Overview

This article provides critical insights into the realm of partitioning chromatography, underscoring its pivotal role in laboratory environments for effective separation techniques. It delves into the latest advancements in technology, highlighting the necessity of optimizing chromatographic conditions. Furthermore, it addresses the increasing dependence on high-performance liquid chromatography (HPLC) solutions, particularly within pharmaceutical applications, which are essential for ensuring quality and safety in drug development. Such insights not only reflect the importance of sophisticated instruments but also emphasize the continuous evolution of methodologies that enhance laboratory practices.

Introduction

In the realm of analytical chemistry, partitioning chromatography emerges as a cornerstone technique, essential for the separation and analysis of complex mixtures. As laboratories increasingly prioritize precision and accuracy in their methodologies, the advancements in high-performance liquid chromatography (HPLC) solutions—especially those provided by JM Science Inc.—have become indispensable.

This article delves into the intricacies of partitioning chromatography, exploring its foundational principles and various techniques while emphasizing the critical role of the partition coefficient in achieving effective separations. Furthermore, it highlights the significance of optimizing mobile phases and examines the impact of temperature and pressure on chromatographic performance.

With a keen focus on pharmaceutical applications and the challenges faced within the field, readers will gain valuable insights into the future trends and innovations that are shaping the landscape of partitioning chromatography.

JM Science HPLC Solutions: Precision in Partitioning Chromatography

JM Science Inc. presents a comprehensive selection of high-performance liquid chromatography (HPLC) solutions meticulously crafted for effective partitioning chromatography. Their product range includes state-of-the-art HPLC columns, fittings, and specialized titrators, notably the AQ-300 Coulometric and AQV-300 Volumetric Karl Fischer Titrators, all engineered to provide accurate and reproducible results in drug and medicine testing, particularly in adherence to the Japanese Pharmacopoeia.

By collaborating with industry leaders such as Agilent Technologies and Thermo Fisher Scientific, JM Science guarantees that its offerings meet the highest standards of quality and performance. This unwavering commitment positions the company as a reliable partner for research facilities striving for precision in their testing processes, particularly through the use of partitioning chromatography.

As research centers progressively embrace HPLC solutions, statistics reveal a growing reliance on these advanced technologies, with many institutions prioritizing precision in their testing methodologies. Projections for 2025 indicate that over 70% of research facilities will utilize HPLC technologies, signifying a significant transition toward enhanced testing capabilities.

JM Science's dedication to innovation and quality, coupled with its extensive support resources, makes it an invaluable asset for facilities looking to refine their analytical skills and respond to evolving scientific demands. The pricing for the AQ-300 and AQV-300 titrators remains competitive, ensuring accessibility for facilities aiming to elevate their testing processes.

As Thomas Redman aptly stated, 'Where there is data smoke, there is business fire,' highlighting the essential role of data precision in laboratory environments. Furthermore, as Vik Paruchuri emphasizes, aspiring data specialists must take charge of their own education, a vital endeavor in the ever-evolving realm of separation science.

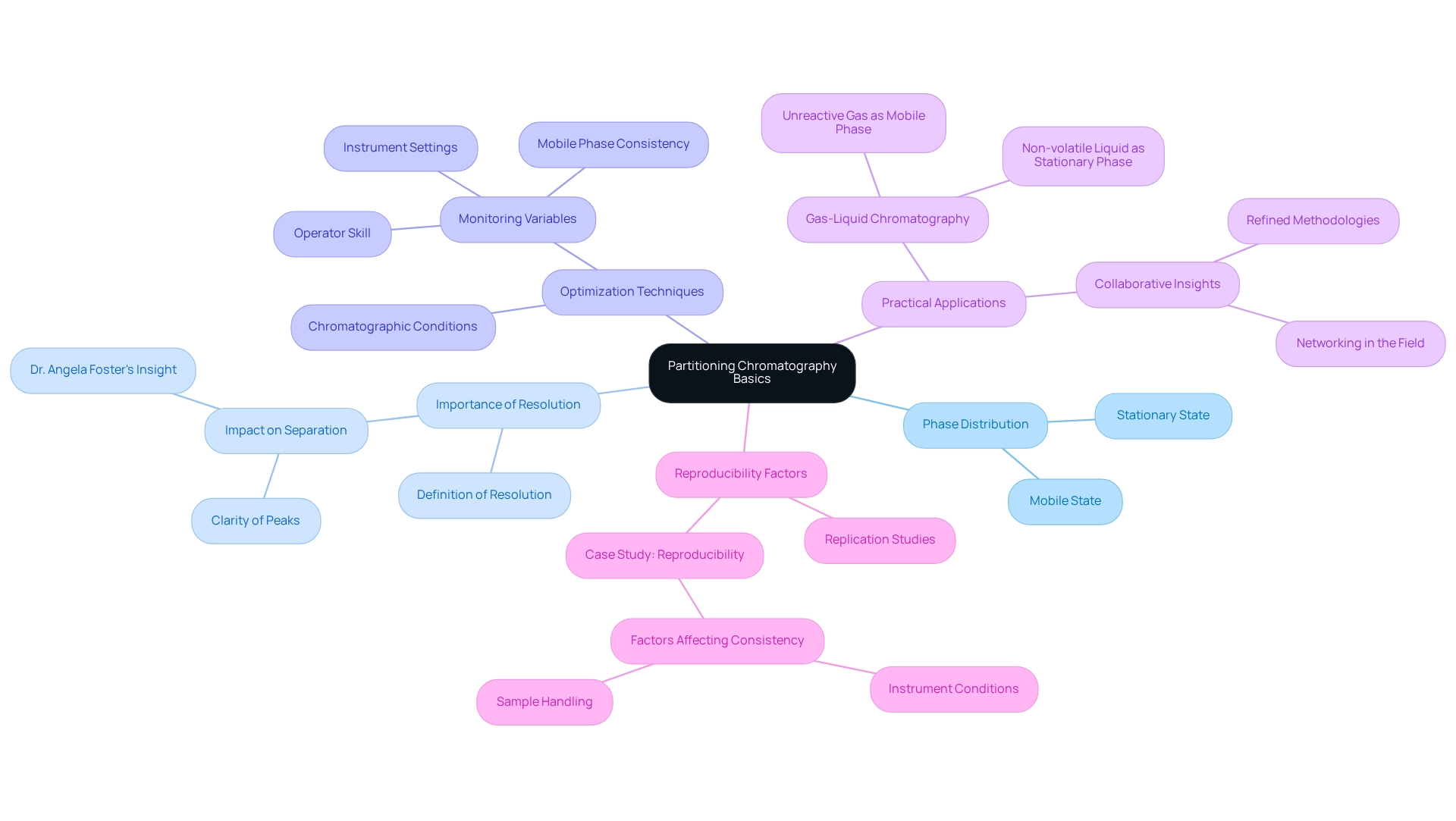

Partitioning Chromatography Basics: Understanding Phase Distribution

Partitioning separation hinges on the distribution of solutes between two non-mixing states: the stationary state and the mobile state. This technique leverages the differential solubility of compounds, a crucial factor for effective separation. Understanding distribution is vital for optimizing chromatographic conditions and achieving desired separation outcomes.

In 2025, advancements in understanding distribution stages have led to improved techniques in separation science. For instance, optimizing chromatographic conditions based on distribution can significantly enhance resolution. As Dr. Angela Foster, an expert in separation techniques, aptly states, "Resolution is the lifeblood of this process—without it, the peaks are just a chaotic blur." This underscores the essential role that resolution plays in realizing effective separations.

Recent studies underscore the importance of solute distribution in separation analysis, revealing that factors such as instrument settings, mobile consistency, and operator skill are critical for reproducibility. A case study titled "Reproducibility: Factors Affecting Consistent Results in Chromatography" illustrates how monitoring these variables can yield consistent and reliable results, thereby reinforcing the credibility of scientific analyses.

Moreover, gas-liquid separation, which utilizes an unreactive gas as the mobile component and a non-volatile liquid as the stationary component, exemplifies the practical applications of distribution principles. By grasping and manipulating these distributions, laboratories can achieve optimal separation and enhance the reliability of their analytical results. Collaborative discussions and networking within the field have yielded valuable insights into separation challenges, such as the necessity for refined methodologies and innovative approaches to phase distribution, thereby further advancing the understanding of partitioning techniques.

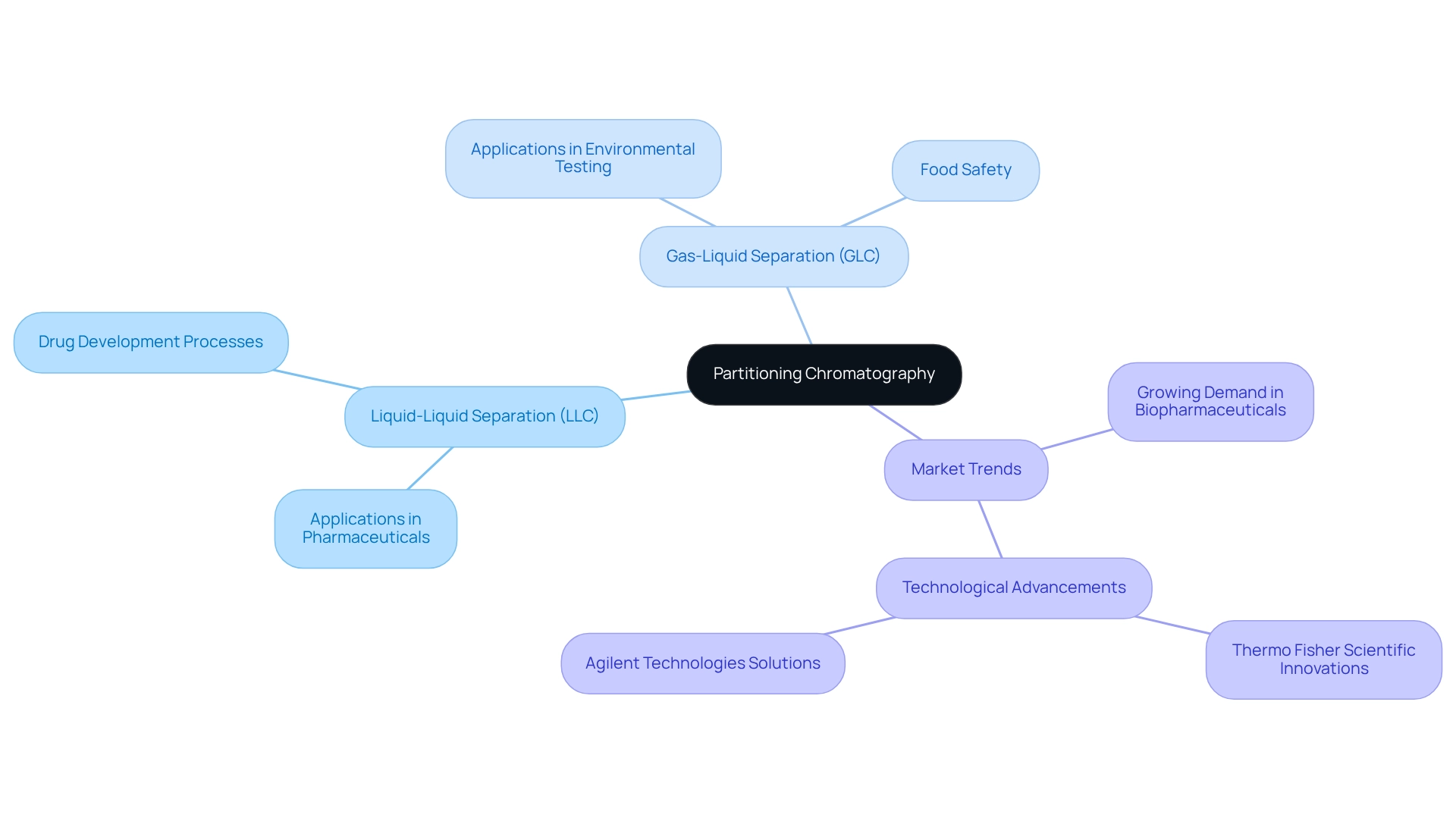

Types of Partitioning Chromatography: Techniques and Applications

Partitioning chromatography encompasses a range of techniques, prominently featuring liquid-liquid separation (LLC) and gas-liquid separation (GLC), each tailored for specific applications. LLC is particularly adept at separating polar compounds, making it indispensable for analyzing substances in pharmaceutical formulations, where polarity is a critical factor. Conversely, partitioning chromatography is optimized for volatile substances, frequently employed in the analysis of gases and low-boiling liquids, which are essential in environmental and food safety testing. Recent market analyses reveal an escalating demand for partitioning chromatography technologies, especially within biopharmaceuticals and personalized medicine, where precise separation techniques are paramount. For instance, LLC is gaining traction in drug development processes, facilitating the effective purification of active pharmaceutical ingredients (APIs). Furthermore, advancements in GLC, such as those showcased in the latest Thermo Fisher Scientific GC/GC-MS instrument portfolio, significantly enhance usability and productivity, reflecting the continuous innovations within the field.

According to recent statistics, the gas chromatography market is experiencing substantial growth across various sectors, driven by the increasing need for precise measurement instruments in pharmaceutical and environmental applications. Agilent Technologies emphasizes that 'Agilent merges advanced technology with customer-focused solutions to provide high-performance evaluation tools,' highlighting the critical role of innovation in meeting laboratory needs, while a comprehensive understanding of the strengths and limitations of partitioning chromatography as well as LLC and GLC empowers pharmaceutical lab managers to make informed decisions regarding their analytical strategies. As the chromatography market evolves, the integration of cutting-edge technologies will broaden the applications of these techniques, ensuring they meet the rigorous demands of contemporary pharmaceutical analysis.

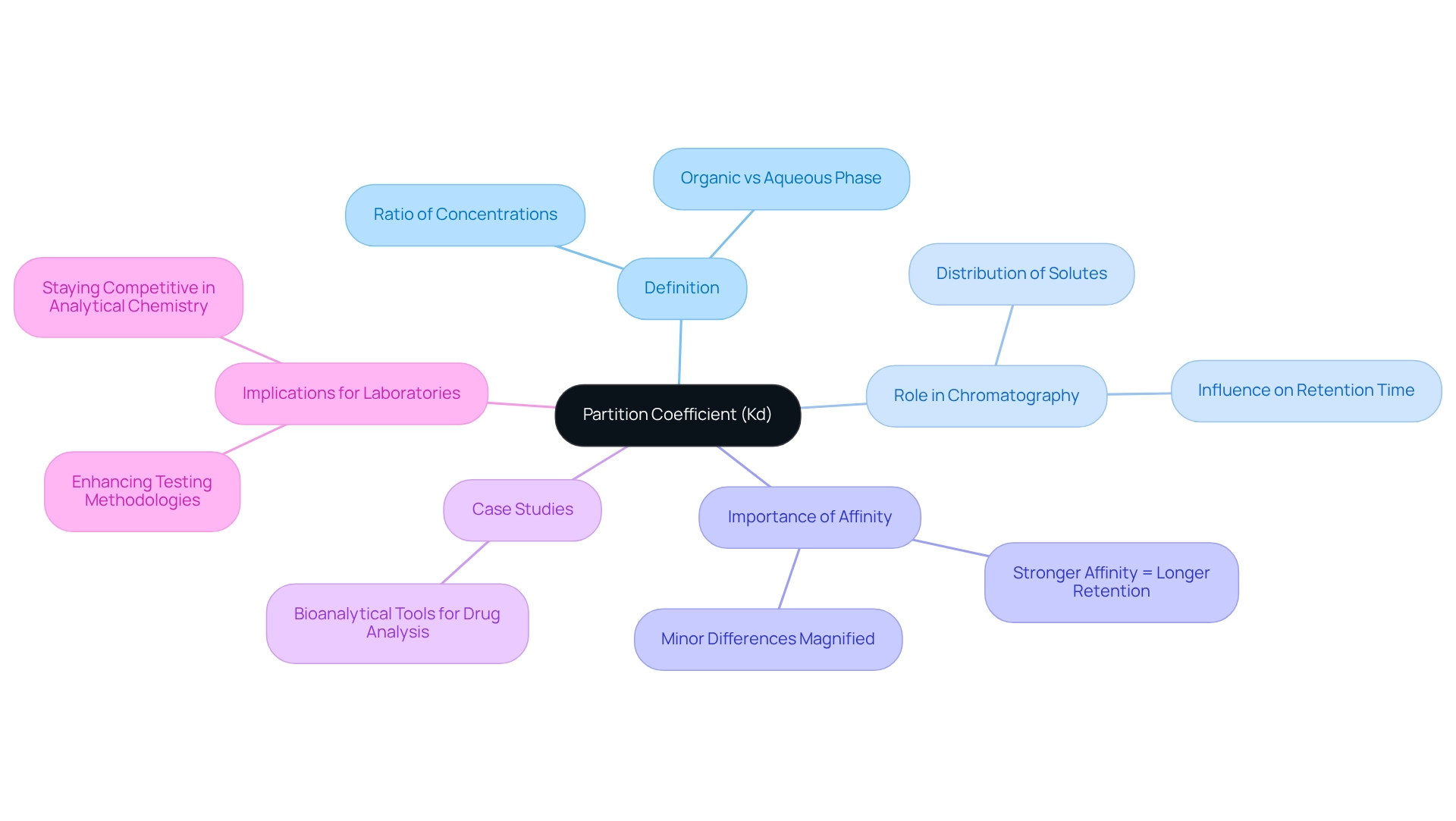

Partition Coefficient: Key to Effective Separation

The partition coefficient (Kd) serves as a vital metric that quantifies the distribution of a solute between the stationary and mobile states at equilibrium. It is defined as the ratio of the concentration of a solute in the organic state to its concentration in the aqueous state. This metric is instrumental in partitioning chromatography separations. A higher partition coefficient indicates a stronger affinity for the stationary phase, leading to prolonged retention times and improved separation efficiency. This relationship is particularly significant, as even minor differences in analyte affinity can become pronounced during their transit through the column, ultimately influencing overall separation outcomes.

As we advance into 2025, understanding the role of partitioning chromatography and its influence on the partition coefficient remains essential for facilities aiming to refine their testing methodologies. Insights from industry leaders underscore that effective separation in partitioning chromatography hinges on a comprehensive understanding of the partition coefficients of target analytes. For example, case studies such as "Bioanalytical Tools for Drug Analysis" demonstrate how the partition coefficient dictates the distribution of analytes, highlighting the critical roles of chemical potential and retention time in achieving reliable results. The research concludes that partitioning chromatography, as a form of chromatographic separation, is fundamentally rooted in equilibrium thermodynamics, and the efficacy of these separations can be assessed through various metrics, including resolution and plate height, which are indispensable for obtaining trustworthy evaluation results.

Average partition coefficients for common analytes exhibit significant variability, necessitating that facilities leverage this data to enhance their chromatographic techniques. Real-world examples illustrate that optimizing partitioning chromatography can yield substantial improvements in separation efficiency, thereby enhancing the reliability of testing outcomes. As the field progresses, remaining abreast of the latest advancements and best practices concerning partition coefficients will be crucial for laboratories striving to maintain a competitive edge in analytical chemistry.

Mobile Phases in Partitioning Chromatography: Optimization Strategies

Enhancing the mobile component is essential for optimizing the performance of partitioning chromatography techniques. Key factors such as solvent composition, pH, and ionic strength significantly influence the separation efficiency in partitioning chromatography. For instance, common ion pairing agents like trifluoroacetic acid (TFA) and heptafluorobutyric acid (HFBA) can enhance the resolution of analytes in complex mixtures. Laboratories are encouraged to experiment with various mobile combinations and conditions in partitioning chromatography to determine the optimal setup tailored to their specific applications.

Partitioning chromatography techniques, such as gradient elution, can further improve resolution and reduce analysis time, making them a valuable strategy in method development. A recent study titled 'Effect of Mobile Phase Composition on Retention of Ionizable Compounds' highlighted the impact of mobile phase composition on partitioning chromatography, demonstrating how variations in solvent composition and pH can optimize the retention of ionizable compounds. This research provides a procedure that relates retention to solvent characteristics, offering practical insights for laboratories.

Experts in partitioning chromatography emphasize that maintaining a careful balance of solvent composition and pH is essential for achieving reproducible results. Calibration curves in human plasma have demonstrated linearity across a broad concentration range, underscoring the significance of accurate mobile phase conditions in measurement applications. By adopting these optimization strategies, laboratories can enhance their performance in partitioning chromatography, leading to more accurate and reliable analytical results.

Temperature and Pressure Effects: Enhancing Chromatographic Performance

Temperature and pressure are critical factors that significantly influence the process of partitioning chromatography. An increase in temperature generally leads to reduced retention times, enhancing mass transfer and facilitating faster separations. This effect is particularly beneficial for optimizing chromatographic performance, as evidenced by empirical studies, including the case study titled 'Empirical Optimization of Pressure-Enhanced LC Methods.' This study highlights the necessity for tailored optimization strategies due to the varying pressure sensitivities of different proteins.

Research indicates that customized temperature settings can optimize the retention characteristics of various solutes in partitioning chromatography, thereby enhancing overall method efficiency. Conversely, elevated pressure can markedly improve partitioning chromatography resolution by intensifying the interactions between analytes and the stationary phase. This improvement is crucial for achieving precise separations, especially in complex mixtures.

Laboratories are encouraged to meticulously monitor and adjust these parameters to fine-tune their chromatographic methods for specific applications. Insights from industry leaders, including Davy Guillarme from the University of Geneva, underscore the importance of empirical optimization strategies that consider both temperature and pressure effects. Such strategies ensure that research facilities can achieve the highest standards of analytical performance.

Recent case studies have demonstrated that the pressure sensitivity of retention increases with solute size, necessitating tailored optimization approaches for effective application in analytical practices. By conducting multiple experiments under controlled conditions, laboratories can statistically analyze variability and refine their methodologies accordingly. This strategic focus on temperature and pressure adjustments not only enhances chromatographic performance but also contributes to advancements in research and healthcare applications.

To implement these insights effectively, lab managers should regularly review and adjust their temperature and pressure settings based on empirical data to optimize their chromatographic methods.

Pharmaceutical Applications: Leveraging Partitioning Chromatography

Partitioning chromatography techniques are essential in the pharmaceutical industry, particularly for the analysis and purification of active pharmaceutical ingredients (APIs) and excipients. This technique is crucial for ensuring the quality and safety of pharmaceutical products. High-performance liquid chromatography (HPLC), a key offering from JM Science Inc., is employed to quantify impurities, evaluate stability, and validate formulations, positioning it alongside partitioning chromatography as a cornerstone of pharmaceutical analysis.

As we look to 2025, the importance of HPLC in pharmaceutical quality control continues to escalate, driven by technological advancements that enhance its capabilities. For instance, optimizing resolution in HPLC not only improves identification but also enhances quantification, thereby increasing confidence in test results. This is particularly vital in light of stringent regulatory requirements and the necessity for precise measurements in drug development. The partition coefficient, denoted as K, is a critical factor in this process; when K = 1, it indicates that the solute is evenly distributed between the two phases, which is essential for accurate analysis.

Real-world applications of HPLC, including the premium HPLC columns and accessories, as well as titrators and Karl Fischer reagents provided by JM Science, underscore its effectiveness in analyzing APIs. Pharmaceutical companies routinely utilize HPLC to ensure their products meet the required purity standards, which is paramount for patient safety. Moreover, effective analytical techniques such as HPLC are crucial for maintaining data integrity and supply chain continuity during crises. For example, during a recent disruption, companies employing HPLC were able to swiftly assess the quality of their products, ensuring compliance and mitigating risks to patient safety. The ongoing commitment to innovation in partitioning chromatography techniques, along with insights from industry leaders, highlights the necessity of HPLC solutions from JM Science for maintaining high standards in pharmaceutical quality control. As the industry evolves, the integration of advanced chromatographic techniques will remain vital in enhancing the reliability and safety of pharmaceutical products.

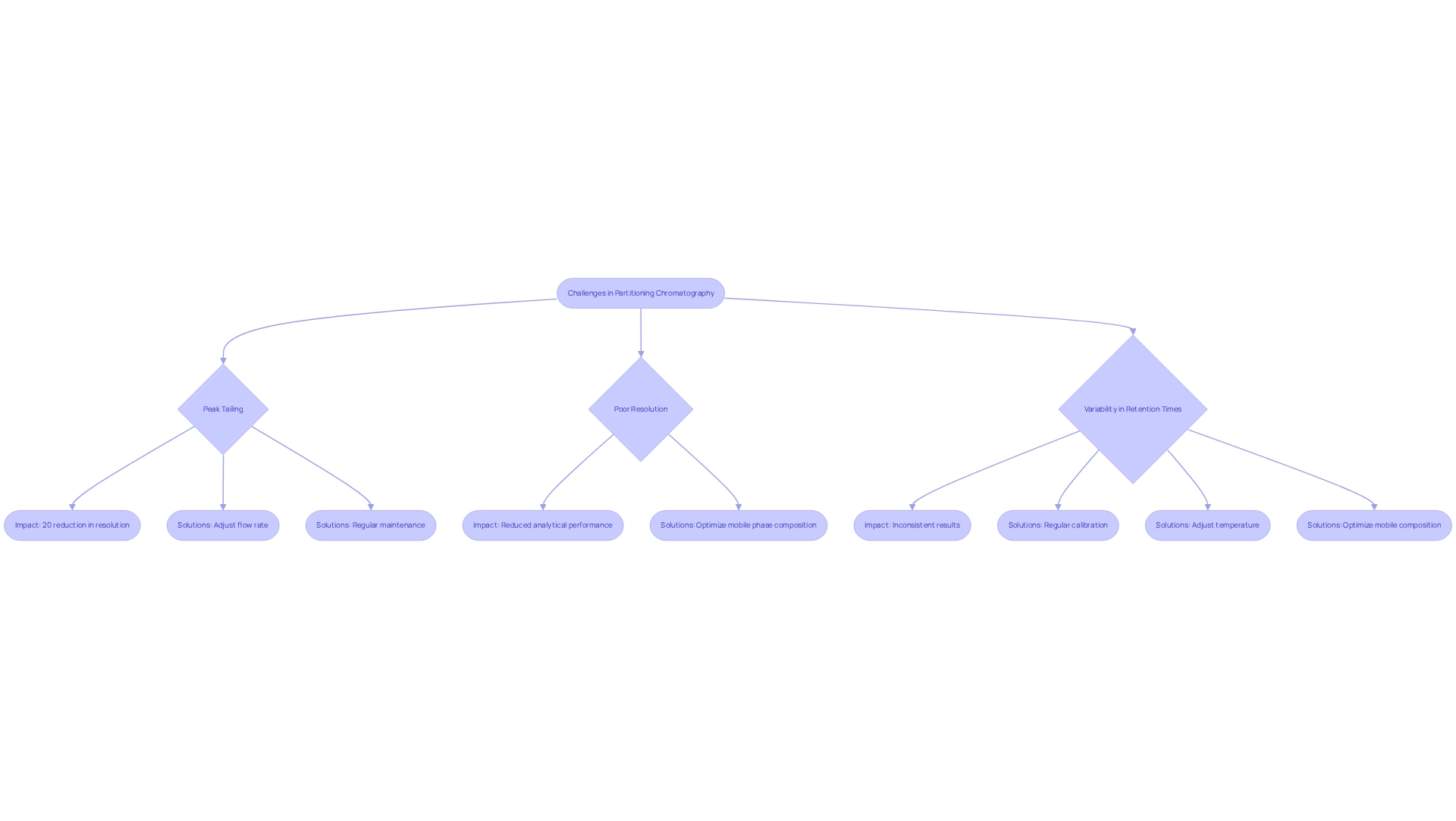

Challenges in Partitioning Chromatography: Troubleshooting Tips

Partitioning chromatography poses significant challenges, such as peak tailing, poor resolution, and variability in retention times. To effectively troubleshoot these issues, laboratories must prioritize the maintenance of their columns and ensure that the mobile mixture is free from contaminants. Adjustments to critical parameters—such as flow rate, temperature, and mobile composition—can substantially mitigate these challenges. Regular calibration and maintenance of equipment are essential for achieving consistent performance in partitioning chromatography.

Statistics reveal that peak tailing can result in a 20% reduction in resolution, highlighting the urgency of addressing this issue promptly. Moreover, the Eco mode of the ICPMS-2040 Series significantly reduces gas consumption during standby, underscoring the importance of efficiency enhancements in analytical processes.

Real-world examples illustrate that optimizing the mobile phase composition can improve resolution by up to 30%, demonstrating the profound impact of methodical adjustments. Additionally, a case study titled "Applications of Chromatographic Techniques" showcases the extensive use of these methods in drug development and environmental monitoring, emphasizing the necessity of addressing separation science challenges in practical applications.

Insights from separation specialists stress the importance of routine checks on column performance in partitioning chromatography, as neglect can exacerbate prevalent issues. Recent developments highlight successful strategies for overcoming scale-up challenges in chromatographic processes, particularly relevant for lab managers seeking to optimize their methodologies. By remaining informed about the latest advancements in separation techniques and implementing best practices, laboratories can enhance their analytical capabilities and ensure reliable results.

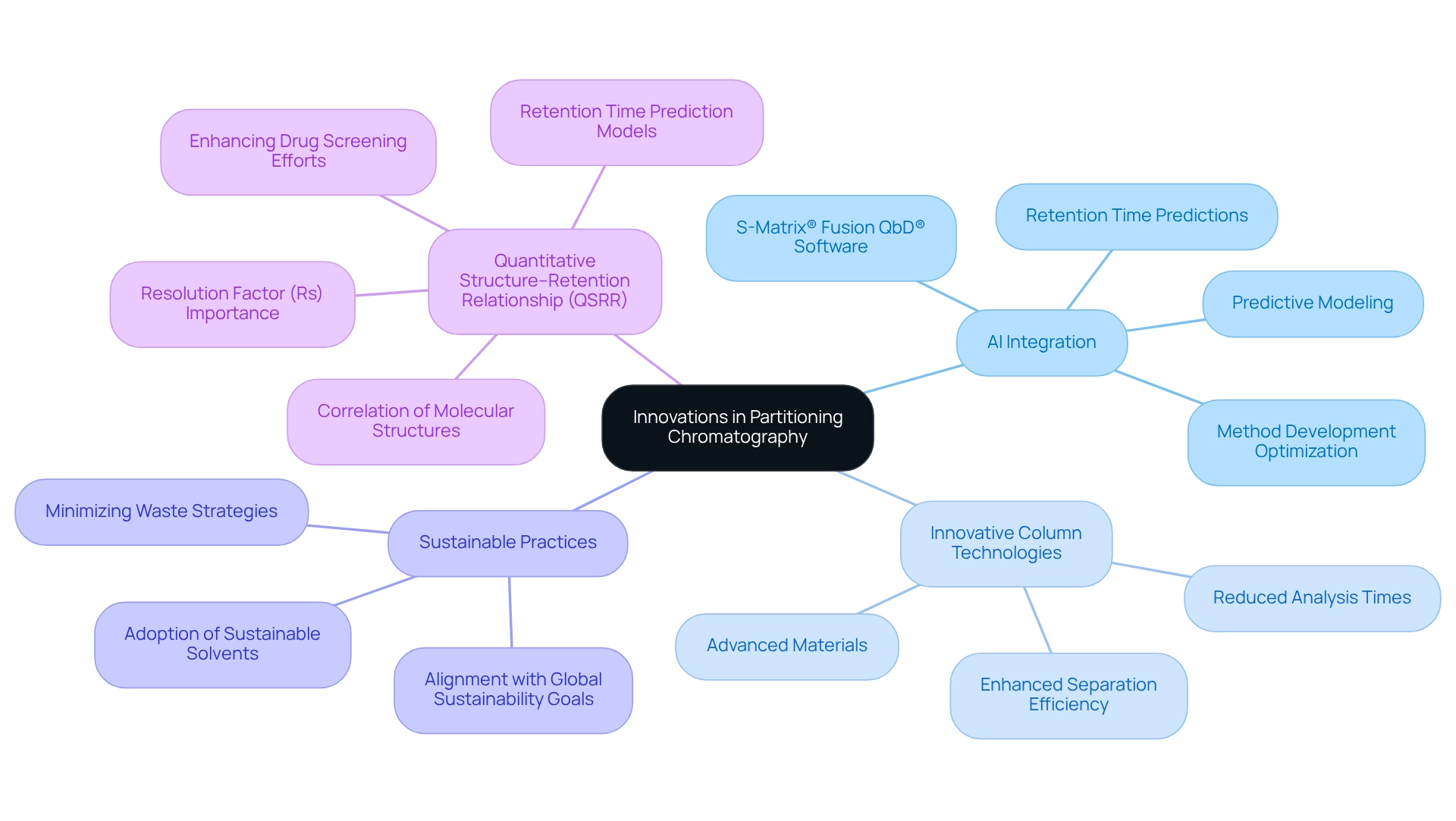

Innovations in Partitioning Chromatography: Future Trends

The future of partitioning chromatography techniques is on the brink of transformative advancements, especially with the integration of artificial intelligence (AI) in method development and optimization. AI is set to streamline workflows, enhance predictive modeling, and improve the accuracy of retention time predictions, thus facilitating more efficient chromatographic analyses. Innovations in column technology, featuring advanced materials and designs, are anticipated to significantly boost separation efficiency while concurrently reducing analysis times. Notably, the S-Matrix® Fusion QbD® software, compatible with Thermo Scientific HPLC systems, exemplifies the quality-by-design approach to method development that is increasingly vital in the industry.

Furthermore, the industry is witnessing a shift towards more environmentally friendly separation techniques. This includes the adoption of sustainable solvents and strategies aimed at minimizing waste, aligning with global sustainability goals. As laboratories increasingly prioritize environmental responsibility, these innovations are becoming essential in the development of new methodologies.

Recent case studies, such as the exploration of Quantitative Structure–Retention Relationship (QSRR) in analytical processes, underscore the potential of AI to correlate molecular structures with retention behaviors, thereby enhancing drug screening efforts and compound identification. This integration of AI not only addresses existing limitations in retention time prediction but also proposes innovative strategies for future research in chromatographic analysis. The outcomes of QSRR studies emphasize the importance of achieving resolution factor (Rs) values above 1.5 to ensure well-separated peaks and superior purity, which are critical for pharmaceutical applications.

As we approach 2025, the convergence of these trends—AI integration, innovative column technologies, and sustainable practices—will revolutionize partitioning chromatography, enhancing its efficiency, accuracy, and environmental sustainability. As a leading researcher in the field remarked, "In analytical chemistry, time is a luxury that few can afford; this technique bridges that gap, providing prompt results that inform crucial decision-making.

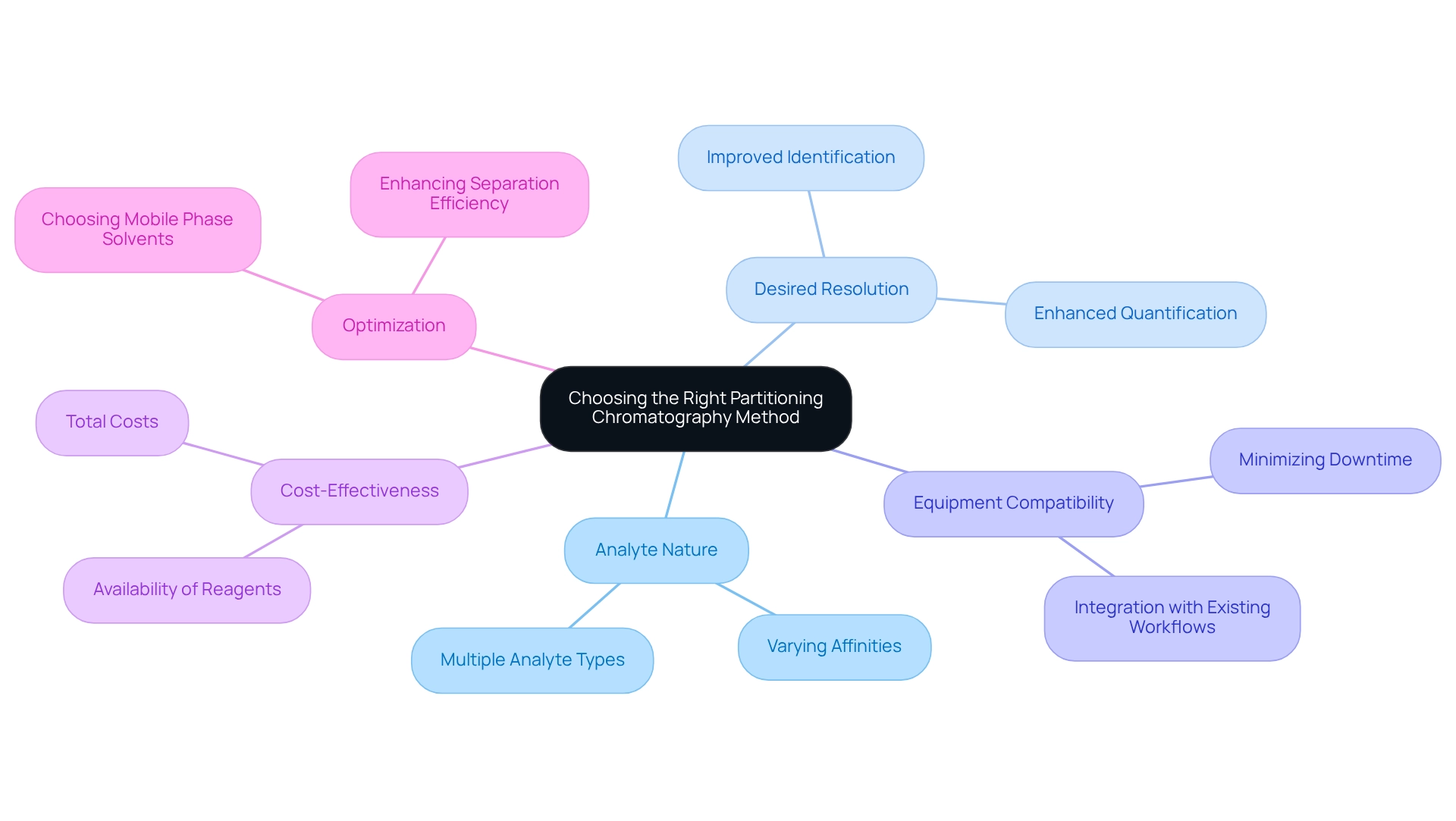

Choosing the Right Partitioning Chromatography Method: Key Considerations

Choosing the appropriate technique for partitioning chromatography requires a careful evaluation of several essential factors. Understanding the nature of the analytes is paramount; different analytes may exhibit varying affinities for stationary and mobile phases, significantly impacting separation efficiency. Desired resolution is also a critical factor, as higher resolution often leads to improved identification and quantification of components within complex mixtures. As one expert noted, "In analytical chemistry, the balance between art and science is where this technique flourishes," emphasizing the complexities involved in method selection.

Laboratories must evaluate the compatibility of the selected separation technique with existing equipment and workflows. This ensures seamless integration and minimizes downtime, which can be exacerbated by maintenance or calibration issues. Instrument downtime can prolong the period before results are achieved, making it essential to choose a separation technique that enhances overall efficiency in the lab. Cost-effectiveness is similarly significant; assessing the total costs related to various separation techniques, including the availability of essential reagents and supplies, assists laboratories in optimizing their budgets while attaining dependable results.

Insights from separation technique experts highlight the importance of assessing analyte compatibility with the chosen method. Real-world scenarios often involve mixtures containing multiple analyte types, which complicates the application of partitioning chromatography. For instance, in reversed phase chromatography, the hydrophobic retention phenomenon allows non-polar constituents to be retained while more polar constituents elute faster, underscoring the necessity of selecting appropriate mobile phase solvents for effective separation.

Furthermore, understanding and optimizing resolution can lead to improved identification, enhanced quantification, and increased confidence in analytical results. In summary, a thorough evaluation of analyte nature, resolution needs, and method compatibility, alongside considerations of cost and available resources, is crucial for laboratories aiming to enhance their chromatographic analyses.

Conclusion

Partitioning chromatography stands as a cornerstone of analytical chemistry, representing a crucial technique for the separation and analysis of complex mixtures. This article has examined the foundational principles of partitioning chromatography, emphasizing the importance of the partition coefficient and the optimization of mobile phases to enhance chromatographic performance. Additionally, the critical roles of temperature and pressure have been highlighted, demonstrating how these variables can be fine-tuned to achieve superior results in analytical applications.

Moreover, the article has addressed the diverse techniques within partitioning chromatography, including liquid-liquid chromatography (LLC) and gas-liquid chromatography (GLC), showcasing their specific applications in fields such as pharmaceuticals and environmental testing. Insights into the challenges faced in this domain, along with troubleshooting tips, underscore the necessity of meticulous method development and adherence to best practices for reliable outcomes.

As the industry evolves, the integration of innovations such as artificial intelligence and sustainable practices is poised to redefine partitioning chromatography. These advancements not only enhance efficiency and accuracy but also align with the increasing demand for environmentally responsible methodologies. With a comprehensive understanding of the principles and trends outlined, laboratories can navigate the complexities of partitioning chromatography more effectively, ultimately enhancing the reliability and safety of their analytical results.

In conclusion, the ongoing commitment to innovation and precision in partitioning chromatography underscores its indispensable role in analytical chemistry. As laboratories continue to adopt advanced methodologies and technologies, they will be well-equipped to meet the rigorous demands of modern scientific inquiry, ensuring that the future of partitioning chromatography remains both bright and impactful.