Overview

This article highlights the crucial components of pipettes that are vital for reliable laboratory performance. It emphasizes the significance of:

- Ergonomic designs

- Nosepiece kits

- Replacement motors

- Rubber inserts

These elements not only enhance efficiency but also prevent contamination and maintain precision in liquid handling. Consequently, they ensure accurate experimental results in various laboratory settings. Understanding the role of these components is essential for any laboratory professional aiming to achieve optimal results.

Introduction

In the realm of laboratory science, precision and reliability stand as imperatives, particularly in the context of pipetting. The Pipet-Aid® XP, along with its essential components, has emerged as a critical asset for professionals aiming to enhance their efficiency and accuracy in liquid handling.

Featuring ergonomic designs that mitigate hand fatigue and innovative nosepiece kits that effectively prevent cross-contamination, these devices are meticulously engineered to satisfy the stringent demands of contemporary laboratories.

As the dependence on accurate pipetting intensifies, grasping the significance of each component—from replacement motors to rubber inserts—becomes vital for preserving the integrity of experimental outcomes.

This article explores the multifaceted aspects of the Pipet-Aid® system, underscoring how these tools not only streamline workflow but also uphold the highest standards of quality in scientific research.

Pipet-Aid® XP: The Essential Pipetting Tool

This device serves as an essential instrument for laboratory professionals, designed to accommodate a range of pipette parts from 1 to 100 mL. Its ergonomic design significantly alleviates hand fatigue, enabling users to perform extended pipetting tasks comfortably. This advantage is particularly critical in high-volume environments, where efficiency is of utmost importance.

The device features three-speed settings, allowing for precise control over liquid aspiration and dispensing, making it adaptable for both standard research activities and complex experimental protocols.

From a performance standpoint, the device offers cordless functionality and achieves a flow rate exceeding 25 mL in just five seconds when using a 100 mL pipette, thereby enhancing productivity during essential operations. Additionally, it operates at a voltage of 110 V and weighs a mere 7.5 oz (212.6 g), positioning it as a lightweight and efficient choice for demanding research environments.

Practical applications of the device have demonstrated its effectiveness in pharmaceutical laboratories, where speed and precision are crucial. For instance, the TPP Turbo-Fix Pipet Controller, noted for its ergonomic design, has shown a 25% increase in liquid handling speed. This performance statistic underscores the advantages of ergonomic transfer tools, including pipette parts, which aim to enhance workflows and boost efficiency and reliability in laboratory settings.

Pipet-Aid® Nosepiece Kits: Enhancing Versatility

Pipet-Aid® nosepiece kits are designed with a variety of pipette components that significantly enhance the adaptability of pipette devices. At the core of these kits are self-locking filters, which are essential in preventing cross-contamination and preserving sample integrity. This is particularly crucial in laboratory environments where accuracy is of utmost importance; even minor contamination can lead to erroneous results, such as ghost peaks in HPLC, GC, and MS chromatograms.

The EZ Grip design facilitates effortless attachment and removal, enabling swift transitions between tasks—an essential feature in high-throughput environments. Utilizing appropriate pipette parts and nosepieces can optimize liquid handling methods tailored for specific applications, whether in microbiology, chemistry, or medical diagnostics. Research has shown that ergonomic pipette components, including specialized nosepiece kits, enhance accuracy and reproducibility in RT-PCR assays. This advantage is especially notable during extended liquid handling sequences, where ergonomic design reduces user fatigue and minimizes errors.

Statistics from 2025 indicate that facilities employing nosepiece kits have experienced a significant reduction in cross-contamination incidents, with some studies reporting decreases of up to 30%. This underscores their effectiveness in maintaining sample purity. Furthermore, microbiologists have commended these kits for their reliability and ease of use, with one expert stating, "Tacta pipettes are easy to clean and are fully autoclavable, which helps you to prevent contamination in cell culture work."

By integrating these advanced elements, research facilities can enhance their liquid handling precision and uphold the highest quality standards in their analytical procedures, fulfilling the essential requirements of pharmaceutical lab supervisors.

Pipet-Aid® Replacement Motor: Ensuring Reliability

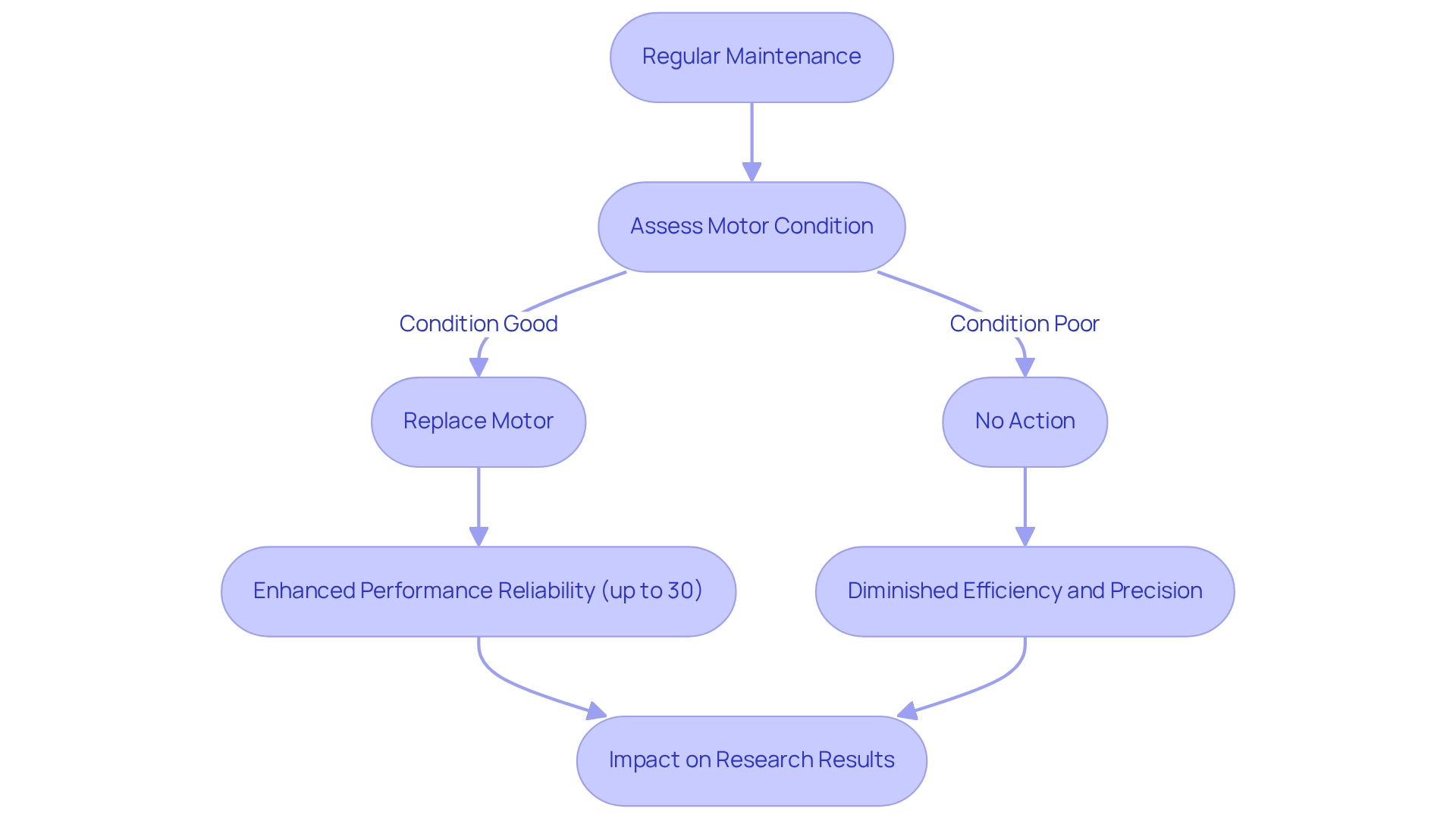

The Pipet-Aid® replacement motor is meticulously engineered to restore the device's original performance, effectively addressing the prevalent issue of motor wear resulting from frequent use. As motors deteriorate, laboratories often face diminished efficiency and precision in liquid handling tasks. By proactively replacing the motor, laboratories can guarantee that their liquid handling devices function at optimal levels, which is crucial for preserving the integrity of experimental results in both research and clinical environments.

Statistics indicate that regular maintenance can significantly reduce wear on liquid handling instruments. Research demonstrates that timely motor replacements can enhance performance reliability by as much as 30%. Moreover, monitoring and measurement should concentrate on critical components that frequently fail, as highlighted by Enesi Y. Salawu et al.

This proactive approach not only extends the lifespan of the Pipet-Aid® but also bolsters the overall reliability of research operations. Lab managers have emphasized that consistent equipment performance is vital for achieving accurate results, with one stating, "Reliable equipment is the backbone of our research; any downtime can lead to significant setbacks."

Incorporating pipette parts, such as replacement motors, into routine maintenance schedules is essential for ensuring that pipetting devices remain dependable. The case study titled 'Basic Rules for Quality in Health Institutions' underscores the importance of adhering to quality standards in medical facilities, reinforcing the necessity of motor replacements. As the demand for precision in laboratory environments continues to escalate, the importance of maintaining and replacing pipette parts cannot be overstated.

This unwavering commitment to equipment reliability ultimately supports advancements in research and clinical practices.

Pipet-Aid® Rubber Inserts: Key for Precision

Pipet-Aid® rubber inserts are essential for establishing a secure connection between the pipette and the device, a critical factor for precise liquid transfer. These inserts create a reliable seal that effectively prevents air leaks, thus preserving the integrity of the liquid being pipetted. Statistics indicate that air leaks can significantly compromise the precision of liquid handling, leading to potential errors in experimental outcomes.

Moreover, liquid displacement utilizes system liquid regulated by a solenoid valve, enhancing the precision of both drawn and dispensed volumes. Regularly replacing these rubber inserts is vital for minimizing contamination risks and ensuring consistent performance. By maintaining these components in optimal condition, laboratories can substantially improve their liquid handling accuracy and decrease the likelihood of experimental errors.

Furthermore, case studies demonstrate that Pipet-Aid rubber inserts not only enhance precision but also contribute to contamination reduction, underscoring their importance in scientific practices. Laboratory technicians consistently stress the need for maintaining pipette parts, noting that the integrity of these components is directly linked to the accuracy of liquid transfer in 2025 and beyond. As one technician remarked, 'The ubiquity of pipettes in laboratories coupled with the potential for failure makes the propensity for error large.'

Insights from simulations of sleeve sealing ring assembly processes reveal wear patterns and the effectiveness of sealing components, further reinforcing the argument for the maintenance of rubber inserts.

Conclusion

The Pipet-Aid® XP and its associated components signify a pivotal advancement in laboratory pipetting, underscoring the critical need for precision and reliability in scientific research. Its ergonomic design not only mitigates hand fatigue but also enhances workflow efficiency, rendering it indispensable for professionals engaged in high-volume tasks. The versatility provided by the Pipet-Aid® nosepiece kits, equipped with self-locking filters, plays a vital role in preventing cross-contamination, thereby safeguarding the integrity of experimental results.

Moreover, regular maintenance through the replacement of motors and rubber inserts is crucial for sustaining the performance and reliability of pipetting devices. A proactive approach to equipment upkeep leads to improved accuracy and a reduction in errors, which is essential for maintaining quality standards in laboratory environments. By emphasizing the significance of these components, laboratories can uphold the highest quality standards in their analytical processes.

In conclusion, the Pipet-Aid® system transcends being merely a tool; it stands as a cornerstone of efficient and accurate laboratory practices. As the demand for precision in scientific research continues to escalate, investing in reliable pipetting devices and their maintenance becomes imperative for achieving successful outcomes. Embracing these advancements not only streamlines workflows but also fortifies the integrity of research, ultimately propelling progress within the scientific community.