Overview

This article delves into the selection and troubleshooting of 0.22 um syringe filters, underscoring their vital role in maintaining sterility and ensuring effective filtration in laboratory applications. It presents essential criteria for selection, including:

- Membrane material

- Sterility

- Specimen volume

- Viscosity

Additionally, it offers troubleshooting tips for common issues such as:

- Clogging

- Leakage

By doing so, it empowers users to make informed decisions and sustain optimal performance in their filtration processes.

Introduction

Understanding the intricacies of syringe filters is essential for anyone involved in laboratory processes, particularly in achieving sterile filtration. The 0.22 µm syringe filter is a vital tool, effectively eliminating bacteria and certain viruses to ensure sample integrity. Selecting the right filter, however, involves navigating a complex landscape of pore sizes, membrane materials, and application-specific requirements.

- What are the implications of making the wrong choice, leading to contamination or inefficient filtration?

- How can one troubleshoot common issues to maintain accuracy?

This guide delves into the critical aspects of 0.22 µm syringe filter selection and troubleshooting, empowering readers to optimize their filtration processes.

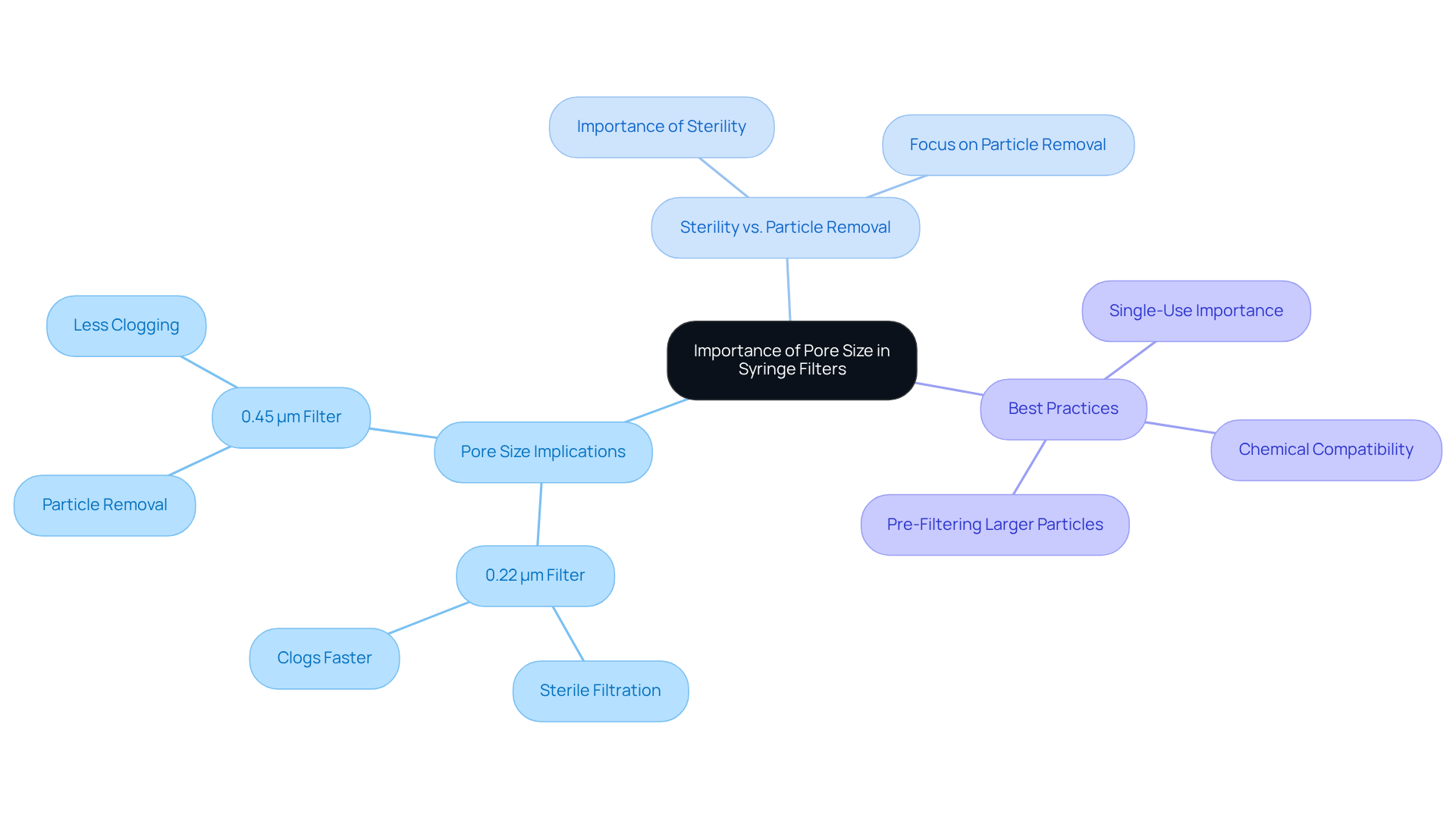

Understand the Importance of Pore Size in Syringe Filters

Pore size is a crucial factor in the effectiveness of injection devices, particularly in situations requiring sterile filtration. A 0.22 um syringe filter is commonly employed for this purpose, as it effectively eliminates most bacteria and certain viruses, thereby ensuring the sterility of the specimen. Conversely, larger pore sizes, such as 0.45 µm, are more suitable for removing particulates without guaranteeing sterility.

It is imperative to understand that syringe screens are generally intended for single-use; reusing them can lead to contamination and compromise the integrity of your samples. When selecting a strainer, consider the , such as whether sterility is essential or if the primary focus is on particle removal. Furthermore, the chemical compatibility of the materials used in the system with the liquid being processed is vital for ensuring the system's effectiveness and longevity.

Understanding these distinctions will aid you in making informed decisions regarding selection, ensuring that your samples are processed accurately and efficiently. Smaller pore sizes, like the 0.22 um syringe filter, tend to clog more quickly than larger sizes, which can affect their overall performance. Therefore, adopting optimal practices, such as pre-filtering larger particles, can help prevent early blockage of the injection device. By comprehending the relationship between pore size and device performance, you can optimize your processes and enhance the consistency of your results.

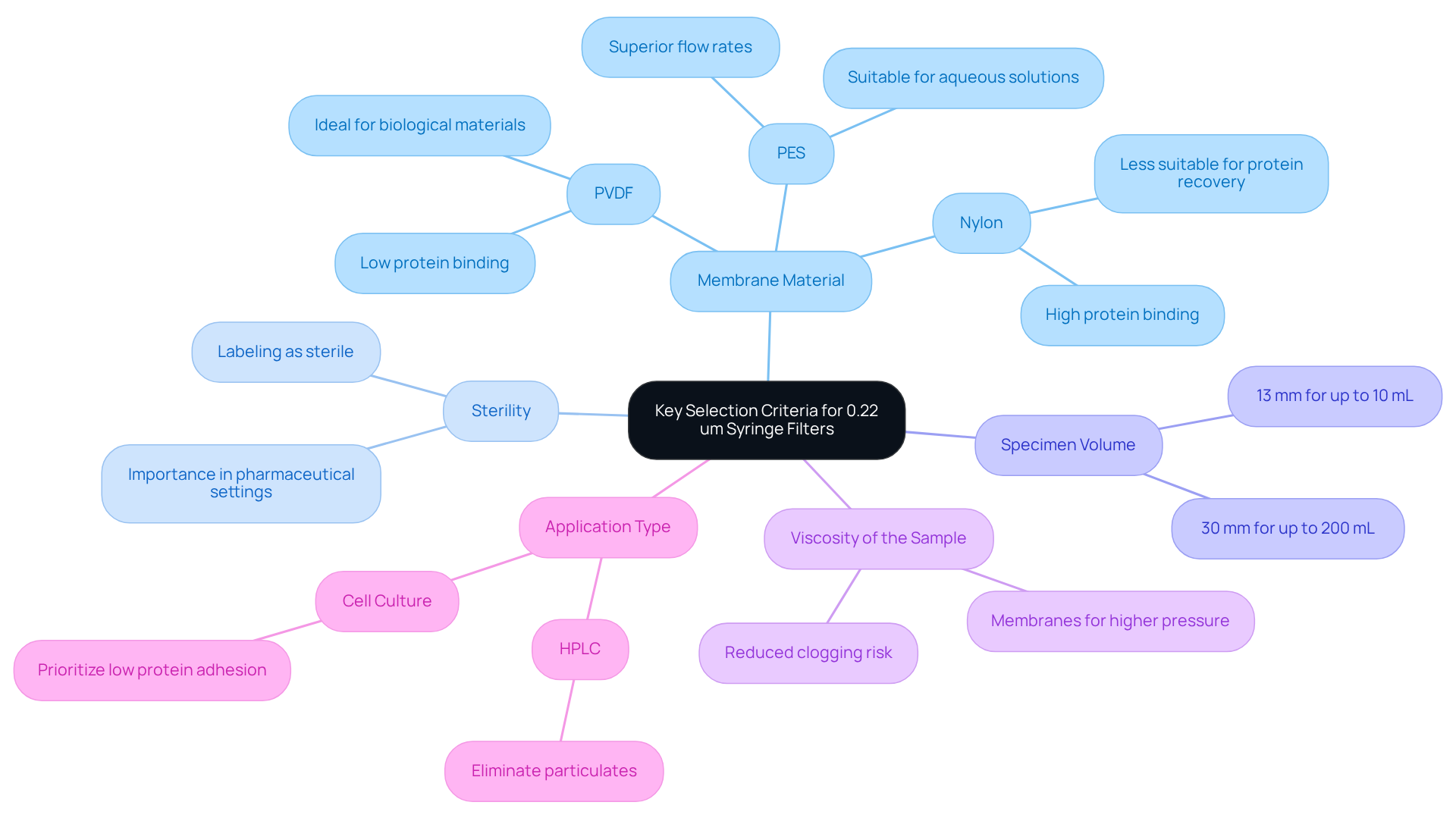

Identify Key Selection Criteria for 0.22 um Syringe Filters

When selecting a , it is essential to consider several key criteria to ensure optimal performance and compliance with sterility requirements.

- Membrane Material: The choice of membrane is critical, as it directly influences filtration efficiency and compatibility with your specimen. Common materials include nylon, PVDF, and PES, each possessing unique chemical resistances and protein binding characteristics. For instance, PVDF is favored for its low protein binding, making it ideal for biological materials, while PES offers superior flow rates, suitable for aqueous solutions. Conversely, nylon's tendency to bind proteins renders it less appropriate for applications where protein recovery is paramount.

- Sterility: In many applications, particularly within pharmaceutical and clinical settings, sterility is of utmost importance. It is crucial to ensure that the device is explicitly labeled as sterile if your process demands it. This precaution is vital for preventing contamination in sensitive experiments or when preparing specimens for microbial analysis.

- Specimen Volume: Evaluate the volume of the specimen to be processed, as syringe membranes are available in varying diameters, such as 13 mm for smaller quantities (up to 10 mL) and 30 mm for larger specimens (up to 200 mL). Choosing the appropriate size is essential for maintaining efficiency and minimizing the risk of clogging.

- Viscosity of the Sample: For samples with higher viscosity, selecting membranes designed to withstand increased pressure is critical. Filters capable of handling higher pressures will reduce the likelihood of clogging and ensure a smooth filtration process.

- Application Type: The intended application—be it HPLC, cell culture, or other uses—will significantly influence the choice of membrane material and design. For example, devices used in HPLC must effectively eliminate particulates to protect delicate instrumentation, while those for cell culture should prioritize low protein adhesion to maintain sample integrity. Furthermore, needle-based screens generally outperform Buchner funnels for routine HPLC analysis, establishing them as a preferred option in laboratory environments.

By carefully evaluating these factors, laboratory managers can select the most suitable 0.22 um syringe filter, ensuring reliable outcomes and compliance with sterility standards. Additionally, employing a color-coded identification system for various types of injection devices can facilitate the swift selection of appropriate components for specific applications.

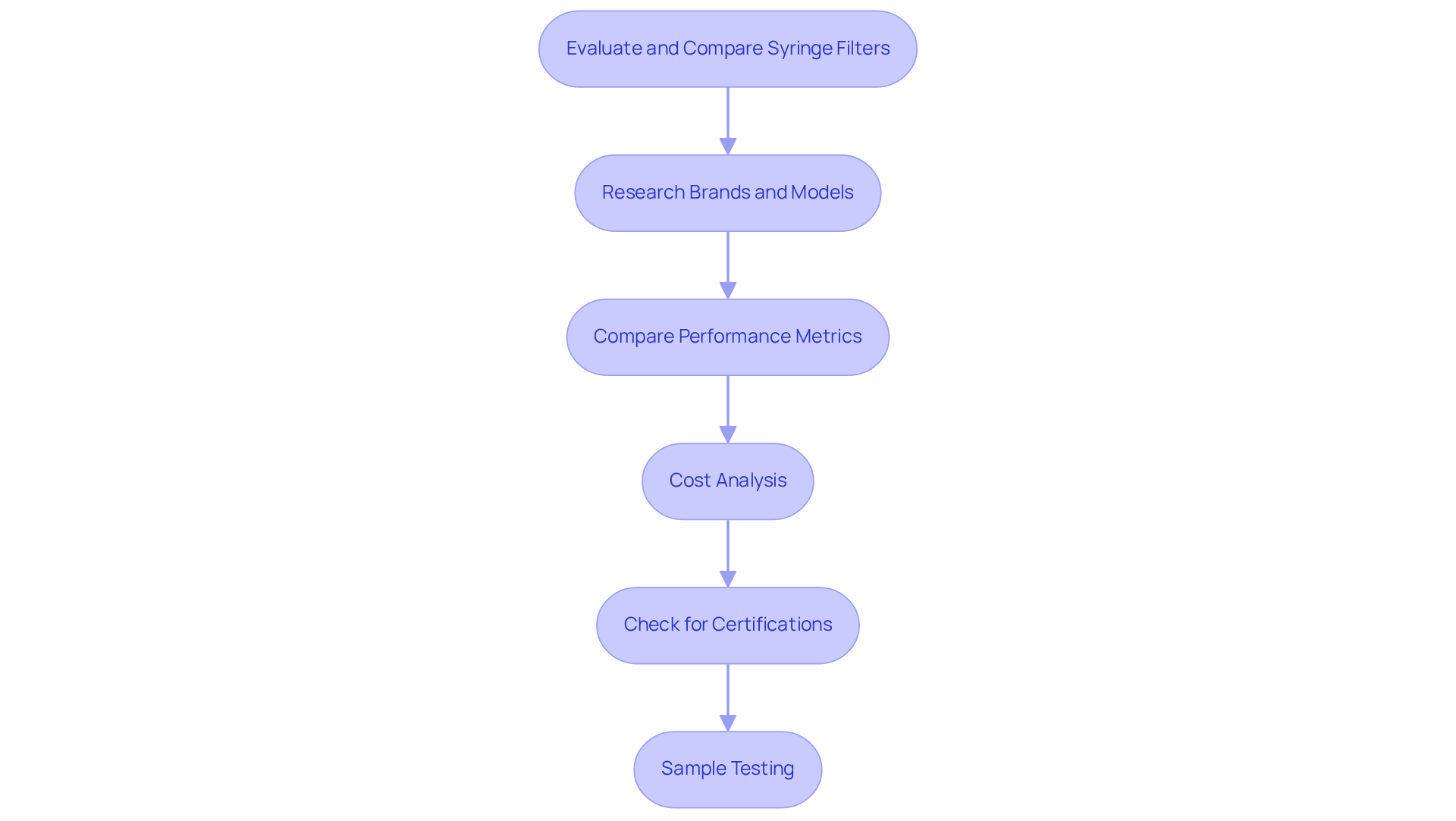

Evaluate and Compare Available Syringe Filter Options

To effectively evaluate and compare available 0.22 µm syringe filters, follow these essential steps:

- Research Brands and Models: Begin by identifying reputable brands recognized for their quality, such as Sigma-Aldrich, Millipore, and CELLTREAT. It is crucial to review product specifications, focusing on performance metrics like flow rates and retention efficiency.

- Compare Performance Metrics: Next, assess key factors, including flow rate, retention efficiency, and compatibility with various solvents. For instance, PES membranes typically offer quicker flow rates and reduced protein binding compared to PVDF membranes, making them suitable for pre-treatment and processing of buffers and culture media.

- Cost Analysis: Conduct a thorough cost analysis by evaluating the price per unit alongside the anticipated lifespan of the device. Investing in higher-quality membranes, such as Millex membranes, known for their rapid flow rates and low binding capabilities, can lead to decreased overall expenses by minimizing sample loss and . This is particularly vital in pharmaceutical applications where precision is paramount.

- Check for Certifications: Ensure that the devices meet relevant industry standards, especially for use in regulated environments like pharmaceuticals. Filters like the 0.22 um syringe filter from Millex® are often CE-marked and FDA registered, ensuring minimal leaching of impurities into filtered solutions.

- Sample Testing: Finally, if feasible, conduct tests with various screens to evaluate their performance in your specific applications. This practical approach can provide valuable insights into which option best meets your laboratory's requirements, particularly for essential processes like dissolution testing and HPLC analysis.

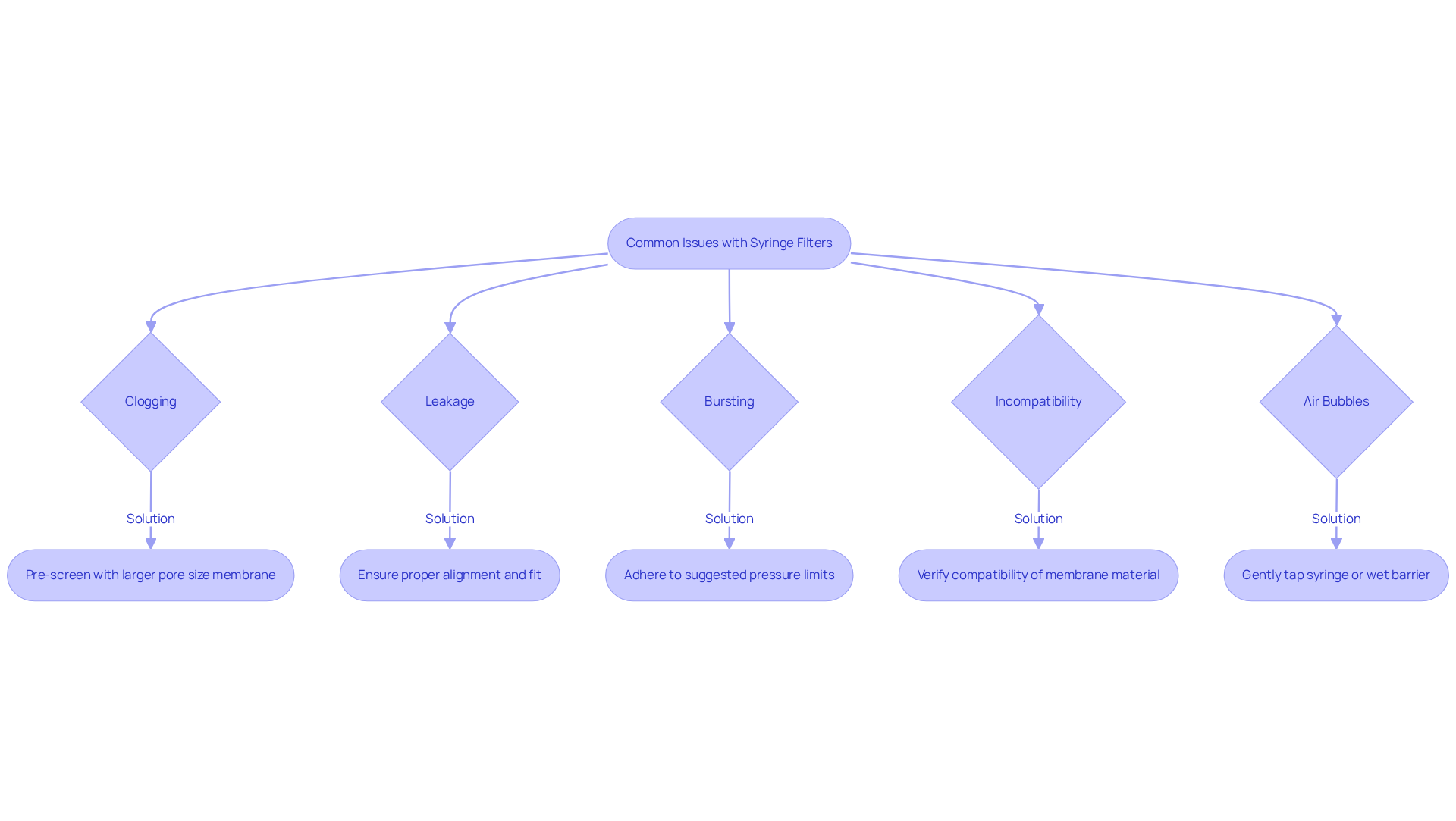

Troubleshoot Common Issues with Syringe Filters

Frequent problems with syringe screens can significantly disrupt your separation process. To effectively address these challenges, consider the following troubleshooting tips:

- Clogging: Clogging is a common issue that can hinder your results. To mitigate this, pre-screen your sample using a to eliminate larger particles before utilizing the 0.22 um syringe filter. This method enhances the effectiveness of your purification process.

- Leakage: Leakage may occur if the strainer is not securely attached to the syringe. Ensure proper alignment and fit to prevent this issue. Regularly inspect connections and utilize Luer-Lok fittings to maintain a secure seal.

- Bursting: Excessive pressure during filtration can lead to the rupture of the mesh. To prevent this, adhere to the suggested pressure limits for your system. If higher pressures are necessary, opt for devices specifically rated for such conditions.

- Incompatibility: If the device fails to perform as expected, verify the compatibility of the membrane material with your sample's chemical properties. Employing screens made from materials like Nylon, PTFE, or PVDF can enhance performance based on the specific solvents utilized.

- Air Bubbles: The presence of air bubbles can disrupt the flow rate. To eliminate them, gently tap the syringe or ensure that the barrier is adequately wetted before use. This practice helps maintain a consistent flow rate and boosts efficiency in separation.

- Compatibility Guidelines: Always adhere to compatibility guidelines to ensure that the material does not degrade when in contact with your sample solvents. This is crucial for preserving the integrity of your results.

- Quality Control Measures: Implementing quality control measures, such as regular performance monitoring and testing of filter effectiveness, is essential for ensuring reliable results.

By addressing these common problems and implementing these solutions, laboratories can secure reliable filtration outcomes with a 0.22 um syringe filter, ultimately enhancing the accuracy of their analyses.

Conclusion

Selecting the appropriate 0.22 um syringe filter is crucial for achieving optimal filtration results across various laboratory applications. Recognizing the significance of pore size—especially its impact on sterility and particle removal—empowers users to make informed choices. This guide underscores the essential factors to consider, including:

- Membrane material

- Sterility requirements

- Specimen volume

- Viscosity

- Application type

Throughout this article, key insights highlight the necessity of thorough evaluation and comparison of available syringe filter options. By researching reputable brands, analyzing performance metrics, conducting cost assessments, and testing samples, laboratory managers can pinpoint the most suitable filters for their applications. Furthermore, addressing common issues such as clogging, leakage, and compatibility is vital for maintaining the integrity of filtration processes and ensuring consistent results.

Ultimately, the selection and proper utilization of 0.22 um syringe filters are foundational to achieving high-quality analytical outcomes. By adhering to the guidelines outlined in this article, users can enhance their filtration processes, minimize errors, and preserve the integrity of their samples. Embracing these best practices not only optimizes laboratory efficiency but also highlights the critical importance of meticulous attention to detail in scientific research and analysis.