Overview

This article delves into the essential options for PVDF syringe filters in pharmaceutical laboratories, underscoring their pivotal role in achieving effective filtration and adhering to regulatory standards. It presents a variety of filter options, including those from JM Science, Whatman, and Labfil, detailing their specifications, applications, and advantages. Each of these aspects collectively highlights the significance of selecting the appropriate syringe filter to guarantee sample integrity and produce reliable analytical results in laboratory environments. Understanding these options is crucial for laboratory professionals committed to maintaining high standards in their work.

Introduction

In the realm of pharmaceutical laboratories, the significance of reliable filtration is paramount. As the demand for precision in analytical processes escalates, the selection of the appropriate PVDF syringe filter becomes a pivotal decision that directly impacts the quality of results and adherence to stringent regulatory standards. This article explores seven essential PVDF syringe filter options, emphasizing their distinct features and benefits. Furthermore, it addresses the challenges that lab managers encounter in ensuring optimal performance.

How can one successfully navigate the multitude of choices to identify the best fit for specific applications while preserving the integrity of critical workflows?

JM Science PVDF Syringe Filters: High-Quality Solutions for Laboratory Filtration

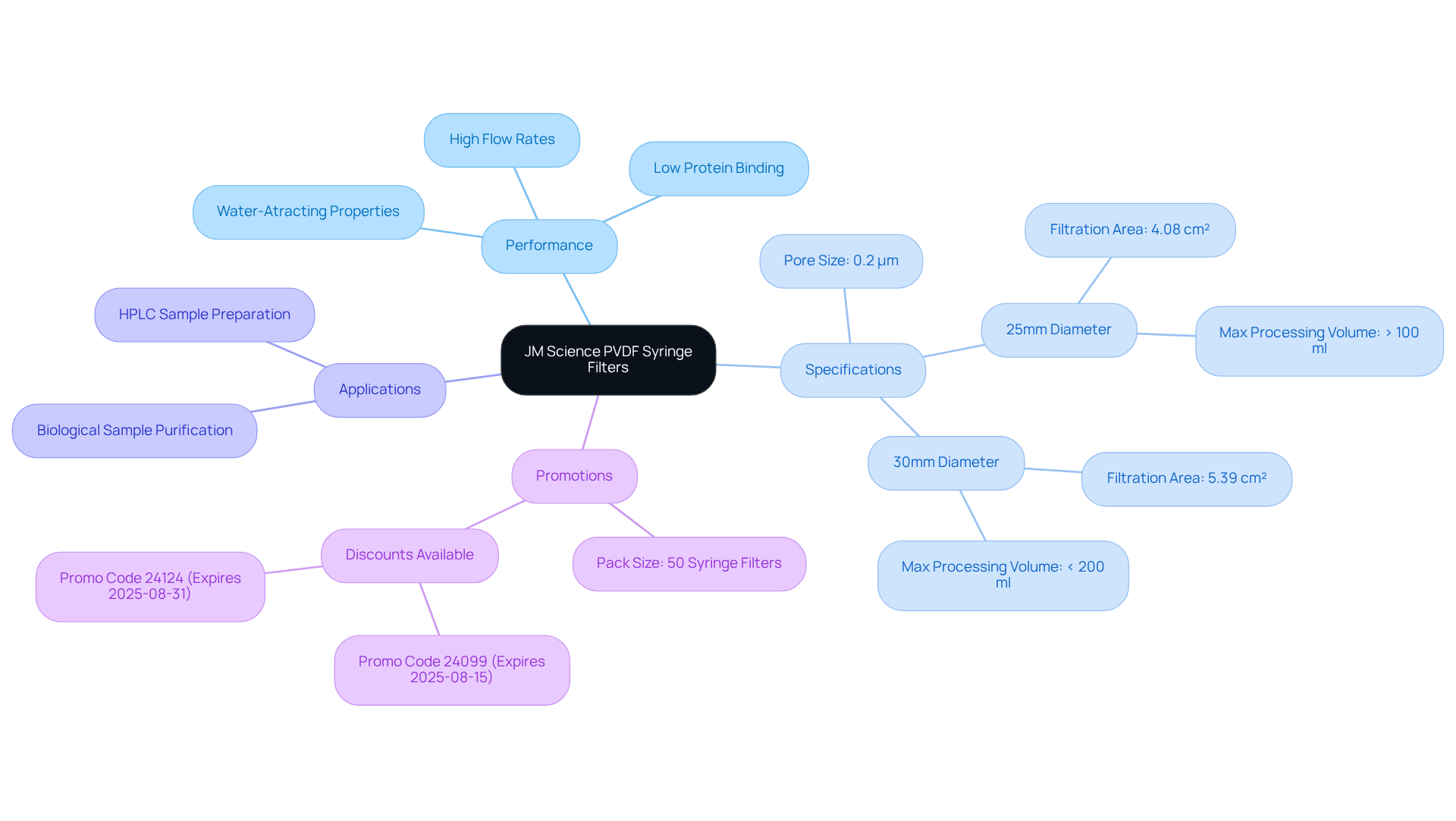

JM Science presents an extensive selection of premium pvdf syringe filters tailored for research applications. These devices are widely recognized for their low protein binding and high flow rates, making them particularly effective in HPLC sample preparation and biological sample purification. Manufactured under stringent quality control standards, they guarantee reliability and performance in critical laboratory settings. With a , these devices accommodate a diverse array of solvents, enhancing their versatility in pharmaceutical laboratories where precision and accuracy are paramount.

The 25mm diameter devices feature a screening area of 4.08 cm² and can handle maximum processing volumes exceeding 100 ml, making them ideal for demanding applications. In addition, the 30mm diameter screens offer a separation area of 5.39 cm² and can manage maximum processing volumes of under 200 ml. The membranes' water-attracting properties and moderate chemical resistance significantly enhance their efficiency across various research environments. Recent advancements in purification technology have further refined their design, ensuring they meet the evolving demands of researchers and analysts.

By integrating innovative features such as pre-filters for high-viscosity samples, JM Science's pvdf syringe filter devices effectively address common challenges faced in scientific processes, thereby improving analytical workflows. Each pack contains 50 syringe filters, presenting a cost-effective solution for laboratories. Additionally, customers can take advantage of promotional offers, including discounts available with specific promo codes, thereby increasing the value of these high-quality purification solutions.

Whatman 6900-2502 GD/X 25 Sterile Syringe Filter: Precision Filtration with PVDF Medium

The Whatman 6900-2502 GD/X 25 Sterile Syringe Filter is engineered for precision filtration and utilizes a PVDF syringe filter membrane that provides excellent chemical compatibility and low protein binding. With a , it effectively removes particulates and microorganisms from specimens, ensuring the integrity of analytical results. This device is especially advantageous for high-particulate-loaded specimens exceeding 10mL, establishing it as a favored option in pharmaceutical laboratories where purity is essential.

The PVDF syringe filter also exhibits good chemical resistance to common HPLC solvents, enhancing its utility in various applications. In the context of utilizing Karl Fischer titrators, like the AQV-300 and AQ-300, the Whatman syringe plays a crucial role in preparing samples for accurate moisture content analysis, ensuring that the titration results are dependable and exact. With a customer satisfaction rating of 4.8 out of 5 stars, users have praised its performance, with one stating, "Simply put… The best money can buy!"

For pharmaceutical lab managers, choosing the appropriate syringe device such as the Whatman 6900-2502 can greatly influence the quality of analytical results, ensuring dependable outcomes in essential applications.

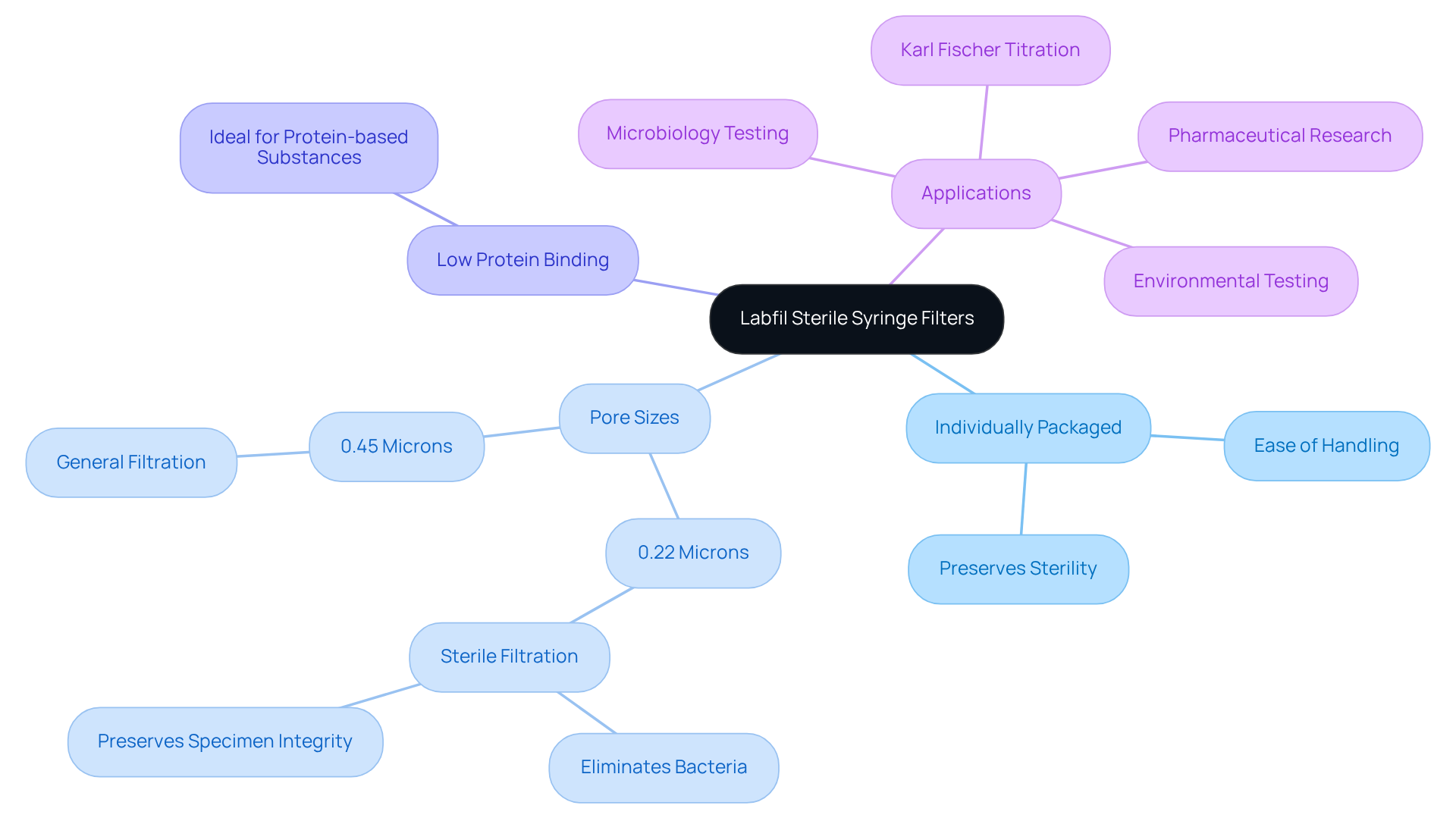

Labfil Sterile Syringe Filters: Individually Packaged PVDF Membranes for Optimal Performance

Labfil Sterile Syringe Filters are equipped with individually packaged PVDF syringe filters, meticulously designed to guarantee optimal performance and sterility in laboratory applications. Available in pore sizes of 0.22 and 0.45 microns, these filters adeptly meet diverse filtration requirements. Notably, the 0.22 μm filters excel in sterile filtration, effectively eliminating bacteria while preserving specimen integrity. This capability is crucial when preparing specimens for analysis using Karl Fischer titrators, such as the Hiranuma Aquacounter AQV-300 and AQ-300, essential tools for drug and medicine testing in compliance with the Japanese Pharmacopoeia.

Individual packaging not only preserves sterility but also enhances ease of handling, significantly mitigating the risk of contamination during use. This characteristic is vital in pharmaceutical facilities, where maintaining is paramount for achieving precise outcomes and adhering to stringent regulatory standards.

Moreover, the low protein binding properties of PVDF syringe filters render them ideal for applications involving protein-based substances, thereby further augmenting their utility in pharmaceutical environments.

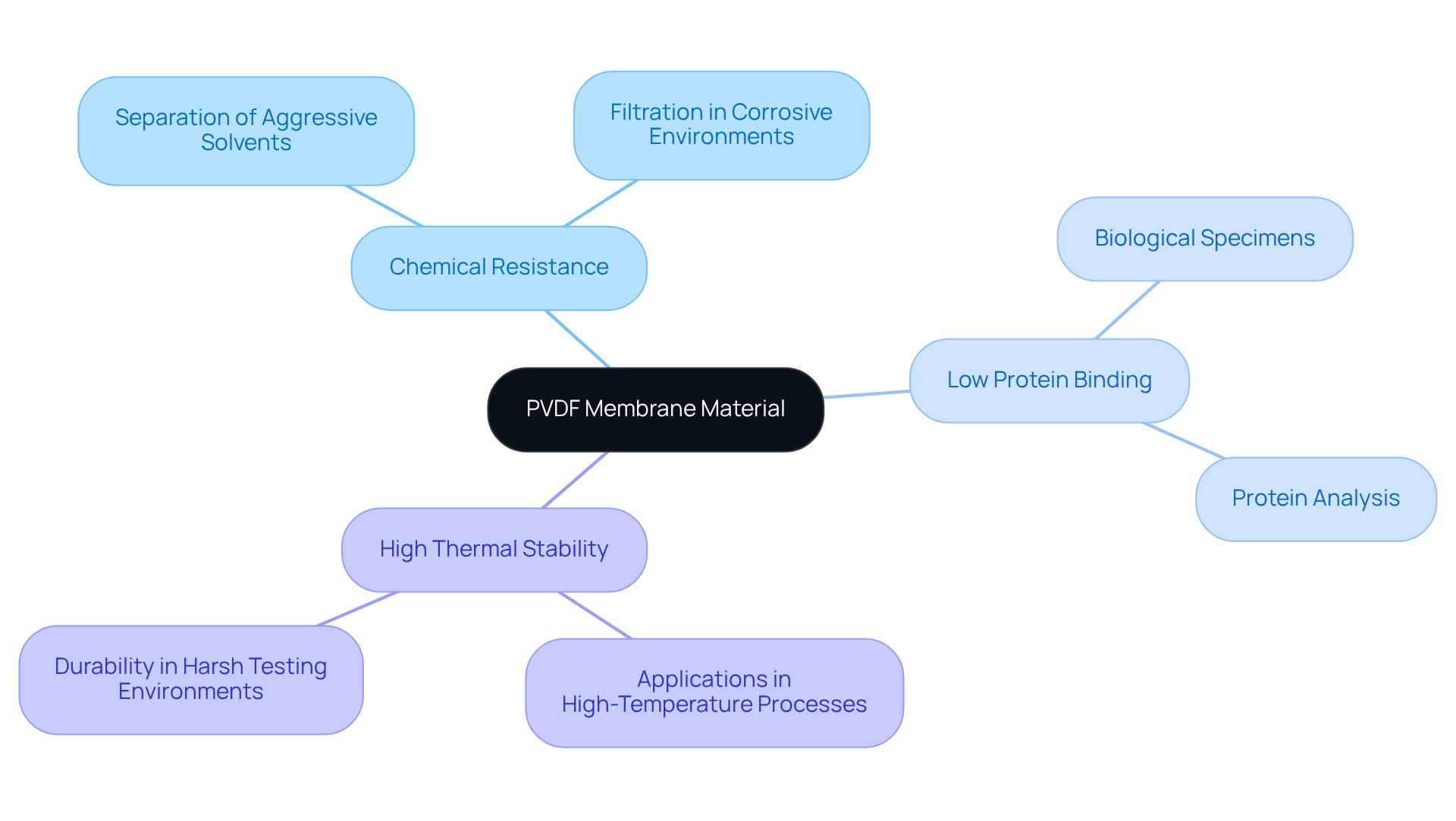

Understanding PVDF Membrane Material: Benefits for Laboratory Applications

PVDF (Polyvinylidene fluoride) stands as a highly versatile membrane material, distinguished by its exceptional chemical resistance, low protein binding, and high thermal stability. These remarkable characteristics make the PVDF syringe filter ideal for a broad spectrum of research applications, particularly in the separation of aggressive solvents and biological specimens.

With its durability, the PVDF syringe filter can withstand harsh testing environments, establishing itself as a for pharmaceutical facilities where precision and reliability are paramount.

In the realm of scientific instruments, the importance of selecting high-quality materials like PVDF cannot be overstated, as they significantly contribute to the success of critical laboratory processes.

Choosing the Right Pore Size: Key Considerations for Effective Filtration

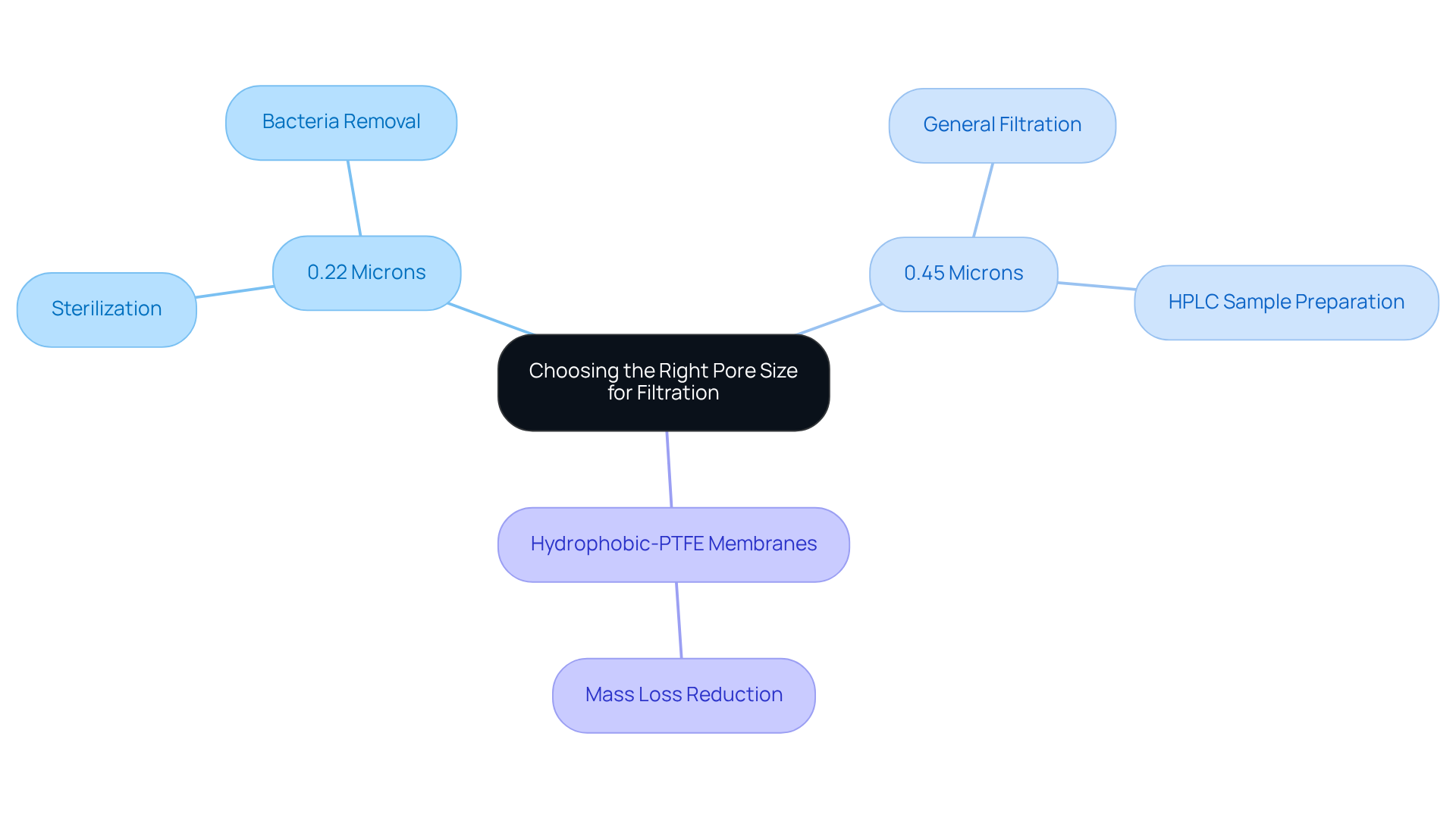

Choosing the appropriate pore size for PVDF syringe filters is essential for achieving efficient separation in laboratory environments. Commonly utilized pore sizes, such as 0.22 microns—ideal for sterilization—and 0.45 microns—suitable for general filtration—play a significant role in this process. The selection of pore size must align with the specific application and the characteristics of the material being filtered.

For instance, a 0.22-micron membrane is recommended for effectively removing bacteria, thereby ensuring a sterile sample, while a 0.45-micron membrane is frequently employed in HPLC sample preparation to eliminate larger particulates without compromising the integrity of the analytes.

Research indicates that hydrophobic-PTFE membranes exhibit the least mass losses for the majority of pharmaceutical and personal care products (PPCPs), making them a preferred choice for efficient separation. Additionally, pre-rinsing screens can substantially reduce mass losses, thereby enhancing the reliability of results.

Understanding these distinctions is crucial for improving and maintaining the precision of subsequent evaluations. By adhering to these pore size guidelines and considering the potential ramifications of inappropriate media selection, laboratories can optimize their filtration processes with a PVDF syringe filter to ensure reliable results.

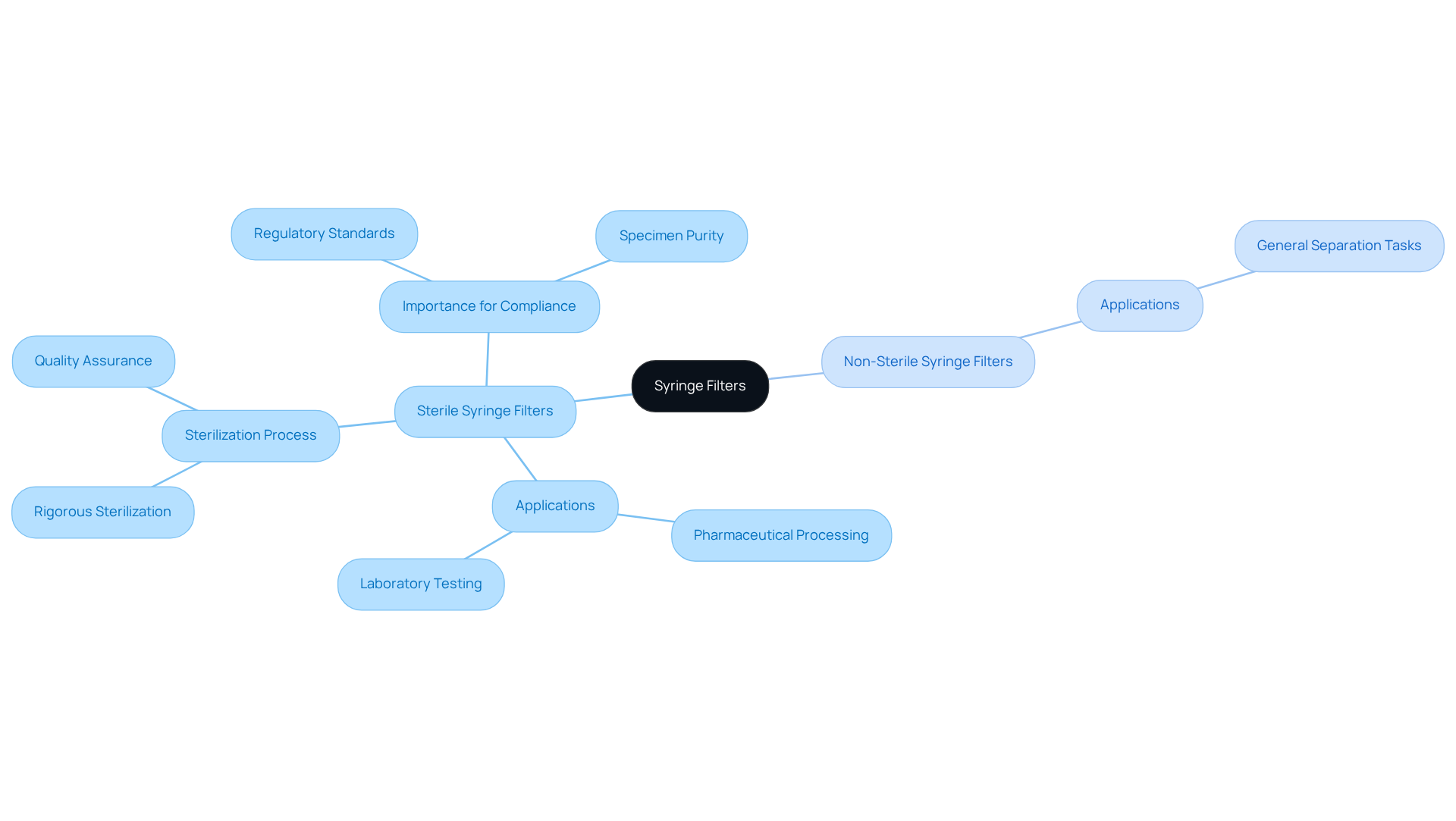

Sterile vs. Non-Sterile Syringe Filters: What You Need to Know for Compliance

The pvdf syringe filter is specifically engineered as a sterile syringe membrane for applications that demand freedom from microorganisms and contaminants. These critical devices undergo rigorous sterilization processes to guarantee their integrity prior to use. Conversely, non-sterile screens are suitable for general separation tasks where sterility is not a concern.

Understanding the distinctions between these two categories of devices, including the pvdf syringe filter, is crucial for compliance with , where the preservation of specimen purity is paramount. Recognizing the significance of high-quality scientific instruments is essential for maintaining laboratory integrity and ensuring the reliability of research outcomes.

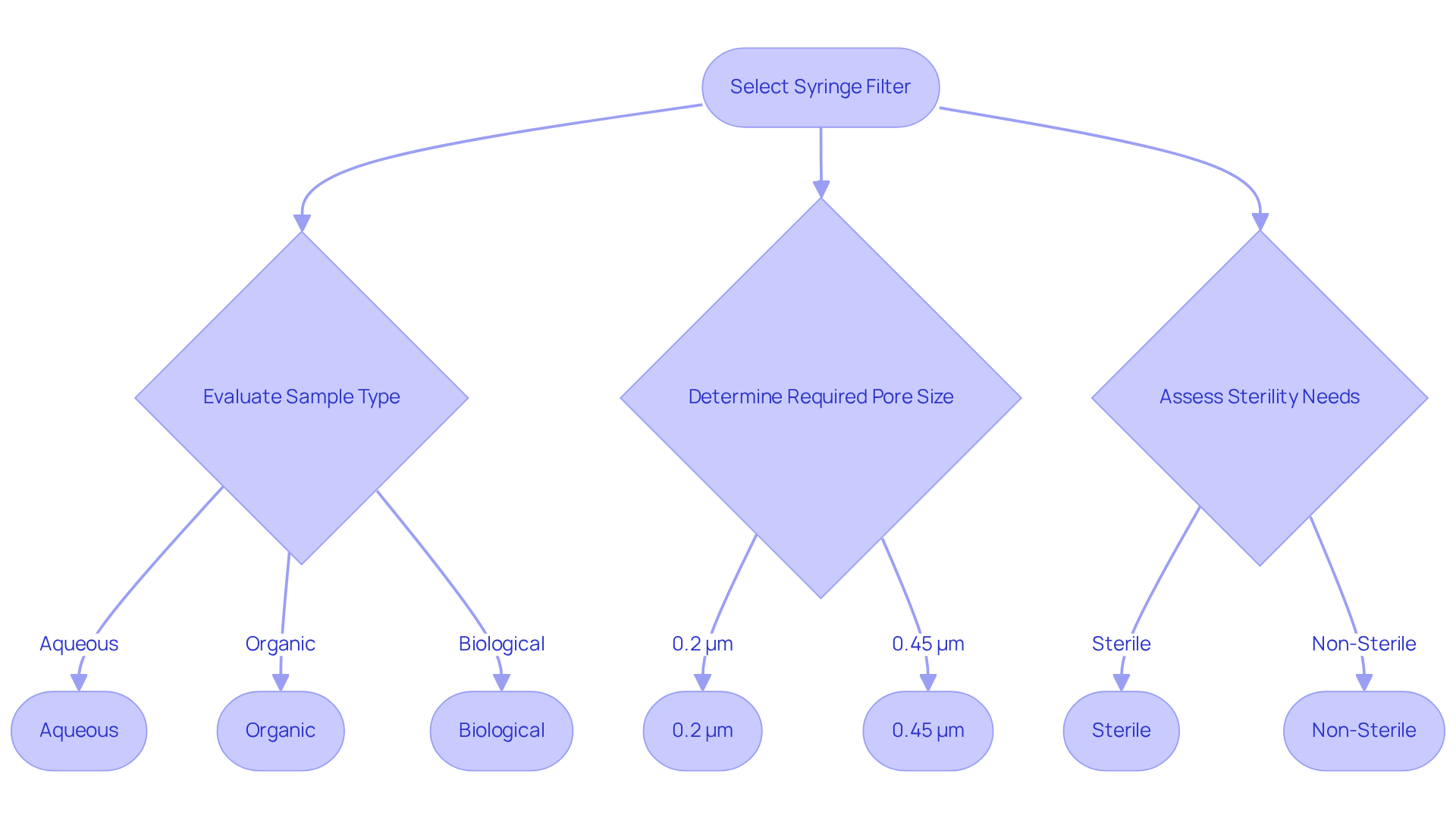

How to Choose the Right Syringe Filter for Your Application: A Practical Guide

Selecting the appropriate pvdf syringe filter is crucial for achieving optimal filtration results in pharmaceutical laboratories. It is essential to consider key factors such as the type of specimen, required pore size, and the need for sterility. Begin by evaluating the characteristics of your sample—whether it is aqueous, organic, or biological—to determine the suitable filtration material. For example, hydrophilic membranes like Polyethersulfone (PES) are ideal for biological samples due to their low protein binding, while hydrophobic membranes such as PTFE are superior for filtering organic solvents. Additionally, the mechanical strength and chemical resistance of the membranes must be taken into account, as these properties are vital for maintaining integrity during operation.

Following this, choose a pore size that aligns with your separation objectives. For sterile separation, 0.2 µm membranes are commonly employed to effectively remove bacteria and viruses, whereas 0.45 µm membranes are more suitable for clarification processes. It is critical to select a membrane with a pore size smaller than the particles you intend to eliminate; for instance, a 0.1 µm membrane is recommended for mycoplasma purification. Consulting solvent compatibility charts can further aid in selecting appropriate pvdf syringe filters and avoiding chemical interactions that could compromise your results.

Moreover, assess whether a sterile or non-sterile device is necessary based on your application. Sterile syringe membranes are essential for minimizing contamination risks during the preparation of biological specimens, while non-sterile membranes are applicable for solutions that will undergo additional filtration.

In practical terms, employing a 13mm syringe membrane for samples ranging from 1-10ml ensures compatibility and efficiency, while a 25mm membrane is advised for 5-100ml samples. Understanding these specifications can significantly enhance and ensure compliance with stringent quality standards. Furthermore, proper disposal techniques for used syringe components are critical for environmental compliance and sustainability in laboratory practices. By following these guidelines, you can effectively navigate the complexities of syringe strainer selection and achieve reliable separation outcomes.

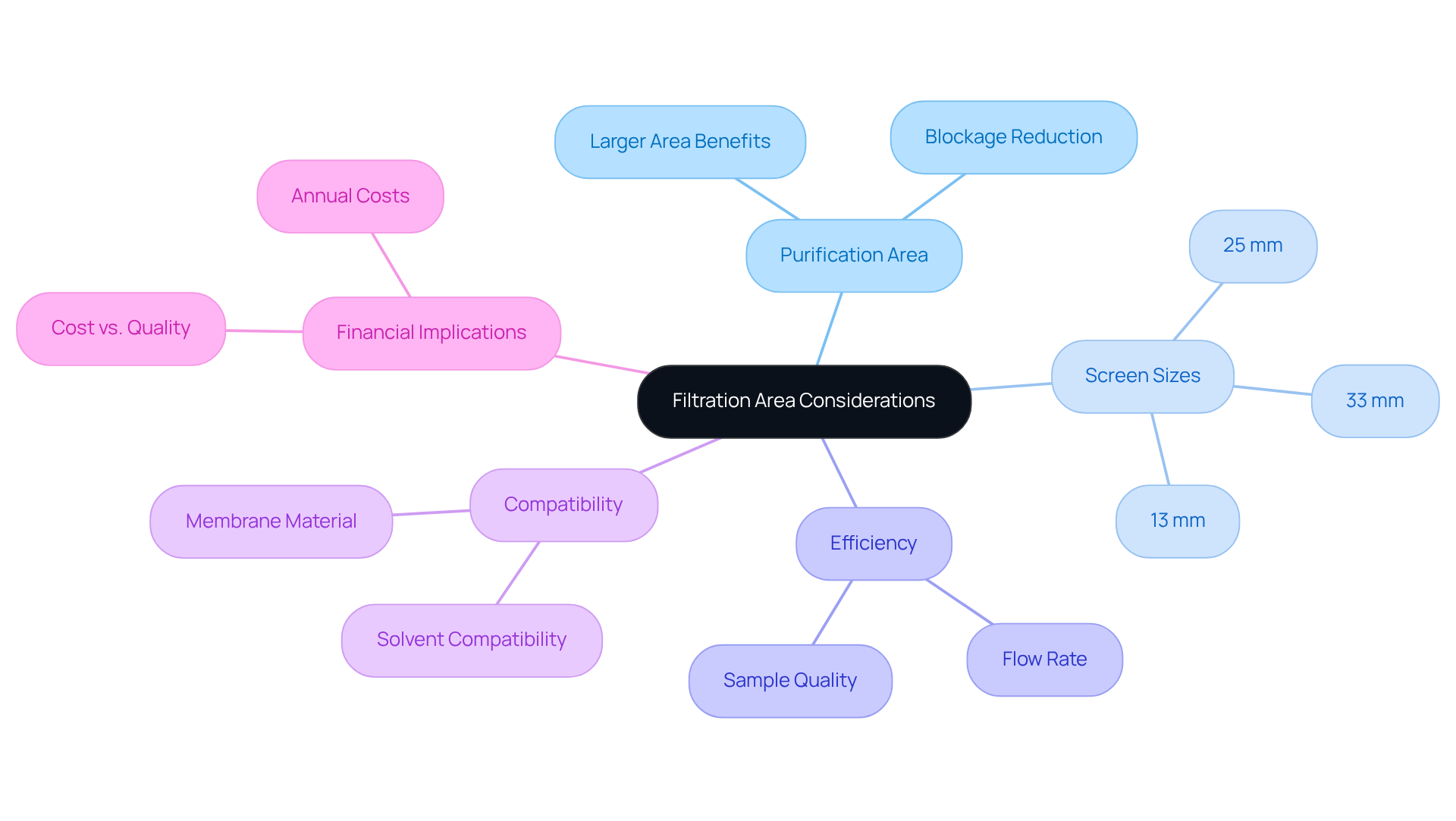

Filtration Area Considerations: Maximizing Efficiency with Syringe Filters

The screening zone of a syringe device is pivotal in determining its effectiveness and throughput. A larger purification area facilitates the handling of greater quantities at an accelerated pace, thereby reducing the risk of blockage and ensuring steady flow rates. When selecting a syringe membrane, it is essential to consider both the and the anticipated particulate load.

Employing screens with larger diameters, such as 25 mm, or utilizing multiple units in parallel can significantly enhance separation efficiency, making them especially suitable for high-throughput laboratory applications. Common sizes for syringe disc screens, including 13 mm, 25 mm, and 33 mm, are designed to meet various blood collection requirements. Furthermore, ensuring compatibility with solvents and solutions is critical to preserving the integrity of the separation process.

In pharmaceutical environments, for instance, employing 25 mm syringe screens can optimize the filtration process for larger blood collections, providing a greater surface area that promotes quicker flow rates and minimizes the likelihood of blockage. This strategic approach not only maximizes throughput but also bolsters the overall reliability of analytical results, safeguarding samples from contaminants that could compromise testing accuracy.

As Emily Carter, a certified phlebotomist with over eight years of experience, asserts, "Choosing the right size can impact the efficiency and accuracy of blood collection." Additionally, considering the financial implications, utilizing 10,000 units each year at $3.00 apiece could exceed $30,000 in annual expenses, underscoring the importance of selection in laboratory operations.

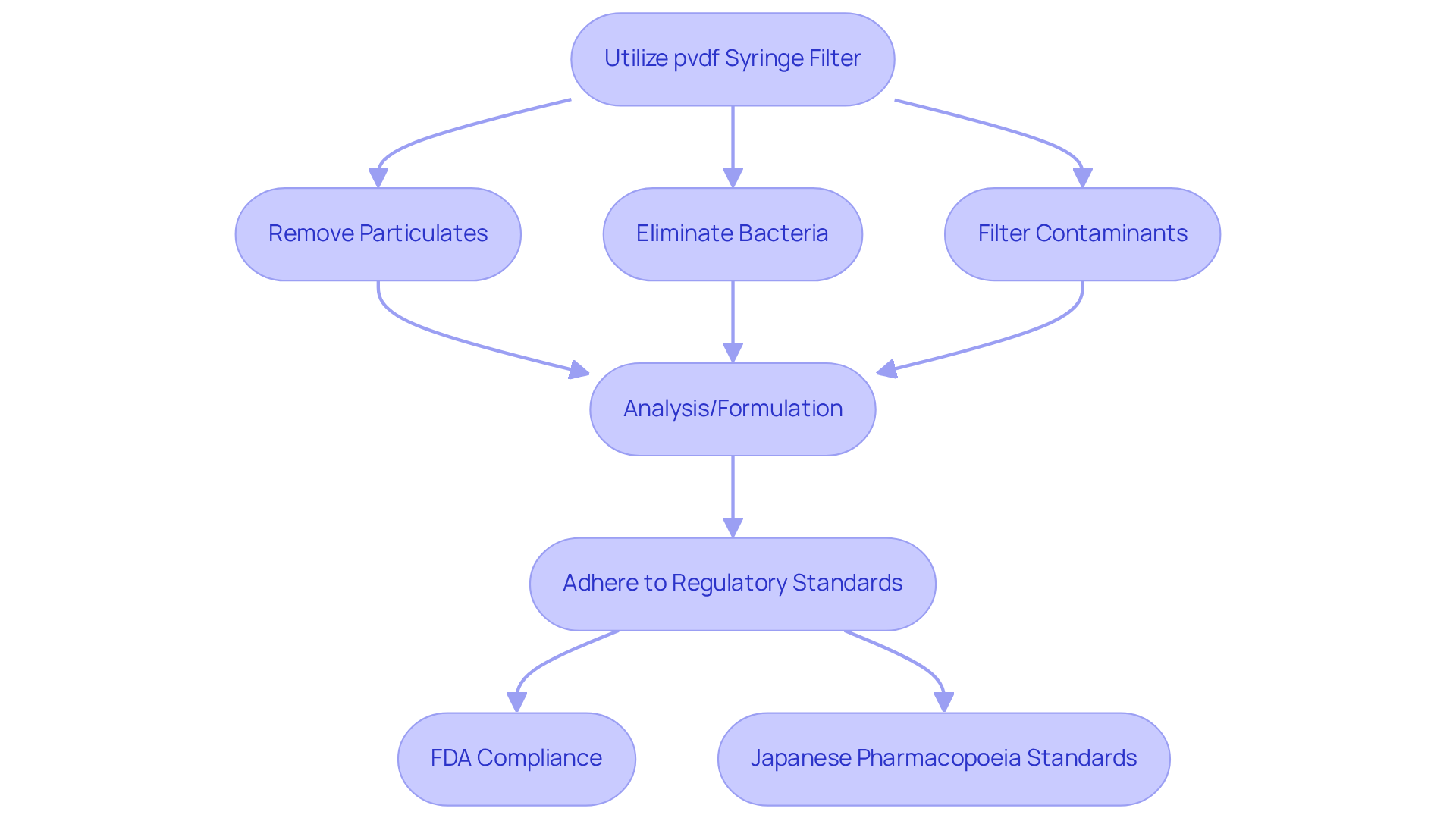

Syringe Filters in Pharmaceutical Applications: Ensuring Quality and Compliance

In pharmaceutical applications, syringe filters are indispensable for ensuring product quality and safety. They effectively use a pvdf syringe filter to remove particulates, bacteria, and other contaminants from samples before analysis or formulation. This process is particularly crucial when utilizing advanced , such as the Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 Coulometric Karl Fischer Titrators. These instruments are essential for drug and medicine testing, adhering to the strict standards set by the Japanese Pharmacopoeia.

Compliance with regulatory standards, including those established by the FDA, necessitates the use of reliable filtration methods like the pvdf syringe filter to maintain the integrity of pharmaceutical products. By employing premium syringe screens, research facilities can enhance their quality assurance procedures, ensuring that their products meet rigorous safety standards.

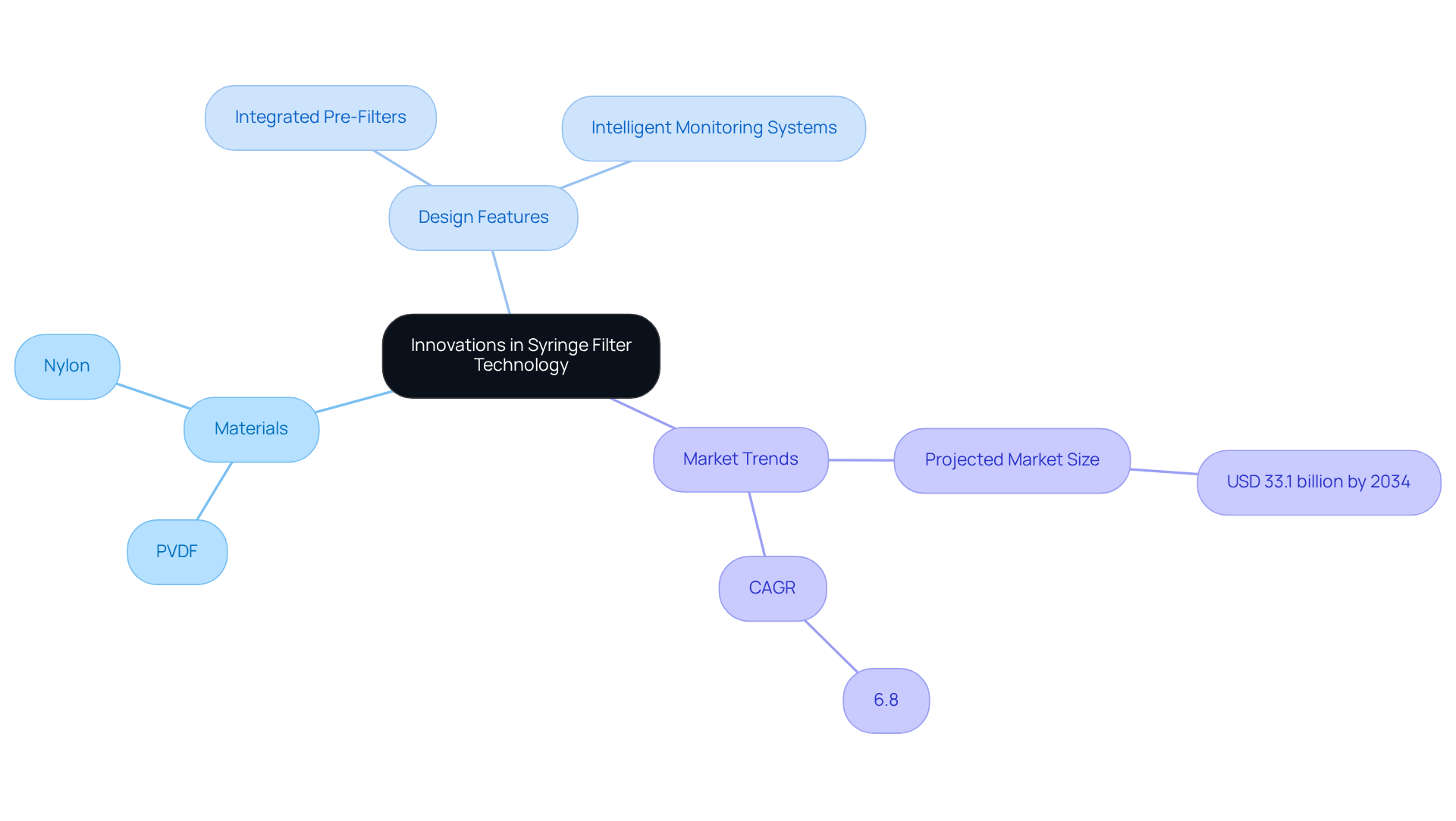

Innovations in Syringe Filter Technology: What’s New in the Market

Recent innovations in syringe membrane technology have focused on enhancing performance, usability, and sustainability. Novel materials, such as polyvinylidene fluoride (PVDF) and nylon, rank among the most frequently utilized in the syringe sector, especially the PVDF syringe filter, which is specifically designed to meet the evolving needs of research facilities with improved chemical resistance and reduced extractables.

Additionally, advancements in design, including integrated pre-filters and intelligent monitoring systems, are streamlining the process for research facilities to achieve optimal purification outcomes. These innovations not only boost efficiency but also contribute to more by minimizing waste and extending the lifespan of filtration systems.

Given that the syringe filter market is projected to grow at a CAGR of 6.8%, reaching USD 33.1 billion by 2034, the emphasis on sustainable materials and advanced designs is becoming increasingly critical for laboratories aiming to enhance their operational effectiveness while adhering to environmental standards.

Conclusion

The significance of selecting the appropriate PVDF syringe filters in pharmaceutical laboratories is paramount. These filters are essential for ensuring the purity and integrity of samples, which directly influences the reliability of analytical results. By comprehensively understanding the various options available, including those from JM Science, Whatman, and Labfil, lab managers can make informed decisions that enhance their filtration processes and uphold compliance with stringent regulatory standards.

Key points highlighted throughout this discussion include:

- The criticality of pore size selection

- The distinction between sterile and non-sterile filters

- The advantages offered by PVDF membrane material

Each filter option presents unique features tailored to specific laboratory needs, whether it involves achieving high flow rates, minimizing protein binding, or effectively removing particulates and microorganisms. Moreover, ongoing innovations in syringe filter technology are paving the way for enhanced performance and sustainability within laboratory practices.

Ultimately, the selection of a syringe filter must align with the specific requirements of each application, ensuring optimal performance and compliance. By prioritizing high-quality filtration solutions, pharmaceutical labs can safeguard their research outcomes and contribute to the advancement of the industry. Evaluating these essential tools is not merely beneficial; it can lead to substantial improvements in both efficiency and accuracy, underscoring the critical role they play in laboratory operations.