Overview

The article delineates seven essential strategies for the effective utilization of normal phase columns in chromatography. It emphasizes critical aspects such as packing techniques, mobile phase selection, and temperature control. Each strategy is underpinned by insights into how these elements enhance separation efficiency and reliability in analytical results. Furthermore, it highlights the significance of comprehending compound properties and prioritizing quality control within laboratory practices, ultimately reinforcing the necessity for high-quality scientific instruments in achieving optimal outcomes.

Introduction

The world of chromatography is evolving rapidly, with high-performance normal phase columns leading this transformation. As laboratories seek precision and reliability in their analyses, grasping the nuances of effective chromatography techniques is essential. This article explores seven key strategies that not only enhance the efficiency of normal phase columns but also tackle the challenges encountered by professionals in the field.

How can laboratories optimize their processes to achieve superior separation outcomes while navigating the complexities of modern analytical demands?

JM Science: High-Performance Normal Phase Columns for Reliable Chromatography

JM Science Inc. delivers a comprehensive array of high-performance materials for the normal phase column, which are crucial for achieving reliable chromatography. These materials are meticulously designed to provide precise separation across various applications, particularly within pharmaceutical and chemical laboratories. By leveraging advanced materials and innovative production techniques, JM Science guarantees dependable results, establishing its offerings as a trusted choice for laboratories committed to precision in their testing protocols.

The standard chromatography market is projected to capture a significant share, with an anticipated market value reaching USD 1.8 billion by 2033. This growth is driven by the increasing demand for reliable analytical methods in pharmaceutical analysis. High-performance normal phase column materials offer notable advantages, including enhanced resolution and sensitivity, which are essential for meeting stringent regulatory standards in drug development and quality assurance.

Successful applications of these materials include:

- The purification of active pharmaceutical ingredients (APIs) like paclitaxel

- The integration of the AQ-300 Coulometric Karl Fischer Titrator

- The AQV-300 Volumetric Titrator in drug and medicine testing

These implementations align with the Japanese Pharmacopoeia standards and significantly bolster the overall reliability of pharmaceutical analyses.

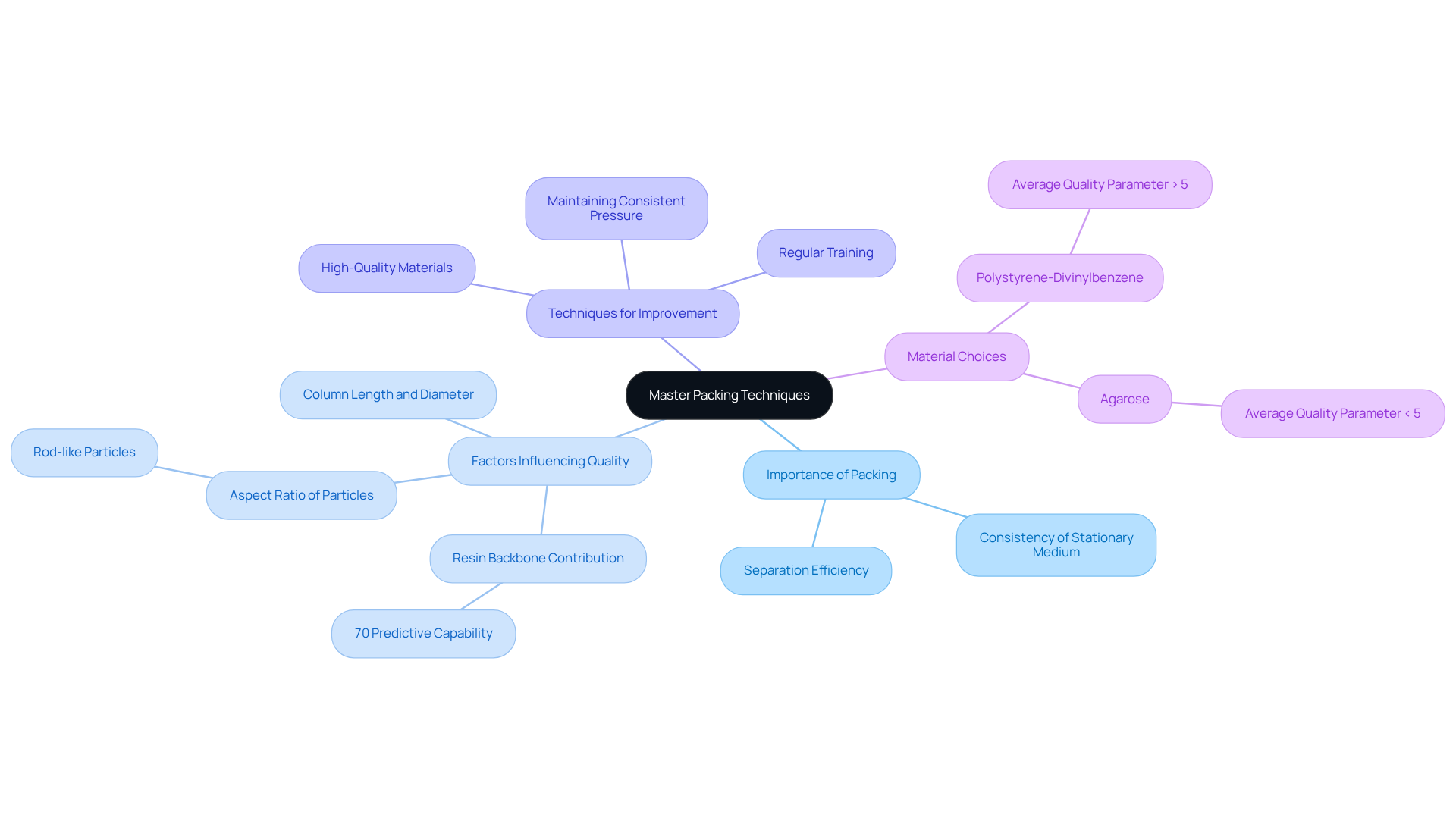

Master Packing Techniques: Ensure Optimal Performance in Normal Phase Columns

Mastering packing methods is crucial for achieving optimal performance in standard setups. Well-packed structures not only reduce channeling but also enhance the consistency of the stationary medium, a vital factor for improved separation efficiency. Studies indicate that the resin backbone contributes approximately 70% to the predictive capability regarding packing quality, as derived from an analysis of packing quality metrics. Techniques such as maintaining consistent pressure during packing and utilizing high-quality materials can significantly lower height equivalent to a theoretical plate (HETP) values, which are critical for effective separation.

For example, the average packing quality parameter for polystyrene-divinylbenzene exceeds 5, while agarose falls well below this threshold, underscoring the impact of material choice. Regular training and adherence to best practices are essential for laboratory personnel to maintain high standards in packing, as stability in packing quality has been observed over time. Implementing these strategies not only enhances the performance of the normal phase column but also contributes to reproducibility and reliability in analytical results, ultimately supporting advancements in research and healthcare.

Choose the Right Mobile Phase: Enhance Separation Efficiency in Normal Phase Chromatography

Selecting the appropriate mobile component is crucial for enhancing separation effectiveness in normal phase column analysis. The polarity of the mobile component must complement that of the stationary component to facilitate optimal interactions with the analytes. Common solvents employed in standard procedures include:

- Hexane

- Ethyl acetate

- Dichloromethane

These solvents play a vital role in this process. A thorough understanding of the solubility and polarity of the compounds under analysis will guide the selection of the most effective normal phase column for the mobile phase. This, in turn, leads to improved resolution and peak shapes, underscoring the importance of careful selection in analytical procedures.

Understand Compound Properties: Tailor Your Approach for Effective Chromatography

To attain efficient separation techniques, understanding the properties of the compounds being analyzed is paramount. Factors such as:

- Polarity

- Molecular weight

- Functional groups

significantly influence retention times and separation efficiency. By customizing the separation technique based on these properties, laboratories can enhance their methods for specific applications. This tailored approach not only results in more precise outcomes but also fosters consistency across analyses. Ultimately, leveraging these insights is essential for laboratories aiming to achieve superior results in their separation processes.

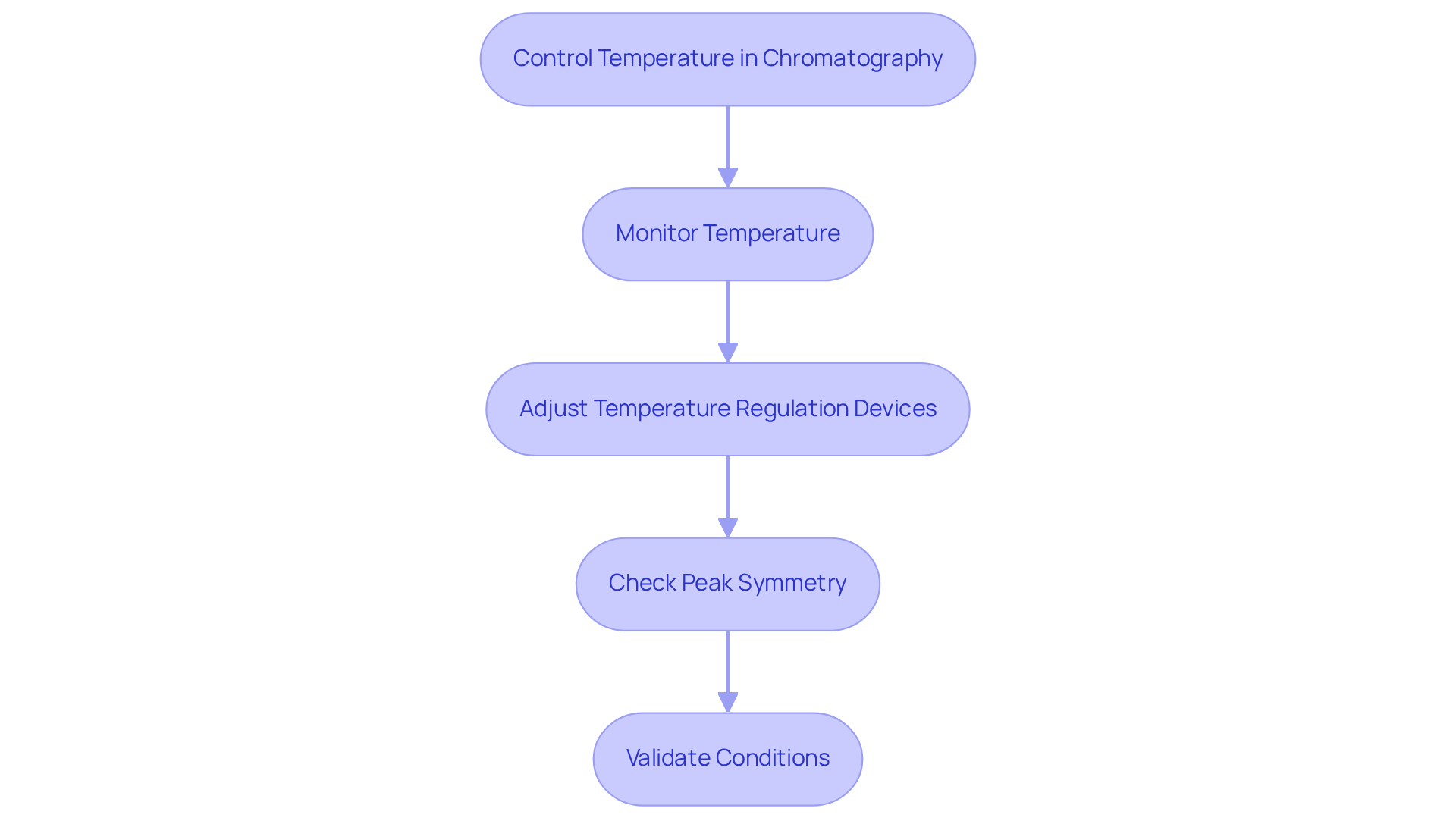

Control Temperature: Optimize Conditions for Sensitive Compounds in Chromatography

Controlling temperature during chromatography is essential for optimizing conditions, especially for sensitive compounds that may degrade or react under varying temperatures. A consistent temperature enhances the stability of analytes and improves peak resolution. Fluctuations in temperature can lead to unpredictable results, such as peak broadening and shifts in retention times, ultimately compromising analytical outcomes. Therefore, laboratories must invest in temperature-controlled environments and regularly monitor conditions to ensure they remain within the optimal range for their specific applications.

Frequent adjustments of temperature regulation devices are crucial to guarantee that the designated temperature aligns with the actual temperature of the apparatus. Moreover, poor peak symmetry can significantly impact the accuracy and reliability of both quantitative and qualitative analyses. While high temperatures can enhance resolution in chromatography, they may also reduce selectivity. This makes it imperative for lab managers to carefully consider these factors. Manual checks and validations are necessary to prevent temperature fluctuations that could jeopardize results.

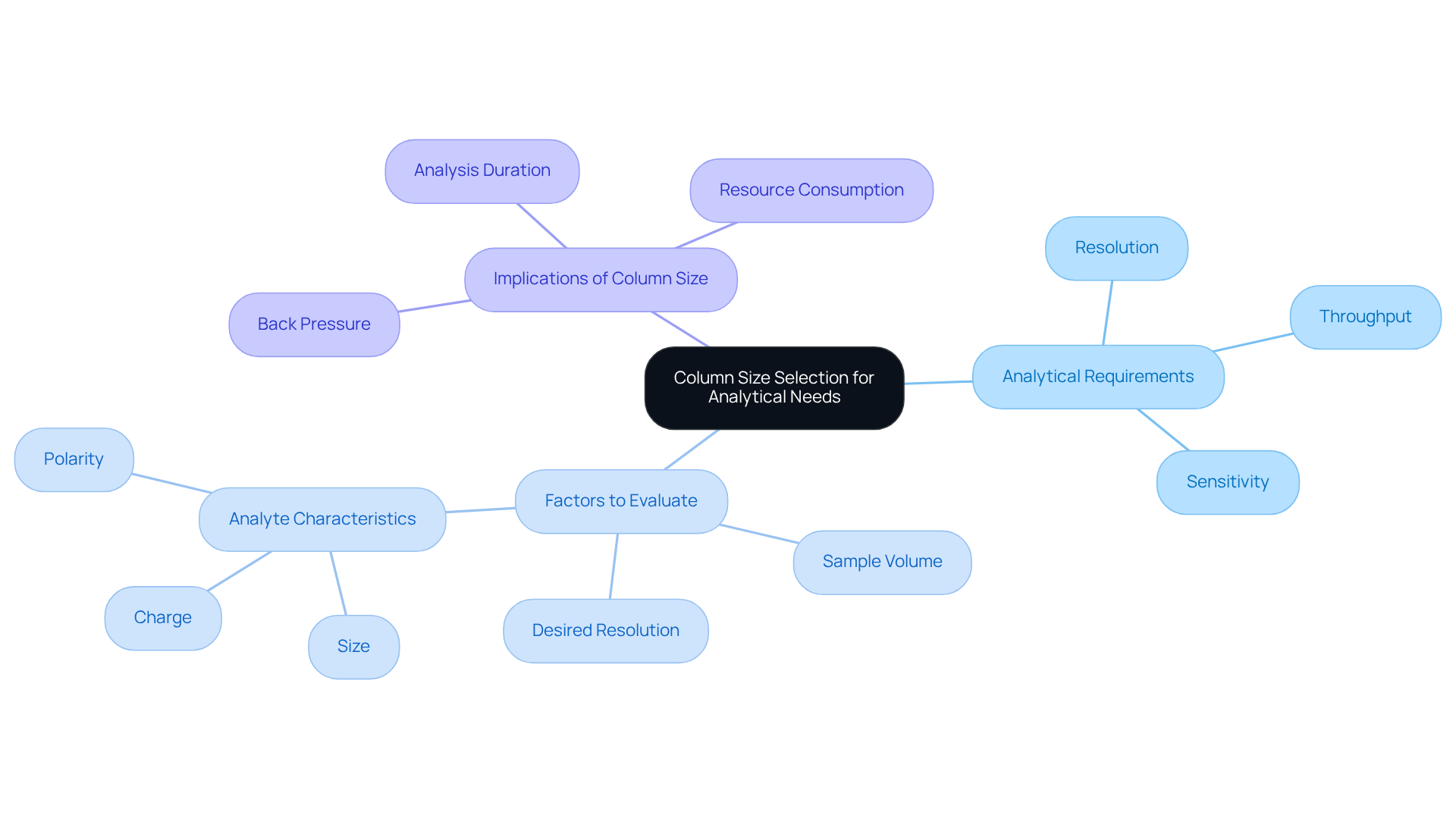

Select the Right Column Size: Match Your Equipment to Your Analytical Needs

Selecting the appropriate dimension size is essential for aligning your equipment with analytical requirements. The dimensions of the normal phase column—length and diameter—are pivotal in determining both resolution and throughput. For instance, longer tubes, generally exceeding 250mm, significantly enhance resolution in pharmaceutical analysis; however, they may also lead to increased back pressure and longer analysis durations. Conversely, shorter structures under 50mm are ideal for rapid separations, making them suitable for screening applications.

Laboratories must evaluate several factors when choosing size options, including:

- Sample volume

- Desired resolution

- Characteristics of the analytes

Narrower tubes (2.1mm or less) provide greater sensitivity and require smaller sample sizes and solvents, which can effectively reduce resource consumption. In contrast, broader sections necessitate larger samples but may compromise sensitivity.

The van Deemter equation illustrates how tube length influences resolution, emphasizing that while longer sections can enhance separation quality, they also introduce practical limitations such as increased back pressure and extended analysis durations. Properly aligning specifications with research objectives not only enhances performance but also improves efficiency in separation techniques that utilize a normal phase column. By comprehending the implications of column dimensions on analytical throughput and results, laboratories can make informed decisions that lead to superior separation quality and operational effectiveness.

Differentiate Between Normal Phase and Reverse Phase: Make Informed Method Choices

Distinguishing between normal and reverse processes is essential for informed method selection in chromatography. Standard normal phase column separation techniques excel with polar compounds, utilizing a non-polar solvent like n-hexane to facilitate interactions with polar stationary materials, such as silica. This method proves particularly advantageous for separating analytes sensitive to aqueous conditions, making it ideal for applications involving sugars, amino acids, and certain environmental samples.

Conversely, reverse phase chromatography is favored for non-polar analytes, relying on hydrophobic interactions with modified silica particles in a mobile phase typically composed of water and organic solvents. This approach is widely utilized in pharmaceutical laboratories due to its flexibility, high reproducibility, and cost-efficiency—factors that are crucial for strict testing procedures and regulatory compliance.

Understanding the characteristics of the compounds and the desired separation outcomes is vital for optimizing analytical workflows. For instance, when handling positional isomers or chiral compounds, using a normal phase column may offer improved control over minor polarity variations. In contrast, reverse mode often serves as the primary option for a diverse range of compounds. However, switching between normal and reverse phase separation techniques can present challenges, such as variations in sample solubility and the necessity for method redevelopment. By leveraging the strengths of each method and considering factors like solubility and regulatory limits, laboratories can enhance their analytical capabilities and achieve reliable results.

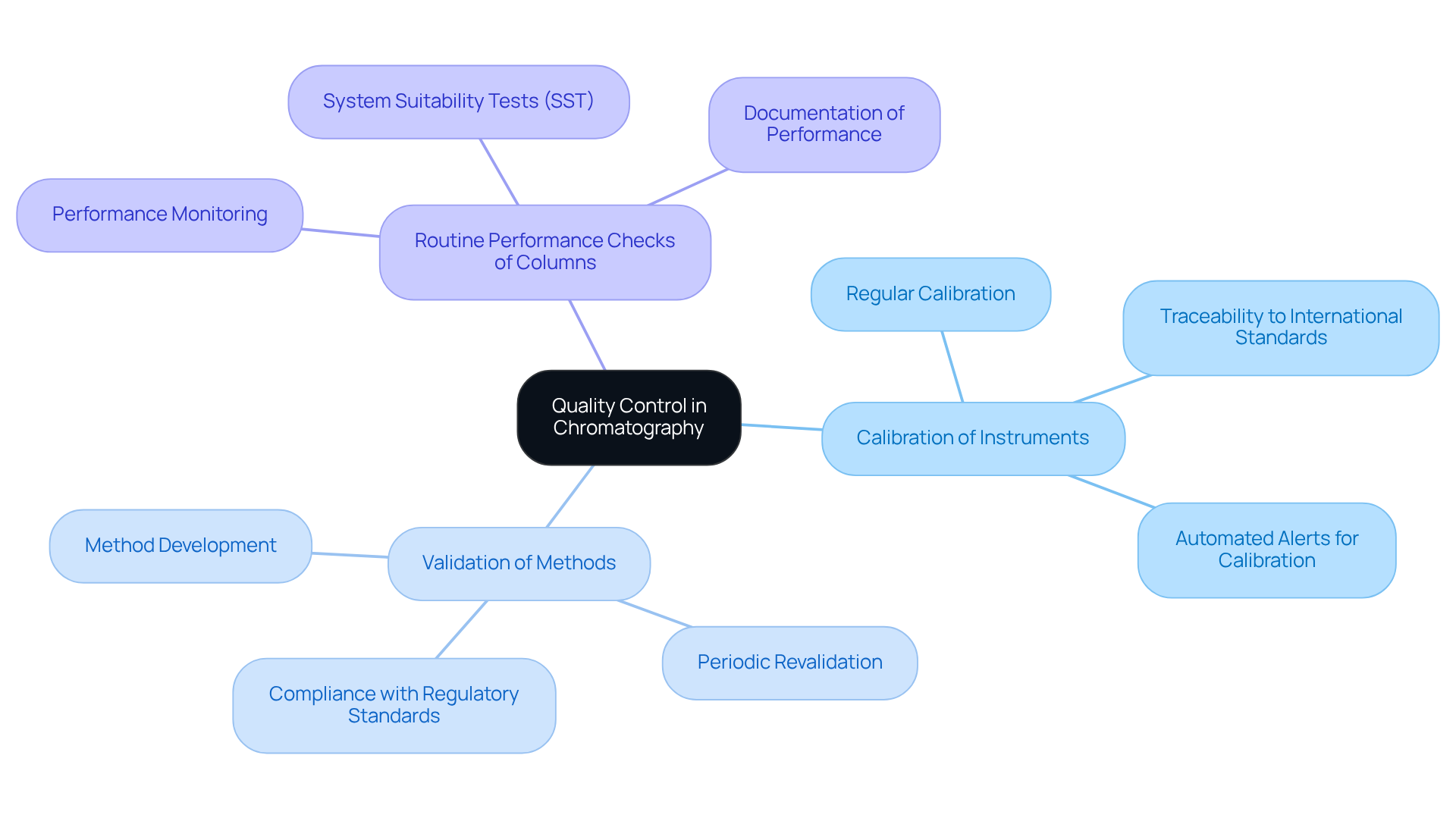

Prioritize Quality Control: Ensure Compliance in Chromatography Practices

Prioritizing quality control in chromatography practices is essential for ensuring compliance with regulatory standards and achieving reliable results. Laboratories must implement robust quality control measures, including:

- Regular calibration of instruments

- Validation of methods

- Routine performance checks of columns

Upholding high standards in quality control not only boosts laboratory credibility but also guarantees the precision of testing results. By committing to these practices, laboratories can enhance their operational integrity and foster trust among stakeholders.

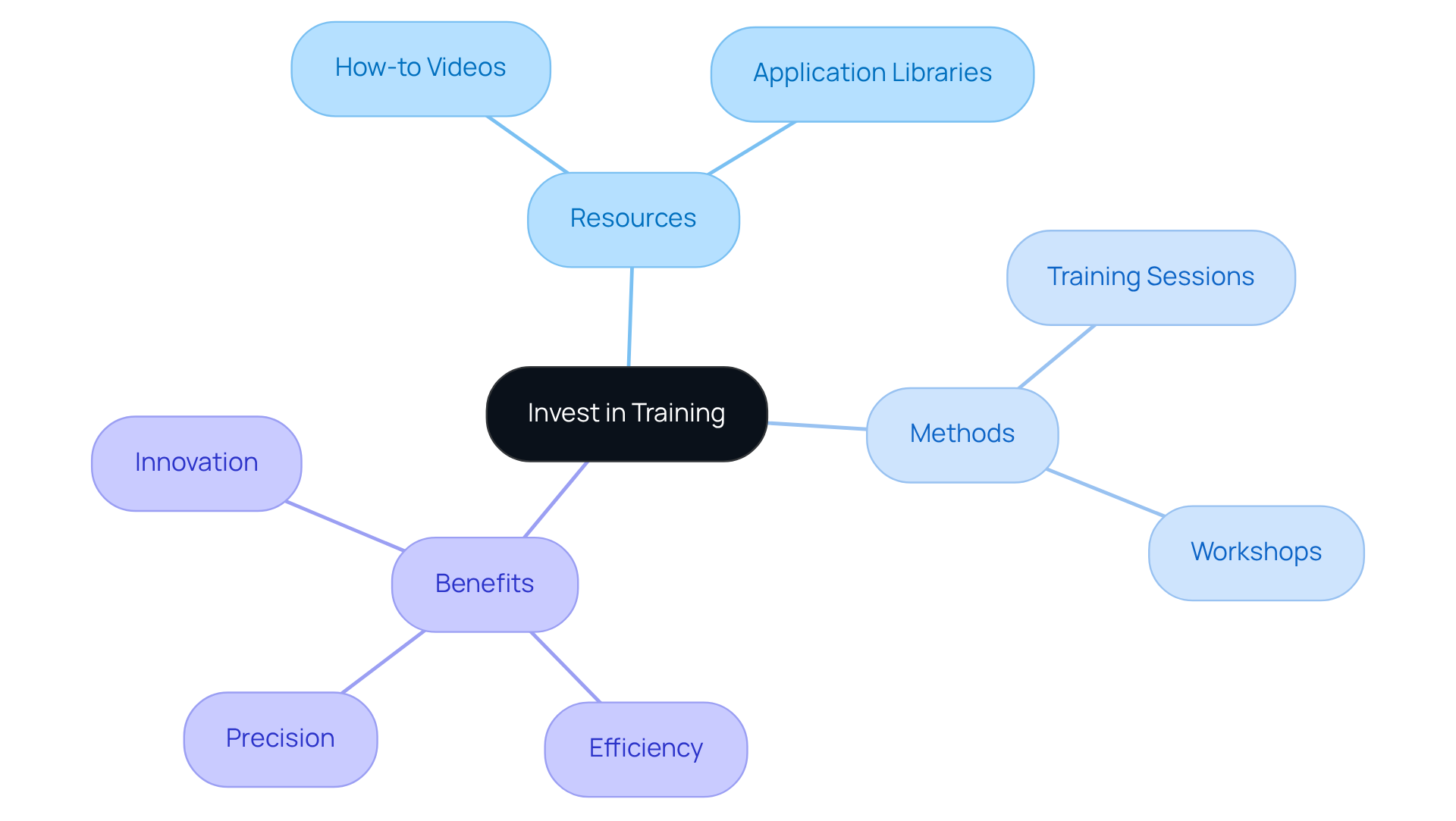

Invest in Training: Equip Your Team with the Latest Chromatography Knowledge

Investing in training for laboratory staff is essential for equipping your team with the latest separation techniques and knowledge. JM Science Inc. is committed to quality and customer support, offering valuable resources such as how-to videos and application libraries that enhance the skills of laboratory personnel. Regular training sessions, workshops, and access to these online resources significantly boost efficiency and precision in evaluation processes.

By fostering a culture of ongoing education, laboratories can adapt to advancements in separation science, ensuring they maintain high operational standards. This dedication to continuous learning not only empowers staff but also drives innovation and excellence in laboratory practices.

As Albert Einstein wisely noted, 'Wisdom is not a product of schooling but of the lifelong attempt to acquire it,' underscoring the critical role of continuous learning in achieving success.

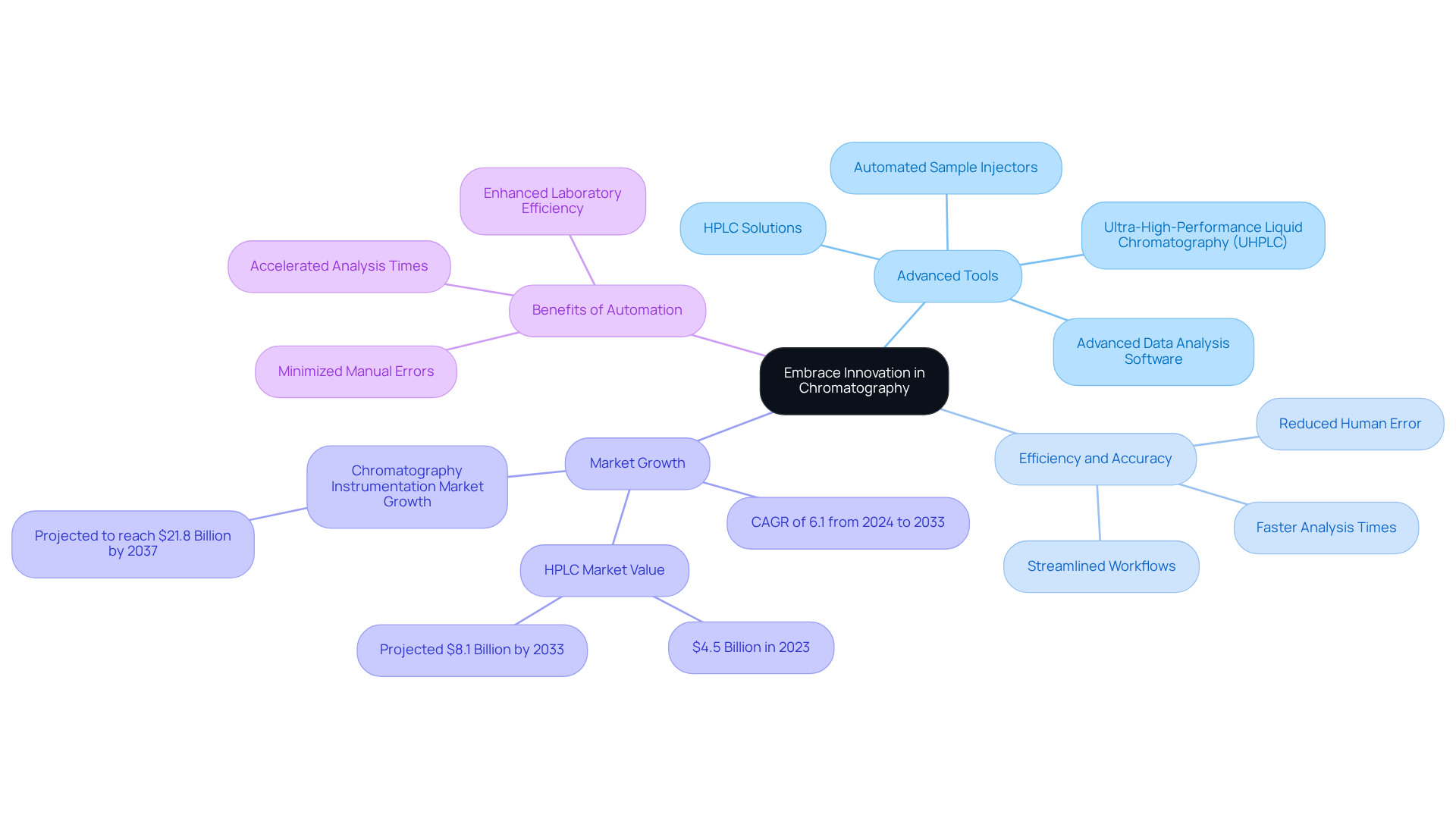

Embrace Innovation: Utilize Advanced Tools for Enhanced Chromatography Results

Embracing innovation in separation techniques is essential for leveraging advanced tools that enhance analytical results. JM Science Inc. offers a diverse range of premium HPLC solutions, including high-performance liquid separation solutions such as normal phase columns and accessories, which are crucial for optimizing separation processes. Technologies such as automated sample injectors, advanced data analysis software, and advancements in Ultra-High-Performance Liquid Chromatography (UHPLC) significantly boost both the efficiency and accuracy of these processes.

The integration of automation features in HPLC systems, particularly those provided by JM Science, streamlines workflows, minimizes human error, and accelerates analysis times—factors that are vital in various scientific fields, including pharmaceutical laboratories, medical diagnostics, and academic research.

Furthermore, the chromatography instrumentation market is projected to grow at a CAGR of over 7.1% from 2025 to 2037, with the HPLC market valued at $4.5 billion in 2023 and expected to reach approximately $8.1 billion by 2033. Laboratories should actively seek out and invest in these innovations, including JM Science's offerings, to optimize their workflows and achieve superior results in their analytical endeavors.

Conclusion

Mastering the use of normal phase columns is essential for achieving reliable and efficient chromatography results. By implementing key strategies—such as selecting the right mobile phase, understanding compound properties, and maintaining optimal packing techniques—laboratories can significantly enhance their analytical capabilities. These practices not only improve separation efficiency but also ensure compliance with stringent regulatory standards, making them vital for pharmaceutical and chemical applications.

The article highlights several critical components that contribute to effective normal phase chromatography. From the importance of temperature control to the careful selection of column dimensions, each aspect plays a crucial role in maximizing performance. Additionally, the distinction between normal and reverse phase methods provides valuable insights for laboratories seeking to optimize their workflows based on the specific characteristics of the compounds being analyzed.

In conclusion, embracing innovation and prioritizing continuous training are paramount for laboratories aiming to stay at the forefront of chromatography advancements. By investing in high-performance materials and advanced technologies, such as those offered by JM Science, laboratories can enhance their operational efficiency and achieve superior results. The commitment to quality control and ongoing education will ultimately foster a culture of excellence in analytical practices, paving the way for reliable and reproducible outcomes in the ever-evolving field of chromatography.