Overview

This article delves into essential septum cap solutions tailored for pharmaceutical laboratories, emphasizing a range of products engineered to uphold sample integrity and optimize laboratory efficiency. Each solution, including the PTFE/Red Silicone septum and pre-slit molded septum caps, is meticulously examined concerning its chemical resistance, sealing effectiveness, and user-friendly features. These attributes underscore their pivotal role in preventing contamination and enhancing analytical accuracy in critical environments. By understanding these solutions, laboratories can significantly improve their operational standards and ensure the reliability of their results.

Introduction

The pharmaceutical industry faces relentless pressure to uphold the integrity and reliability of its analytical processes, where even the slightest oversight can have profound consequences. With advancements in septum cap technology, laboratories are now equipped with innovative solutions that enhance sample preservation and optimize workflows. However, as laboratory requirements evolve, how can facilities identify the most effective septum caps to address their unique challenges? This article delves into nine essential septum cap solutions designed to elevate operational efficiency while maintaining the highest standards of quality in pharmaceutical laboratories.

JM Science PTFE/Red Silicone Septa with Blue Screw Cap: Reliable Sealing for Vials

The JM Science PTFE/Red Silicone Septum Cap with Blue Screw Cap is expertly engineered to deliver a reliable sealing solution for vials, a critical element in preserving sample integrity during both storage and analysis. This innovative combination of PTFE and silicone offers exceptional chemical resistance and withstands temperatures up to 250°C, making it ideal for a variety of solvents and reagents typically encountered in pharmaceutical environments. With partition dimensions of 22 mm × 0.060 in. and a thickness of 5 mm, it ensures a precise fit for vials. Furthermore, these membranes are conveniently packaged in sets of 100, catering to the practical needs of laboratory supervisors. By effectively preventing contamination, this septum cap significantly mitigates specimen degradation, aligning with the stringent quality control standards that pharmaceutical laboratories must uphold.

Laboratory managers emphasize the critical nature of maintaining specimen integrity, often noting that even minor contamination can lead to flawed results and compromised research outcomes. In fact, studies indicate that improper sealing can elevate contamination rates, negatively impacting experimental validity. A laboratory manager remarked, "Maintaining sample integrity is paramount; even trace contamination can skew results and lead to costly errors."

Real-world applications of the PTFE/Red Silicone septum cap illustrate its effectiveness in high-stakes environments, where the purity of active pharmaceutical ingredients (APIs) is essential. However, it is vital to consider compatibility issues, as certain chemicals, such as aromatic hydrocarbons and strong acids, can degrade PTFE, affecting its sealing performance. Regular maintenance and inspection of septa are crucial for ensuring long-term sealing performance and system integrity. This product exemplifies JM Science's dedication to providing advanced solutions that meet the evolving demands of the pharmaceutical industry.

11mm Clear Snap Cap Seal with Pre-Slit Molded Septum: Enhanced Accessibility for Sample Collection

The 11mm Clear Snap Cap Seal with Pre-Slit Molded Septum Cap is designed for optimal accessibility, enabling swift and effective sample collection without the need for additional tools. This innovation is especially advantageous in high-throughput laboratory environments, where time efficiency is paramount. The pre-slit design permits easy penetration by syringes or needles, ensuring rapid access to samples for immediate analysis.

Two types of pre-slit septum cap are available:

- Single slit

- Cross slit; the latter provides a larger target area for needle penetration.

This capability not only streamlines workflows but also significantly enhances the productivity of pharmaceutical laboratories, establishing it as an essential component for contemporary analytical practices. Standard carousels typically accommodate between 20 and 25 container units, underscoring the efficiency of this product.

Furthermore, pre-slit membranes improve injection consistency, with autosamplers retrieving over 50µL of liquid from a 2mL vial, further underscoring the product's advantages in analytical procedures.

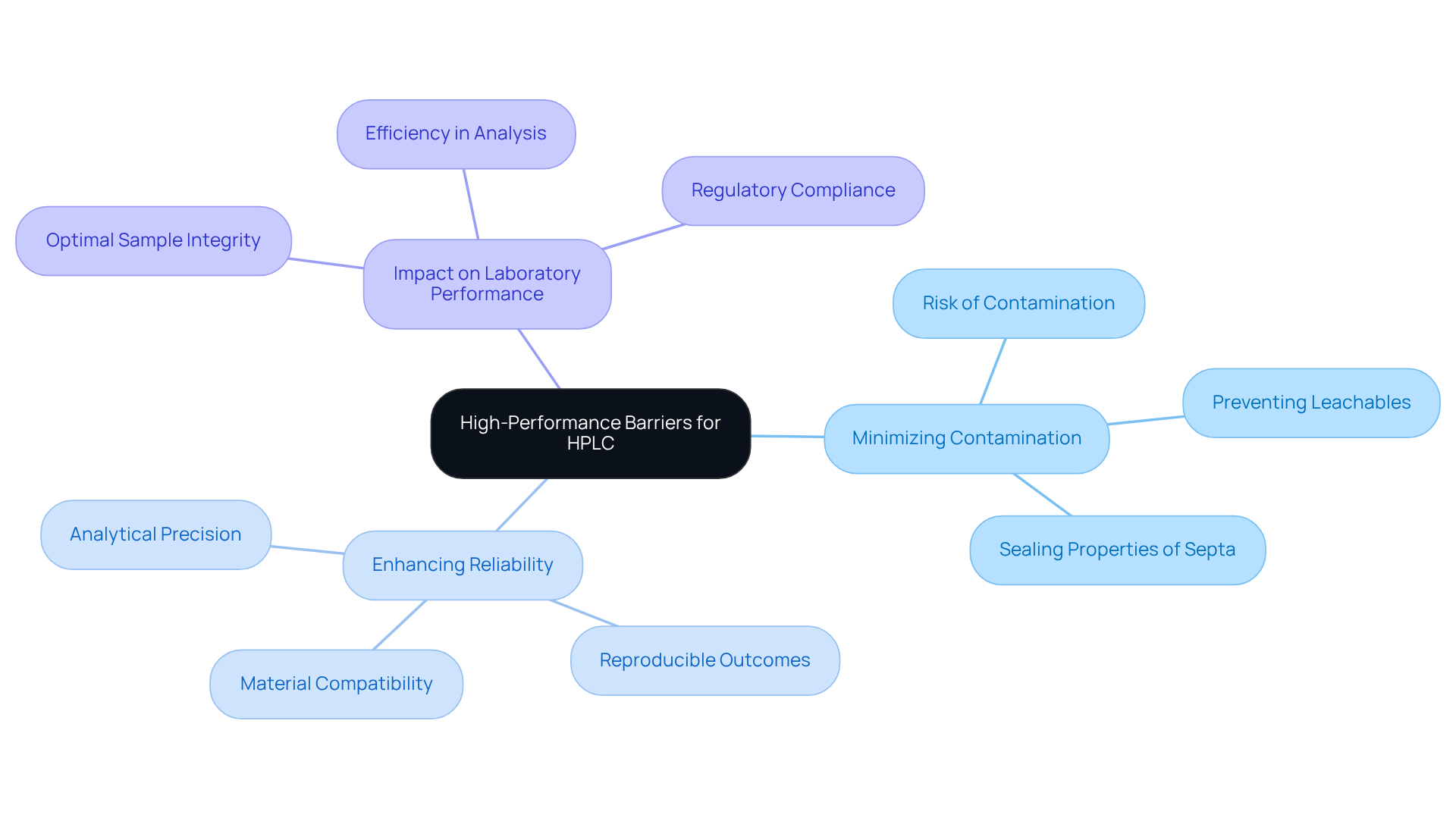

15-425 Sample Vial Cap with PTFE/Silicone Septa: Optimal for HPLC Applications

The 15-425 Sample Vial Cap with PTFE/Silicone Septum Cap is purposefully engineered for high-performance liquid chromatography (HPLC) applications, where preserving sample integrity is of utmost importance. The unique combination of PTFE and silicone provides exceptional chemical compatibility, significantly mitigating the risk of leachables that could compromise analytical results. This feature is particularly advantageous for laboratories that demand precision and accuracy in their chromatographic analyses.

In practical terms, employing PTFE/Silicone barriers effectively prevents contamination and ensures that volatile components remain stable throughout the testing process. A case study underscored that inadequate sealing techniques led to specimen evaporation and data inconsistency, thereby emphasizing the critical nature of selecting the appropriate vial cap. By adopting the 15-425 cap, laboratories can significantly reduce such risks, thus enhancing the reliability of their results.

Moreover, the necessity of minimizing leachables cannot be overstated, as they can disrupt chromatographic analysis and result in erroneous conclusions. The PTFE/Silicone membrane not only establishes a robust barrier against chemical interactions but also assists in adhering to stringent regulatory standards in pharmaceutical testing.

As professionals in the field assert, maintaining sample integrity is essential for achieving accurate and reproducible results in HPLC. Regularly inspecting caps and seals for visible flaws prior to use is vital to prevent contamination. Additionally, wearing gloves while handling caps and seals contributes to maintaining hygiene within the work environment. The 15-425 Sample Vial Cap, featuring a septum cap, stands out as a reliable option for facilities committed to excellence in their analytical practices. As noted by experts at Mastelf, 'Our expertise ensures that you get reliable and precise products tailored to your specific requirements.

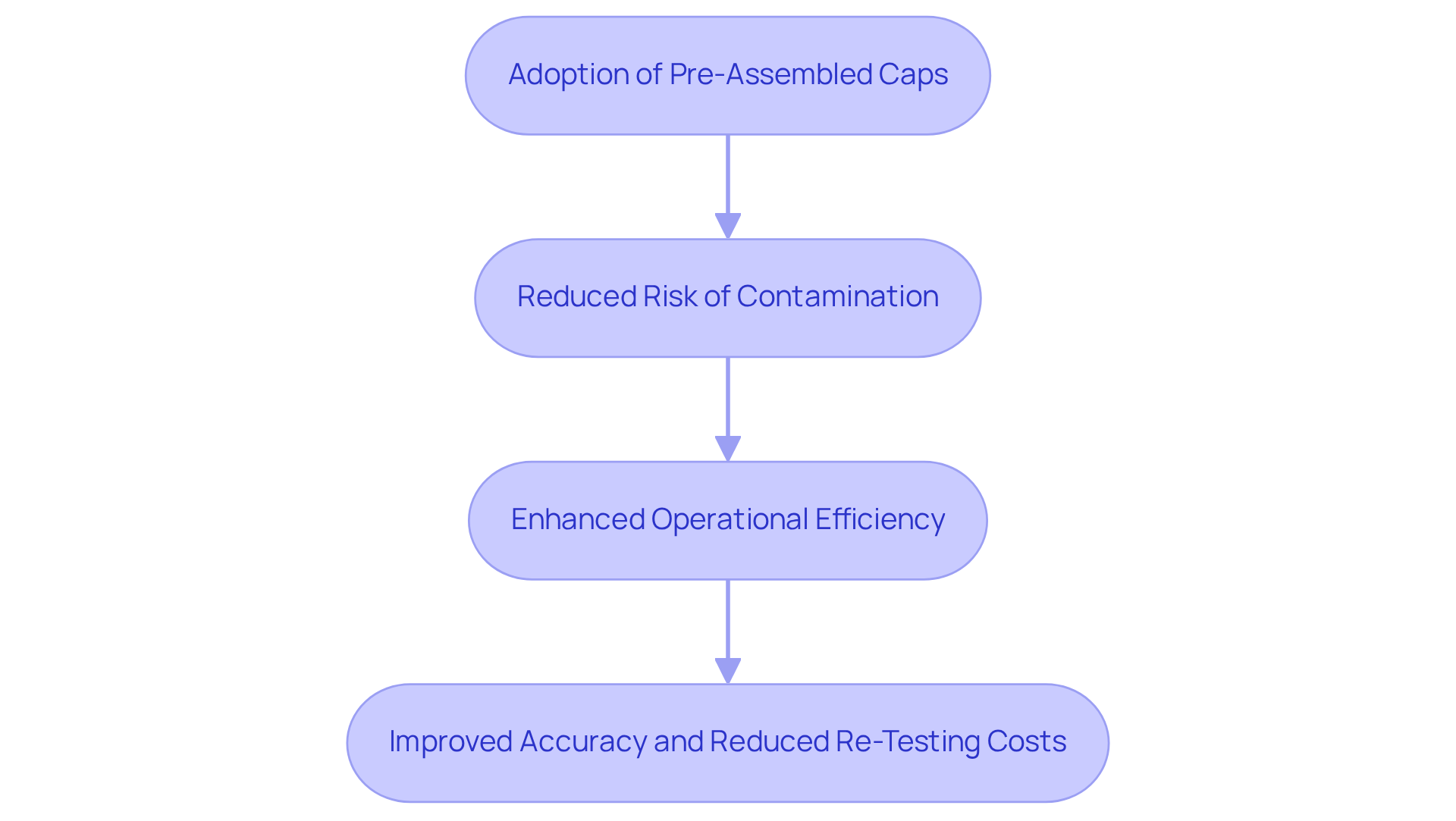

Pre-Assembled Caps and Septa: Streamlined Handling for Laboratory Efficiency

Pre-assembled caps and the septum cap present a highly effective solution for laboratories seeking to optimize their workflows. By eliminating the need for separate assembly, these products significantly reduce the risk of contamination, ensuring consistent performance across various applications. This efficient method proves especially advantageous in high-throughput environments where numerous specimens are processed simultaneously, allowing technicians to concentrate on analysis rather than preparation.

Laboratory managers have reported a remarkable decline in contamination rates following the adoption of pre-assembled systems, with some noting reductions of up to 30% compared to conventional separate assembly techniques. The user-friendly nature of these caps not only enhances operational efficiency but also fosters improved accuracy in results, as the likelihood of human error during assembly is minimized.

Practical examples underscore the effectiveness of these approaches; for instance, a pharmaceutical laboratory that transitioned to pre-assembled caps experienced a significant drop in contamination incidents of specimens, leading to more reliable data and reduced re-testing costs. As one lab manager remarked, "No more bent needles, no more contamination of specimens, and significantly less maintenance time."

As research facilities continue to pursue optimization strategies in 2025, the integration of pre-assembled caps and the septum cap emerges as a vital tactic for enhancing workflow efficiency and safeguarding specimen integrity.

9-425 Blue Threaded Cap with Press-Fit PTFE Red Rubber Septum: Durable and Secure Closure

The 9-425 Blue Threaded Septum Cap with Press-Fit PTFE Red Rubber emerges as a robust solution for research facilities that demand reliable sealing mechanisms. Its innovative press-fit design ensures a secure fit, effectively preventing leaks and contamination during storage and transport. This septum cap is particularly beneficial for facilities handling volatile solvents or delicate specimens, where maintaining the integrity of the specimen is paramount.

Studies have shown that inadequate sealing can result in significant leak rates, which jeopardize the quality and reliability of specimens. In experimental environments, threaded caps have demonstrated leak rates that can exceed acceptable thresholds if not sufficiently tightened. According to the acceptance criteria for leak test method validation:

- All negative controls must pass.

- Positive controls exhibiting leaks at or above the detection limit must fail.

Real-world applications underscore the effectiveness of this cap in pharmaceutical laboratories, where maintaining a sterile environment is critical. As noted by Crystal Booth, an Independent Pharmaceutical Microbiology Consultant, "secure closures are not merely a preference but a requirement when handling volatile solvents, ensuring that specimens remain uncontaminated and dependable for analysis.

Chrominex White PTFE/Red Silicone Septa: Quality Assurance for Sample Integrity

The Chrominex White PTFE/Red Silicone septum cap stands as a pinnacle of quality assurance for specimen integrity in pharmaceutical environments. Its innovative blend of PTFE and silicone ensures exceptional chemical resistance, effectively thwarting contamination during both storage and analysis. This characteristic is paramount for laboratories adhering to rigorous quality control standards, as it significantly mitigates the risk of material degradation.

In 2025, the preservation of specimen integrity is of utmost importance, making the use of high-quality seals like this one essential for achieving reliable analytical results. Quality control supervisors consistently observe that subpar barriers can compromise specimen integrity, underscoring the critical need to invest in superior materials.

Real-world applications of the septum cap, made from PTFE silicone, in quality control protocols have consistently demonstrated their efficacy in maintaining specimen integrity, ultimately yielding more accurate and trustworthy outcomes in pharmaceutical research and diagnostics.

Convenience Pack 2.0mL Clear Snap Seal Vial: User-Friendly Design for Quick Access

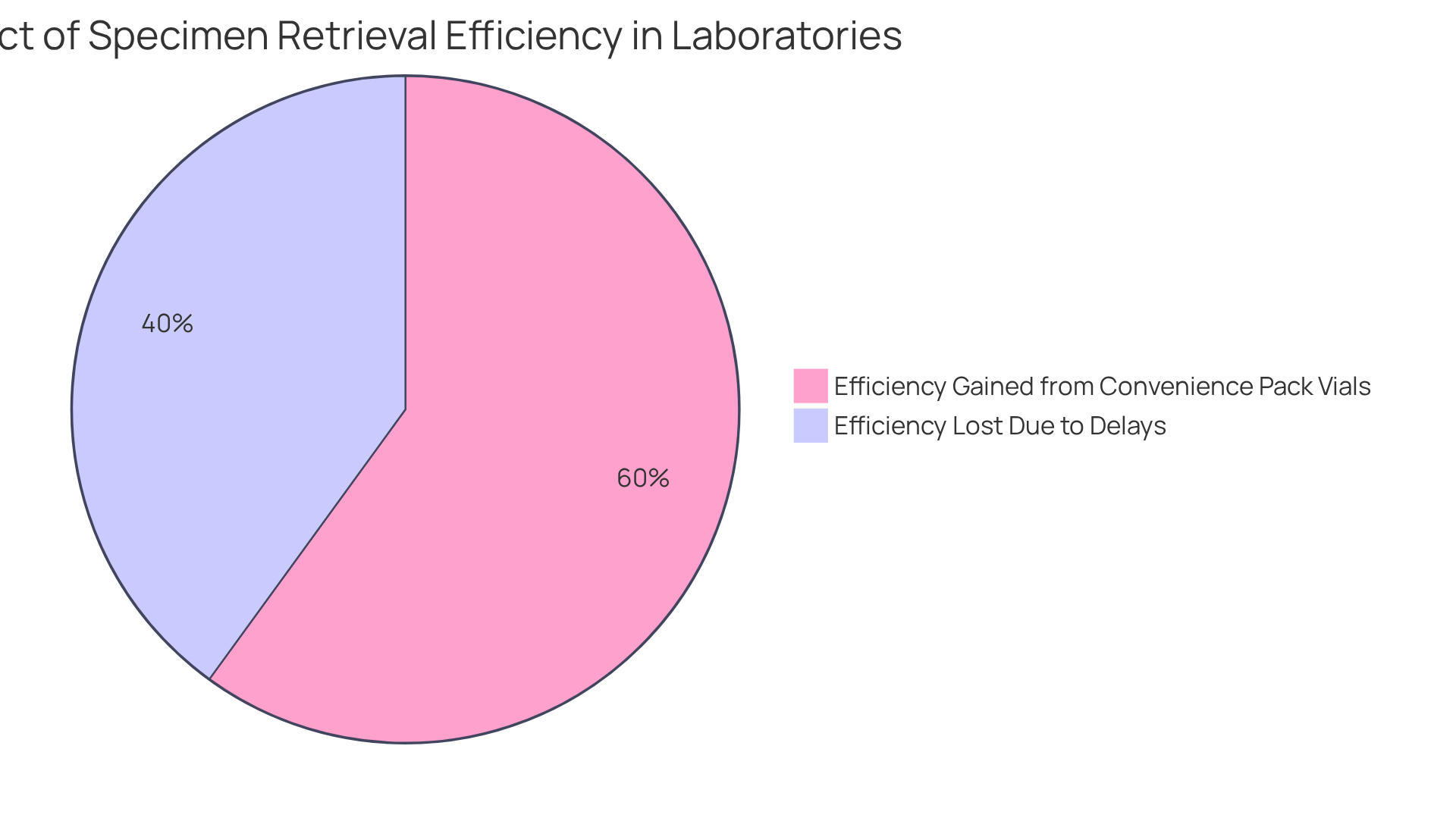

The Convenience Pack 2.0mL Clear Snap Seal Vial showcases a user-friendly design that facilitates quick access to specimens, a critical feature in high-throughput laboratories where efficiency is essential. The innovative snap seal mechanism guarantees a secure closure while allowing for effortless opening, making it particularly suitable for environments that demand rapid retrieval without sacrificing safety.

Retrieval times in high-throughput laboratories have a significant impact on overall productivity; research indicates that delays in accessing specimens can lead to a 20% reduction in operational efficiency. Lab technicians emphasize the necessity of swift material access, with one stating, "In our lab, every second matters." The quicker we can obtain specimens, the more tests we can perform, ultimately enhancing our throughput.

Real-world applications of quick access methods, including the septum cap and Convenience Pack vials, have demonstrated substantial improvements in workflow efficiency. For instance, a leading pharmaceutical facility reported a 30% decrease in collection times after adopting these vials, underscoring the tangible benefits of investing in user-centered solutions. Additionally, JM Science's commitment to quality and customer support ensures that facilities receive reliable products that bolster their operational capabilities.

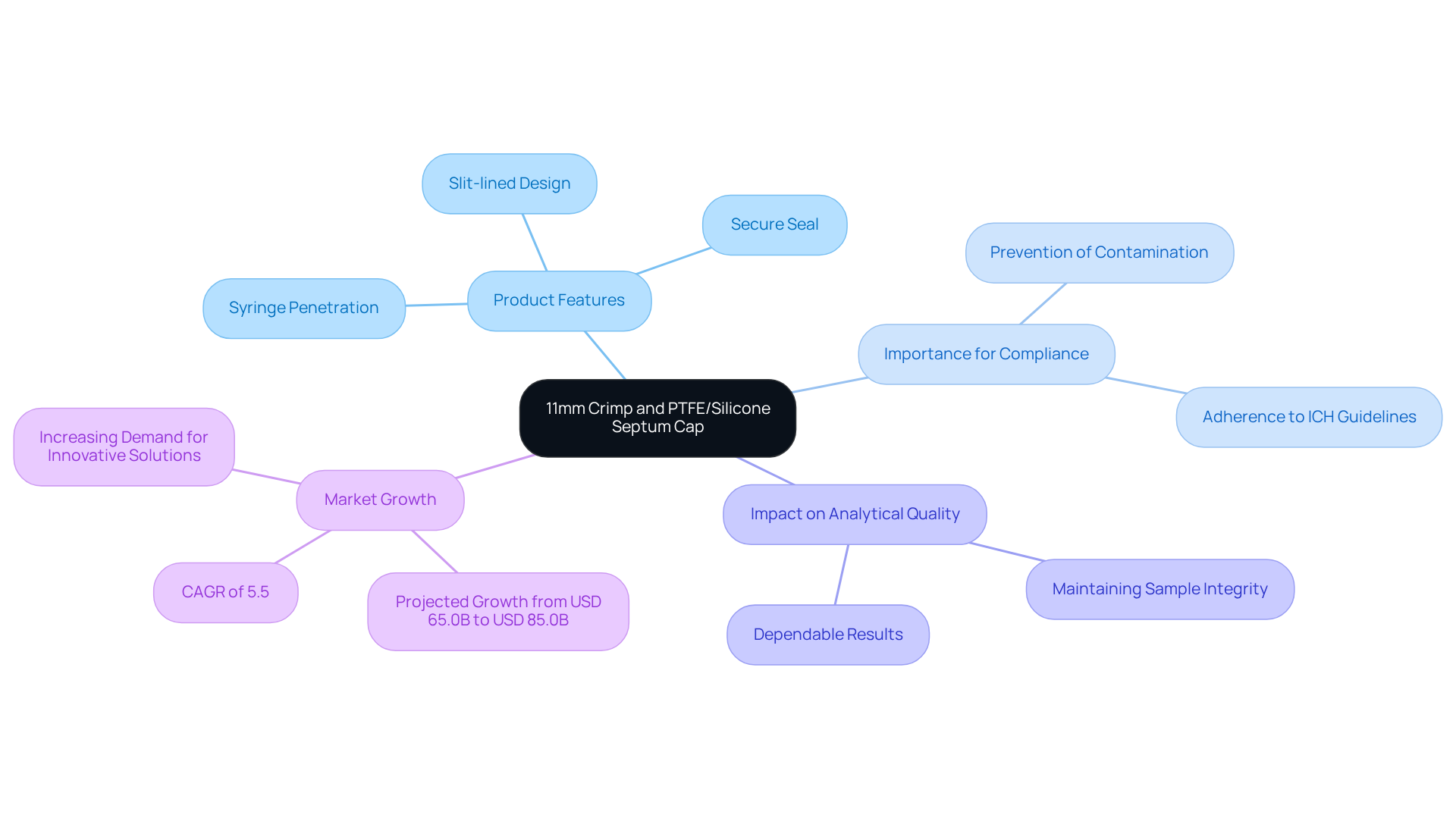

11mm Crimp and PTFE/Silicone with Slit Lined Cap: Precision for Analytical Procedures

The 11mm Crimp and PTFE/Silicone with Slit Lined Cap is meticulously engineered as a septum cap to optimize precision in analytical procedures. Its innovative slit-lined design facilitates effortless syringe penetration while ensuring a secure seal, which is crucial for maintaining sample integrity. This septum cap is particularly beneficial for facilities conducting sensitive analyses, where the precision of results is essential for adhering to compliance regulations.

Recent training materials released by the International Council for Harmonisation (ICH) on ICH Q2(R2) and ICH Q14 underscore the significance of secure seals in maintaining compliance. By preventing contamination, this approach assists laboratories in achieving dependable results, thereby highlighting the importance of high-quality septum caps in improving the overall standard of analytical procedures.

With the caps and closures market projected to grow from USD 65.0 billion in 2021 to USD 85.0 billion by 2026, the relevance of such innovative solutions is increasingly recognized within the industry.

High-Performance Septa for HPLC: Ensuring Sample Purity and Accuracy

High-performance barriers for HPLC applications are essential for ensuring sample purity and precision. These barriers are specifically designed to minimize the risk of contamination and leachables that can compromise analytical results. By investing in high-performance devices, laboratories can enhance the reliability of their HPLC analyses. This, in turn, leads to more precise and reproducible outcomes, reinforcing the critical role these instruments play in achieving optimal laboratory performance.

Flexible OEM Service for Custom Septa Solutions: Tailored Options for Unique Laboratory Needs

The adaptable OEM service for custom septum cap offerings empowers facilities to acquire personalized solutions that align with their specific requirements. This service proves invaluable for laboratories that necessitate unique configurations or materials to enhance their workflows. By providing tailored options, JM Science Inc. elevates operational effectiveness, ensuring that laboratories are equipped with the precise instruments necessary for their applications.

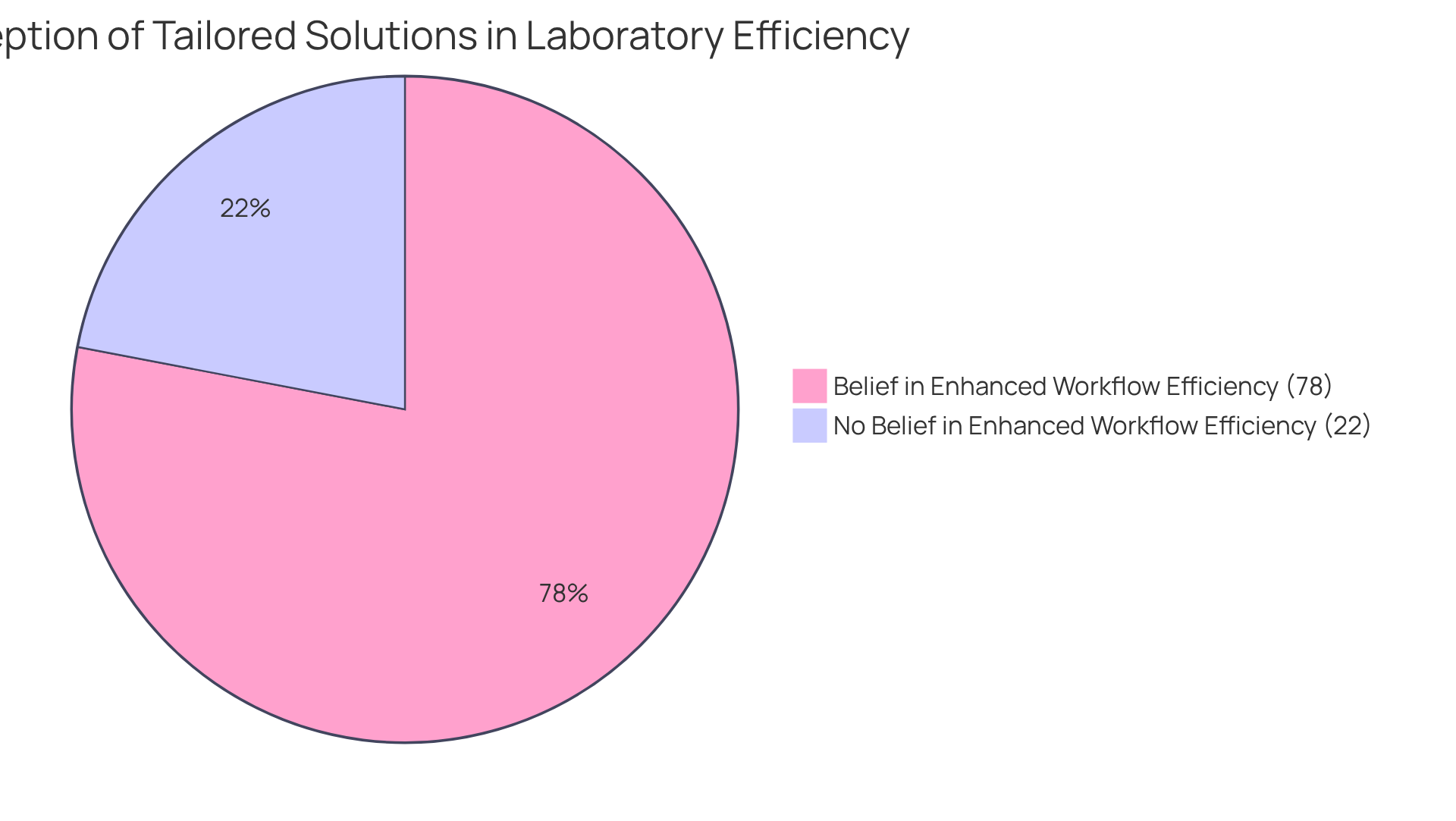

Indeed, a substantial percentage of managers in research facilities have articulated the demand for customized tools, underscoring that such personalization not only streamlines processes but also boosts overall productivity. A survey conducted by PanGlobal Media revealed that 78% of lab managers believe that tailored approaches significantly enhance their workflow efficiency.

Practical examples demonstrate that laboratories utilizing custom septum cap alternatives have experienced notable improvements in their analytical precision and turnaround times, emphasizing the critical role of personalized solutions in modern laboratory environments. One illustrative case involved a pharmaceutical lab that, after adopting a septum cap solution, achieved a 30% reduction in sample processing time, resulting in expedited results and heightened client satisfaction.

Conclusion

The exploration of essential septum cap solutions for pharmaceutical labs underscores the critical role these components play in maintaining sample integrity and enhancing laboratory efficiency. Each product discussed not only offers unique features but also meets the stringent demands of modern pharmaceutical environments, where precision and reliability are paramount.

Key insights from the article reveal that innovations such as pre-slit molded septa, PTFE/silicone combinations, and pre-assembled caps significantly mitigate contamination risks and streamline workflows. These advancements contribute to improved analytical accuracy and operational efficiency, crucial for laboratories striving to uphold high standards in research and testing.

In conclusion, the significance of investing in high-quality septum caps cannot be overstated. As the pharmaceutical industry evolves, embracing these advanced solutions will enhance the reliability of analytical results and foster a culture of excellence within laboratories. By adopting tailored options and innovative designs, facilities can ensure they remain at the forefront of research capabilities, ultimately leading to more reliable outcomes and greater client satisfaction.