Overview

The essential features of an autosampler for pharmaceutical laboratories encompass:

- Precision in sample handling

- Advanced automation capabilities

- Compatibility with various instruments

- User-friendly interfaces

These attributes collectively enhance both efficiency and accuracy in testing processes. By detailing how these features contribute to the reduction of human error, increased throughput, and improved data management, the article underscores their significance in ensuring reliable and cost-effective laboratory operations.

Introduction

In the realm of pharmaceutical analysis, precision and efficiency are non-negotiable. Autosamplers have emerged as indispensable tools, revolutionizing the way laboratories manage sample injections and data management. Their ability to deliver accurate volumes, automate processes, and integrate seamlessly with various analytical instruments enhances laboratory workflows while minimizing human error.

As the demand for rapid and reliable testing grows, the advantages of autosamplers—ranging from high sample throughput to customizable settings—become increasingly vital.

This article explores the multifaceted benefits of autosamplers, emphasizing their critical role in optimizing pharmaceutical research and ensuring compliance with stringent industry standards.

Precision Sample Handling

The autosampler plays a critical role in ensuring that precise volumes are drawn and injected into the analytical system, which is vital for applications involving the Karl Fischer titrators AQV-300 and AQ-300. These titrators are specifically employed for drug and medicine testing in accordance with the Japanese Pharmacopoeia, where accuracy is of utmost importance.

A well-calibrated autosampler can achieve injection volumes within ±1% of the target, significantly mitigating the risk of human error associated with manual sampling. This level of precision not only minimizes variability but also enhances the reproducibility of results, which is essential for maintaining the integrity of pharmaceutical analyses.

Ultimately, investing in a reliable autosampler is crucial for laboratories aiming to uphold the highest standards in their testing processes.

Automation Capabilities

Contemporary autosamplers are equipped with advanced automation features that facilitate the scheduling of numerous injections without manual intervention. This capability significantly enhances laboratory efficiency, ensuring consistent specimen processing. For instance, an autosampler can be programmed to operate overnight, processing hundreds of specimens while staff are off-duty. Such automation not only maximizes throughput but also optimizes resource allocation, allowing personnel to concentrate on critical tasks like patient care and outreach initiatives.

The integration of automation within pharmaceutical environments is projected to continue its upward trend, driven by the demand for improved safety and efficiency. Automation minimizes exposure to hazardous materials, thereby reducing the risk of repetitive strain injuries and bolstering workplace safety. Research indicates that automation can yield substantial time savings in testing environments, with some facilities reporting processing time reductions of up to 50%.

Moreover, the capability to arrange multiple test injections with an autosampler allows facilities to optimize workflows and enhance operational efficiency. Case studies, such as "Safety Enhancements with Automation," illustrate that research facilities utilizing automated systems can achieve significant advancements in throughput, with some institutions managing thousands of samples weekly. As Jeff Gaus, President and CEO, highlights, these advancements not only lead to cost savings but also empower companies in the pharmaceutical sector to reinvest in research and development, thereby fostering innovation in drug development.

Instrument Compatibility

In contemporary facilities, particularly in the pharmaceutical sector, autosamplers are indispensable due to their compatibility with a range of analytical instruments, including HPLC, GC, and mass spectrometers. This essential compatibility allows facilities to incorporate autosampler devices into their existing workflows with minimal modifications. Notably, a significant percentage of laboratories currently utilize autosamplers alongside their analytical instruments, underscoring their widespread acceptance and efficacy.

Many autosamplers are specifically engineered to integrate seamlessly with standard HPLC systems, such as those offered by JM Science Inc., which facilitates straightforward adoption in pharmaceutical laboratories without necessitating substantial additional investments. Moreover, compatibility statistics reveal that most devices, including autosamplers, can efficiently interface with both HPLC and GC systems, ensuring versatility across various analytical applications.

Importantly, Crimp Caps provide a robust seal that is less prone to leakage under varying pressure conditions, thereby enhancing the reliability of sample holders in testing environments. Case studies illustrate the successful integration of automatic sampling devices into research workflows, exemplified by the study titled 'Adaptation to Evolving Needs,' which highlights how JM Science Inc. addresses the evolving demands of the scientific community through its innovative product offerings.

By leveraging the capabilities of an autosampler, laboratories can optimize their processes, ultimately fostering advancements in research and healthcare. Additionally, ongoing innovations in vial technology are further enhancing performance to meet the dynamic requirements of analytical chemistry.

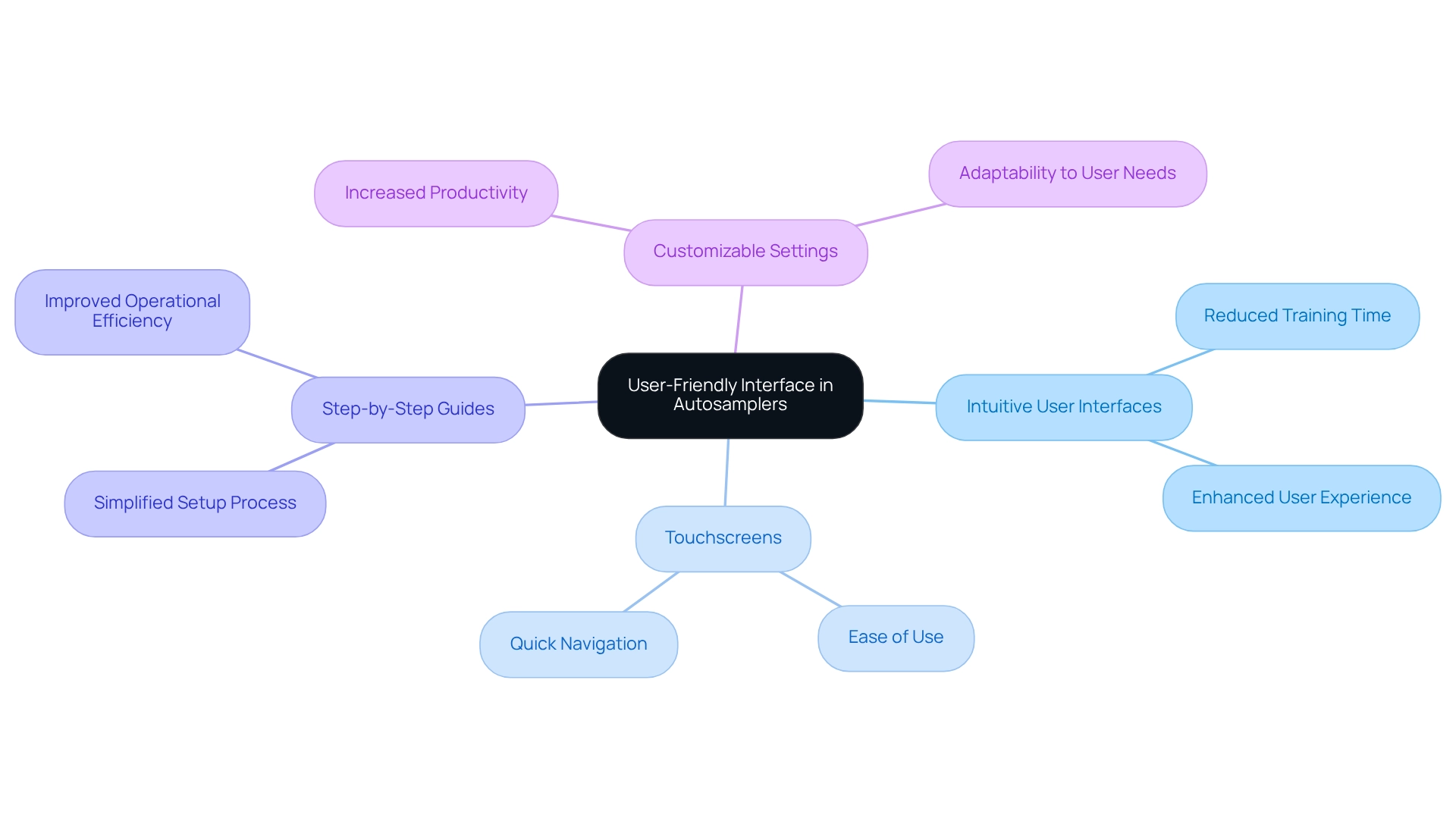

User-Friendly Interface

Modern autosamplers are equipped with intuitive user interfaces that significantly enhance the setup and operational processes. These advanced interfaces often feature touchscreens, step-by-step guides, and customizable settings, enabling users to swiftly adapt the system to their specific requirements.

For instance, an autosampler with a graphical user interface can drastically reduce the time needed for training new staff, allowing them to achieve proficiency in operating the equipment much more quickly. This efficiency not only streamlines laboratory workflows but also contributes to overall productivity, underscoring the critical role of high-quality scientific instruments in laboratory settings.

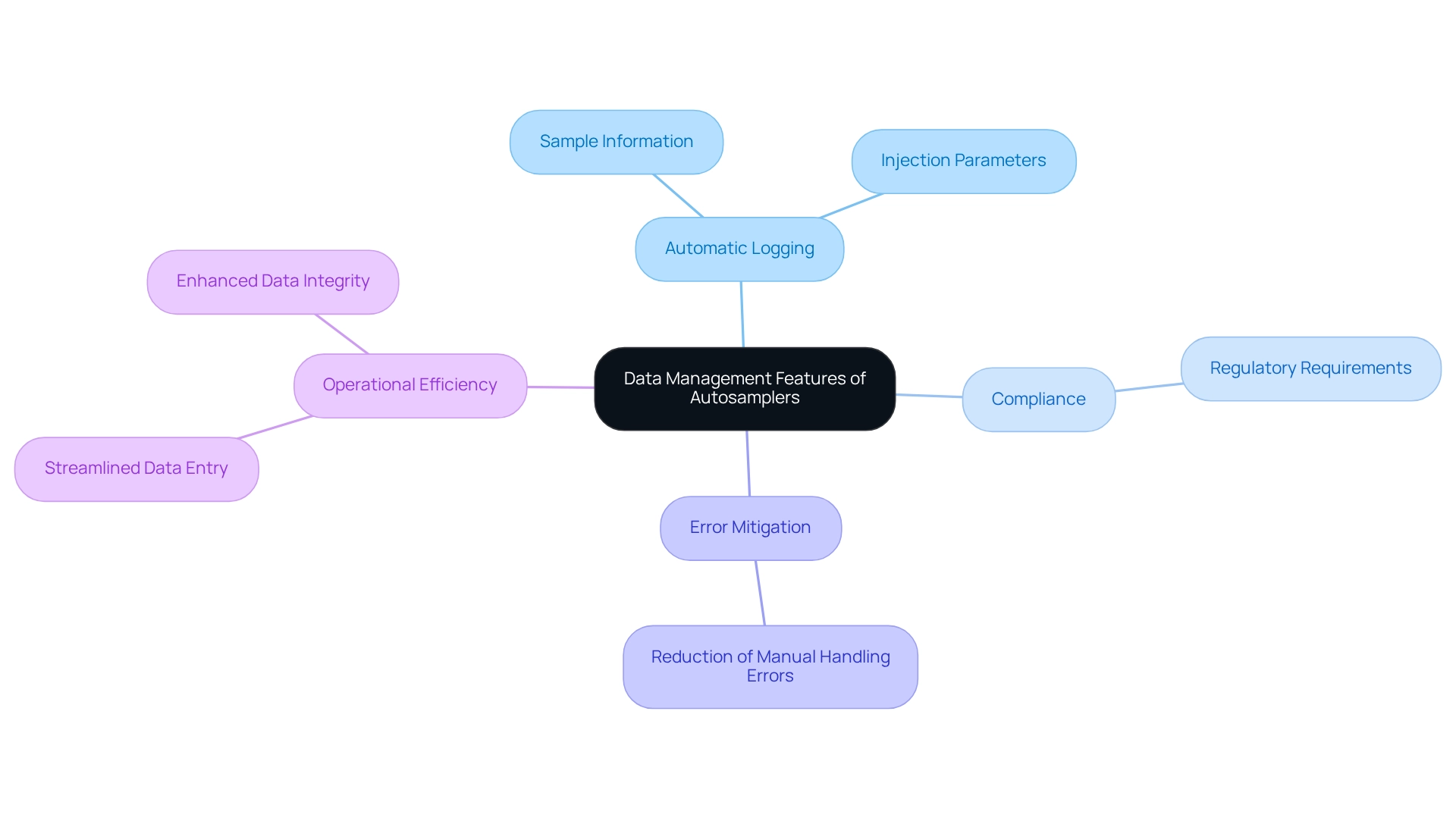

Data Management Features

Autosampler devices are equipped with advanced data management features that facilitate automatic logging of sample information, injection parameters, and results. This capability is essential for ensuring compliance with regulatory requirements, as it guarantees that all data is accurately recorded and readily retrievable.

For example, an autosampler that integrates with laboratory information management systems (LIMS) significantly streamlines data entry and mitigates the risks of errors associated with manual data handling. By leveraging such technology, laboratories can enhance operational efficiency and uphold the integrity of their data management processes.

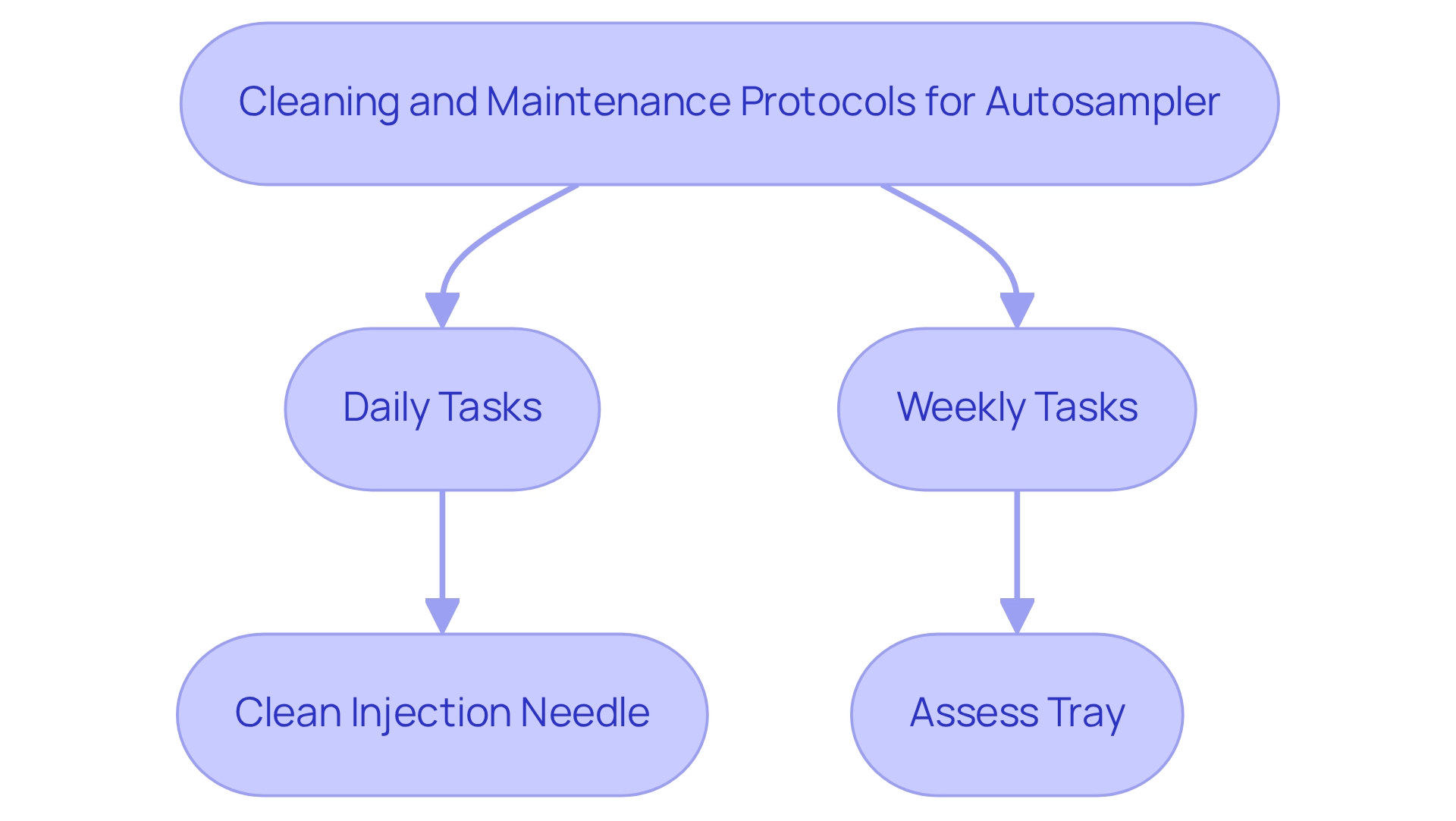

Cleaning and Maintenance Protocols

To ensure optimal performance of the autosampler, regular cleaning and maintenance are essential. This involves systematic inspections of the tray, needle wash station, and injection port to mitigate the risks of carryover and contamination. A well-defined maintenance timetable, which includes:

- Daily cleaning of the injection needle

- Weekly assessments of the tray

can significantly enhance the reliability of the autosampler's performance. By prioritizing these maintenance practices, laboratories can uphold the integrity and accuracy of their scientific instruments.

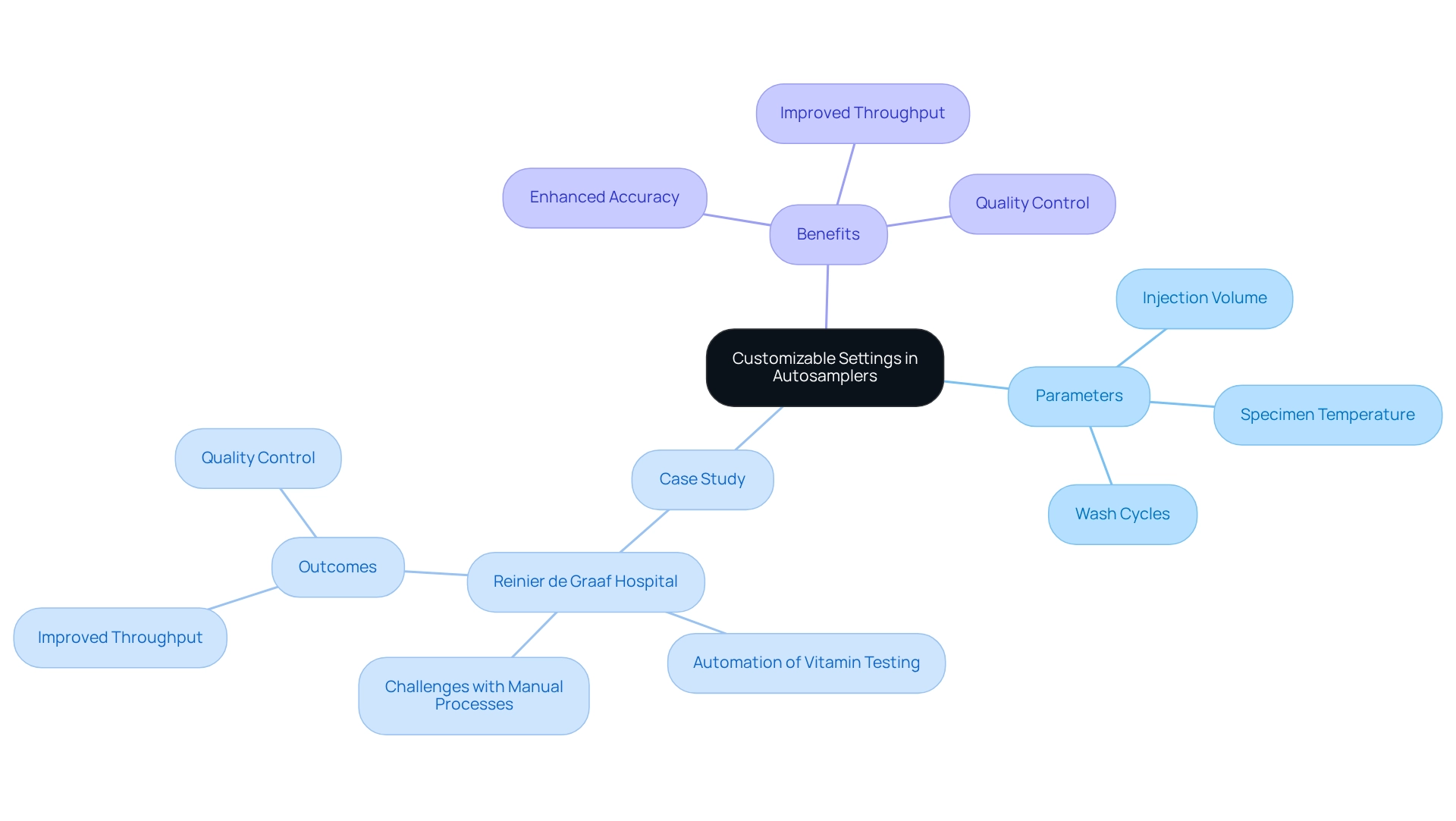

Customizable Settings

Autosampler systems equipped with customizable settings offer significant advantages in pharmaceutical environments by enabling precise adjustments to parameters such as injection volume, specimen temperature, and wash cycles. This adaptability is essential, as various assays frequently require specific conditions to guarantee optimal performance. For example, an autosampler designed to establish unique wash protocols for different specimen types can effectively minimize the risk of cross-contamination, thus enhancing the accuracy of analytical results.

The importance of these customizable features is underscored by a case study from the Reinier de Graaf Hospital, where the implementation of an automated system addressed challenges associated with labor-intensive manual specimen preparation processes. By automating specimen preparation with adjustable parameters, the facility not only streamlined its operations but also significantly decreased errors linked to manual handling, resulting in improved throughput and quality control in vitamin testing.

Statistics reveal that facilities employing customizable settings in their autosampler experience a notable increase in assay accuracy, with many achieving enhanced reproducibility in their results. The complete automation of preparation protocols marks a significant advancement for medical facilities. This flexibility in testing automation equipment not only optimizes workflow but also satisfies the stringent demands of pharmaceutical applications, ultimately leading to more reliable and efficient testing outcomes.

High Sample Throughput

The design of autosamplers facilitates high throughput, enabling laboratories to efficiently manage significant volumes of specimens. Specific models can handle up to 192 instances in one run, which significantly reduces analysis time. This efficiency is crucial in pharmaceutical labs, where rapid turnaround times are essential for meeting project deadlines. The introduction of advanced systems, such as the autosampler AS Vision, exemplifies this trend. Designed for use with vapor pressure and FTIR analyzers, it enables swift and ongoing testing of various specimens with a single button press. This innovation not only enhances technical performance by reducing carryover and rinsing cycles but also significantly decreases cross-contamination risks, thereby improving overall handling and throughput efficiency. As Rand Price, a commentator at Grabner Instruments, noted, 'With its corrosion-resistant design, the autosampler AS Vision is exceptionally suited to testing aggressive materials.'

Moreover, the Automated Total Nitrosamine Analyser by Ellutia illustrates how autosamplers can effectively manage large volumes of specimens while ensuring compliance with safety regulations. This capability is essential for preserving product integrity and accelerating the development process in the healthcare sector. In high-throughput labs, the ability to examine specimens swiftly can lead to time reductions of up to 30%, directly impacting project timelines and enabling quicker decision-making.

The advantages of managing large quantities of specimens quickly extend beyond mere efficiency; they also enhance the facility's capacity to address urgent testing needs, ultimately facilitating the rapid advancement of drug research and development.

Reliable Performance

A dependable autosampler is essential for achieving consistent performance in pharmaceutical laboratory analysis. Key features that enhance reliability include:

- Robust construction

- High-quality components

- Regular calibration

Autosamplers employing advanced syringe technology significantly reduce the risk of mechanical failures, ensuring accurate and consistent sample injections over time. A case study on calibration sampling revealed that the average box coefficient was determined to be 2.25, highlighting the variability in box coefficients due to a broken bottle on one sampling date. This underscores the necessity of precise sampling methods for reliable sediment concentration data.

Furthermore, statistics indicate that rigorous quality control and maintenance practices can minimize mechanical failure rates in autosamplers, reinforcing the importance of these reliability features. As Paul Voelker aptly stated, "Put another way, can a research workflow handle change? Does it work efficiently? Can you count on the workflow to deliver the required goods?"

By prioritizing these reliability features, facilities can enhance their analytical capabilities and ensure dependable results in their research and testing processes.

Cost-Effectiveness

Investing in an autosampler represents a compelling and cost-effective solution for facilities aiming to enhance their analytical capabilities. By automating sample injections, these systems significantly reduce reliance on manual labor, leading to substantial operational cost savings. Facilities utilizing automatic samplers often report labor expense reductions of up to 30%, allowing personnel to focus on more critical tasks.

However, it is essential to consider the high initial investment costs associated with automated sampling devices, which can be significant for some laboratories. Lab managers must carefully weigh this aspect against the long-term benefits. The improved throughput and precision offered by autosamplers not only elevate the quality of results but also help mitigate expenses related to rework and retesting. This is particularly vital in the pharmaceutical sector, where accuracy is non-negotiable. Moreover, the financial benefits of automation extend beyond immediate savings; facilities can achieve a return on investment (ROI) within 12 to 18 months, depending on usage and operational scale.

Recent case studies underscore a growing trend towards environmentally sustainable designs for autosamplers, which consume less energy and produce less waste, aligning with both cost-saving and sustainability objectives. These advancements contribute not only to environmental goals but also enhance the overall cost-effectiveness of operational processes. As the demand for efficient analytical techniques escalates, the financial implications of adopting such technologies become increasingly favorable.

Expert perspectives further highlight the significance of these investments, with numerous industry leaders advocating for the integration of automation in research environments. Keith Bratchford, Vice President and General Manager of Agilent's Atomic Spectroscopy Division, asserts that advanced technologies like the ADS 2 will have substantial applications in the advanced materials market, particularly in battery research, setting them apart from competitors. The upcoming nitrosamine webinar scheduled for August 15, 2024, will delve into the Automated Total Nitrosamine Analyser, showcasing advancements that further enhance the cost-effectiveness of operational processes. By embracing automation, pharmaceutical laboratories not only streamline their workflows but also position themselves for enduring financial success.

Conclusion

The integration of autosamplers into pharmaceutical laboratories signifies a pivotal advancement in achieving precision, efficiency, and reliability in sample analysis. These sophisticated instruments guarantee accurate sample handling, significantly minimizing human error and variability—an essential factor in adhering to stringent regulatory standards. By automating processes, autosamplers not only enhance throughput but also optimize resource allocation, enabling laboratory personnel to focus on more critical tasks.

Furthermore, the compatibility of autosamplers with various analytical instruments highlights their versatility, allowing for seamless integration into existing workflows. Their user-friendly interfaces and advanced data management features simplify operations and uphold compliance, while customizable settings cater to specific assay requirements, thereby enhancing accuracy and reproducibility. Regular maintenance protocols are vital to ensure these instruments perform reliably, contributing to consistent analytical outcomes.

Additionally, the cost-effectiveness of autosamplers warrants attention. While the initial investment may be considerable, the long-term savings in labor costs, coupled with improved operational efficiency, provide a favorable return on investment. As the demand for rapid and reliable testing escalates, the role of autosamplers in pharmaceutical research becomes increasingly indispensable. By embracing these technologies, laboratories not only bolster their analytical capabilities but also advance pharmaceutical development, ultimately leading to improved healthcare outcomes.