Overview

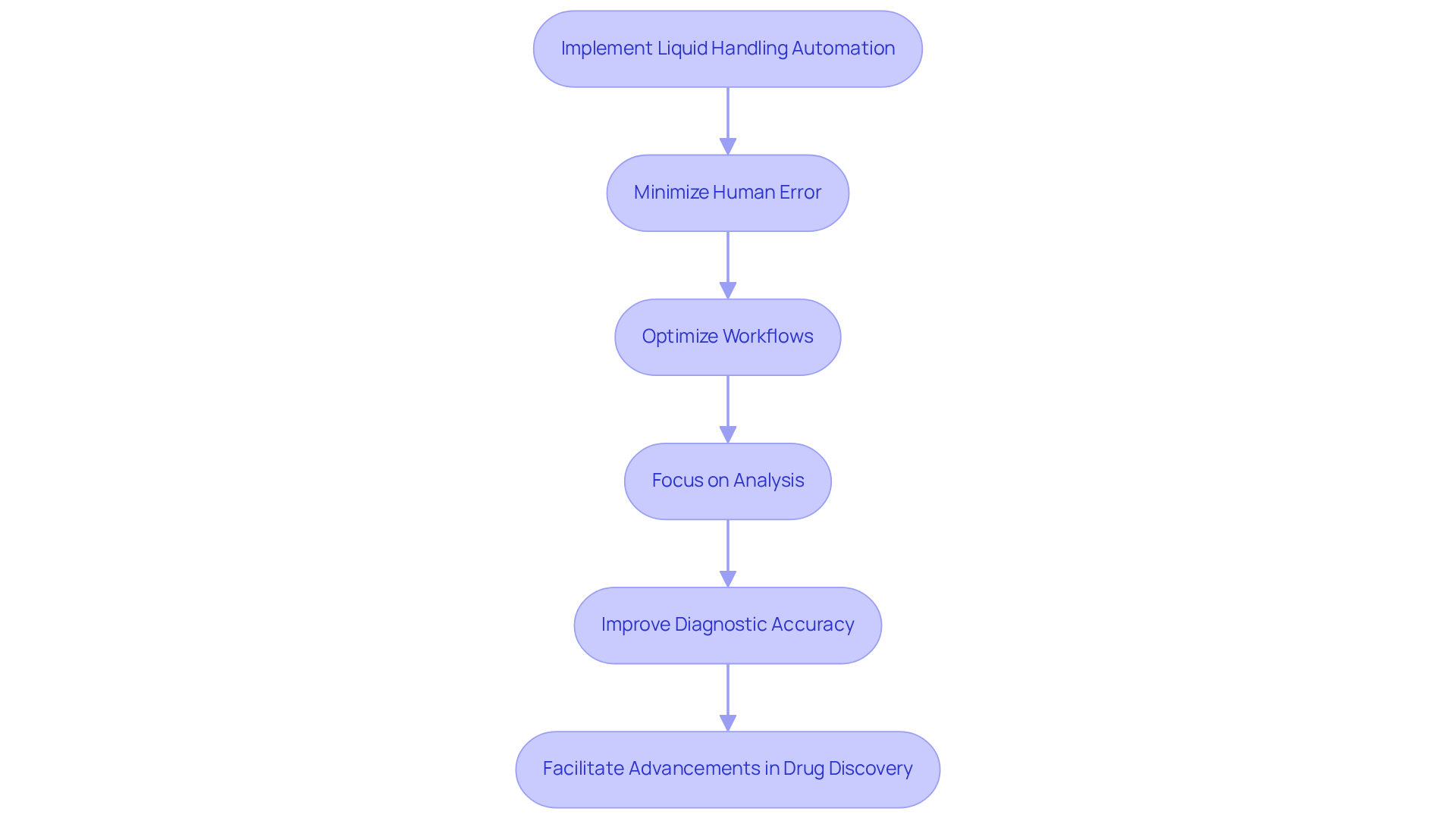

Liquid handler automation presents substantial advantages for pharmaceutical laboratories, notably in accuracy enhancement, labor cost reduction, and operational efficiency improvement. These automated systems significantly minimize human error, streamline workflows, and bolster compliance with regulatory standards. As a result, they contribute to superior research outcomes and expedite drug discovery processes. In an industry where precision and efficiency are paramount, the adoption of liquid handler automation is not merely beneficial; it is essential for advancing scientific progress.

Introduction

Liquid handling automation is revolutionizing pharmaceutical laboratories, delivering unparalleled precision and reliability essential for achieving successful research outcomes. By significantly reducing human error and streamlining workflows, these sophisticated systems enable researchers to concentrate on what truly matters: the science. As the demand for efficiency and accuracy escalates, laboratories must consider how to effectively harness these technologies to not only meet but surpass industry standards. This article delves into nine compelling advantages of liquid handler automation, illuminating how these innovations are transforming the landscape of pharmaceutical research.

JM Science Liquid Handling Automation: Precision and Reliability

JM Science Inc. provides advanced liquid handler automation solutions for fluids, significantly enhancing accuracy and reliability in pharmaceutical laboratories. These sophisticated systems are engineered to minimize variability in fluid handling processes, a critical element in preserving the integrity of experimental results. By integrating high-performance chromatography (HPLC) components and other state-of-the-art instruments, JM Science amplifies the precision of transfers, thereby reinforcing the rigor of scientific research and development within the pharmaceutical sector.

The significance of precision in pharmaceutical laboratories is paramount. Liquid handler automation minimizes human error and optimizes workflows, enabling researchers to focus on analysis rather than manual tasks. For example, the Munich Leukemia Laboratory has effectively adopted Freedom EVO workstations, processing over 60,000 samples annually while improving diagnostic accuracy and efficiency. This shift towards automation has proven vital in addressing the growing demands for testing, particularly in intricate fields such as cytogenetics and molecular analysis.

Industry leaders recognize the transformative impact of liquid handler automation in the industry. The integration of liquid handler automation and other automated technologies leads to substantial improvements in experimental outcomes, ultimately facilitating advancements in drug discovery and clinical applications. With the fluid management market projected to rise from USD 4.20 billion in 2023 to USD 6.95 billion by 2032, the trend towards liquid handler automation in pharmaceutical laboratories is unmistakable, driven by the need for enhanced operational efficiencies and high-quality diagnostics. Collaborating with proficient providers like JM Science is essential for effective automation, ensuring that research facilities can successfully implement these advanced technologies.

Cost Savings: Reducing Labor and Material Waste with Automation

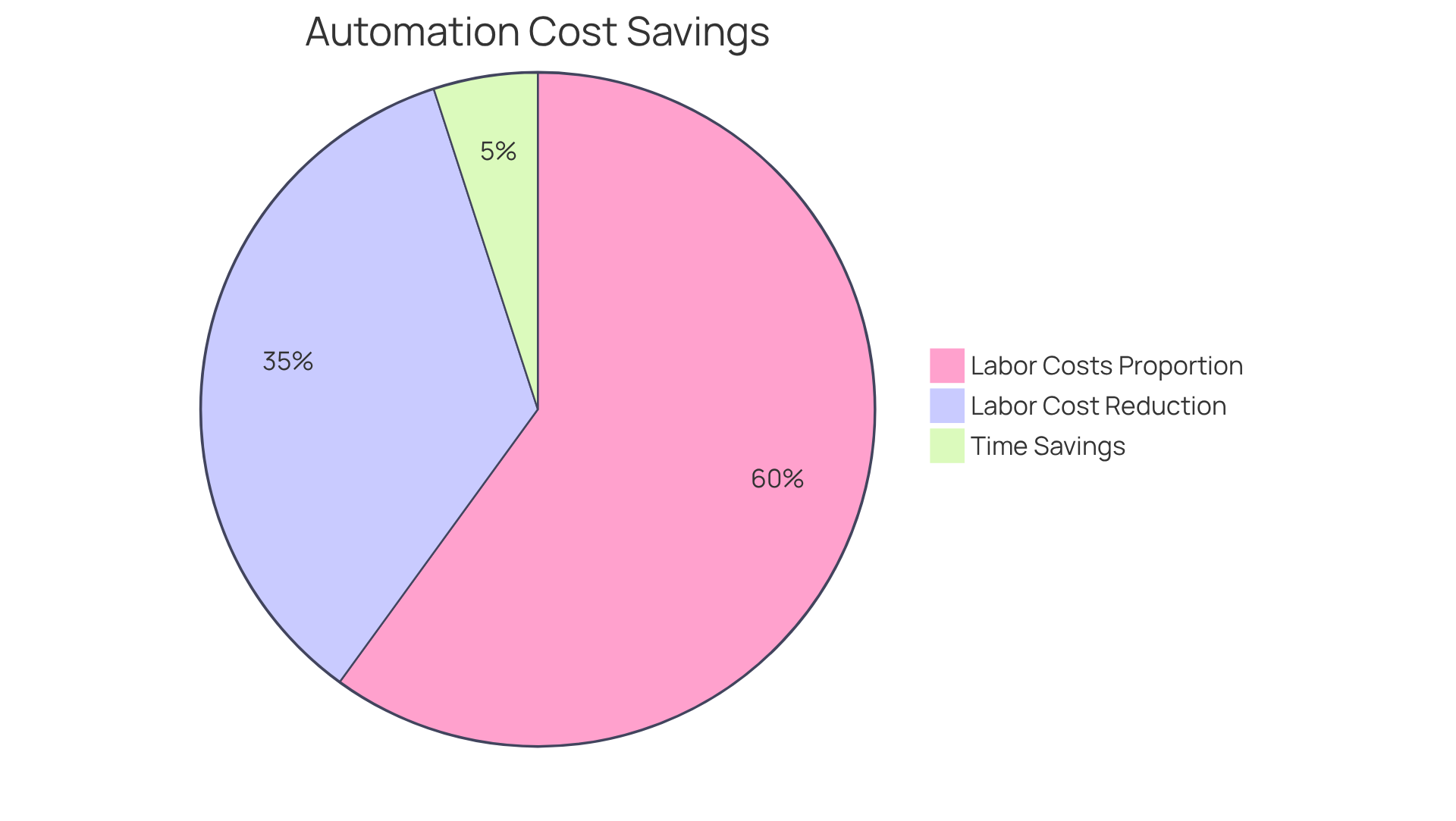

Liquid handler automation is revolutionizing pharmaceutical facilities by significantly reducing labor costs and minimizing material waste. By utilizing liquid handler automation to automate manual pipetting tasks, these devices eliminate time-consuming processes that are often susceptible to human error. For instance, studies indicate that automation can lead to labor cost reductions of 20-50%, allowing research facilities to reallocate resources to more critical research and development areas. Given that labor costs represent 50-70% of total operating expenses in labor-intensive industries, these reductions are especially impactful.

Furthermore, these systems improve operational efficiency by ensuring accurate liquid transfers, which conserves valuable reagents and consumables. This precision not only decreases the need for disposable items, such as pipette tips, but also contributes to creating a more sustainable workspace. As a result, research facilities can achieve significant reductions in material expenses, enhancing their financial effectiveness and enabling them to focus on advancing their scientific endeavors.

Looking ahead to 2025, the adoption of liquid handler automation solutions is anticipated to continue driving down labor costs, with many facilities reporting substantial decreases in operational expenses. Automation can save up to 80% of time in testing procedures, allowing staff to concentrate on higher-priority tasks. The financial advantages of automation are evident: by reducing labor and material waste, pharmaceutical laboratories can enhance their bottom line while upholding high standards of accuracy and reliability in their research. Moreover, businesses that integrate AI with automation realize three times more labor cost savings compared to those relying solely on traditional automation, underscoring the potential for even greater savings through advanced technologies.

Increased Accuracy: Minimizing Human Error in Liquid Handling

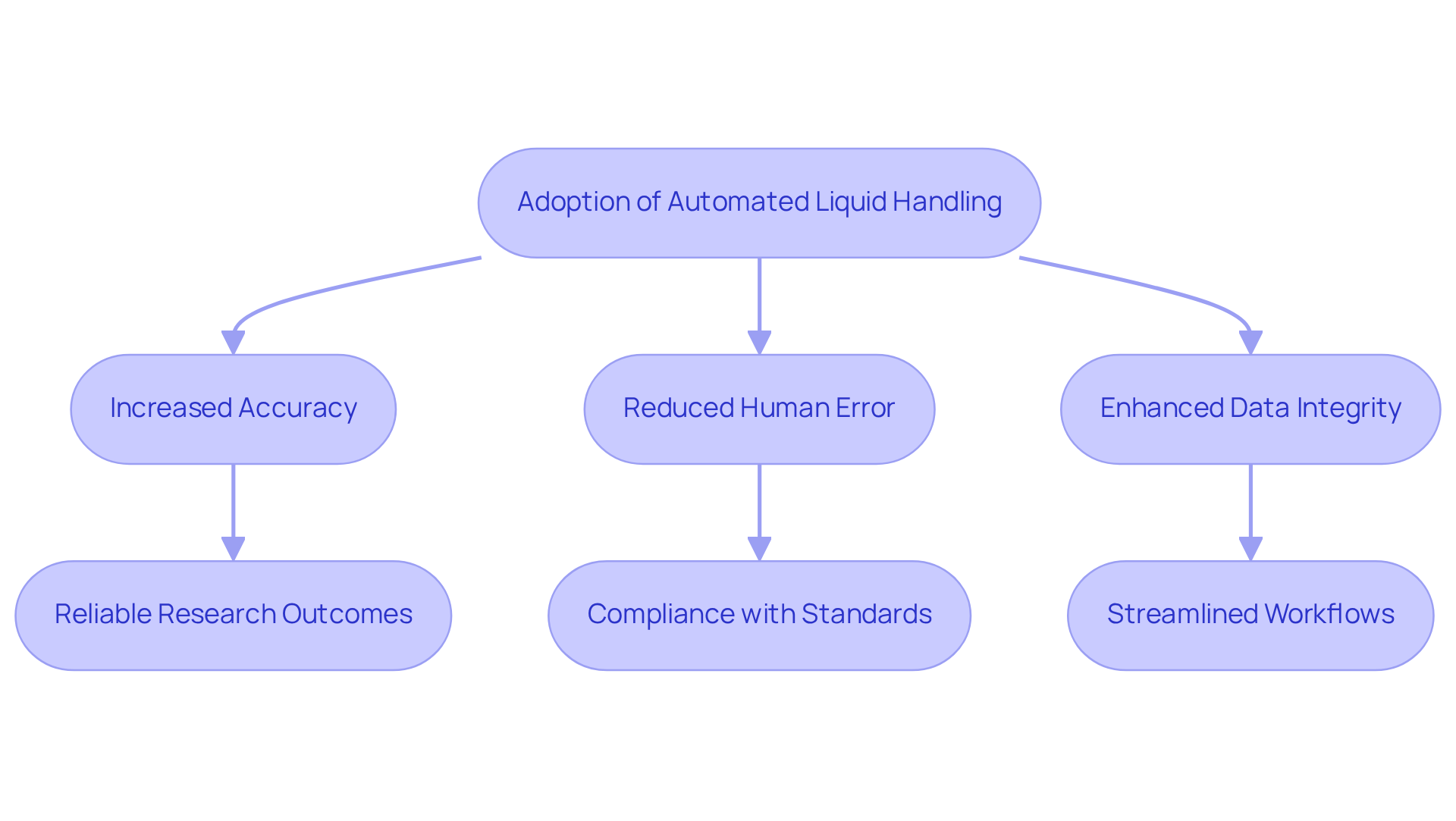

Automated fluid handling devices significantly enhance accuracy in pharmaceutical settings by executing transfers with remarkable precision. These systems are meticulously designed to perform fluid transfers with high accuracy, effectively minimizing the variability often associated with manual pipetting. This crucial reduction in human error is vital in pharmaceutical laboratories, where even minor inaccuracies can lead to substantial repercussions in research outcomes.

For instance, the Endosafe Nexus 200 adeptly handles both undiluted and complex serial dilutions for diverse testing applications, underscoring its versatility and importance in research environments. By integrating liquid handler automation, research facilities can achieve reliable and repeatable outcomes, which are essential for effective drug development.

Moreover, liquid handler automation significantly mitigates the risk of human error, thereby enhancing data integrity and ensuring compliance with regulatory standards. The user-friendly Freedom EVOware® software facilitates a seamless transition to automation, streamlining workflows and enabling researchers to concentrate on high-priority tasks, such as data interpretation.

As highlighted by Birgit Girshick, the demand for reliable, compliant, and high-throughput automated solutions, such as liquid handler automation, in pharmaceutical manufacturing is on the rise. To fully leverage the benefits of automation, research facilities should consider adopting these advanced technologies to enhance efficiency and foster innovation in pharmaceutical studies.

Scalability: Adapting Liquid Handling Systems to Laboratory Needs

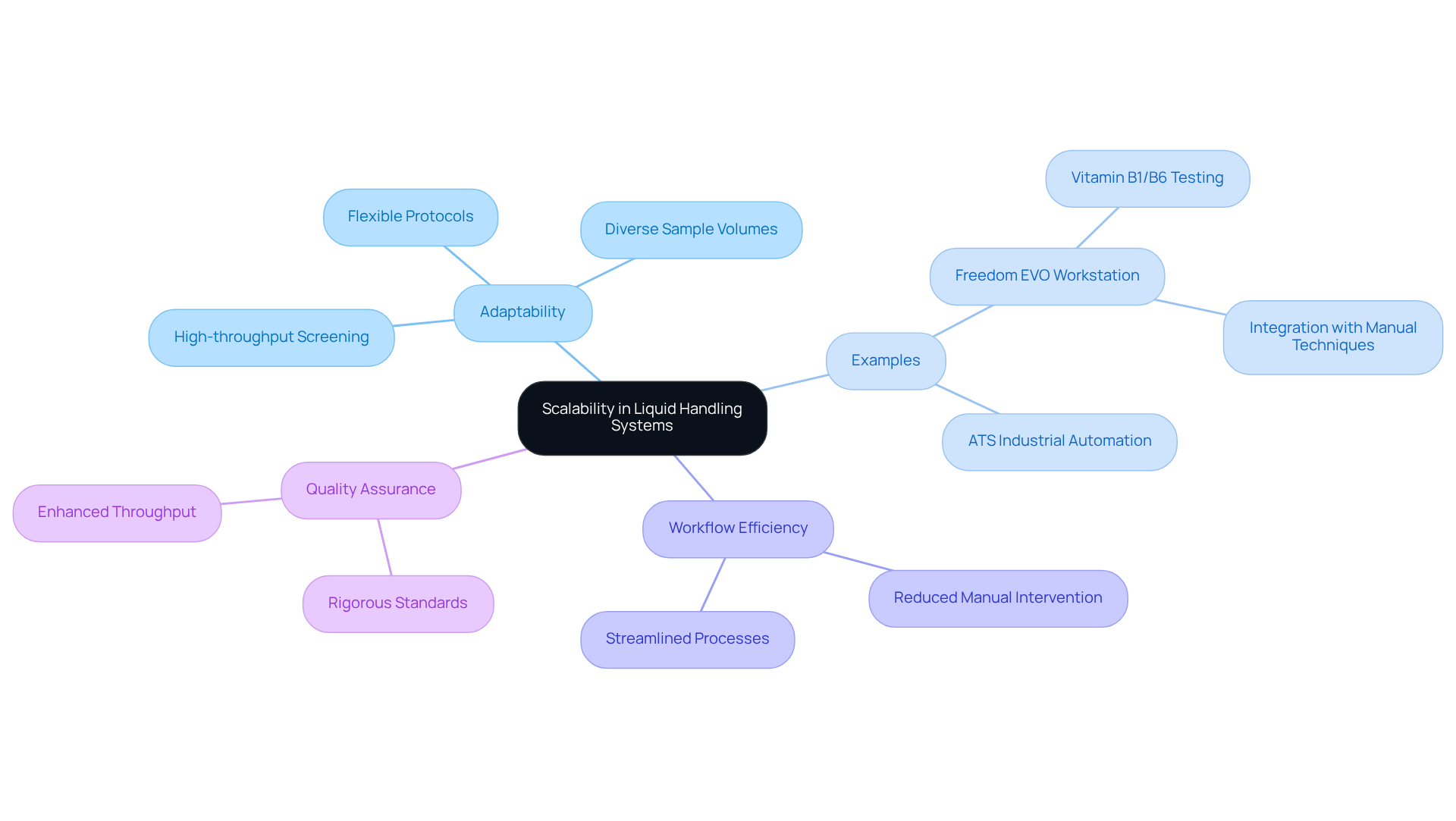

Liquid handler automation solutions present exceptional scalability, enabling facilities to tailor their operations to meet specific needs. Whether engaged in high-throughput screening or smaller-scale experiments, these systems can be configured to handle a diverse array of sample volumes and types. The adaptability of liquid handler automation streamlines workflows, significantly reducing the necessity for manual intervention.

For example, the Freedom EVO workstation has been effectively implemented across various environments, showcasing its ability to automate intricate protocols such as vitamin B1/B6 testing, which is frequently labor-intensive and susceptible to errors when conducted manually.

By fine-tuning fluid management configurations with liquid handler automation to align with the requirements of each test, facilities can enhance throughput while maintaining rigorous quality assurance standards. This level of flexibility not only boosts productivity but also optimizes resource management, solidifying automated fluid management as an indispensable asset in modern pharmaceutical laboratories.

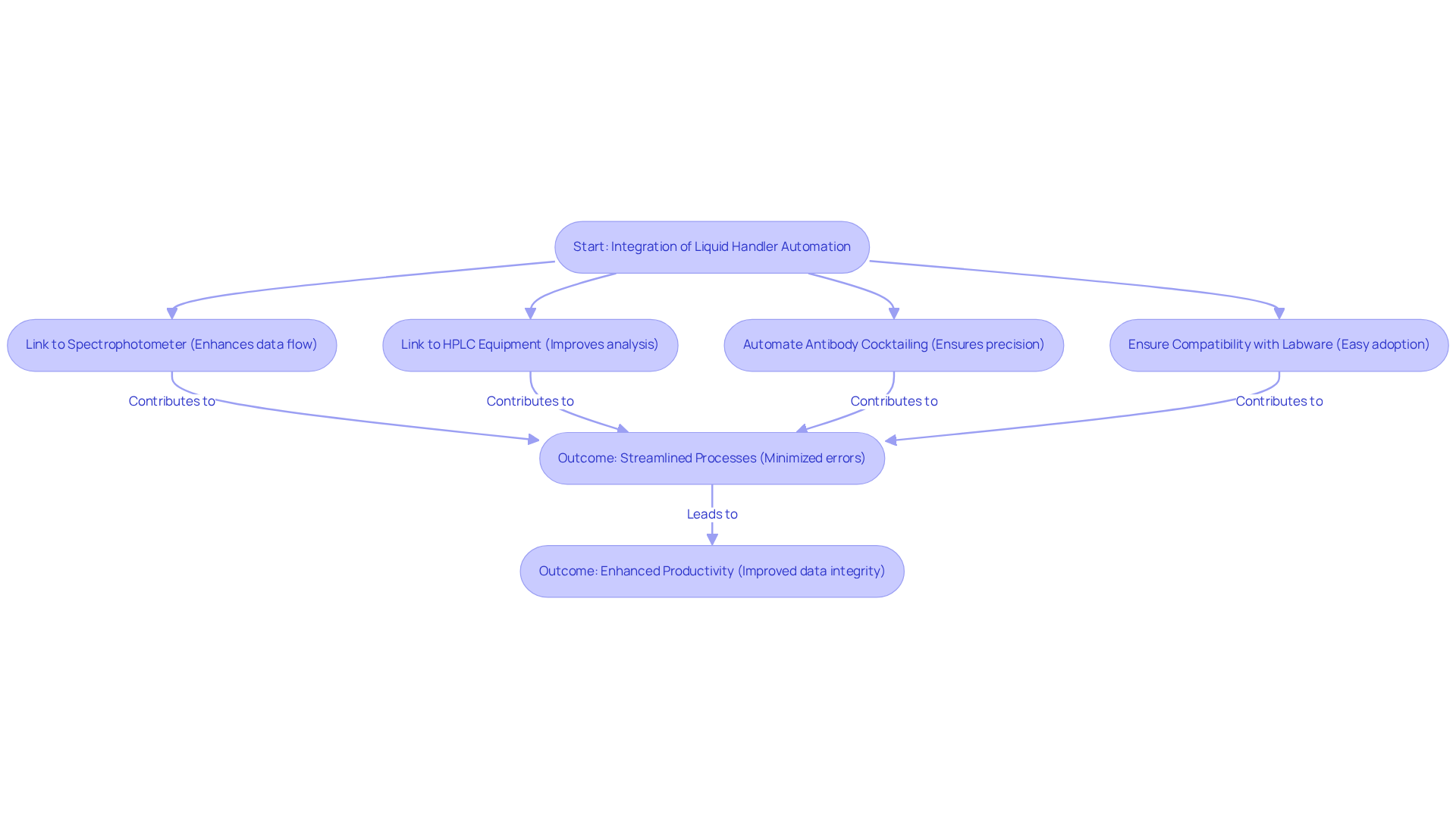

Integration: Streamlining Workflows with Existing Laboratory Equipment

Incorporating liquid handler automation technologies with current lab equipment significantly enhances workflow efficiency in pharmaceutical facilities. By linking these setups to instruments such as spectrophotometers and HPLC equipment, laboratories can establish a cohesive environment where data flows seamlessly between devices. This integration not only streamlines processes but also minimizes the potential for errors related to manual data transfer, thereby strengthening the reliability of experimental results.

For instance, the Pluto framework's ability to automate antibody cocktailing allows labs to mix up to 96 antibodies effortlessly, ensuring precise and reproducible results while reducing manual effort and human errors. Furthermore, the platform's compatibility with standard 96-well microplates and other labware promotes easy adoption within existing setups, making the transition to automated workflows straightforward with minimal assay optimization needed.

As specialists emphasize, including Holden Maecker from Stanford University, who noted that they achieved comparable or superior stain index with the Pluto setup, the adoption of liquid handler automation and integrated fluid management solutions can lead to significant improvements in productivity and data integrity. Ultimately, this evolution can revolutionize operational processes in laboratories.

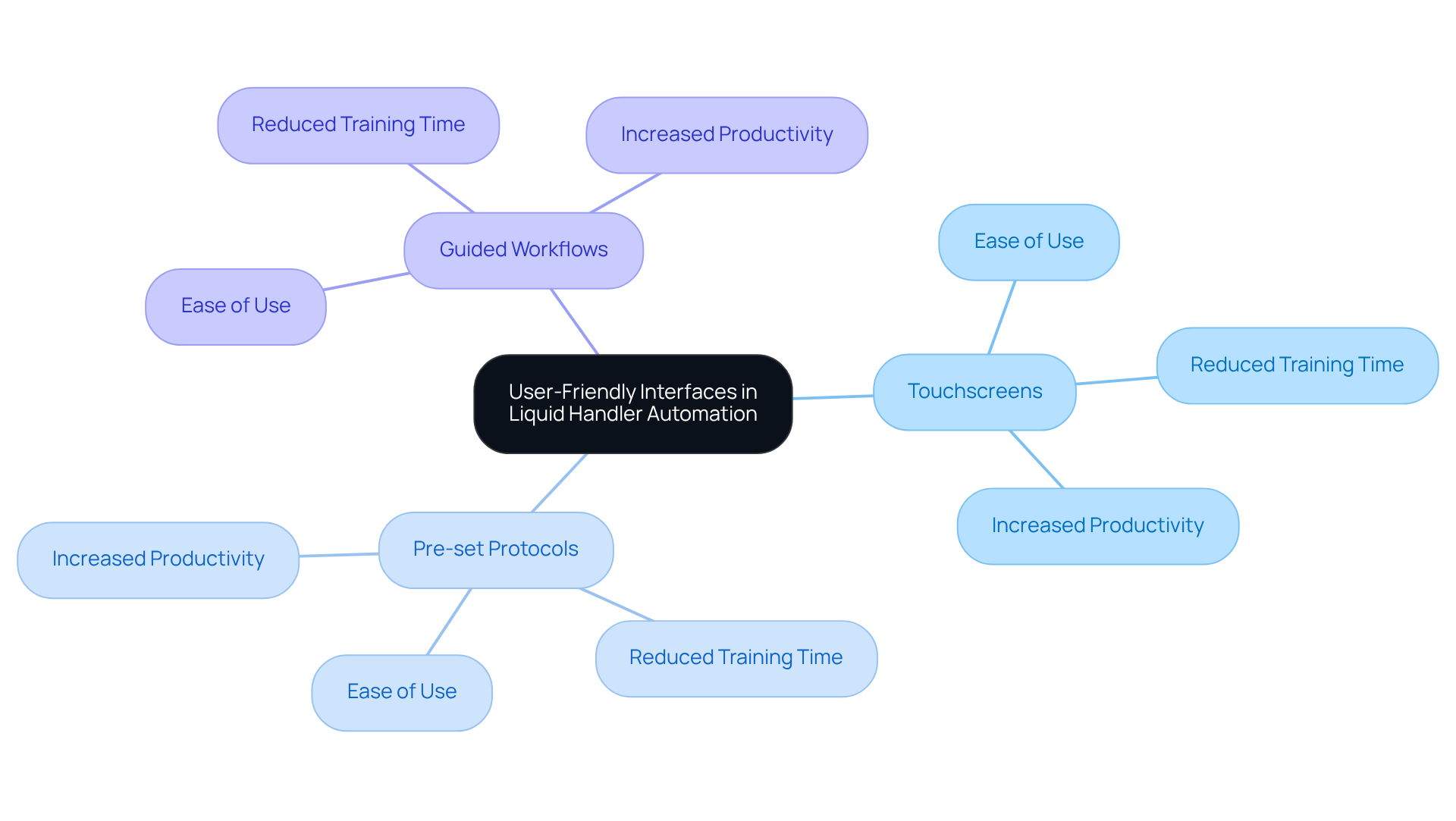

User-Friendly Interfaces: Enhancing Operator Efficiency

Contemporary solutions for liquid handler automation command attention with their user-friendly interfaces, significantly enhancing operator efficiency. These intuitive designs empower staff to program and operate the systems effortlessly, requiring minimal technical training. Key features such as touchscreens, pre-set protocols, and guided workflows in liquid handler automation streamline the user experience, allowing operators to concentrate on their research instead of navigating complex machinery. This simplicity accelerates turnaround times and boosts productivity within testing environments.

The liquid handler automation market is projected to grow from USD 4.34 billion in 2024 to USD 6.75 billion by 2030, underscoring the increasing reliance on these efficient tools. Lab managers have observed that integrating user-friendly designs fosters smoother operations and improved outcomes. As LOC Scientific emphasizes, 'A practical layout innovation aids lab users in achieving optimal performance,' reinforcing that well-designed liquid handler automation is crucial for maximizing lab efficiency.

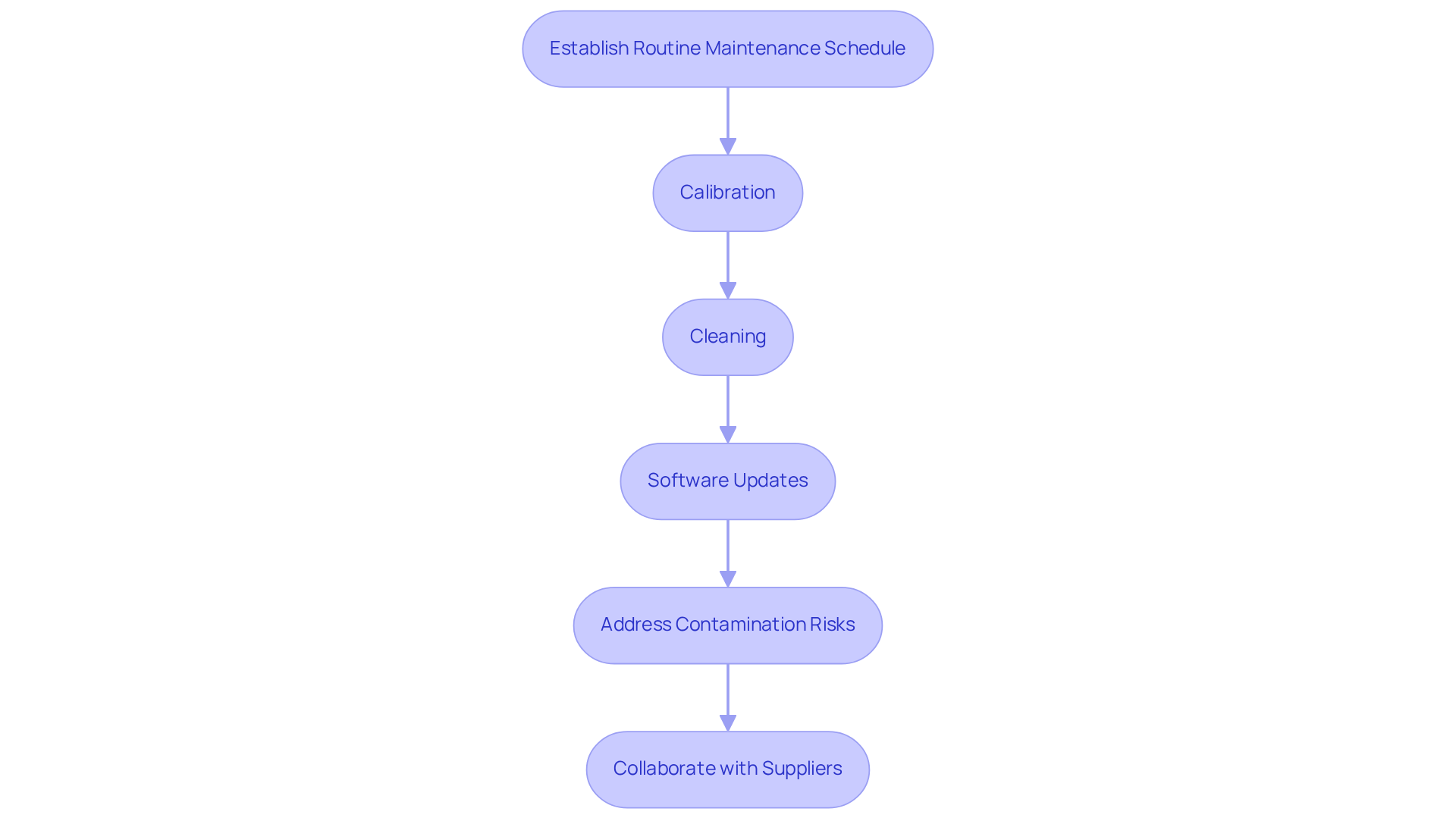

Maintenance and Support: Ensuring Longevity of Liquid Handling Systems

To ensure the longevity and optimal performance of liquid handler automation, regular maintenance and support are paramount. Establishing a routine maintenance schedule that encompasses calibration, cleaning, and software updates is critical for preserving functionality in liquid handler automation. Research indicates that liquid handler automation and consistent upkeep significantly reduce average downtime, allowing facilities to operate more efficiently.

As Sachin Rawat observes, "Routine maintenance can prevent these errors from creeping in," underscoring the necessity of diligent upkeep. Moreover, addressing contamination risks from residual reagents is essential; to ensure effective liquid handler automation, permanent pipette tips must be cleaned regularly to avert potential issues.

Collaborating with suppliers such as JM Science for ongoing assistance not only provides access to expert guidance but also enhances troubleshooting capabilities, thereby reinforcing reliability. By prioritizing these maintenance practices, facilities can minimize downtime and uphold high standards of accuracy and efficiency in liquid handler automation, ultimately leading to improved operational outcomes.

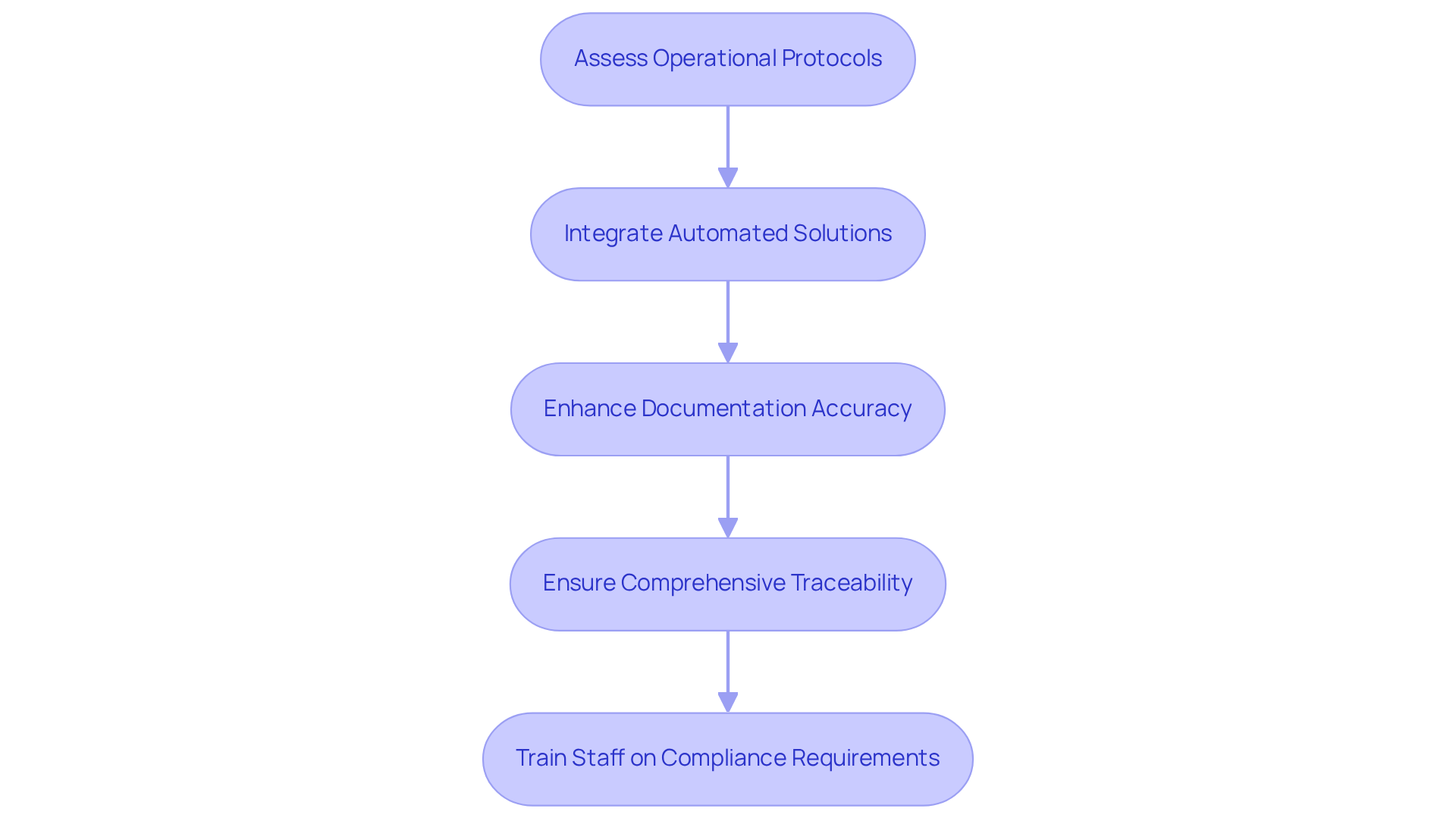

Regulatory Compliance: Meeting Standards with Automated Liquid Handling

Liquid handler automation solutions are indispensable for research facilities striving to meet stringent regulatory compliance standards, particularly in the pharmaceutical industry. Advanced technologies, such as the Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 Coulometric Karl Fischer Titrators, deliver accurate and consistent results that are essential for adherence to the rigorous standards of the Japanese Pharmacopoeia.

By integrating these automated solutions, facilities can significantly improve their documentation processes, ensuring comprehensive traceability and consistency across all procedures. This unwavering commitment to compliance not only safeguards the integrity of research but also streamlines successful regulatory submissions.

Moreover, automation enhances documentation accuracy, thereby minimizing the risk of errors that could compromise compliance. As regulatory landscapes evolve, the adoption of liquid handler automation, such as the AQV-300 and AQ-300 titrators for automated fluid transfer solutions, becomes increasingly vital for maintaining operational effectiveness and meeting the elevated expectations within the pharmaceutical sector.

To fully leverage the advantages of these titrators, research facilities must routinely assess their operational protocols and ensure that staff receive training on the latest compliance requirements.

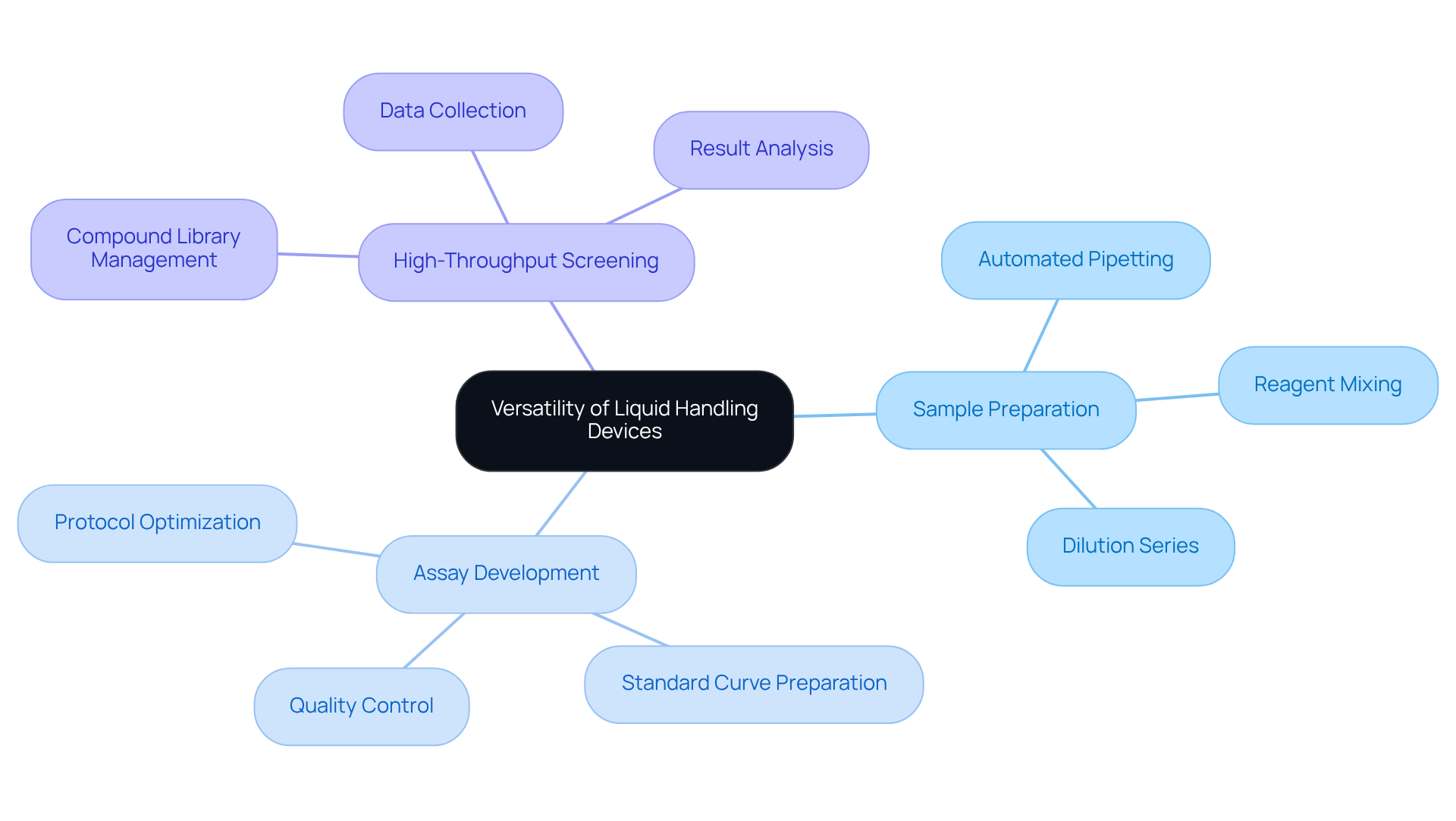

Versatility: Performing Multiple Liquid Handling Tasks Efficiently

Automated liquid handling devices serve a crucial role in modern research environments, effectively executing a wide range of tasks. From fundamental pipetting to complex multi-step protocols, these instruments demonstrate remarkable adaptability across various applications, including:

- Sample preparation

- Assay development

- High-throughput screening

This versatility not only allows research facilities to streamline their workflows but also reduces the need for multiple specialized tools. Consequently, organizations can enhance productivity and optimize resource utilization, making these devices indispensable in the laboratory setting.

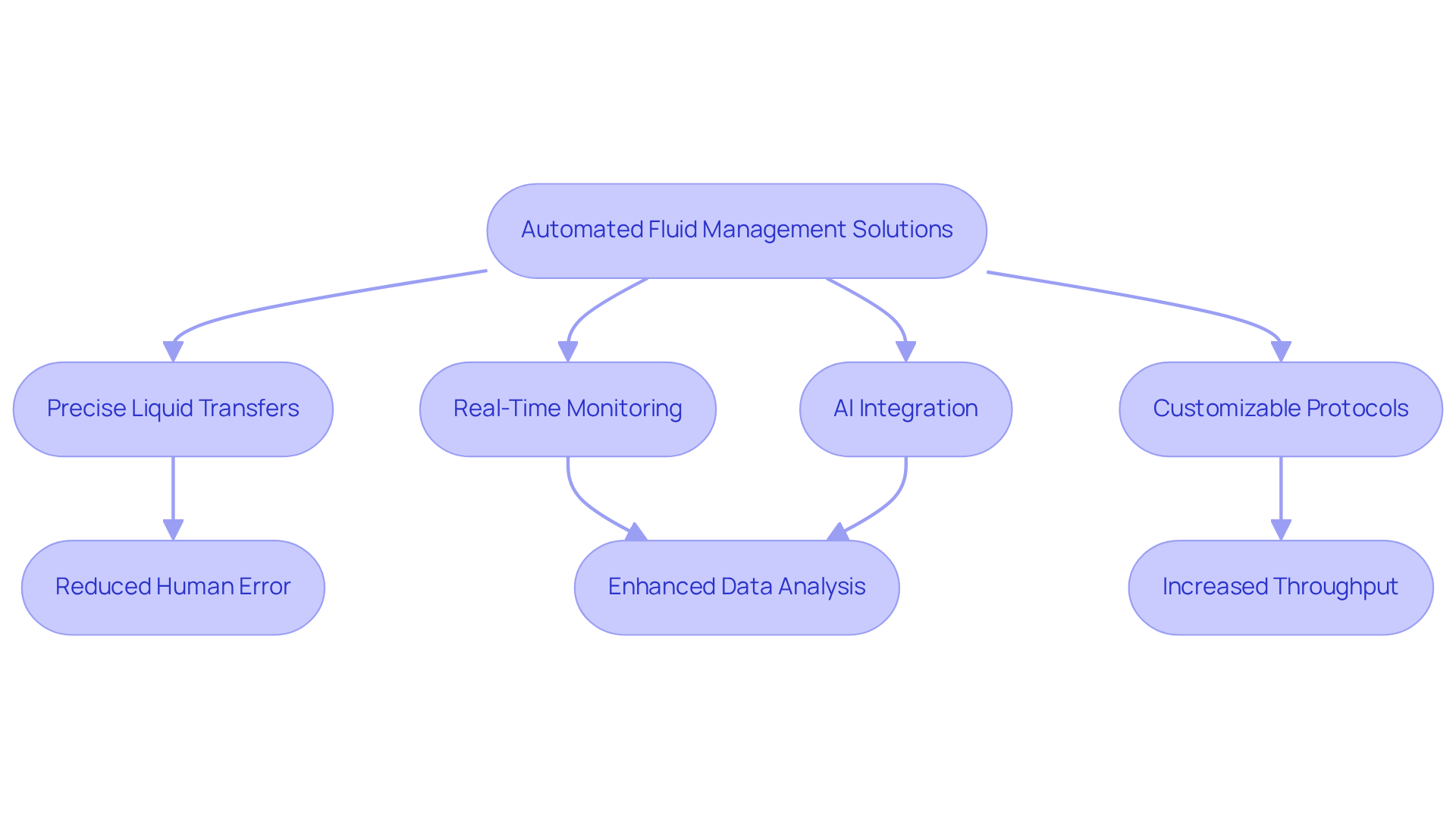

Innovative Features: Boosting Productivity in Pharmaceutical Labs

Contemporary automated fluid management solutions, particularly liquid handler automation, are revolutionizing efficiency in pharmaceutical research facilities with their cutting-edge functionalities. These frameworks integrate advanced robotics that ensure precise liquid transfers, significantly reducing human error and enhancing reproducibility. Integrated software solutions facilitate real-time monitoring and data analysis, enabling immediate adjustments to protocols based on experimental requirements. For example, automated platforms can process up to 14,000 samples per day, drastically minimizing turnaround times and increasing throughput. A single aspiration-dispense cycle for 5,460 samples would take approximately 4.5 hours using a single-channel pipetting instrument, which underscores the efficiency gains achieved through automation. This capability is vital in a sector where timing is critical for patient care and research outcomes.

Moreover, customizable protocols empower laboratories to swiftly adapt to evolving experimental needs, further streamlining workflows. The integration of artificial intelligence and machine learning into these frameworks is an emerging trend, enhancing data analysis and protocol optimization. Consequently, pharmaceutical labs can expedite their research and development processes, leading to quicker drug discovery and improved patient outcomes. Industry leaders assert that automation not only enhances productivity but also boosts employee satisfaction by alleviating repetitive tasks, allowing staff to concentrate on more complex and rewarding work. This transition towards automation is essential for maintaining competitiveness in an increasingly digital landscape. Liquid handler automation plays a pivotal role in research development by minimizing human intervention in experimental workflows, ensuring that it remains an indispensable tool for scientists, facilitating new discoveries and innovations.

Conclusion

Liquid handler automation is a transformative force in pharmaceutical laboratories, fundamentally reshaping research methodologies. By enhancing precision, minimizing human error, and streamlining workflows, these advanced systems allow scientists to concentrate on critical analysis rather than tedious manual tasks. The integration of automation not only boosts operational efficiency but also fosters innovation and accuracy in drug development.

Key benefits of liquid handler automation include:

- Significant cost savings through reduced labor and material waste

- Increased accuracy in liquid handling

- Scalability of systems to meet diverse laboratory needs

Furthermore, seamless integration with existing laboratory equipment and user-friendly interfaces, coupled with the importance of regular maintenance, reinforces the value of these automated solutions. Meeting stringent regulatory compliance standards through accurate documentation and reliable results is an essential advantage for pharmaceutical research facilities.

As the pharmaceutical industry evolves, the adoption of liquid handler automation will play a critical role in enhancing productivity and ensuring high-quality outcomes. Embracing these innovative technologies not only improves research capabilities but also positions laboratories to thrive in a competitive landscape. Investing in liquid handler automation is not merely a trend; it is a strategic move towards achieving excellence in pharmaceutical research and development, ultimately leading to better patient outcomes and accelerated drug discovery.