

Enhance Workflow Efficiency: Streamlining Processes with Sterile Syringe Filters

Incorporating sterile needle devices into research processes significantly enhances efficiency by accelerating sample preparation. These devices are engineered for effortless connection to syringes, facilitating rapid purification without the need for intricate setups. This streamlined approach not only conserves precious time but also minimizes the risk of human error, leading to more consistent and reliable outcomes across various experiments.

Studies have shown that facilities utilizing needle screens experience a marked decline in human error rates, which bolsters data integrity. Lab managers have reported considerable time savings, allowing for a more concentrated focus on critical research tasks. For instance, one research facility optimized its sample processing with a sterile syringe filter, achieving a 30% reduction in preparation time. Such advancements underscore the crucial role of injection devices in enhancing research activities.

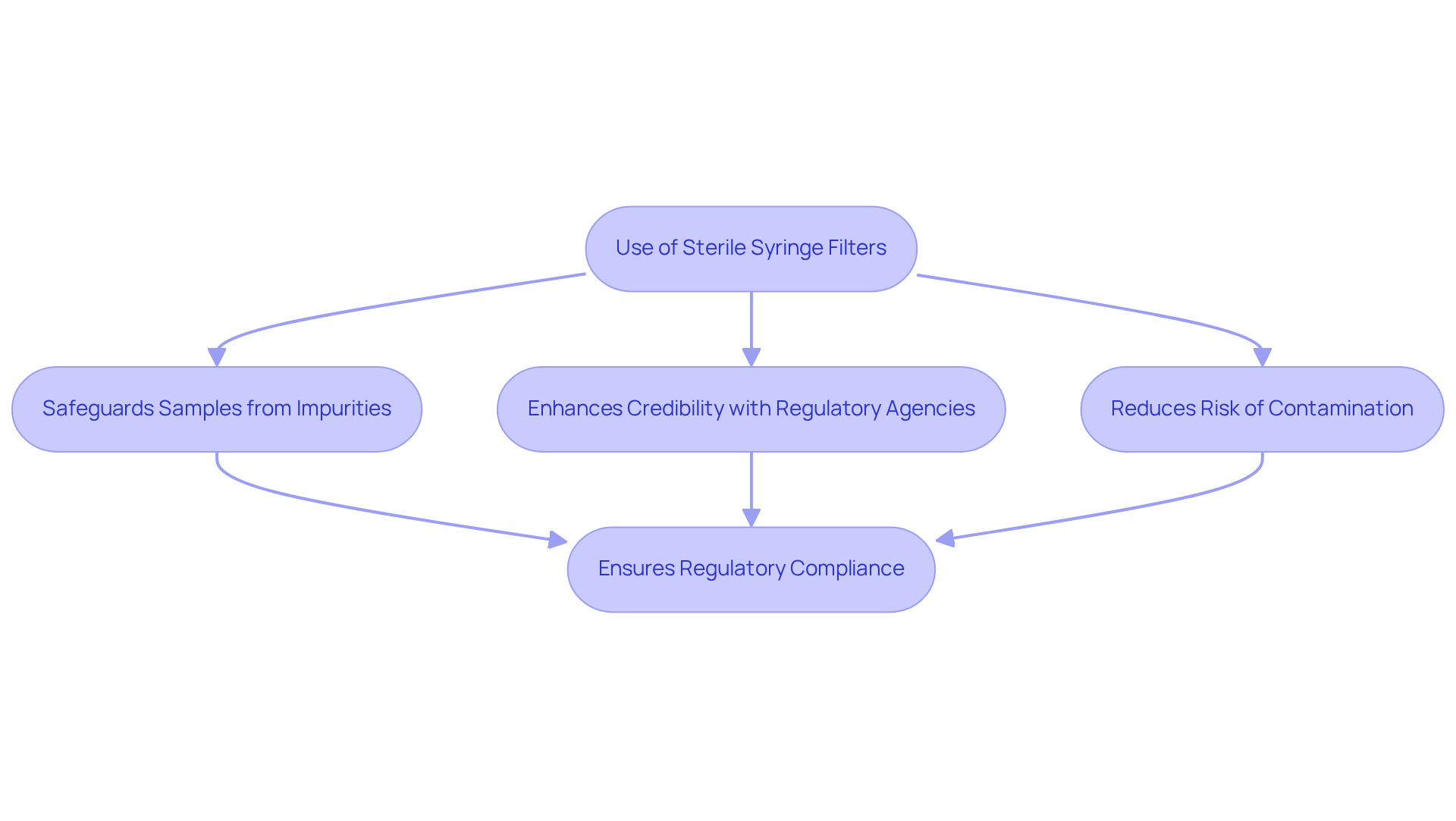

Maintain Regulatory Compliance: The Importance of Sterile Syringe Filters

The use of sterile syringe filters is essential for ensuring compliance with regulatory requirements in research facilities, particularly within the pharmaceutical and biotechnology sectors. These devices are pivotal in safeguarding samples from impurities, a fundamental necessity across various regulatory standards. By implementing sterile syringe filters, facilities not only uphold quality and safety but also enhance their credibility with regulatory agencies.

Regulatory specialists emphasize that effective pollution management is vital for maintaining the integrity of research facilities and adhering to stringent industry standards. Facilities that consistently utilize sterile needle screens demonstrate their commitment to quality assurance, significantly reducing the risk of impurities that could jeopardize regulatory approval processes.

The ramifications of contamination on these procedures can be severe, potentially resulting in delays or rejections of product approvals. Therefore, the integration of sterile syringe filters is not merely a best practice; it is a critical component of regulatory compliance, ensuring that facilities can adeptly navigate the complexities of the pharmaceutical landscape.

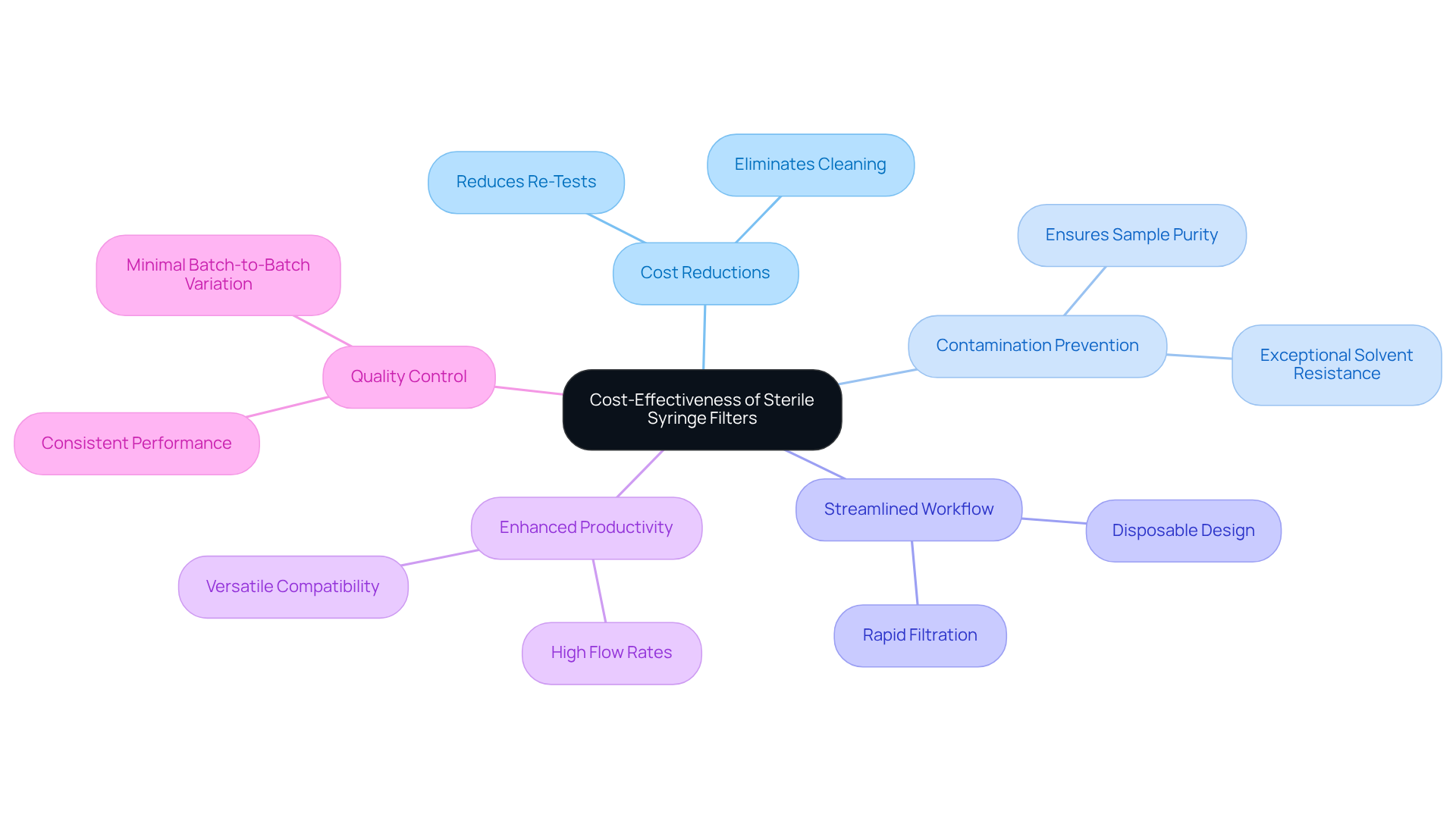

Achieve Cost-Effectiveness: Financial Benefits of Sterile Syringe Filters

Investing in sterile syringe filters presents a compelling opportunity for research facilities to achieve significant cost reductions. By effectively preventing contamination and ensuring sample integrity, the use of a sterile syringe filter in these devices mitigates the risk of costly re-tests and experiments. Their disposable design eliminates the need for extensive cleaning and sterilization processes, such as those required for a sterile syringe filter, streamlining workflow and conserving valuable time and resources. Moreover, the use of a sterile syringe filter in PTFE injection devices facilitates rapid filtration, enhancing productivity in research, while their optimized membrane design minimizes flow resistance and achieves excellent particle retention.

The consistent performance and minimal batch-to-batch variation of sterile syringe filters bolster quality control, ensuring reliable analytical outcomes. This reliability translates into financial advantages, particularly in pharmaceutical research, where a sterile syringe filter can help prevent contamination costs that severely impact operational processes. For example, the exceptional solvent resistance of PTFE injection devices ensures sample purity during critical analytical workflows when used in conjunction with a sterile syringe filter, positioning them as essential tools for maintaining high standards of quality and productivity.

In summary, the strategic application of sterile syringe filters not only enhances the financial efficiency of laboratory operations but also establishes these devices as vital assets in the pursuit of scientific excellence.

Versatile Applications: Utilizing Sterile Syringe Filters Across Scientific Fields

Sterile syringe filters serve as versatile tools with extensive applications across various scientific domains, including pharmaceuticals, environmental testing, and clinical research. Their ability to efficiently eliminate contaminants makes them suitable for a multitude of tasks, such as:

- Utilizing a sterile syringe filter for sample preparation in chromatography

- Sterilizing culture media in microbiology

This remarkable adaptability ensures that laboratories can reliably utilize these devices for diverse experimental needs, significantly enhancing their overall utility.

The global medical device market was valued at USD 16.77 billion in 2023 and is projected to reach USD 27.7 billion by 2031, reflecting a compound annual growth rate of 6.72%. This growth trajectory is fueled by:

- Increasing environmental regulations

- The escalating demand for dependable testing methods

- A shift towards the development of eco-friendly needle devices

Furthermore, many needle cartridges, such as the Minisart PP Needle Cartridges, are manufactured under stringent ISO standards, including ISO 9001 and ISO 13485 certifications for medical device models. This adherence to high standards ensures their reliability and effectiveness in critical applications.

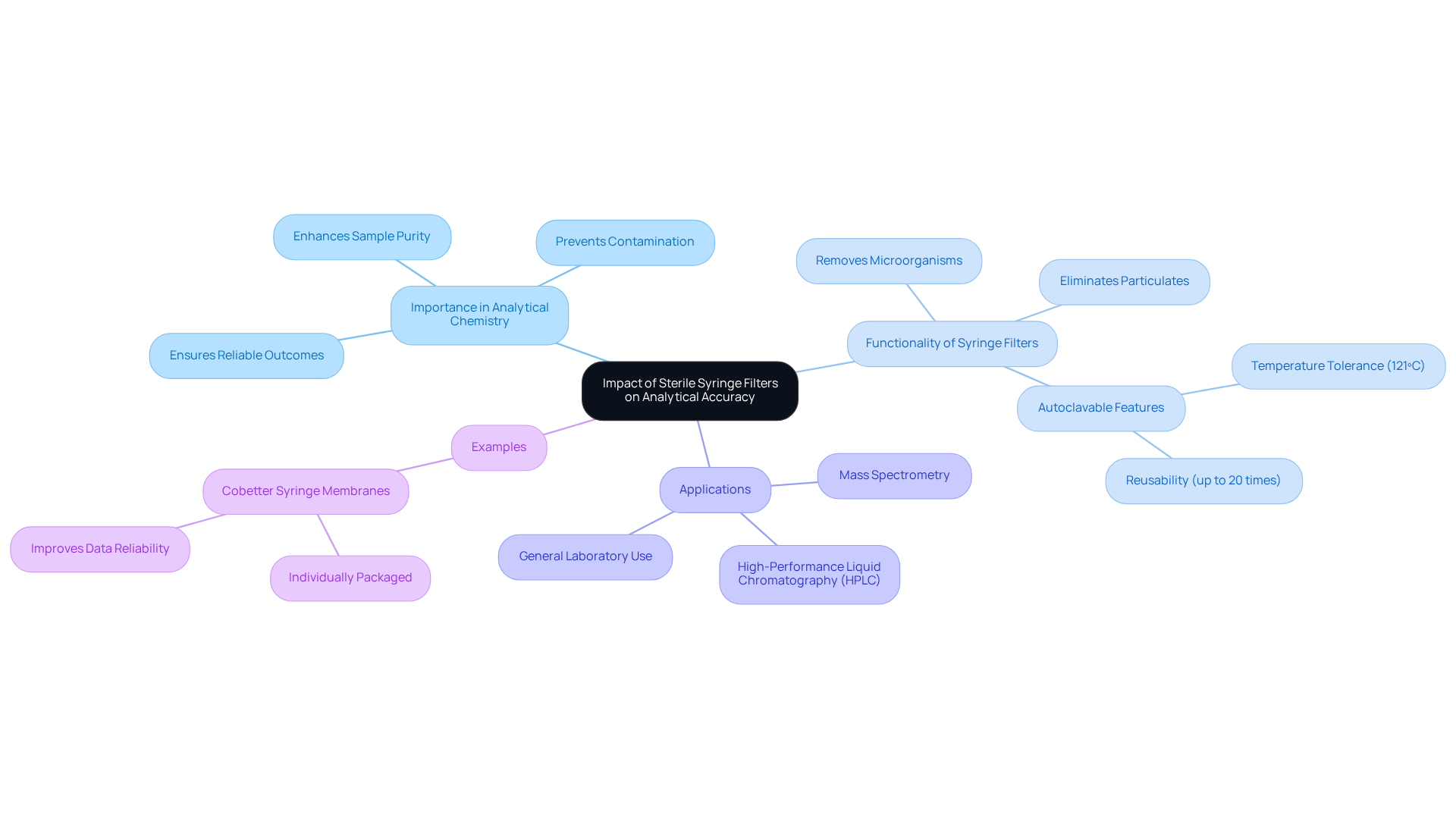

Improve Analytical Accuracy: The Impact of Sterile Syringe Filters

Sterile syringe filters are essential in enhancing analytical precision by ensuring that only uncontaminated samples are examined. These devices effectively eliminate particulates and microorganisms with the use of a sterile syringe filter, thereby mitigating interference that could compromise results. This is particularly vital in high-precision applications such as high-performance liquid chromatography (HPLC) and mass spectrometry, where the use of a sterile syringe filter is essential to prevent even trace contaminants that can result in significant errors in data interpretation. Analytical chemists assert that the use of a sterile syringe filter is essential for maintaining sample purity and achieving reliable outcomes.

For instance, studies have demonstrated that the use of Cobetter autoclavable syringe membranes, which endure autoclaving at 121ºC and can be reused up to 20 times, markedly improves data reliability. Furthermore, these sterile syringe filters are individually packaged to ensure optimal performance free from contamination, underscoring their importance in laboratory settings. By integrating these mechanisms, laboratories not only enhance the reliability of their data but also ensure reproducibility across experiments, ultimately contributing to more robust scientific findings.

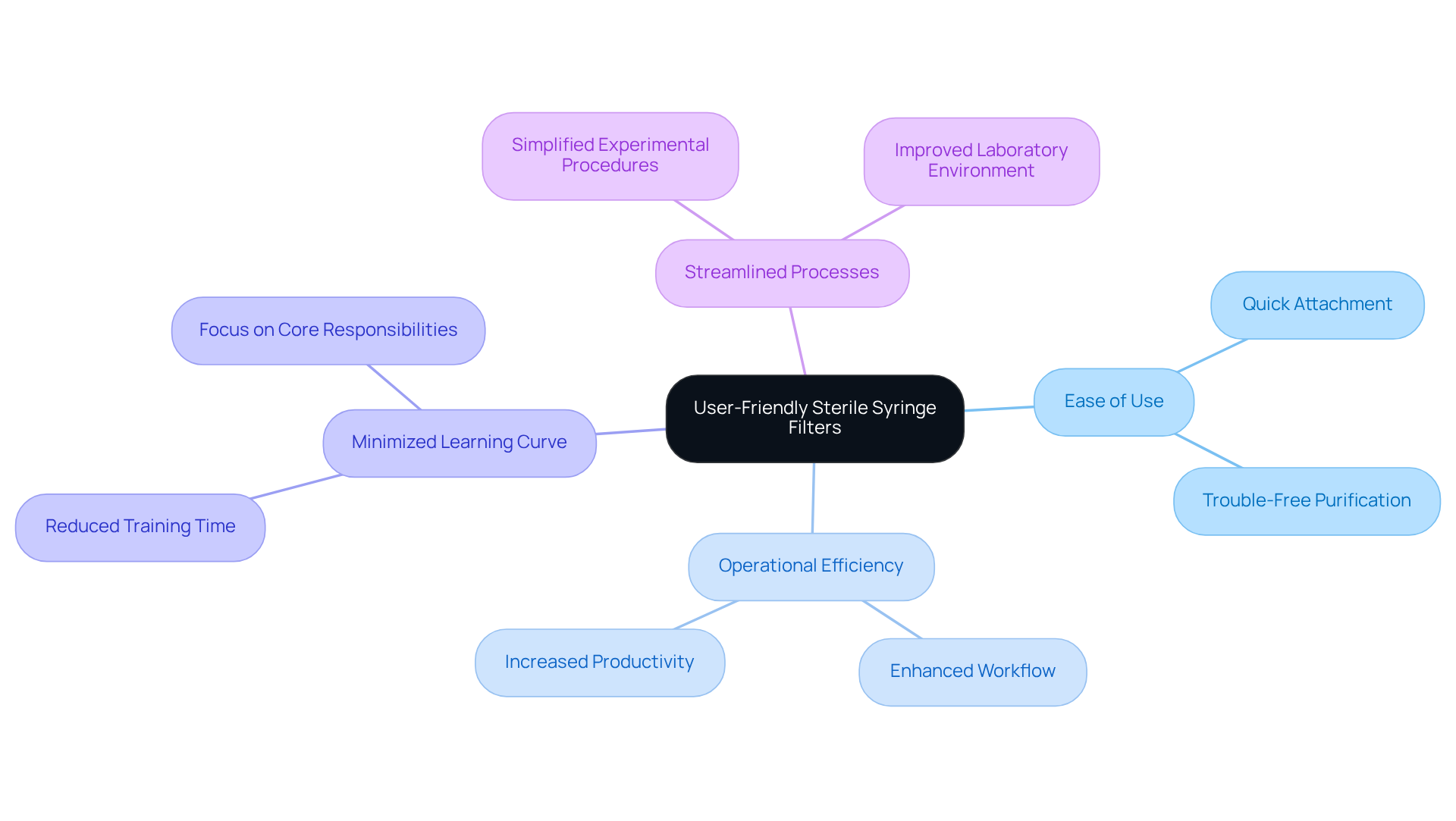

Simplify Laboratory Procedures: User-Friendly Sterile Syringe Filters

Sterile syringe filters are designed with user convenience as a priority. Their straightforward attachment mechanisms facilitate rapid and trouble-free purification, significantly enhancing operational efficiency. This ease of use minimizes the learning curve for staff, allowing them to focus on their primary responsibilities rather than struggling with complex equipment. By streamlining experimental processes, these devices contribute to a more efficient and productive laboratory environment. In summary, investing in high-quality sterile syringe filters not only simplifies workflows but also fosters a culture of efficiency and effectiveness in scientific research.

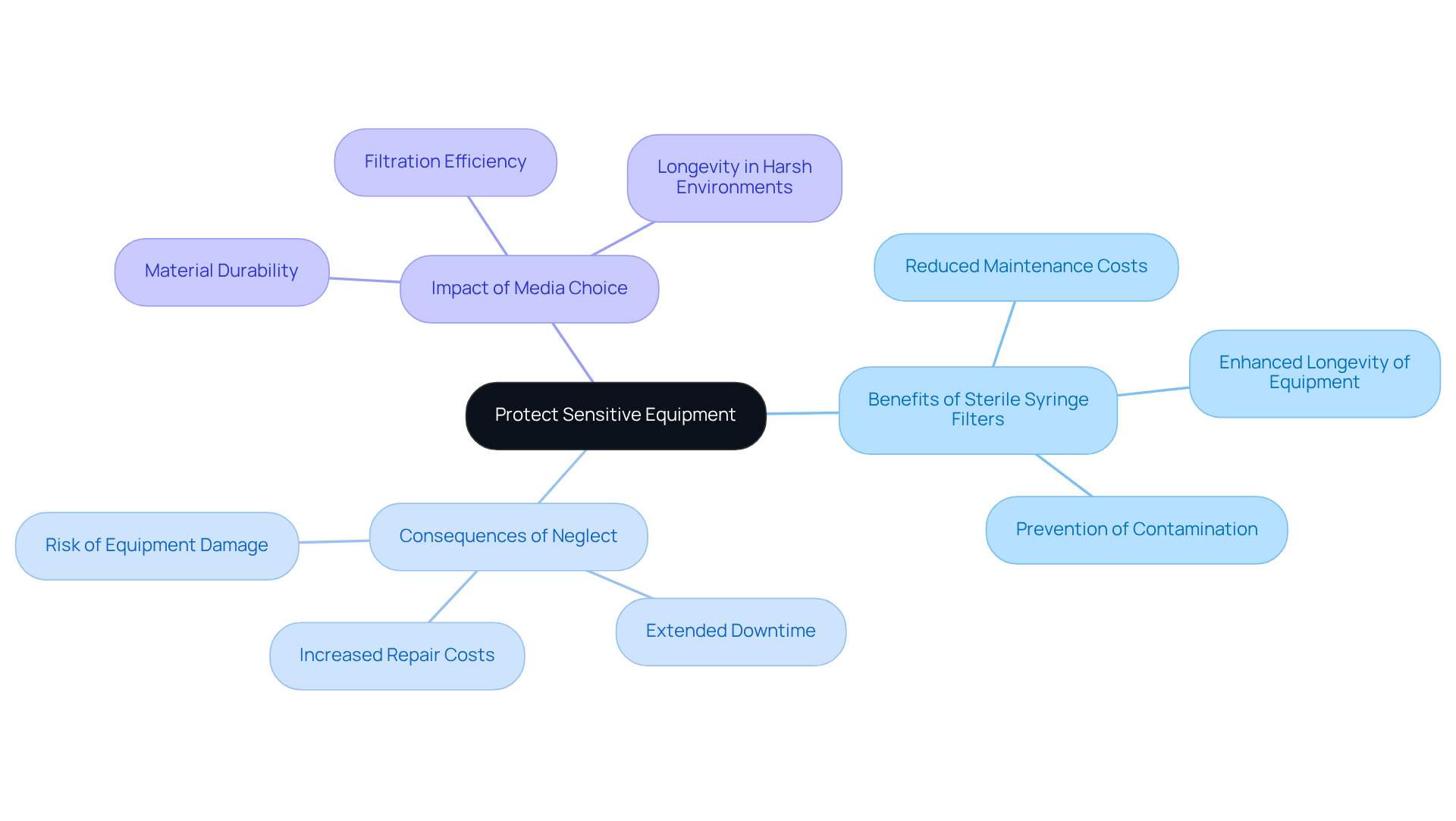

Protect Sensitive Equipment: The Role of Sterile Syringe Filters

Sterile medical devices are essential protective barriers for delicate laboratory instruments, such as chromatography systems and spectrophotometers. By effectively eliminating particulates and contaminants before they enter these systems, these devices significantly reduce the risk of clogs and damage. High-efficiency inline devices can remove ultra-fine particulate matter as small as 0.01 microns, highlighting the effectiveness of sterile syringe filters in preventing contamination.

This preventative measure is crucial; maintenance costs for chromatography systems without screens can escalate quickly, often leading to expensive repairs and extended downtime. Research shows that neglecting proper filtration can lead to maintenance expenses that far exceed the cost of a filtration system.

Additionally, the choice of media impacts purification efficacy and longevity, with robust casings typically made from high-quality plastics or metals providing durability in demanding research environments. Sterile syringe filters not only enhance the longevity and performance of costly lab equipment but also ensure that facilities maintain operational efficiency. Their role in safeguarding against contamination is vital, enabling research facilities to function seamlessly and effectively.

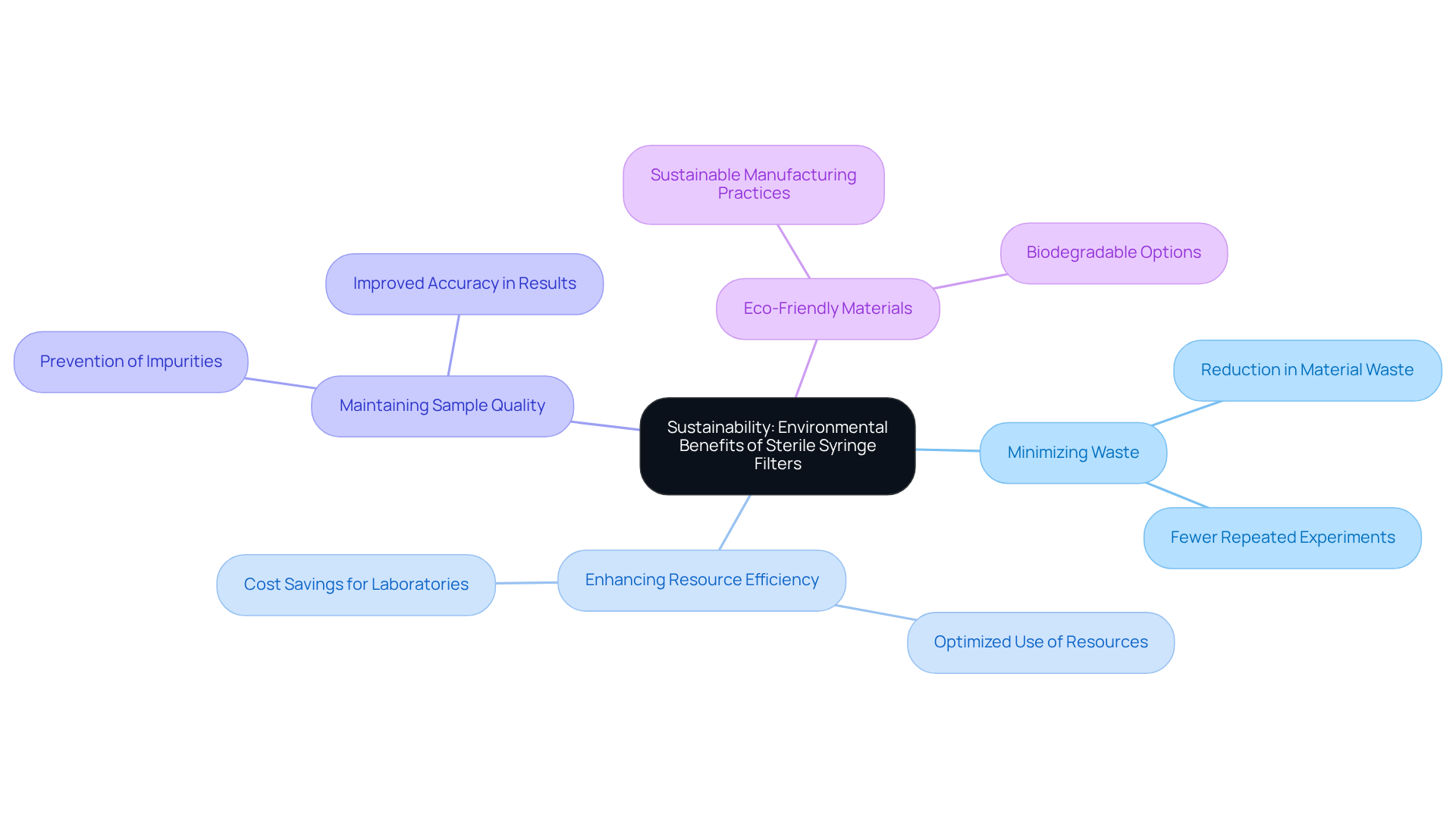

Promote Sustainability: Environmental Benefits of Sterile Syringe Filters

The application of sterile syringe filters is pivotal in promoting sustainability within laboratory practices. By minimizing waste and enhancing resource efficiency, these devices ensure that samples remain free from impurities, significantly reducing the need for repeated experiments and the associated material waste. Furthermore, a growing number of manufacturers are now producing these devices using environmentally friendly materials, thereby bolstering their sustainability profile. Laboratories that prioritize the use of sterile syringe filters not only uphold high standards of quality and accuracy but also play a crucial role in contributing to a more sustainable future.

Conclusion

Utilizing sterile syringe filters in laboratory settings is essential for achieving reliable, contamination-free results. These devices play a crucial role in preventing microbial intrusion and particulate contamination, thereby ensuring the integrity of samples and the accuracy of experimental outcomes. Their design not only streamlines workflows but also enhances compliance with regulatory standards, making them indispensable tools for research facilities across various scientific fields.

Several key benefits of sterile syringe filters have been highlighted:

- They significantly reduce the risk of sample contamination.

- They enhance operational efficiency.

- They contribute to cost-effectiveness by minimizing the need for re-tests and extensive cleaning processes.

- Their versatile applications in pharmaceuticals, environmental testing, and clinical research demonstrate their broad utility and importance in maintaining high standards of quality and precision in laboratory work.

Ultimately, the adoption of sterile syringe filters is not just a matter of best practice; it represents a commitment to scientific excellence and sustainability. By investing in these devices, laboratories can enhance their reliability, protect sensitive equipment, and promote environmentally friendly practices, paving the way for advancements in research and healthcare. Embracing sterile syringe filters is a proactive step toward ensuring that scientific endeavors remain trustworthy, efficient, and impactful.