Overview

This article addresses the critical issue of HPLC peak tailing often faced in pharmaceutical laboratories. It presents a comprehensive overview of effective solutions designed to mitigate this challenge. Key strategies include:

- The implementation of specialized column supports

- Adjustments to the mobile phase

- Adherence to routine maintenance practices

Collectively, these approaches significantly enhance chromatographic performance and ensure the accuracy of analytical results. By tackling the pervasive problem of peak tailing, laboratories can achieve more reliable outcomes in their analyses.

Introduction

Addressing HPLC peak tailing is crucial for pharmaceutical laboratories striving to maintain analytical precision and reliability. This common issue can lead to distorted results and compromised data integrity. Therefore, understanding the underlying causes and exploring effective solutions is essential.

What innovative strategies can laboratories implement to mitigate peak tailing and ensure accurate quantification in their analyses? By tackling this challenge head-on, laboratories can enhance their analytical capabilities and uphold the highest standards of data integrity.

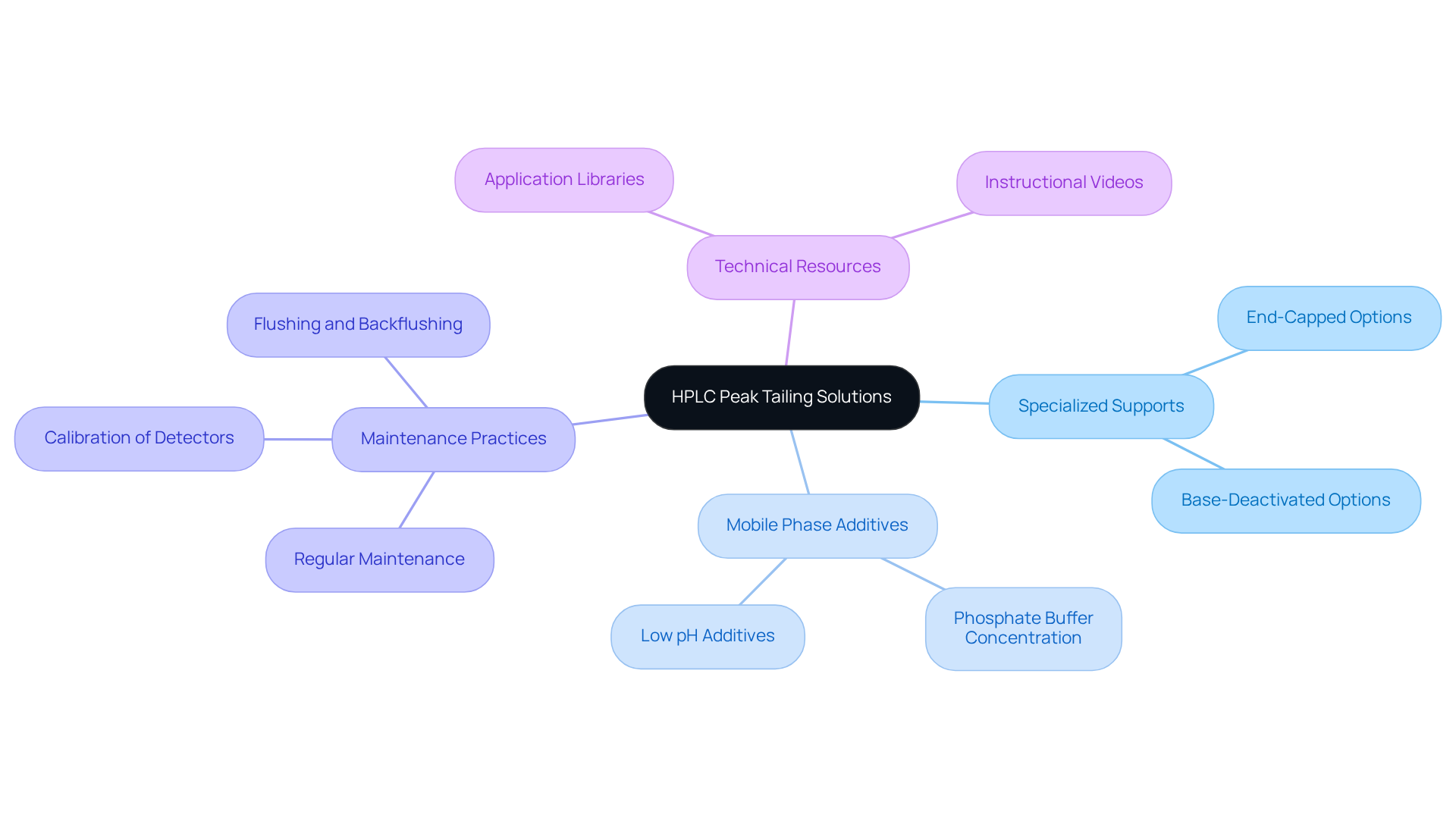

JM Science HPLC Solutions: Addressing Peak Tailing Issues

JM Science delivers a comprehensive array of HPLC solutions meticulously engineered to address the issue of HPLC peak tailing, a common challenge faced in pharmaceutical laboratories. Their specialized supports, including end-capped and base-deactivated options, significantly mitigate interactions with residual silanol groups, which often lead to HPLC peak tailing. For instance, the utilization of highly deactivated supports can markedly enhance signal shape by minimizing secondary interactions, as evidenced by case studies that demonstrate the efficacy of these supports in improving chromatographic performance.

Beyond specialized columns, JM Science underscores the importance of mobile phase additives in fine-tuning chromatographic performance. Increasing the phosphate buffer concentration from 10 mM to 25 mM at pH 7.0 has been shown to reduce maximum distortion, particularly for basic analytes. Additionally, low pH additives, such as 0.1% formic acid, play a crucial role in establishing conditions that diminish maximum distortion. Regular maintenance and precise adjustments of chromatography systems are vital for maintaining quality integrity and minimizing distortions, as improper sample preparation and mobile phase formulation can lead to significant issues, including HPLC peak tailing.

To empower users in achieving optimal results, JM Science offers extensive , including application libraries and instructional videos. As noted by Dilshan Kangara, a Quality Control Officer, "Peak accumulation can arise from poor column performance and incorrect pH of the mobile phase." These resources assist laboratory personnel in optimizing their chromatographic setups, ensuring improved shapes and resolutions. By concentrating on innovative solutions and robust support, JM Science positions itself as an essential partner in enhancing analytical accuracy and efficiency within pharmaceutical laboratories.

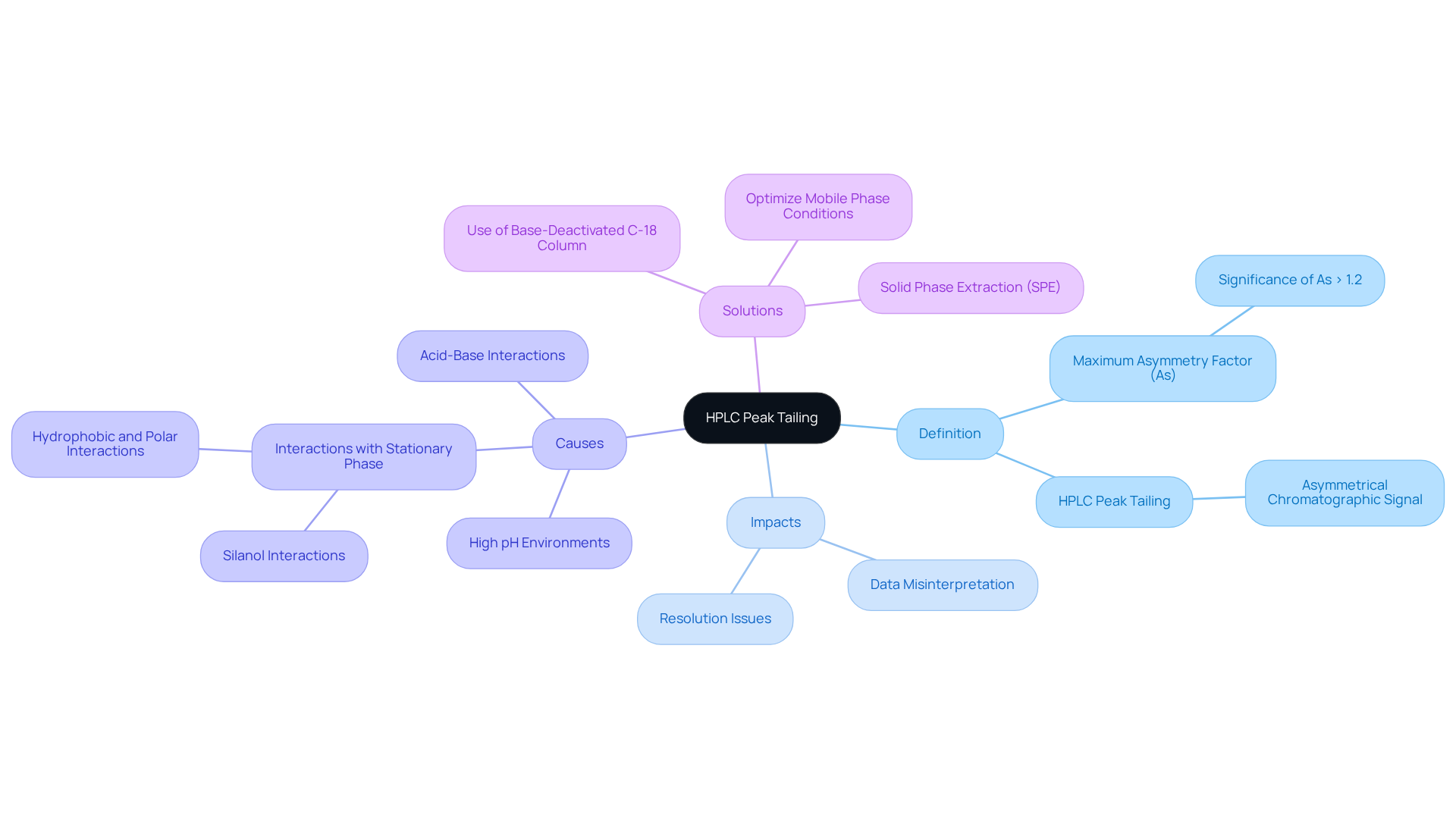

Understanding Peak Tailing in HPLC: Key Concepts

Maximum trailing is characterized by an asymmetrical chromatographic signal, commonly known as HPLC peak tailing, where the rear portion is disproportionately extended compared to the leading edge. This distortion can significantly undermine the accuracy of quantification and can lead to HPLC peak tailing, affecting the resolution of HPLC analyses. The maximum asymmetry factor (As) is a critical indicator of this issue, where values exceeding 1.2 are associated with significant HPLC peak tailing. In pharmaceutical laboratories, where precision is paramount, understanding and addressing HPLC peak tailing is essential for reliable analytical outcomes. A maximum asymmetry factor greater than 1.2 can lead to HPLC peak tailing, resulting in data misinterpretation and adversely affecting the quality of research and product development.

Identifying the causes of maximum depletion, such as interactions between analytes and the stationary phase, is vital for implementing effective solutions. Utilizing a is recommended to mitigate signal distortion, as it minimizes unwanted interactions that contribute to this problem. Furthermore, it is important to recognize that maxima in high-performance liquid chromatography typically exhibit approximately a 5% extension, which underscores the necessity of addressing HPLC peak tailing.

By focusing on enhancing shape profiles and understanding the impacts of high pH environments and acids, laboratories can improve the reliability of their chromatography results. This ensures compliance with the stringent standards required in pharmaceutical applications, ultimately fostering trust in analytical outcomes.

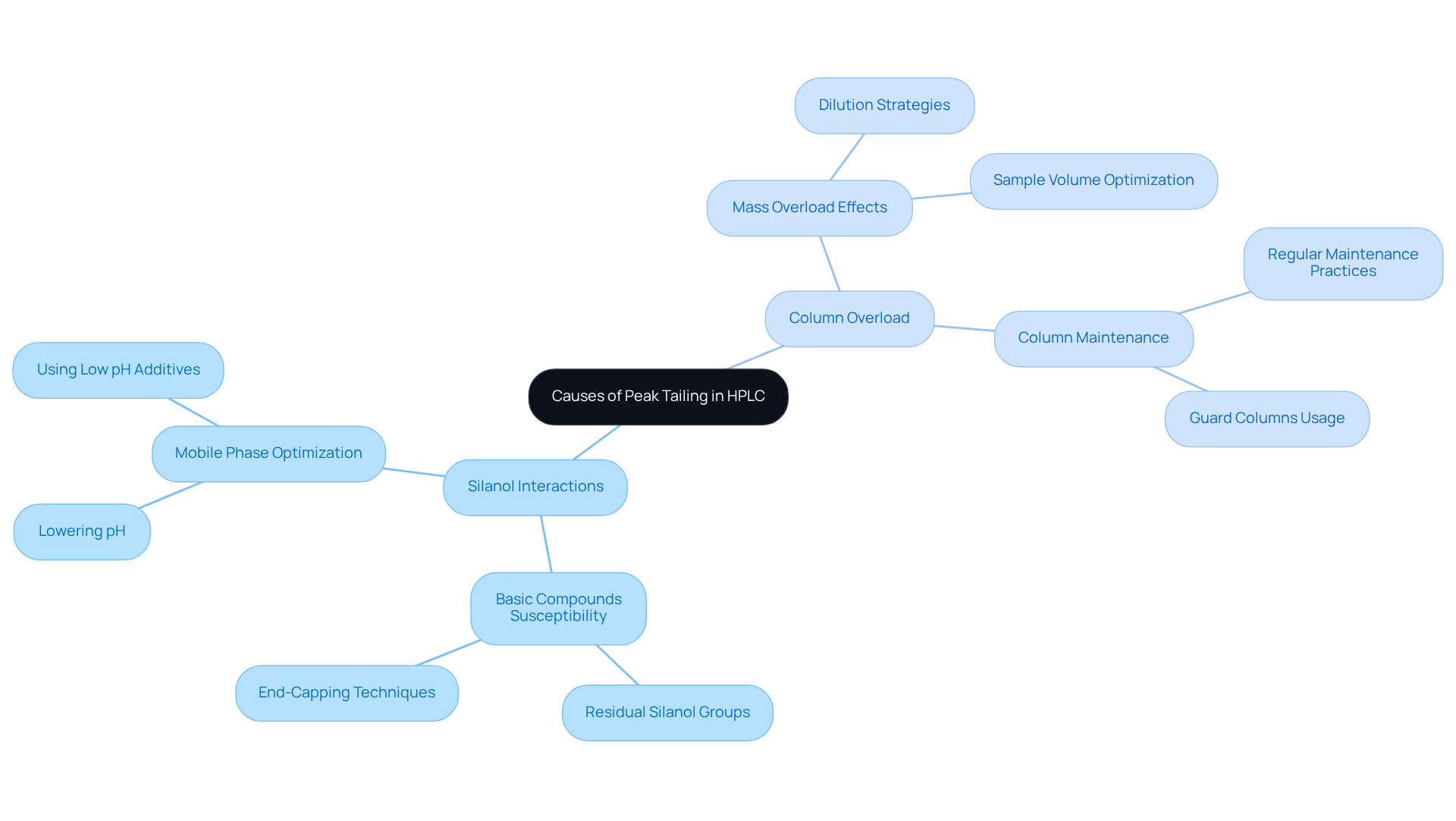

Causes of Peak Tailing: Analyzing Silanol Interactions and Column Overload

Peak distortion in HPLC is frequently associated with interactions between analytes and residual silanol groups present on the stationary phase of the apparatus. Basic compounds are particularly susceptible to these interactions, which can lead to significant distortion of the peak maximum. Additionally, overloading the stationary phase—due to the injection of excessive sample volumes—can exacerbate HPLC peak tailing by altering the expected shapes of the signals. For example, when the sample concentration exceeds the column's capacity, it may result in mass overload, which causes all chromatographic signals to show HPLC peak tailing. This phenomenon underscores the critical need to optimize sample sizes to maintain peak integrity. Diluting the sample can assist in evaluating the shapes of the peak maxima and identifying potential HPLC peak tailing issues.

To illustrate, the implementation of end-capped or base-deactivated structures, which chemically bond free silanol groups with agents such as trimethylsilyl (TMS), has demonstrated effectiveness in reducing these interactions, thereby enhancing peak shapes for basic analytes. Furthermore, advancements in separation technologies since the early 2000s, including the development of silica-based phases capable of operating at elevated pH levels, have significantly mitigated the impact of silanol interactions. Routine maintenance, which includes using guard supports, preparing the mobile phase correctly, and consistently replacing solvent filters to avoid frit blockage, is essential for alleviating these challenges.

Understanding the dynamics of column overload and silanol interactions is vital for of liquid chromatography methods to minimize HPLC peak tailing. As John Dolan aptly stated, "If something in your sample is interacting with the stationary phase in a bad way, add something to the mobile phase that looks like the analyte." By addressing these factors, laboratories can enhance the reliability and accuracy of their chromatographic analyses.

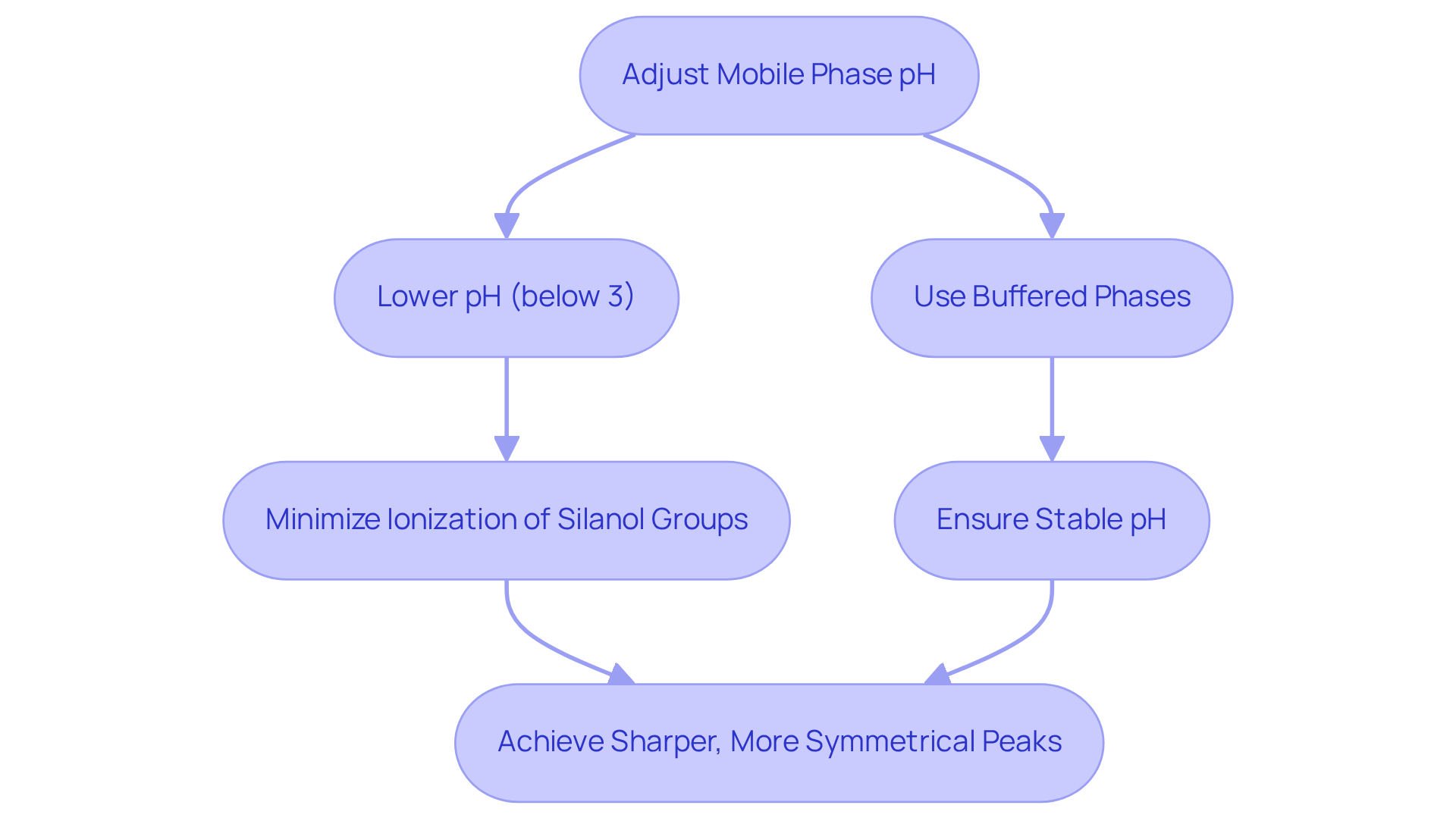

Mobile Phase and pH: Their Role in Peak Tailing

The composition and pH of the mobile phase are pivotal in addressing HPLC peak tailing issues. Operating at a lower pH, typically below 3, effectively suppresses the ionization of silanol groups, thereby minimizing their interaction with basic analytes. This adjustment is essential, as research indicates that even minor changes in pH—especially when close to the analyte’s pK—can lead to substantial alterations in retention time and signal shape, particularly for ionizable compounds.

Furthermore, employing buffered mobile phases ensures stable pH throughout the analysis, which is crucial for consistent performance. For instance, incorporating triethylamine into the mobile phase formulation has been shown to enhance shape and reduce HPLC peak tailing. Under , both trimethoprim and sulfamethoxazole demonstrate appropriate symmetry and width, underscoring the effectiveness of pH modifications.

It is also critical to note that if a peak exhibits a Symmetry Factor (As) greater than 1.0, it is considered skewed, increasing the likelihood of false positives and negatives in results. By strategically adjusting these parameters, laboratories can achieve sharper, more symmetrical maxima, ultimately leading to more precise and reliable analytical outcomes.

Column Selection and Maintenance: Preventing Peak Tailing

Selecting the appropriate is crucial for minimizing broadening. It is advisable to use columns with end-capped or base-deactivated phases, as these significantly reduce interactions with silanol groups. Routine maintenance, which includes proper cleaning and storage of structures, is vital to prevent contamination and deterioration that can lead to maximum residue. Notably, research indicates that 43% of participants possess structures that last for at least 18 months, highlighting the benefits of diligent maintenance.

Additionally, employing high-purity silica-based materials with low trace metal content can mitigate peak tailing effects. Establishing a regular maintenance schedule is imperative, especially considering that 17% of users do not track lifespan on a monthly basis. By prioritizing these maintenance practices, laboratories can significantly enhance the performance and reliability of their HPLC systems, ultimately leading to improved analytical outcomes.

As Tony Taylor emphasizes, minimizing extraneous column effects is essential for maintaining efficiency.

![]()

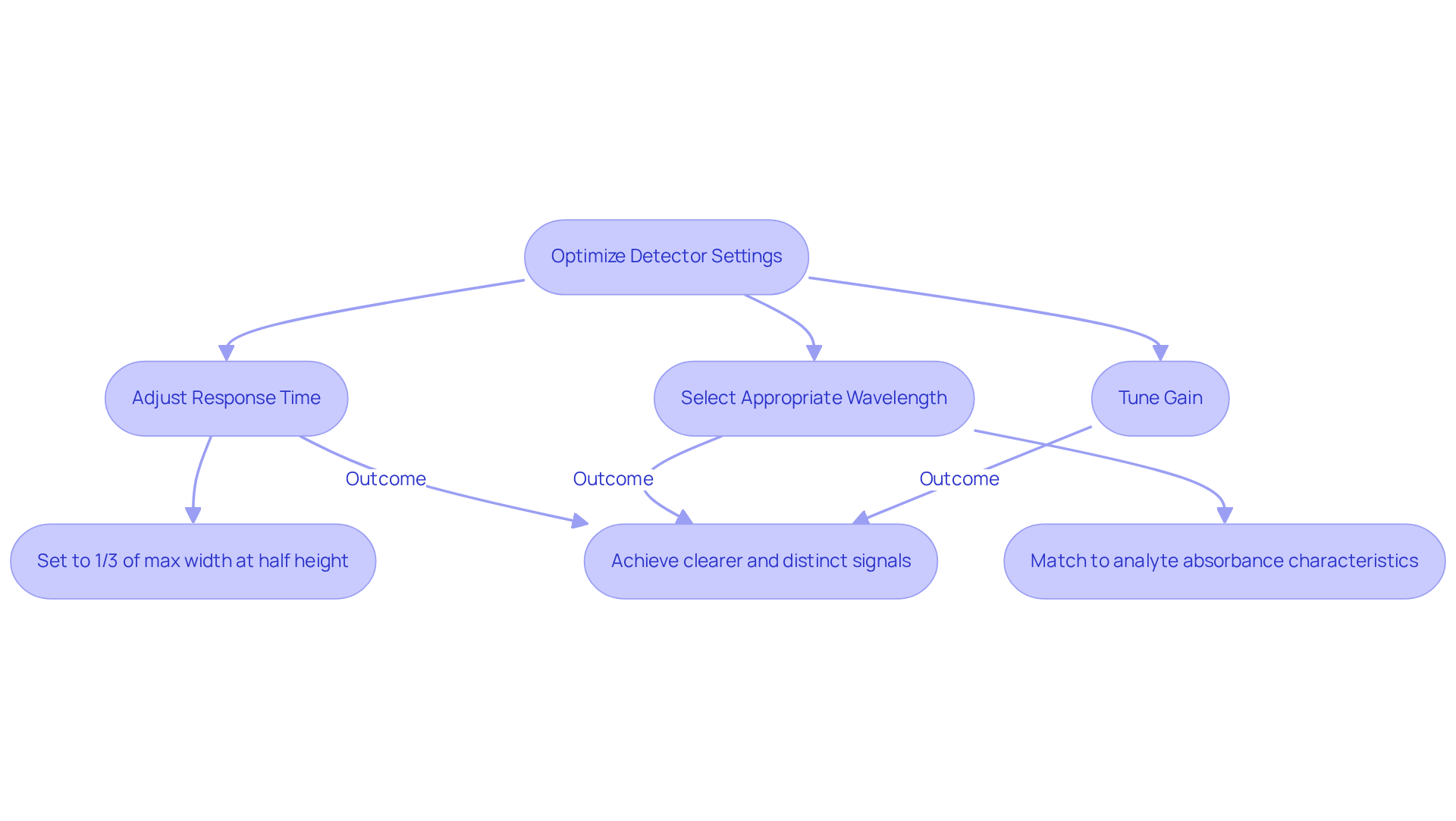

Detector Settings: Optimizing for Peak Resolution

To achieve , fine-tuning detector settings such as wavelength, response time, and gain is essential. Adjusting the response time to one-third of the maximum width at half height can significantly enhance detection capabilities. Additionally, selecting the appropriate wavelength based on the analyte's absorbance characteristics not only improves sensitivity but also reduces noise. These adjustments ultimately lead to clearer and more distinct signals, reinforcing the importance of precision in laboratory settings.

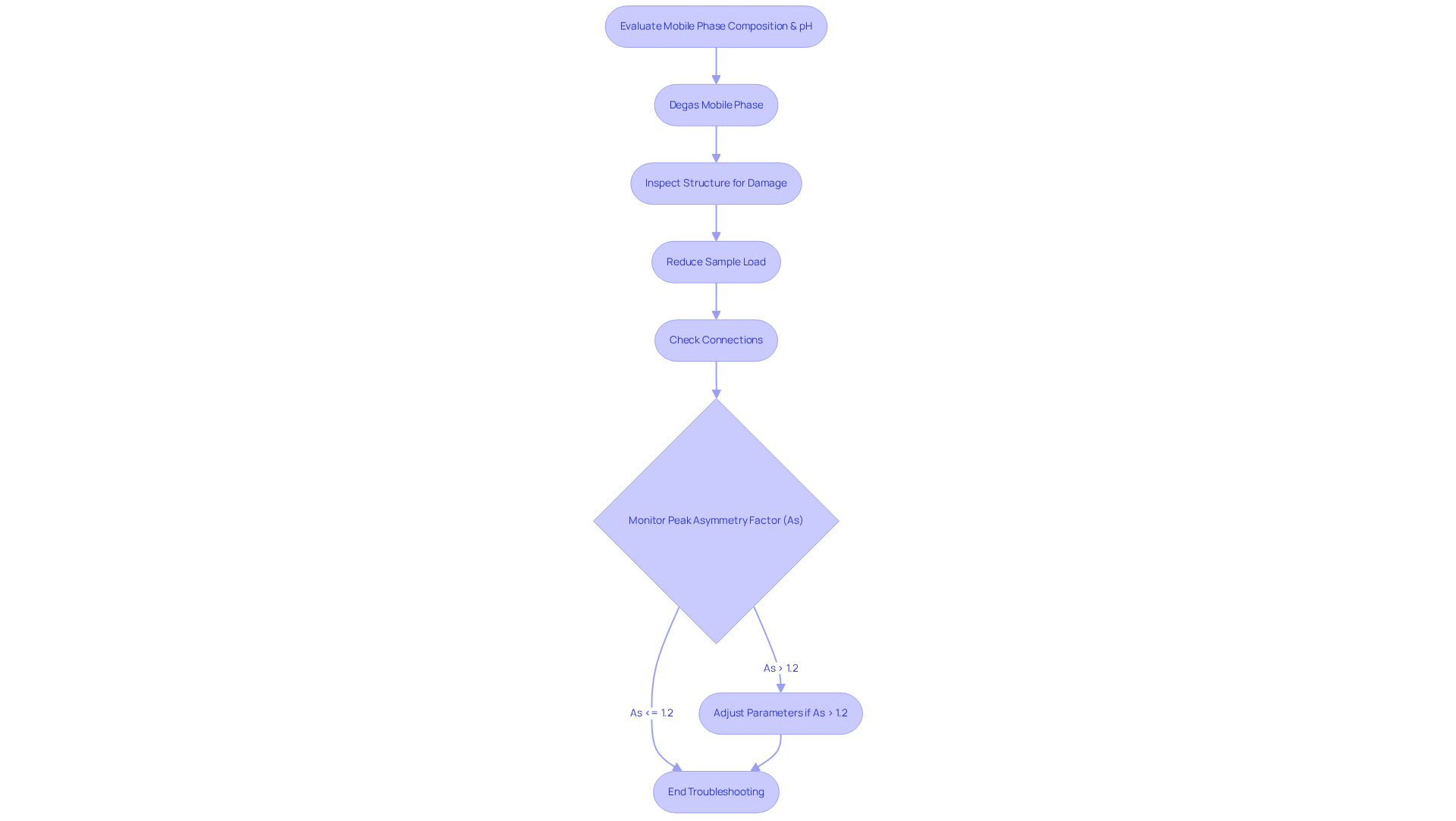

General Troubleshooting Strategies for Peak Tailing

To effectively tackle maximum residue, a systematic troubleshooting method is essential. Start by evaluating the mobile phase composition and pH, as these factors can dramatically affect [HPLC peak tailing](https://jmscience.com) in the shape of the signals. For instance, decreasing the mobile phase pH to approximately 3.0 can protonate ionizable silanol groups, thus minimizing secondary retention and reducing signal distortion.

It is crucial to ensure that the mobile phase is degassed to prevent retention time variations. Additionally, assessing the structure for damage or contamination is vital; routine upkeep and flushing can significantly enhance performance. A maximum asymmetry factor (As) greater than 1.2 indicates pronounced distortion, which is related to HPLC peak tailing and warrants careful observation.

Reducing the sample load is another effective strategy to prevent system overload, which often results in HPLC peak tailing and distorted signals. Furthermore, ensure that all connections in the flow path are secure and free of obstructions, as improper fittings can create dead volume, exacerbating high-end distortion.

Utilizing can help minimize baseline noise, contributing to improved overall performance. By regularly examining and adjusting these parameters, including the use of a reliable thermostat for the column, laboratories can maintain optimal liquid chromatography performance and enhance the reliability of their analytical results.

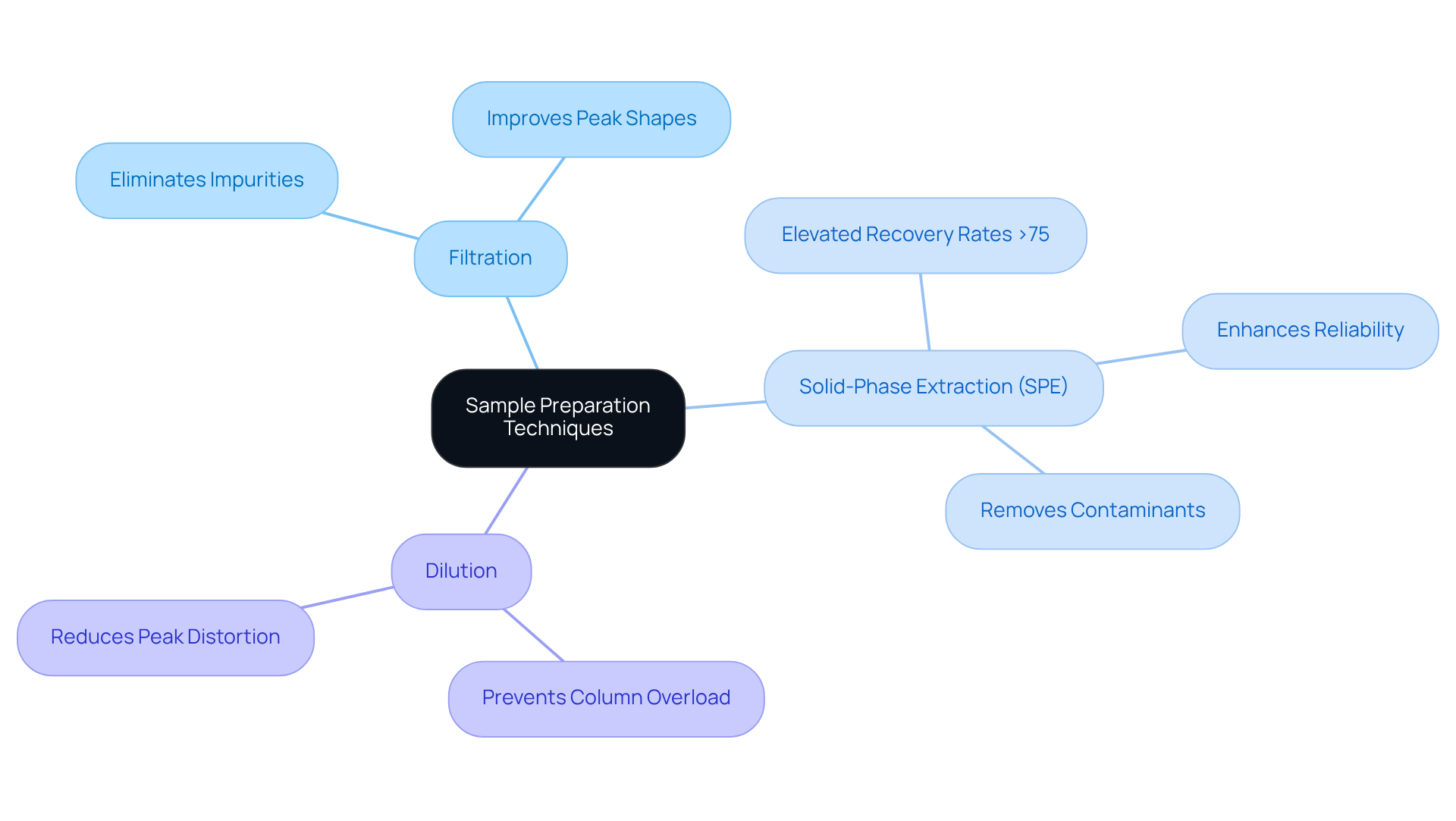

Sample Preparation Techniques: Reducing Peak Tailing

Efficient sample preparation methods are vital for minimizing tailing in high-performance liquid chromatography analyses. Filtration and solid-phase extraction (SPE) are crucial in eliminating impurities and contaminants that can jeopardize analytical results. Notably, SPE has demonstrated elevated recovery rates, often exceeding 75%, when retrieving diverse analytes from complex matrices, thereby enhancing the reliability of chromatographic outcomes.

Furthermore, diluting concentrated samples effectively prevents column overload, a frequent cause of peak distortion. Alarmingly, approximately 80% of chromatography-related issues stem from poor water quality, underscoring the necessity of utilizing high-quality water in sample preparation.

The Claristep filtration system facilitates the simultaneous filtration of multiple high-performance liquid chromatography samples, significantly improving the efficiency of the preparation process. By ensuring that samples are meticulously prepared and free from particulates, laboratories can achieve cleaner results and improved peak shapes. This meticulous approach not only enhances the precision of quantitative analyses but also contributes to overall technique performance, emphasizing the critical importance of in high-performance liquid chromatography applications.

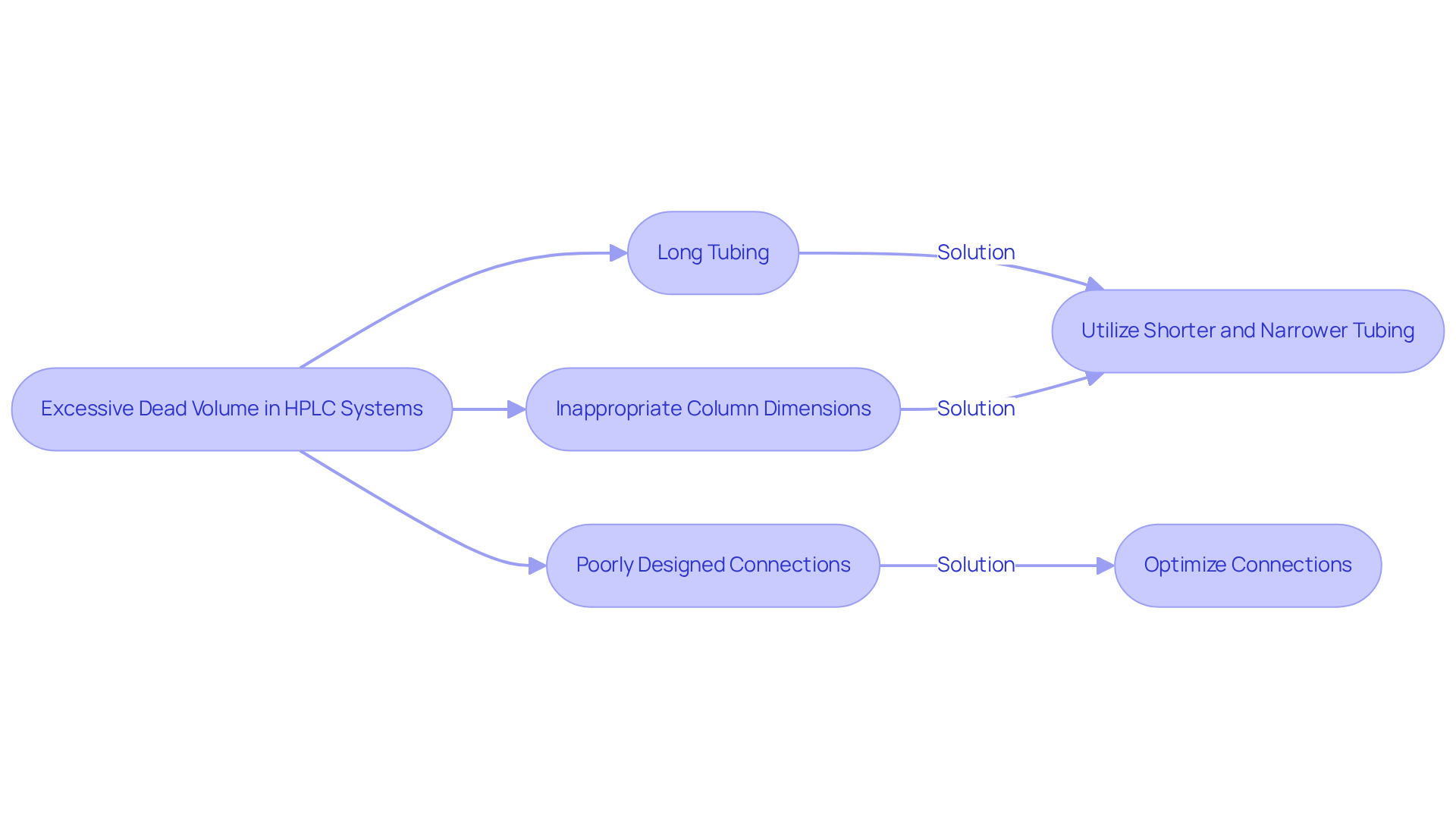

Excessive Column Dead Volume: A Hidden Cause of Peak Tailing

Excessive in HPLC systems is a critical issue that can lead to tailing and widened signals, undermining the integrity of chromatographic results. This dead volume typically arises from factors such as:

- Long tubing

- Poorly designed connections

- Inappropriate column dimensions

To address this challenge effectively, it is essential to:

- Utilize shorter and narrower tubing

- Ensure that all connections are optimized to minimize dead volume

Regular evaluation of the system for dead volume is not merely advisable; it is imperative for sustaining optimal integrity and enhancing overall chromatographic performance. By taking these proactive measures, laboratories can significantly improve the reliability and accuracy of their analytical results.

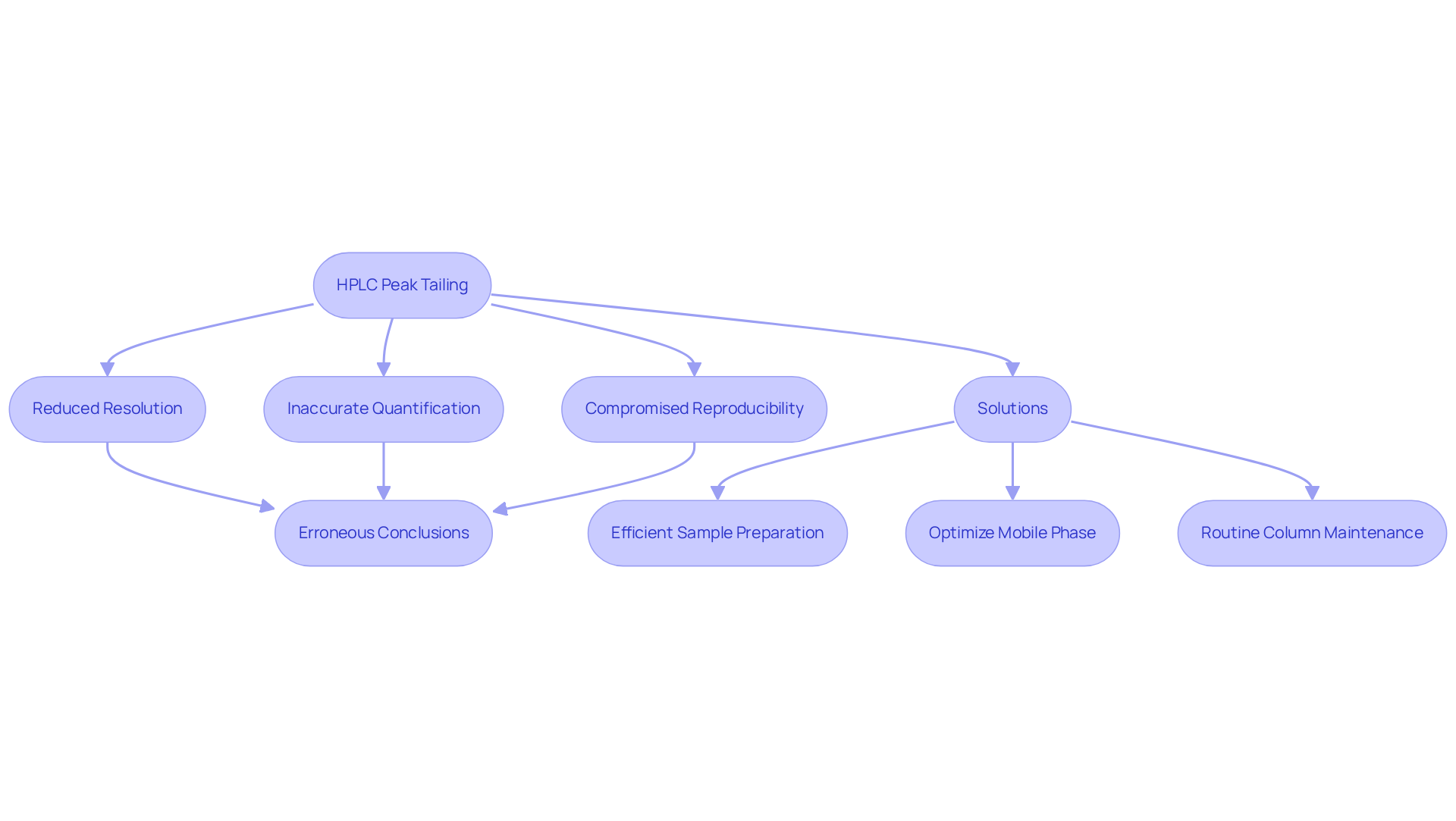

Impact of Peak Tailing on Analytical Results: Why It Matters

The peak phenomenon, especially HPLC peak tailing, presents significant obstacles in analytical chemistry, particularly in pharmaceutical research, where accuracy is paramount. This phenomenon can lead to , inaccurate quantification, and compromised reproducibility, ultimately resulting in erroneous conclusions that can impact drug development and safety assessments. For instance, research has shown that maximum HPLC peak tailing effects can obscure critical information, complicating the identification of closely eluting compounds and increasing the risk of false positives and negatives. A notable case involved a pharmaceutical laboratory that encountered considerable reproducibility challenges due to signal distortion, hindering their ability to reliably measure active components in their formulations.

Addressing maximum waste is not merely a technical issue; it is vital for maintaining the validity of research results. Implementing efficient sample preparation methods, such as Solid Phase Extraction (SPE), can significantly improve shape and enhance the precision of chromatographic analyses. Appropriate clean-up methods are essential for reducing maximum residuals, as they facilitate the attainment of clear, well-defined summits. Furthermore, optimizing mobile phase composition and pH levels is crucial in preventing signal distortion, as these factors directly influence signal symmetry. The use of buffers in the mobile phase can stabilize pH and mask residual silanol interactions, further mitigating signal distortion.

Experts emphasize that preserving optimal shapes is critical for reliable data interpretation. As one expert noted, 'Peak accumulation can impact resolution, sensitivity, and accuracy, leading to flawed quantification and identification.' Additionally, routine column upkeep and conditioning are vital strategies to minimize maximum residue, ensuring consistent performance. By prioritizing methods to reduce HPLC peak tailing, laboratories can enhance the reliability of their analytical results, ultimately contributing to more robust scientific findings and advancing pharmaceutical research.

Conclusion

Addressing HPLC peak tailing is essential for ensuring the accuracy and reliability of analytical results in pharmaceutical laboratories. By implementing targeted solutions—such as specialized columns, mobile phase adjustments, and meticulous sample preparation techniques—laboratories can significantly enhance chromatographic performance and data integrity. Understanding the underlying causes of peak tailing, including silanol interactions and column overload, further underscores the importance of a comprehensive approach to optimization.

The article outlines several key strategies to combat peak tailing. These include:

- The use of end-capped and base-deactivated columns

- Optimization of mobile phase pH

- Regular maintenance of chromatography systems

Additionally, effective troubleshooting methods and sample preparation practices play a vital role in minimizing distortions and enhancing peak resolution. By prioritizing these best practices, laboratories can create a more accurate and efficient analytical environment.

Ultimately, the significance of addressing HPLC peak tailing extends beyond technical performance; it is crucial for maintaining the integrity of pharmaceutical research and ensuring the safety and efficacy of drug development. Laboratories are encouraged to adopt these solutions and strategies to enhance their analytical capabilities, thereby contributing to the advancement of pharmaceutical science and the reliability of their findings.