Overview

The article delineates seven pivotal benefits of employing sterile syringe filters in laboratory environments. These advantages encompass:

- Contamination prevention

- Enhanced efficiency

- Cost-effectiveness

- Adherence to regulatory standards

Each benefit is substantiated by compelling evidence demonstrating improved operational workflows and accuracy in results. Furthermore, these filters are essential in preserving sample integrity across diverse laboratory applications. By understanding these critical roles, laboratories can make informed decisions that bolster their operational effectiveness.

Introduction

Syringe filters are indispensable tools in laboratory environments, where precision and purity are critical. Their effectiveness in removing contaminants guarantees that specimens remain uncontaminated, which is essential for achieving reliable and reproducible results. This article explores the numerous advantages of utilizing sterile syringe filters, demonstrating how they enhance laboratory efficiency and compliance while significantly cutting costs related to contamination.

As research facilities increasingly emphasize quality control, a pivotal question emerges: how can laboratories fully harness the benefits of these vital instruments to elevate their operational standards and outcomes?

JM Science: Premium Sterile Syringe Filters for Laboratory Use

JM Science Inc. provides a comprehensive range of high-quality syringe filter sterile membranes tailored for diverse laboratory applications. Engineered for superior performance and reliability, these products are indispensable for researchers and technicians dedicated to preserving the integrity of their specimens and results. By collaborating with leading manufacturers, JM Science ensures that its syringe filter sterile products adhere to stringent industry standards, which is crucial for maintaining purity in pharmaceutical laboratories. The product line includes various membrane materials and pore sizes, featuring the widely utilized 0.45 µm pore size, which effectively removes bacteria and larger particles from liquid samples.

Recent data indicates that the implementation of high-quality testing equipment, such as premium injection devices, significantly improves the accuracy of test results, with numerous facilities reporting enhanced reliability in their analyses. Successful applications of these devices in research institutions demonstrate their effectiveness in preventing contamination, thereby ensuring the validity of experimental outcomes. Expert insights underscore the critical importance of quality in laboratory injection devices, emphasizing that investing in superior options can lead to enhanced performance and reduced operational challenges. By prioritizing quality and innovation, JM Science remains committed to empowering laboratories in achieving their research objectives efficiently.

Prevent Contamination: The Role of Sterile Syringe Filters

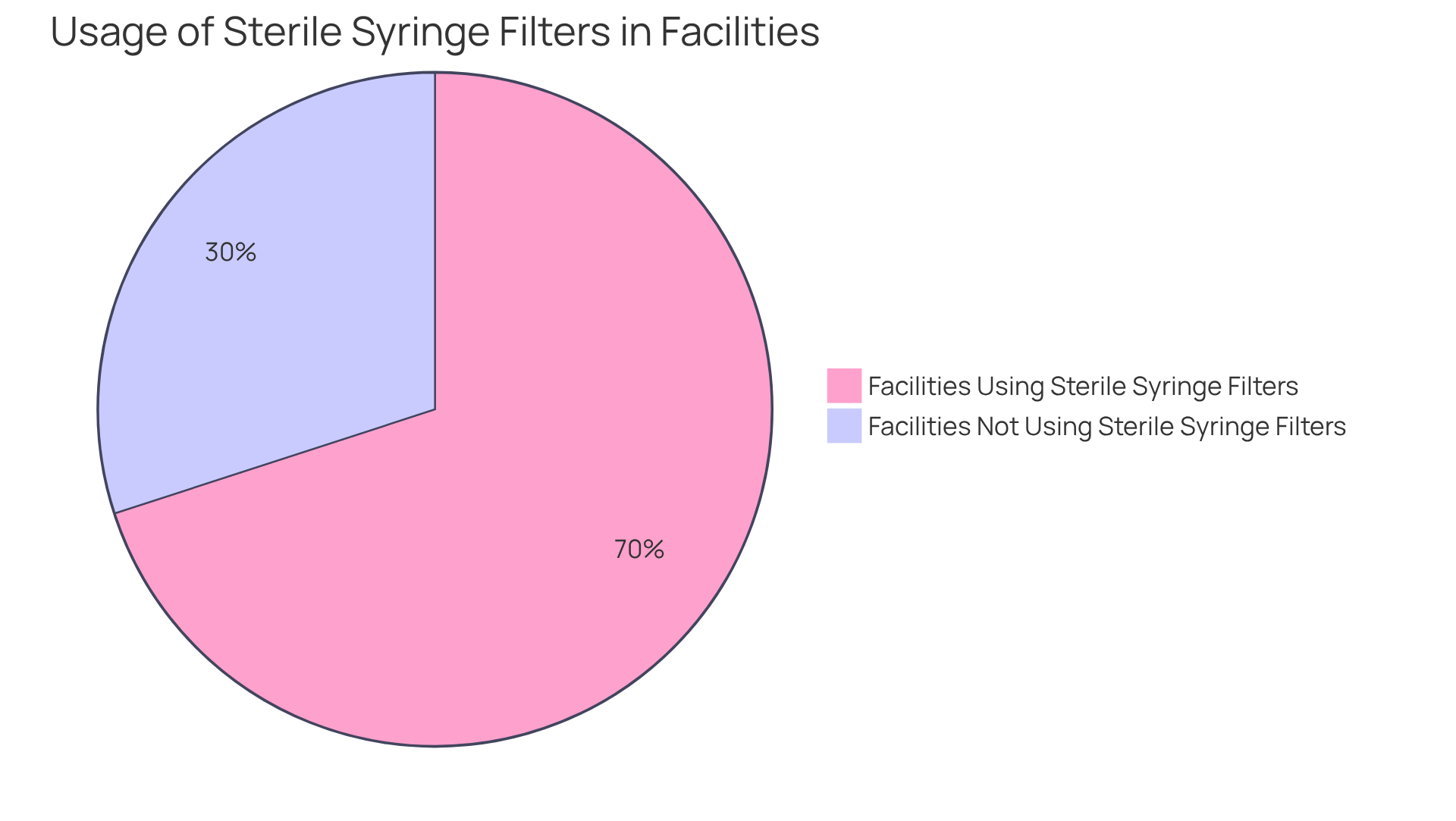

Syringe filter sterile devices play a critical role in preventing contamination during specimen preparation and analysis. By effectively eliminating bacteria, particulates, and other impurities, these syringe filter sterile devices ensure that specimens remain uncontaminated, which is vital for achieving reliable and reproducible results. Approximately 70% of facilities utilize sterile injection devices, underscoring their significance in maintaining specimen integrity. This is especially crucial in sensitive applications such as pharmaceuticals and clinical diagnostics, where even minor contamination can result in substantial analytical errors.

Laboratory managers emphasize that the use of syringe filter sterile membranes is indispensable for quality control, as they enhance the accuracy of diagnostic tests and ultimately contribute to improved patient care. As one lab manager remarked, "Using sterile needle screens is essential for preserving the integrity of our specimens and ensuring precise outcomes." By safeguarding the purity of samples, sterile needle separators significantly bolster the reliability of results, rendering them essential tools in modern scientific practices.

To optimize their effectiveness, it is advisable to choose the appropriate pore size and membrane material tailored to the specific application. Moreover, the injection device market is projected to grow at a compound annual growth rate (CAGR) of 6.72%, reflecting the increasing demand for these vital instruments in research environments.

Enhance Efficiency: Streamlining Laboratory Workflows with Sterile Filters

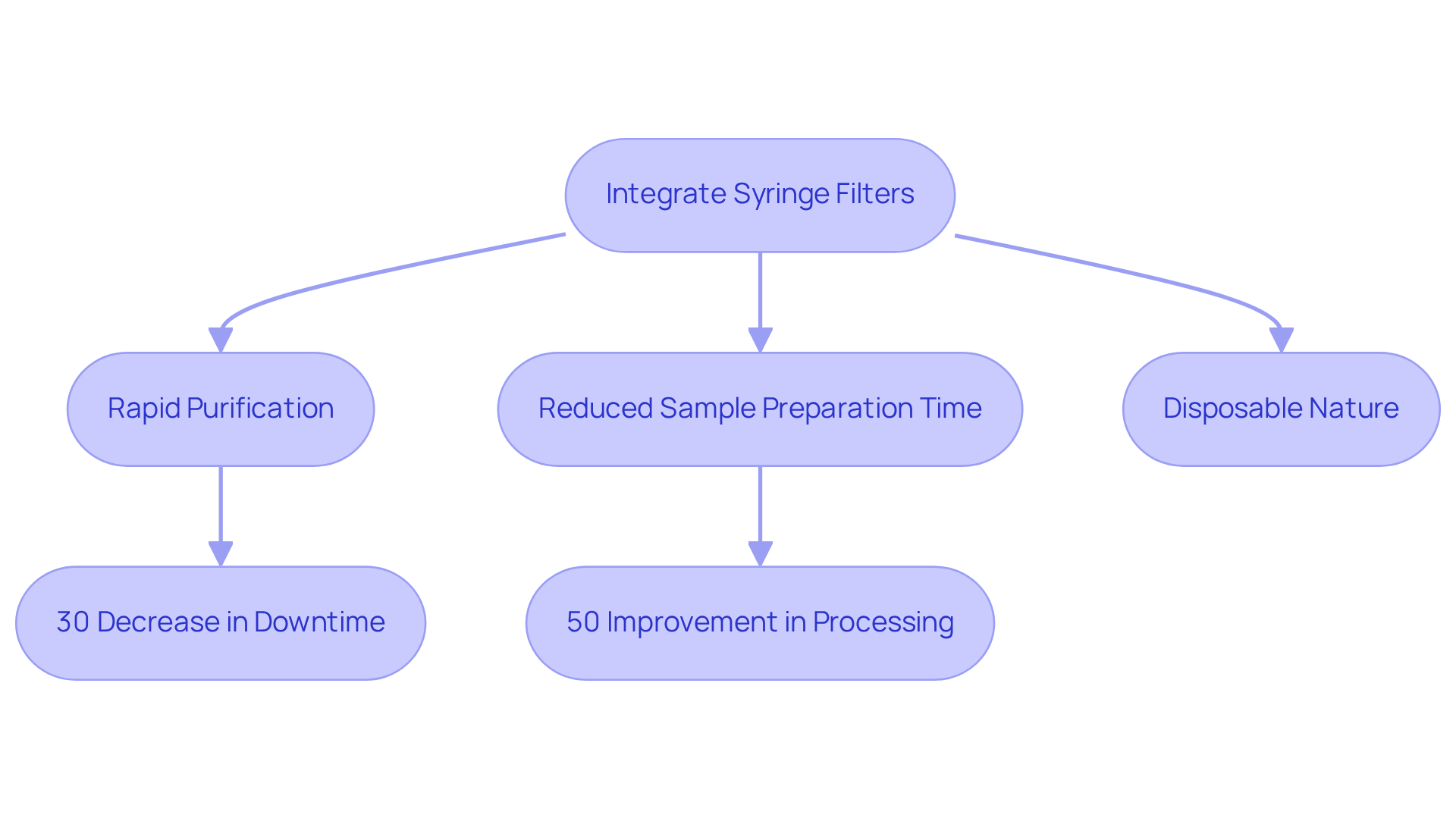

Utilizing a syringe filter sterile significantly enhances efficiency within the workspace by optimizing workflows. These devices are designed for swift and straightforward connection to syringes, enabling rapid purification of substances without necessitating complex arrangements. This ease of use reduces the time allocated to sample preparation, allowing staff to focus on more critical tasks. Furthermore, the disposable nature of these devices eliminates the need for cleaning and sterilization, further conserving both time and resources.

Facility managers have noted that employing sterile needle screens can decrease downtime in research processes by as much as 30%, leading to substantial time and cost savings. For instance, in pharmaceutical quality control processes, the utilization of a syringe filter sterile with a 0.22µm pore size is essential for ensuring that specimens are sterile and free of particulate matter, which is crucial for maintaining product integrity.

Moreover, research indicates that facilities employing needle strainers can improve their processing durations by up to 50% compared to traditional techniques. This enhanced efficiency not only boosts throughput but also guarantees contamination-free analytical results, which are vital for precise diagnostics and research outcomes. By integrating syringe filter sterile injection devices into their operations, facilities can achieve a balance between speed and accuracy, ultimately enhancing overall productivity and reliability in their processes.

Cost-Effective Solutions: Financial Benefits of Sterile Syringe Filters

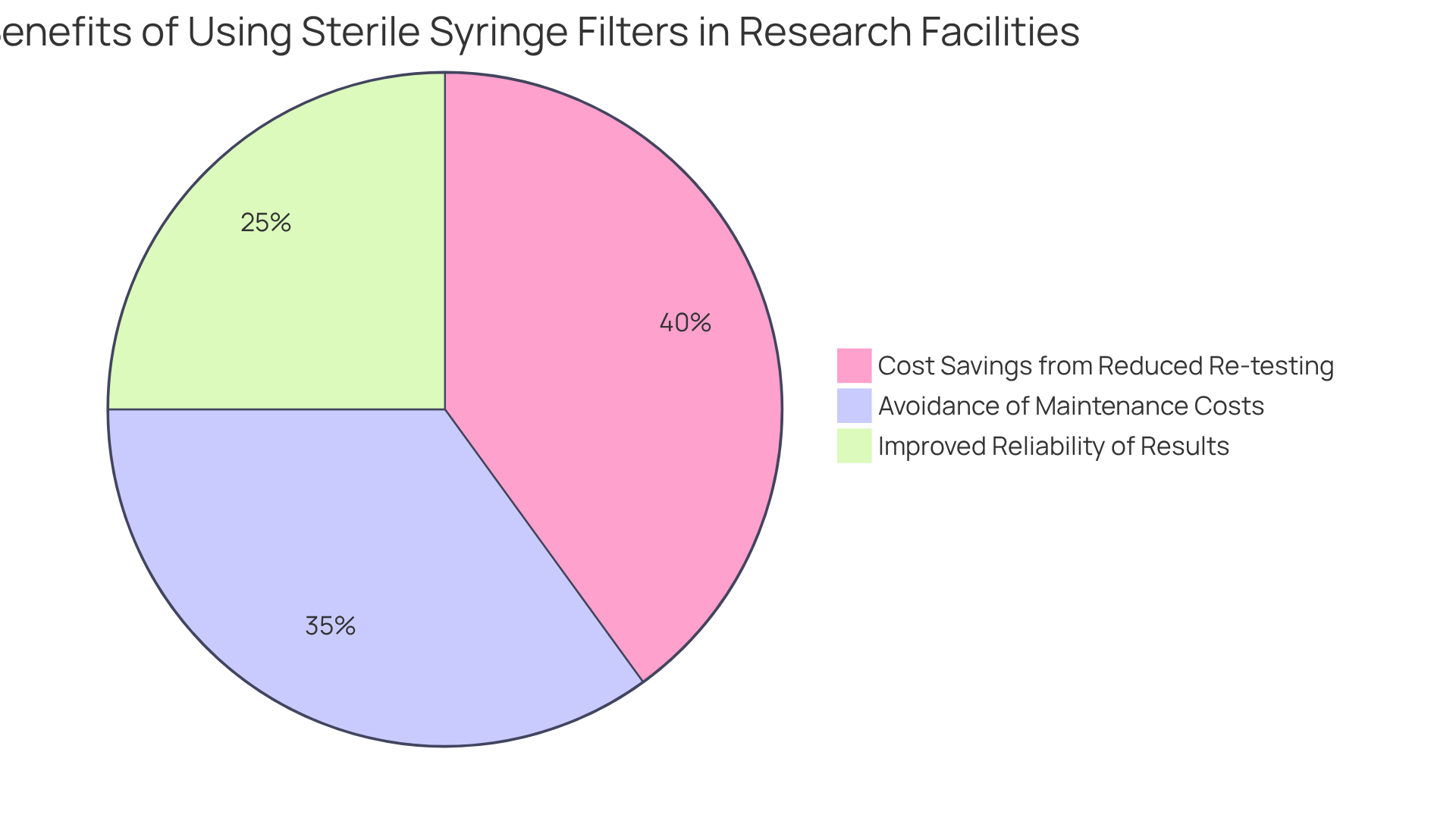

Syringe filter sterile screens represent a cost-effective solution for research facilities, significantly reducing the risk of contamination and the associated expenses of re-testing and specimen loss. By ensuring that samples remain free from impurities, these devices uphold the integrity of experiments, ultimately leading to more reliable results and a reduction in costly errors.

Furthermore, the single-use nature of devices like a syringe filter sterile allows facilities to avoid the financial burden linked to the cleaning and maintenance of reusable filtration systems. This strategic choice not only enhances operational efficiency but also safeguards the quality of scientific research.

Ensure Compatibility: Integrating Sterile Syringe Filters with Laboratory Equipment

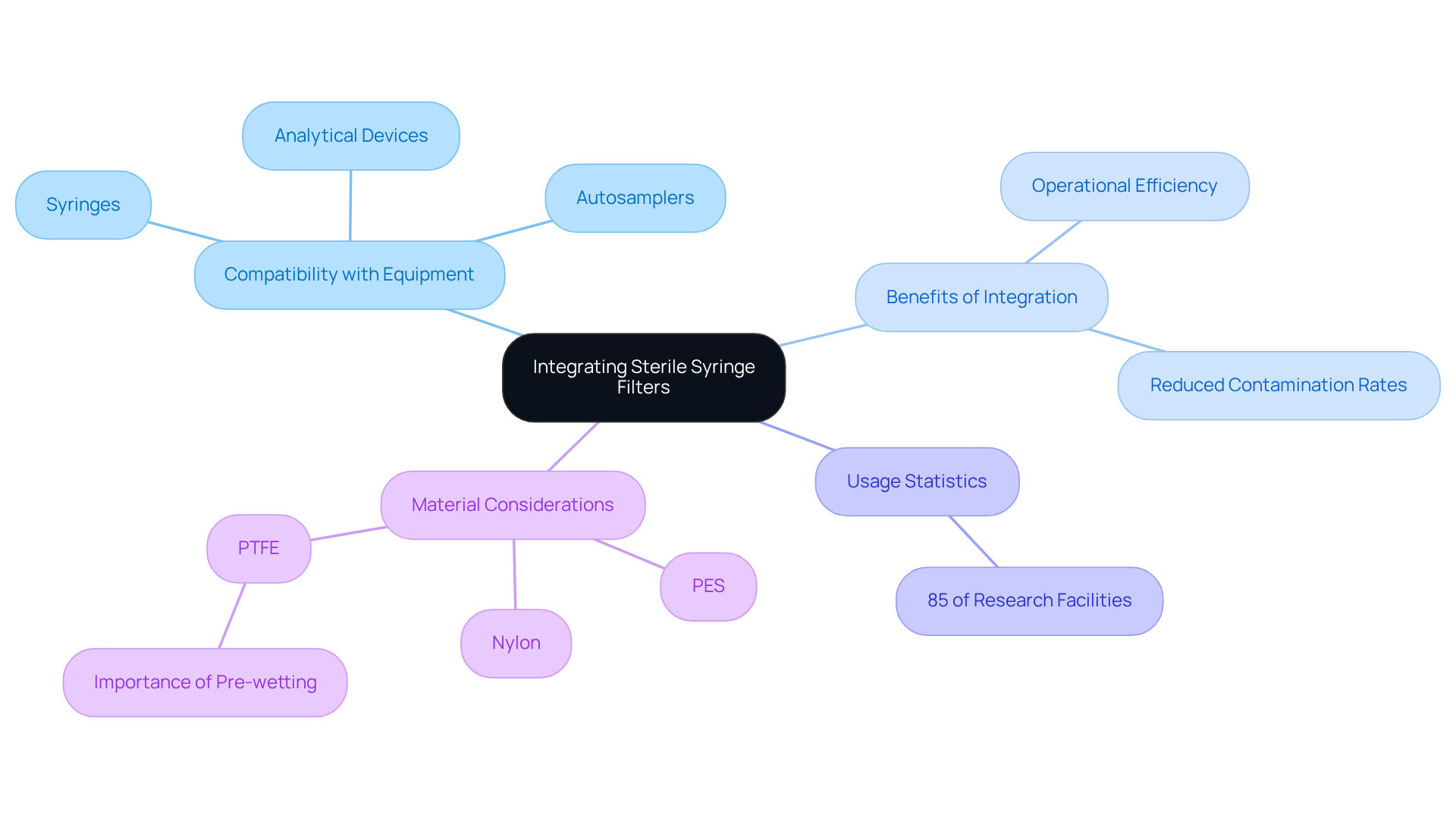

Sterile syringe filter sterile are meticulously designed to ensure smooth compatibility with various lab equipment, including syringes, autosamplers, and analytical devices. This inherent compatibility allows facilities to seamlessly integrate these systems into their existing processes, eliminating the need for costly modifications or additional expenditures. By carefully selecting screens that align with their specific apparatus, facilities can significantly enhance their separation procedures, leading to improved operational efficiency.

Recent studies indicate that approximately 85% of research facilities utilize compatible purification systems, underscoring the widespread recognition of the importance of incorporating syringe filter sterile into research workflows. This statistic exemplifies the trend among facilities that implement filtration systems to ensure specimen integrity and operational efficiency.

Successful case studies illustrate how laboratories have optimized their workflows through the adoption of these devices, resulting in reduced contamination rates and increased reliability in analytical outcomes. Laboratory technicians emphasize the critical role of integrating syringe filter sterile screens into their workflows, asserting that selecting the right syringe filter sterile not only streamlines processes but also guarantees specimen quality. As one technician remarked, 'Integrating sterile membranes has revolutionized our method of preparation, enabling us to uphold high standards of quality and precision.' This sentiment is echoed by others in the industry, who recognize that using screens made from materials such as nylon, polyethersulfone (PES), and polytetrafluoroethylene (PTFE) can enhance filtration results.

Moreover, it is essential to pre-wet PTFE injection devices with alcohol prior to use with aqueous samples to ensure optimal performance. The availability of various pore sizes, including 0.1 μm, 0.22 μm, and 0.45 μm, empowers managers to select the appropriate syringe filter sterile for their specific applications, further supporting the trend of adopting sterile injection devices as a standard practice for achieving optimal outcomes in research environments.

Achieve Compliance: Meeting Regulatory Standards with Sterile Filters

Syringe filter sterile are indispensable for facilities striving to meet stringent regulatory standards. These meticulously crafted devices align with the rigorous criteria established by regulatory authorities, guaranteeing that all processed specimens are devoid of impurities that could jeopardize safety and efficacy. By integrating syringe filter sterile into their operations, facilities not only reinforce their commitment to quality but also enhance their compliance—a vital component for maintaining accreditation and fostering trust among clients and stakeholders.

For instance, facilities utilizing a syringe filter sterile can proficiently eliminate particulate matter, bacteria, and other contaminants from liquid samples, thereby ensuring analytical precision. This capability is particularly vital in industries such as pharmaceuticals and biotechnology, where strict adherence to quality control standards is critical during drug development. The increasing demand for sterile purification solutions is underscored by the projected growth of the syringe filter sterile market, which is anticipated to reach USD 33.1 billion by 2034, with a compound annual growth rate (CAGR) of 6.8% from 2025 to 2034. Historical market data from 2019 to 2023 indicates a consistent upward trend in demand, further highlighting the importance of these devices in research environments.

Moreover, compliance with industry standards not only enhances operational efficiency but also mitigates contamination risks by using a syringe filter sterile, ultimately leading to improved performance. As facilities continue to prioritize sterility in their processes, the role of syringe filter sterile will remain critical in achieving and maintaining high standards of quality and safety. To effectively integrate sterile injection device screens into research workflows, it is recommended that facilities establish standard operating procedures (SOPs) that include regular training for personnel on the proper use and maintenance of these screens.

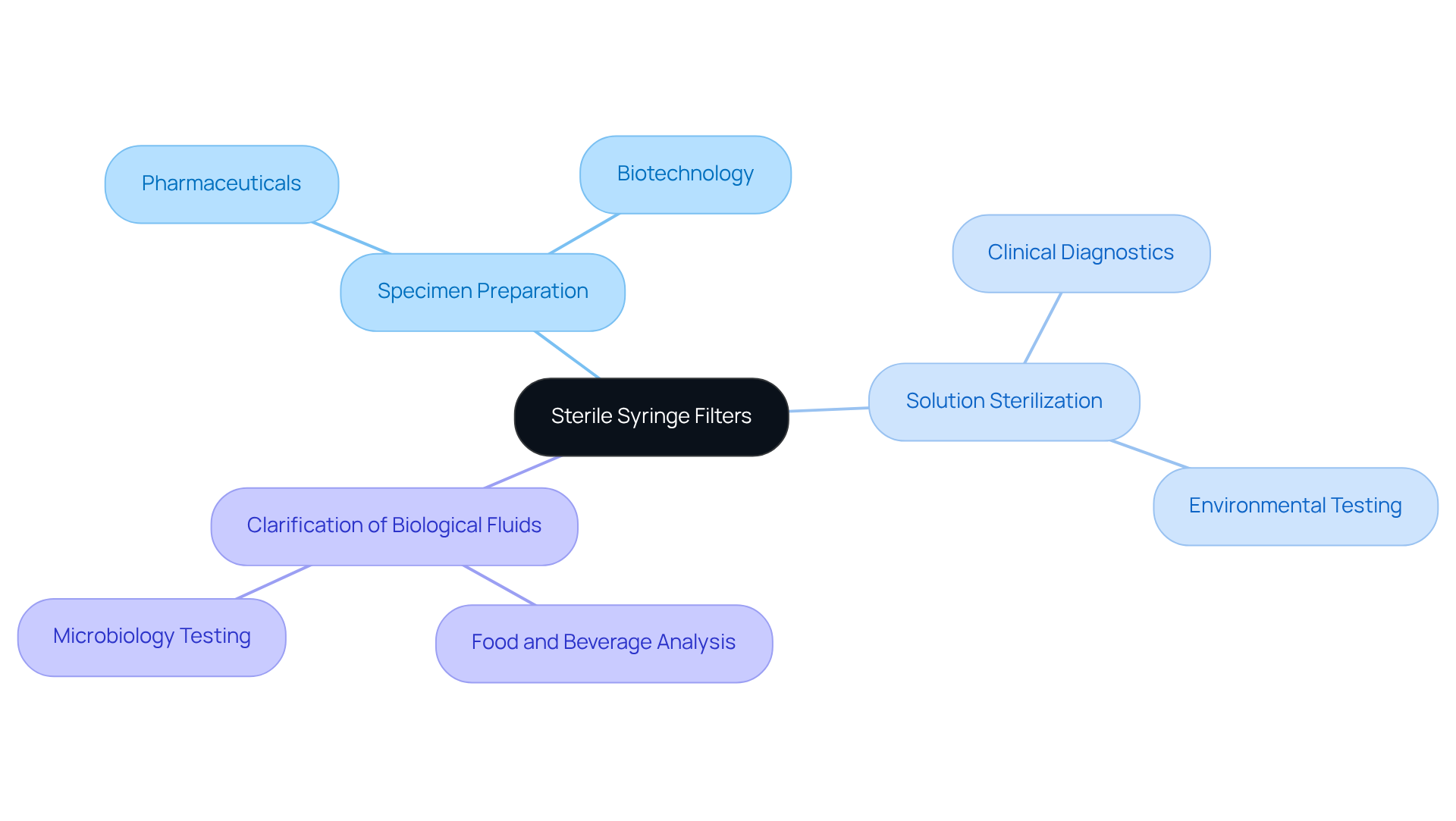

Versatile Applications: Utilizing Sterile Syringe Filters Across Laboratories

Sterile needle devices serve as indispensable instruments within laboratories, offering a wide array of applications such as specimen preparation, solution sterilization, and the clarification of biological fluids. Their efficacy in eliminating particulates and microorganisms renders them crucial in sectors including pharmaceuticals, environmental testing, food and beverage analysis, and clinical diagnostics.

For instance, in microbiology laboratories, these devices play a vital role in preserving sample purity by effectively removing bacteria and fungi, thereby preventing contamination. In 2023, the injection device market was valued at approximately USD 820 million, with projections indicating growth to USD 1.36 billion by 2032, underscoring the rising reliance on these devices across various industries.

Notably, North America accounted for around 35% of the global market share for filtration devices in 2023, emphasizing its significant role in this sector. Researchers have noted that the utilization of sterile injection screens markedly enhances the accuracy of microbiological assessments by efficiently eliminating contaminants.

Commonly employed pore sizes, such as 0.22 micron for sterilization and 0.45 micron for general filtration, are critical considerations for laboratory managers when selecting appropriate membranes. This versatility not only boosts operational efficiency but also reinforces the significance of sterile injection devices in maintaining high standards of quality assurance within research environments.

As Jinming Zhou states, "The Nylon Syringe Filter has become an essential tool in the toolkit as specialists and researchers seek effective methods to achieve accurate results.

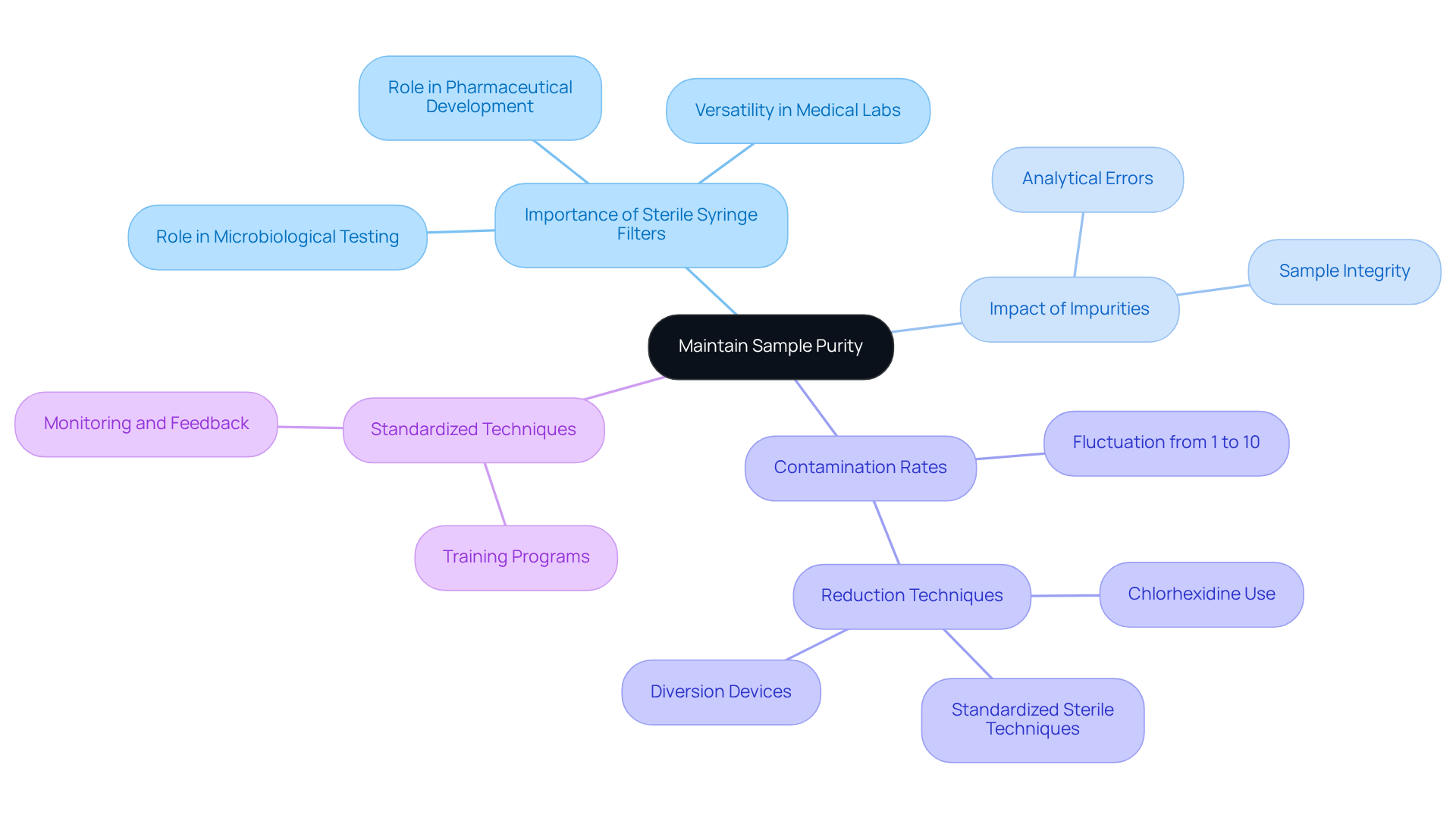

Maintain Sample Purity: The Critical Role of Sterile Syringe Filters

Syringe filter sterile screens play a critical role in preserving the purity of specimens within laboratory environments. By effectively eliminating impurities, these devices ensure that specimens remain uncontaminated, which is vital for achieving accurate and reliable analytical results. Their importance is particularly evident in sensitive applications, such as microbiological testing and pharmaceutical development, where even minor impurities can result in significant analytical errors.

Research underscores the necessity of maintaining specimen integrity; as one pharmaceutical researcher noted, 'The reliability of experimental results relies on the purity of the specimen and the precision of operations.' Furthermore, studies indicate that blood culture contamination rates can fluctuate from 1% to over 10%, highlighting the urgent need for rigorous purification methods.

By prioritizing sample cleanliness through the use of a syringe filter sterile, research facilities can significantly enhance the reliability of their findings and maintain the integrity of their studies. Additionally, employing a standardized sterile technique for obtaining blood cultures has been shown to decrease contamination rates by an average of 56%. In this context, sterile needle strainers serve as indispensable tools that elevate the overall quality and precision of laboratory testing.

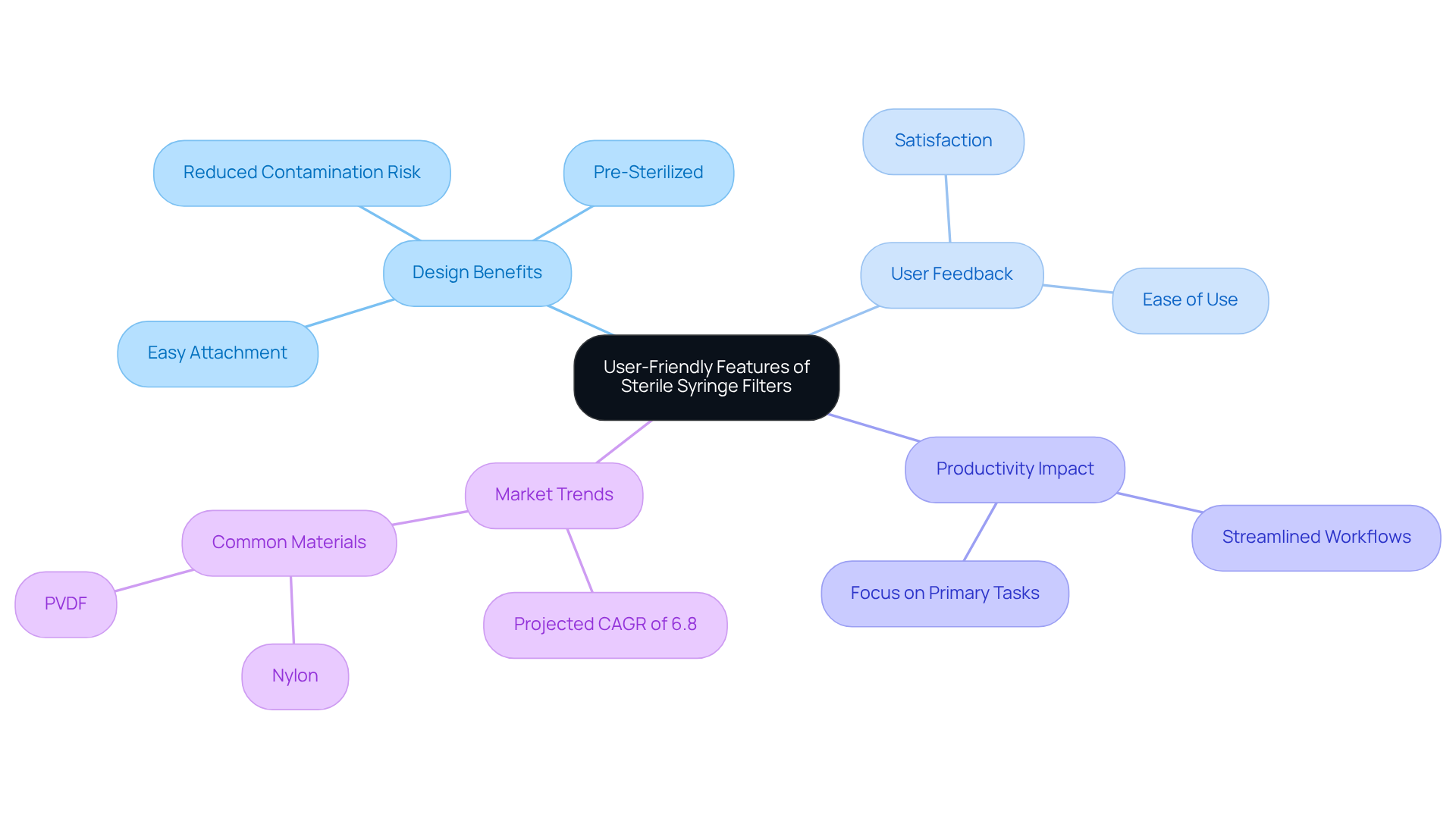

Simplify Operations: User-Friendly Features of Sterile Syringe Filters

Sterile syringe screens are engineered with user-friendly features that significantly streamline the filtration process. Their intuitive design allows for easy attachment to syringes, facilitating rapid and efficient filtration without the complexities of cumbersome setups. Many of these devices come pre-sterilized and individually packaged with a syringe filter sterile, ensuring they are ready for immediate use. This convenience minimizes the risk of contamination during handling, empowering staff to concentrate on their primary tasks, ultimately boosting productivity.

Laboratory personnel have noted that the straightforward nature of these filtration systems has transformed their workflows, with numerous users expressing satisfaction with the devices' uncomplicated operation and reliability. Evaluations of ease of use for sterile injection products consistently highlight the advantages of these sterile devices, including the importance of syringe filter sterile products, reinforcing their vital role as essential tools in modern research facilities.

Furthermore, the injection device market is projected to grow at a CAGR of 6.8% from 2025 to 2034, reflecting the increasing demand for reliable purification solutions across various sectors. Common materials used in these devices, such as Nylon and PVDF, enhance their effectiveness and reliability, further contributing to laboratory productivity.

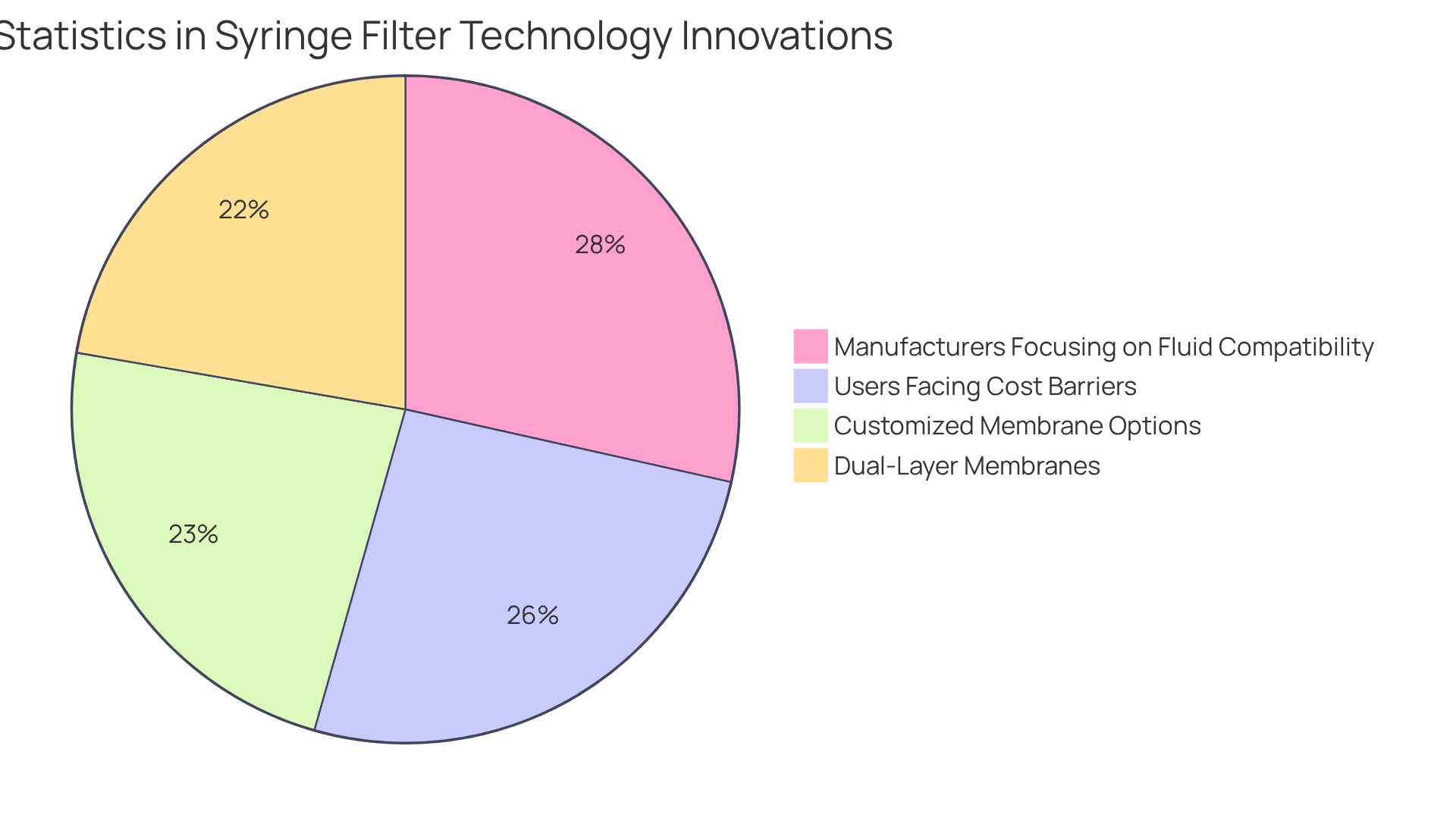

Leverage Technology: Innovations in Sterile Syringe Filter Design

Recent innovations in sterile needle design have significantly enhanced filtration efficiency and overall performance. Advanced membrane technologies, particularly the development of hydrophilic and hydrophobic materials, have improved the systems' capabilities to effectively eliminate contaminants while maintaining high flow rates. Notably, over 43% of newly launched needle cartridges now feature dual-layer membranes, which extend lifespan and enhance filtration speed. Additionally, approximately 45% of syringe membrane suppliers are expanding production lines to offer customized membrane options, reflecting the growing demand for tailored solutions. Certain devices are also equipped with RFID tagging for tracking and monitoring usage, thereby improving operational efficiency and ensuring compliance with stringent regulatory standards.

However, over 50% of users report that rising costs of sterile and disposable devices pose a barrier to adoption, highlighting a significant challenge within the market. These technological advancements not only refine filtration processes but also contribute to achieving superior analytical outcomes, making them indispensable tools in modern research facilities. Industry leaders assert that the integration of innovative membrane materials is essential for boosting filtration efficiency, with over 55% of manufacturers concentrating on enhanced fluid compatibility and performance under varying conditions. As the market continues to evolve, these advancements are anticipated to drive further growth and the adoption of syringe filter sterile across diverse applications. As noted by a leading industry expert, "The continuous evolution of membrane technology is vital for meeting the increasing demands of laboratory filtration processes.

Conclusion

Syringe filter sterile devices are indispensable tools in laboratory settings, playing a pivotal role in ensuring specimen purity, enhancing operational efficiency, and meeting regulatory standards. Their capacity to eliminate contaminants such as bacteria and particulates directly contributes to the reliability of analytical results, making them essential for researchers committed to accuracy in their work. The integration of these filters into laboratory processes not only boosts productivity but also reinforces the commitment to quality and compliance that is crucial in today’s scientific landscape.

Throughout this discussion, the key benefits of using syringe filter sterile devices have been underscored, including:

- Their effectiveness in preventing contamination

- Streamlining workflows

- Providing cost-effective solutions for research facilities

The versatility of these filters allows for application across various industries, from pharmaceuticals to environmental testing, showcasing their critical role in maintaining high standards of quality assurance. Furthermore, advancements in technology, such as innovative membrane designs and improved compatibility with laboratory equipment, significantly enhance their functionality and efficiency.

As the demand for reliable and efficient laboratory solutions continues to escalate, the importance of incorporating sterile syringe filters into research workflows cannot be overstated. Facilities are urged to prioritize the selection of appropriate filters tailored to their specific applications, ensuring optimal performance and compliance with industry standards. By embracing these advancements and recognizing the significant advantages offered by syringe filter sterile devices, laboratories can enhance their research capabilities and contribute to the overall integrity of scientific inquiry.