Overview

This article presents nine strategies for effective column packing in high-performance liquid chromatography (HPLC), emphasizing the optimization of support materials, hardware design, and operational techniques to enhance analytical performance. Key strategies include:

- Adjusting slurry temperature

- Implementing constant-flow or constant-pressure methods

Research supports these approaches, demonstrating their significant impact on achieving uniform packing and improving separation efficiency. Ultimately, these strategies lead to more reliable chromatographic results, underscoring the importance of high-quality scientific instruments in laboratory settings.

Introduction

Achieving optimal separation efficiency in high-performance liquid chromatography (HPLC) is fundamentally dependent on the effectiveness of column packing. With the advent of advanced technologies and materials, laboratories are now equipped with a diverse array of strategies to enhance this critical facet of chromatography. As the demand for precision and reproducibility in analytical results intensifies, laboratories face the challenge of navigating the complexities of:

- Packing methods

- Particle selection

- Hardware design

What innovative techniques can laboratories adopt to ensure their column packing processes not only meet but exceed contemporary performance standards?

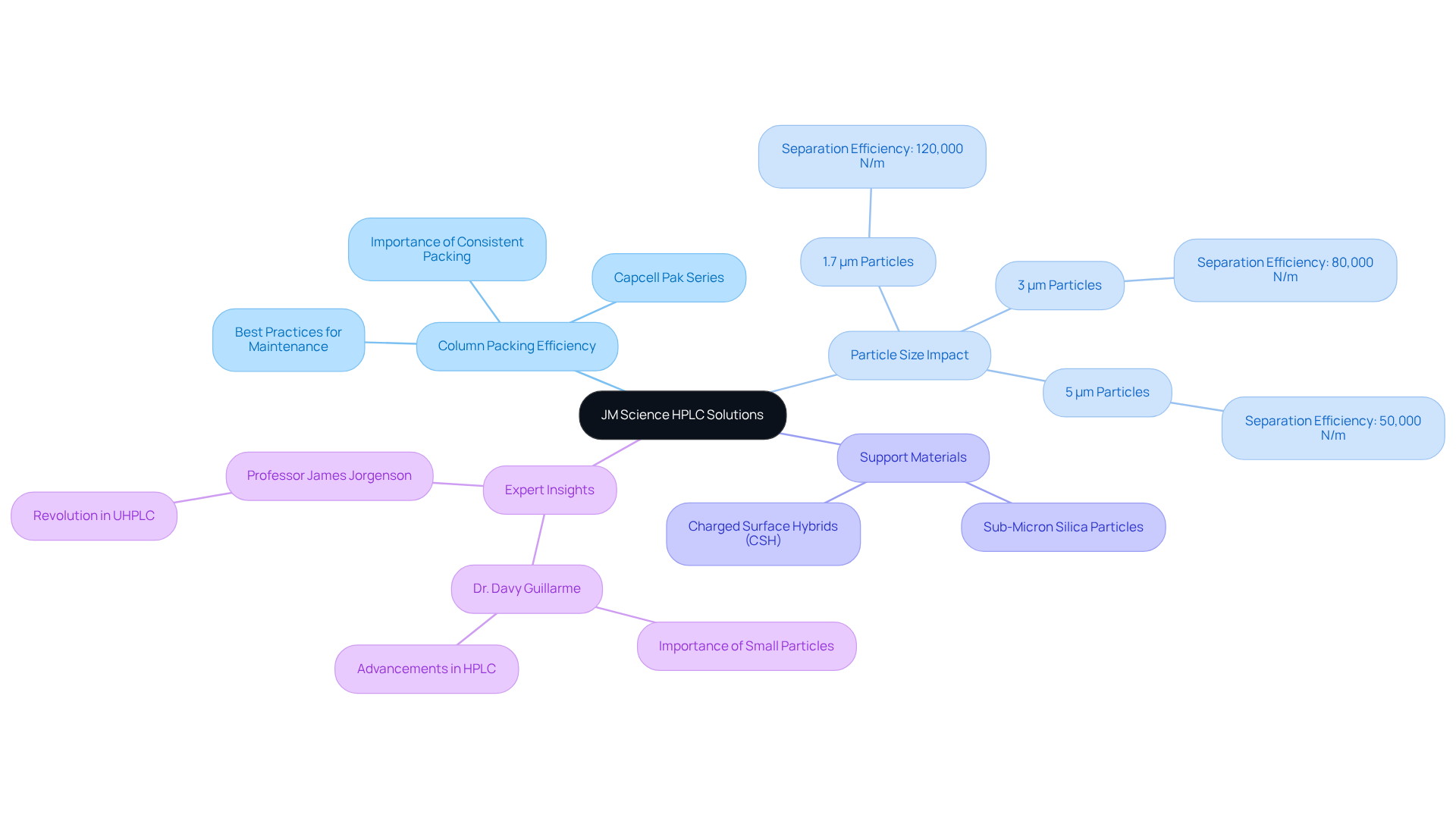

JM Science HPLC Solutions: Optimize Your Column Packing Efficiency

offers a comprehensive range of high-performance liquid chromatography solutions designed to enhance the effectiveness of support materials. Their advanced HPLC systems and accessories are meticulously engineered to ensure consistent column packing, a crucial factor for achieving optimal separation efficiency. By leveraging JM Science's products, laboratories can significantly elevate their analytical capabilities and improve the reproducibility of their results. For instance, specialized supports like the Capcell Pak series are known to minimize variability in density arrangement, resulting in more uniform performance during chromatographic analyses.

The impact of effective support arrangements, such as column packing, on analytical performance is profound. Research indicates that smaller particle sizes lead to increased system efficiency, with 1.7 μm particles achieving an impressive separation efficiency of 120,000 N/m, compared to traditional high-performance liquid chromatography's 50,000 N/m and supercritical fluid chromatography's 150,000 N/m. This development is vital for laboratories striving to enhance their analytical outcomes. Moreover, the implementation of innovative packaging techniques, particularly those involving column packing with sub-micron silica particles, is facilitating improved separations of complex samples, including biomolecules and chiral compounds.

Industry experts underscore the importance of these advancements. Dr. Davy Guillarme notes that contemporary separation technologies allow for faster and more efficient analysis of complex samples, underscoring the need for superior materials in high-performance liquid chromatography systems. Additionally, Professor James Jorgenson points to the revolution in ultra-high pressure LC (UHPLC) that began in 1997, which has resulted in significant enhancements in separation efficiency. As laboratories continue to pursue improvements in their analytical processes, JM Science remains at the forefront, delivering solutions that not only meet but surpass the evolving demands of the scientific community.

Understand the Science Behind High-Efficiency Column Packing

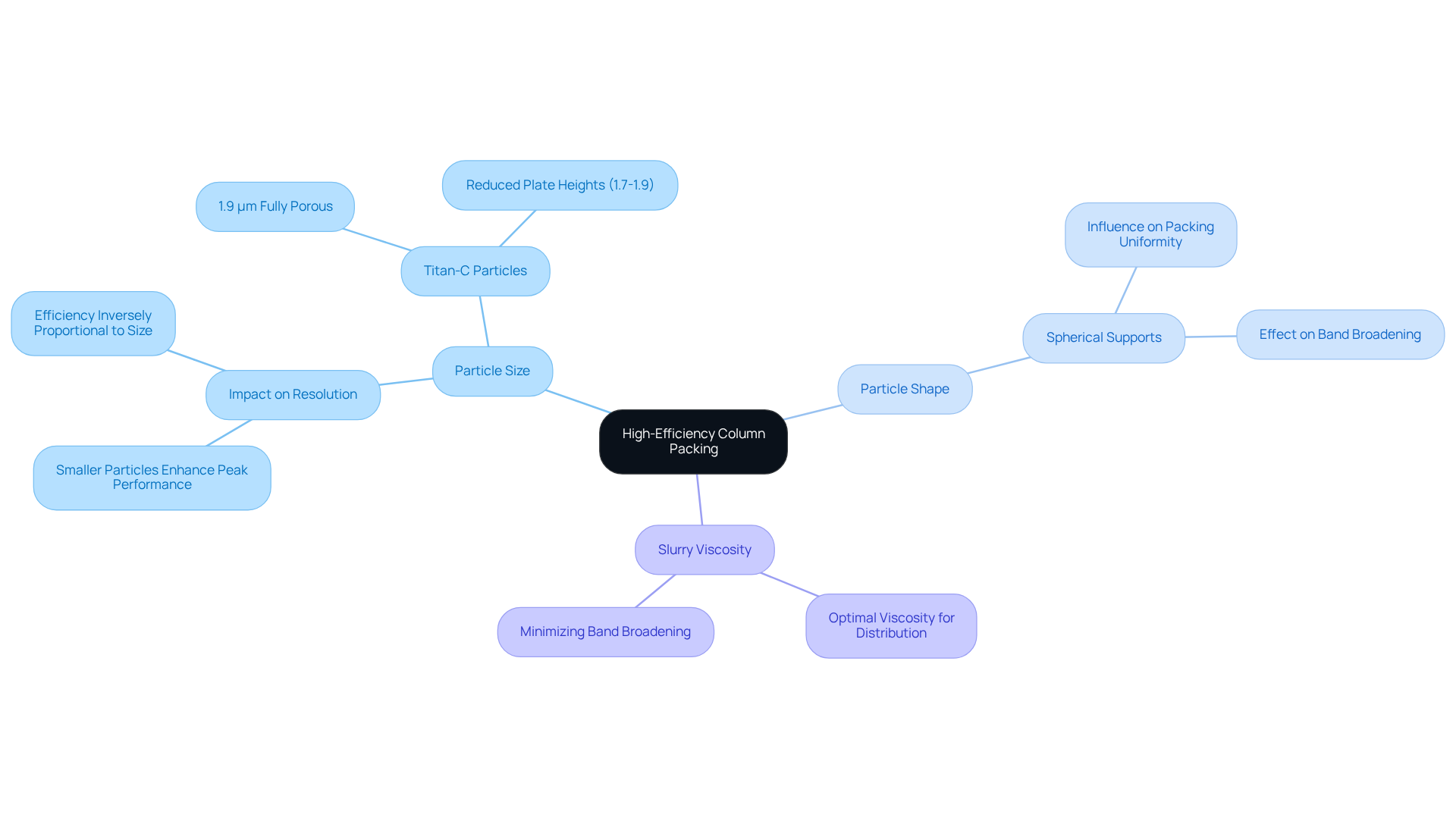

Achieving high-efficiency column packing in HPLC is fundamentally dependent on the uniform distribution of the stationary phase throughout the column. This critical process necessitates a thorough understanding of the interactions between the container material and the mobile phase, as well as the physical characteristics of the particles utilized. Key factors influencing this uniformity include:

- Particle size

- Shape

- The viscosity of the slurry used in column packing

Notably, research on Titan-C particles reveals that smaller particle dimensions, particularly those under 2 µm, significantly enhance peak performance and analyte resolution, culminating in superior chromatographic outcomes. Specifically, the minimum intrinsic reduced plate heights of supports packed with 1.9 μm fully porous Titan-C particles were determined to be between 1.7 and 1.9, indicating high performance for analytical size supports.

Furthermore, the viscosity of the slurry plays an essential role; optimal viscosity ensures even particle distribution, thereby minimizing band broadening and maximizing resolution. Proper column packing is imperative for achieving the high performance anticipated in liquid chromatography applications, as it directly influences the effectiveness and quality of separations. The resolution equation in separation science, encompassing , underscores the significance of these factors in delivering reliable analytical outcomes.

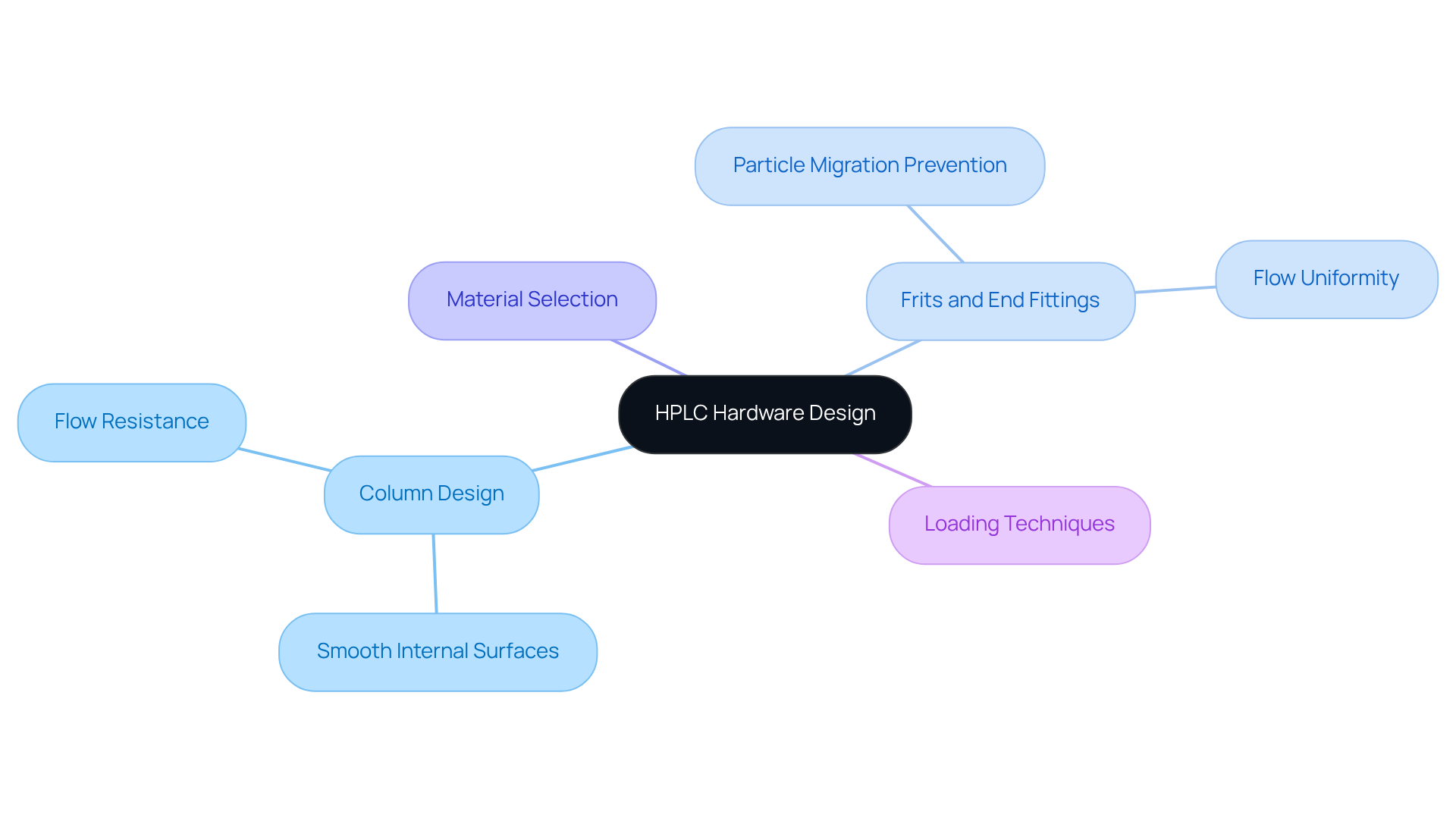

Implement Critical Hardware Design for Enhanced Packing Efficiency

Enhancing the effectiveness of HPLC systems hinges on the integration of crucial hardware design characteristics. Utilizing columns with smooth internal surfaces significantly reduces flow resistance, thereby promoting a uniform distribution of filler material. This strategic design choice is substantiated by industry insights, which indicate that smoother surfaces lead to improved storage efficiency and reduced dead volume.

As J J Kirkland articulates, 'Columns utilizing column packing still are the most popular devices for high-performance liquid chromatography (HPLC) separations because of their great utility, excellent performance, and wide variety.'

Moreover, the inclusion of high-quality frits and end fittings is vital to ensure effective column packing, preventing particle migration and upholding the integrity of the packed bed. For example, Mott’s pressed and sintered porous metal frits are meticulously engineered to enhance flow uniformity and filter contaminants effectively, ensuring reliable chromatographic results.

JM Science provides a diverse array of hardware options designed to optimize material performance, empowering laboratories to achieve exceptional analytical outcomes. Additionally, the hybrid approach of constant flow and pressure can further enhance loading effectiveness, allowing for improved control during the loading process.

Optimal practices in high-performance liquid chromatography hardware design necessitate a careful selection of materials and shapes, underscoring the impact of internal surface smoothness on overall efficiency and flow dynamics. To implement these concepts effectively, laboratories should against these best practices to pinpoint areas for enhancement.

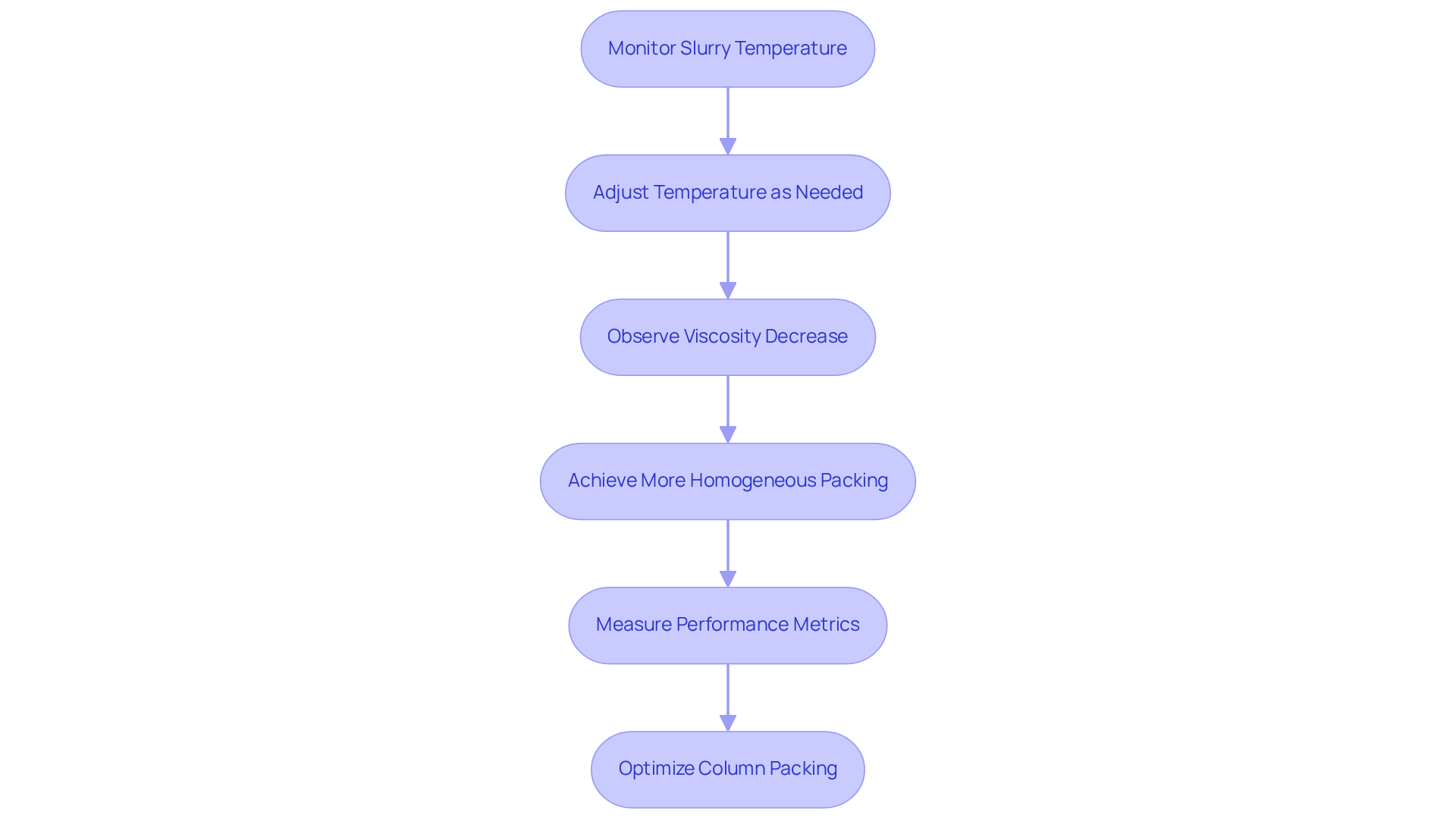

Utilize Slurry Temperature to Improve Packing Outcomes

Effectively utilizing slurry temperature is crucial for enhancing results in HPLC applications. Increased temperatures lead to a decrease in slurry viscosity, which enhances the flow and distribution of materials within the column packing. This results in a more homogeneous column packing, which is essential for achieving high-resolution separations.

Research indicates that optimizing slurry conditions, including temperature adjustments, can significantly reduce localized heterogeneities and improve column packing performance. For instance, studies have shown that structures utilizing column packing at elevated temperatures exhibit decreased plate heights and improved performance metrics, achieving efficiencies that surpass conventional methods.

Specifically, packed sections subjected to sonication have demonstrated performance with diminished plate heights nearing 1, achieving an impressive 470,000 plates/m. Therefore, it is advisable to utilize instruments such as digital thermometers or temperature-regulated water baths to consistently during the filling process, thereby enhancing the efficiency of column packing in HPLC.

Adopt Constant-Flow or Constant-Pressure Techniques for Uniform Packing

The choice between constant-flow and constant-pressure methods during the filling process is crucial for achieving uniformity in column packing. Constant-flow techniques maintain a steady flow rate, effectively preventing sedimentation of the material, which can lead to inconsistencies. Conversely, constant-pressure techniques guarantee even column packing of the material throughout the column, fostering a more uniform bed structure.

Research demonstrates that employing column packing with constant-flow materials can lead to a more uniform plate height distribution compared to constant-pressure methods, which often exhibit significant axial variation. For instance, a study revealed that packing capillaries with 3-µm C18 FPP at elevated temperatures under sonication produced higher plate counts than packing at room temperature, underscoring the advantages of optimized packing conditions.

The experimental was reported as 17.6% for a single section and 20.1% for two sections in series, highlighting the effectiveness of these optimized conditions. Furthermore, industry leaders emphasize that minimizing stress differences during bed consolidation can yield more consistent particle rearrangement throughout the diameter. Ken Broeckhoven noted that for gradients ranging from 5 to 95% organic modifier, a reduction in analysis time can be anticipated at around 20%.

Laboratories must thoroughly assess their specific needs and select the approach that aligns with their shipping criteria to achieve optimal outcomes in chromatography applications.

Identify and Resolve Fundamental Packing Issues Early

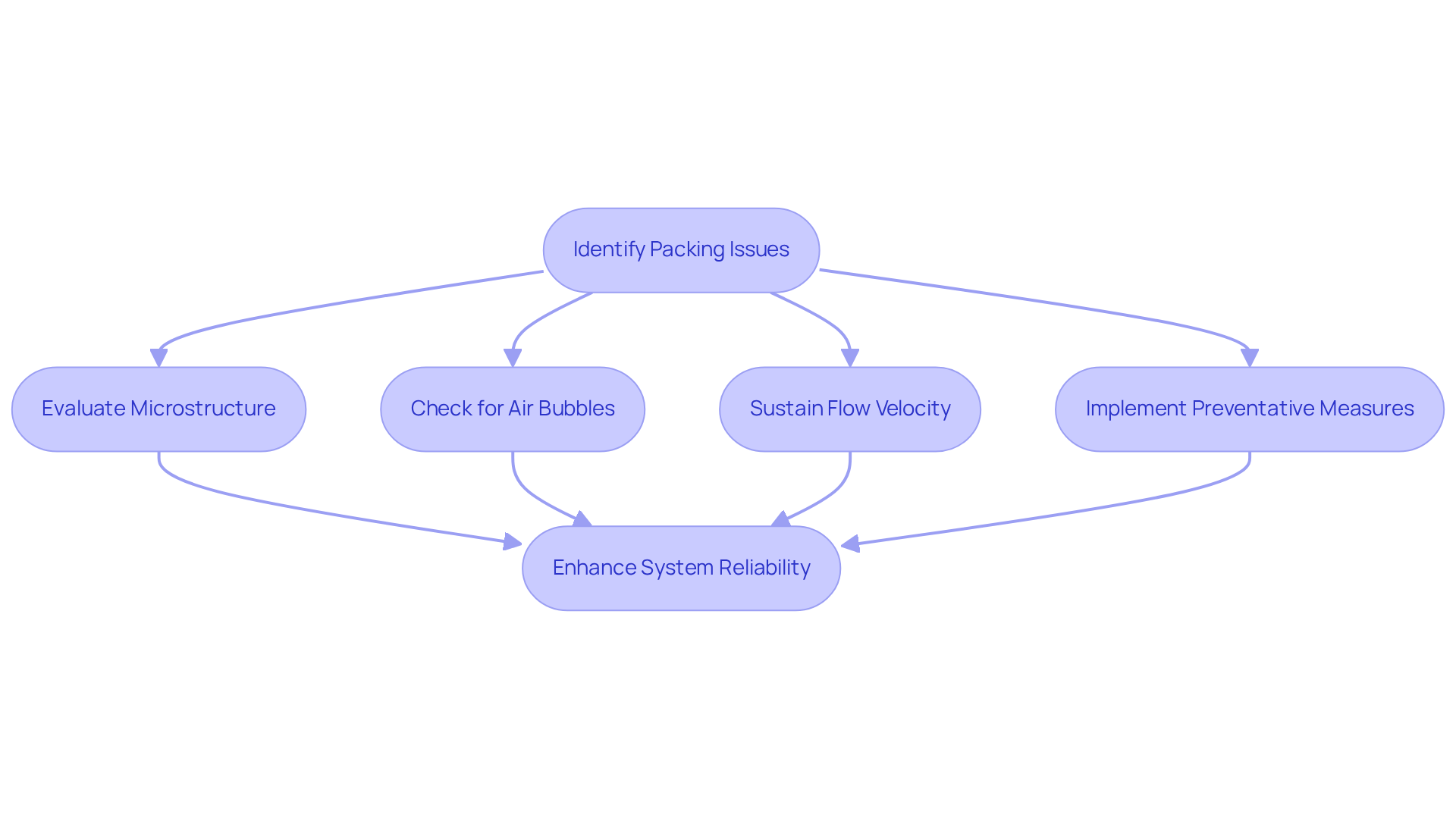

Recognizing and addressing basic storage problems early is essential for sustaining the efficiency of HPLC systems. Frequent issues such as inconsistent loading, air pockets, and channeling can lead to subpar separation performance. Research indicates that packaging flaws can elevate zone dispersion, significantly diminishing the . For instance, longitudinal dispersivity values of 10.32 cm and 4.35 cm have been noted, underscoring the impact of compaction issues on performance. Consistent oversight of column packing conditions, along with quality control measures, can help identify these problems before they escalate.

To troubleshoot uneven arrangement, evaluating the microstructure is crucial, ensuring that structures are devoid of air bubbles that can disrupt fluid flow. Sustaining a steady flow velocity—tested values of 1.76 cm³/sec and 6.27 cm³/sec—proves vital, as fluctuations can influence longitudinal dispersivity and compromise structural integrity. Implementing preventative measures, such as in-line filters and guard columns, can mitigate the risk of air entrapment and enhance the uniformity of materials.

Leveraging resources from JM Science, including how-to videos and application libraries, can provide valuable guidance in resolving packaging issues. Expert insights stress the importance of routine maintenance tasks, such as changing inlet solvent filters and inspecting for leaks, to minimize downtime and ensure optimal performance. By prioritizing early identification and employing effective problem-solving techniques, laboratories can enhance the reliability and performance of their liquid chromatography systems.

Explore Future Directions in Column Packing Techniques

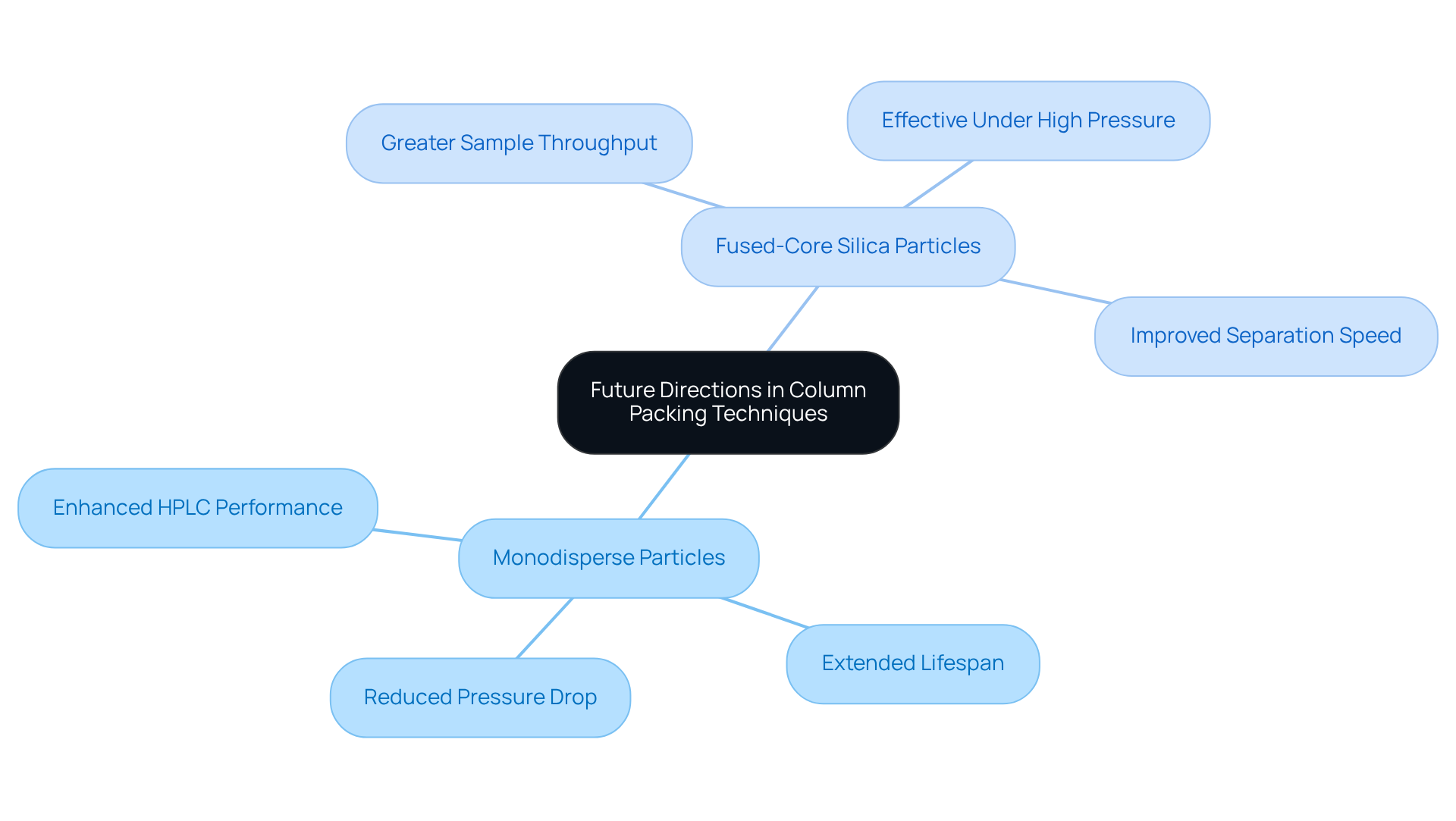

The investigation of future paths in column packing methods is crucial for laboratories aiming to excel in analytical chemistry. The adoption of monodisperse particles has emerged as a pivotal innovation, significantly enhancing HPLC performance. Research indicates that employing monodisperse particle-size distribution (PSD) correlates with improved performance, extended lifespan of the setup, and reduced pressure drop. For instance, Titan C18 particles, introduced in 2012, are 1.9-µm in size and have demonstrated reduced plate heights as low as 1.7, underscoring their effectiveness in high-performance applications. The typical and similar types is approximately 0.9 mL/min, further emphasizing their operational efficiency.

Moreover, advanced column packing methodologies are increasingly embraced by laboratories to optimize their HPLC systems. The introduction of Fused-Core silica particles, which combine a solid core with porous microspheres, in 2007 has revolutionized conventional performance, enabling greater sample throughput while maintaining effectiveness at elevated flow rates. This innovation is recognized for its ability to function effectively under high pressure, establishing it as a preferred choice for contemporary analytical techniques.

Engagement with industry conferences and publications is essential for laboratories to remain informed about these emerging trends. Insights from thought leaders in chromatography, such as Richard A. Henry, highlight the importance of optimizing flow velocities for various solutes to achieve maximum efficiency. He notes that a narrow PSD is associated with greater efficiency and prolonged equipment lifespan. As the field continues to evolve, laboratories that leverage these advancements will not only enhance their analytical performance but also maintain a competitive edge.

Overcome Challenges with Microbore Columns for Better Performance

Overcoming challenges with microbore tubes is vital for enhancing performance in HPLC applications. Due to their reduced size and diminished flow rates, these supports require precise methods of arrangement. Implementing strategies such as:

- Utilizing high slurry concentrations

- Optimizing column packing pressure

can ensure uniform column packing, thereby minimizing issues like peak broadening. Furthermore, laboratories must consider the specific requirements of their analyses when selecting microbore tubes to guarantee compatibility with their HPLC systems. This careful selection process is essential for in laboratory settings.

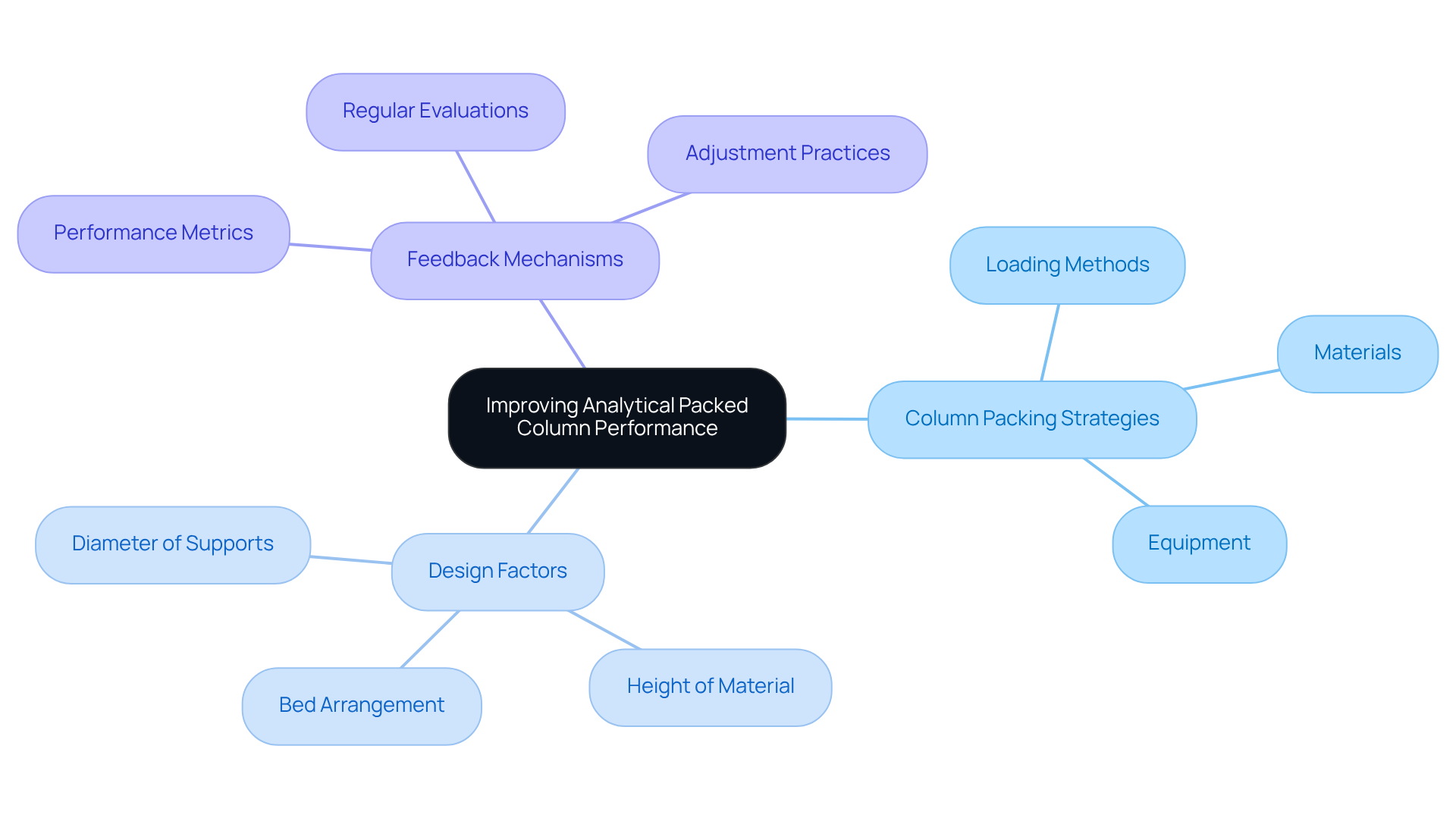

Continuously Improve Performance of Modern Analytical Packed Columns

Enhancing the performance of contemporary analytical packed structures through effective column packing is essential for laboratories aiming for excellence in their analyses. Regular evaluations of loading methods, materials, and equipment can lead to substantial improvements in the of column packing. By implementing feedback loops and performance metrics, laboratories can identify areas for enhancement and adjust their practices accordingly.

Qihao Jiang from the Institute of Bioengineering emphasizes that "pre-packed units have been increasingly utilized in process development and biomanufacturing due to their simplicity and reliability." Additionally, crucial design factors such as the diameter of supports, column packing, height of material, and bed arrangement significantly influence performance.

Alois Jungbauer notes that "the effectiveness of pre-filled tubes is guaranteed by the producer prior to the sale, with fill quality assessed in relation to the height equivalent to a theoretical plate (HETP) and asymmetry." By adopting these strategies and learning from successful laboratories that have implemented these practices, laboratories can markedly improve their separation efficiency in high-performance liquid chromatography.

Summarize Essential Techniques for Effective Column Packing

In summary, effective support in filling HPLC requires several essential techniques:

- Optimizing the use of JM Science's premium HPLC solutions

- Understanding the science behind filling

- Implementing critical hardware design

- Utilizing slurry temperature

- Adopting constant-flow or constant-pressure techniques

- Identifying and resolving filling issues early

- Exploring advancements in filling materials

- Overcoming challenges with microbore tubes

- Continuously improving performance

Notably, most modern UHPLC columns deliver plate heights ranging from 1.4 to 2.5, setting performance expectations for laboratories. Furthermore, filling capillaries with 3-µm C18 FPP at 70 °C yields higher plate counts compared to those filled at room temperature, underscoring the significant impact of slurry temperature on filling efficiency. The case study titled 'Column Packing Techniques in Chromatography' underscores the critical role of column packing methods in achieving reproducible and accurate chromatographic results. By applying these strategies, laboratories can enhance their analytical capabilities and achieve more reliable outcomes. As Melese Asfaw from the Department of Chromatography asserts, 'Proper arrangement guarantees that the stationary phase within the tube is evenly distributed, facilitating optimal interaction with the mobile phase and analytes.' This commitment to best practices in HPLC column packing, bolstered by JM Science's innovative solutions, is essential for advancing research and healthcare applications.

Conclusion

Achieving optimal column packing in high-performance liquid chromatography (HPLC) is fundamental for enhancing analytical precision and reproducibility. The strategies outlined in this article underscore the necessity of employing advanced techniques and comprehending the underlying science to ensure a uniform distribution of materials within the column. By leveraging the insights provided, laboratories can significantly enhance their chromatographic outcomes and sustain a competitive edge in analytical chemistry.

Key arguments presented include:

- The critical role of particle size and slurry viscosity in achieving high-efficiency packing.

- The significance of hardware design in minimizing flow resistance.

- The advantages of temperature optimization during the packing process.

Furthermore, this article emphasizes the importance of early identification and resolution of common packing issues, as well as the exploration of innovative materials and methods that can elevate performance in HPLC applications.

As laboratories continue to evolve and adapt to the demands of modern analytical challenges, embracing these strategies will be essential. Continuous improvement in column packing techniques not only enhances the reliability of results but also furthers the broader objectives of research and healthcare. Engaging with emerging trends and utilizing cutting-edge solutions from industry leaders like JM Science can pave the way for breakthroughs in analytical performance, ultimately contributing to more accurate and efficient scientific discoveries.