Overview

Digital measurement is crucial in the pharmaceutical context, significantly enhancing precision and operational efficiency in drug development and laboratory activities through the integration of electronic instruments and technologies. This article underscores the importance of best practices, such as:

- Regular calibration

- Adherence to standard operating procedures

- Implementation of advanced analytical tools

Collectively, these practices contribute to improved accuracy and ensure compliance with regulatory standards in the industry. By prioritizing digital measurement, pharmaceutical companies can not only enhance their operational capabilities but also reinforce their commitment to quality and safety.

Introduction

Digital measurement is revolutionizing the pharmaceutical industry, ushering in an era where precision and efficiency are paramount. Laboratories are increasingly adopting electronic instruments and advanced analytical tools, unlocking a treasure trove of real-time insights that enhance drug development and clinical trials.

However, this transformation presents the challenge of navigating complex regulatory standards and ensuring compliance while maximizing the benefits of digital technologies.

How can pharmaceutical labs effectively implement these innovative measurement strategies to not only meet regulatory expectations but also achieve superior operational outcomes?

Define Digital Measurement in Pharmaceutical Context

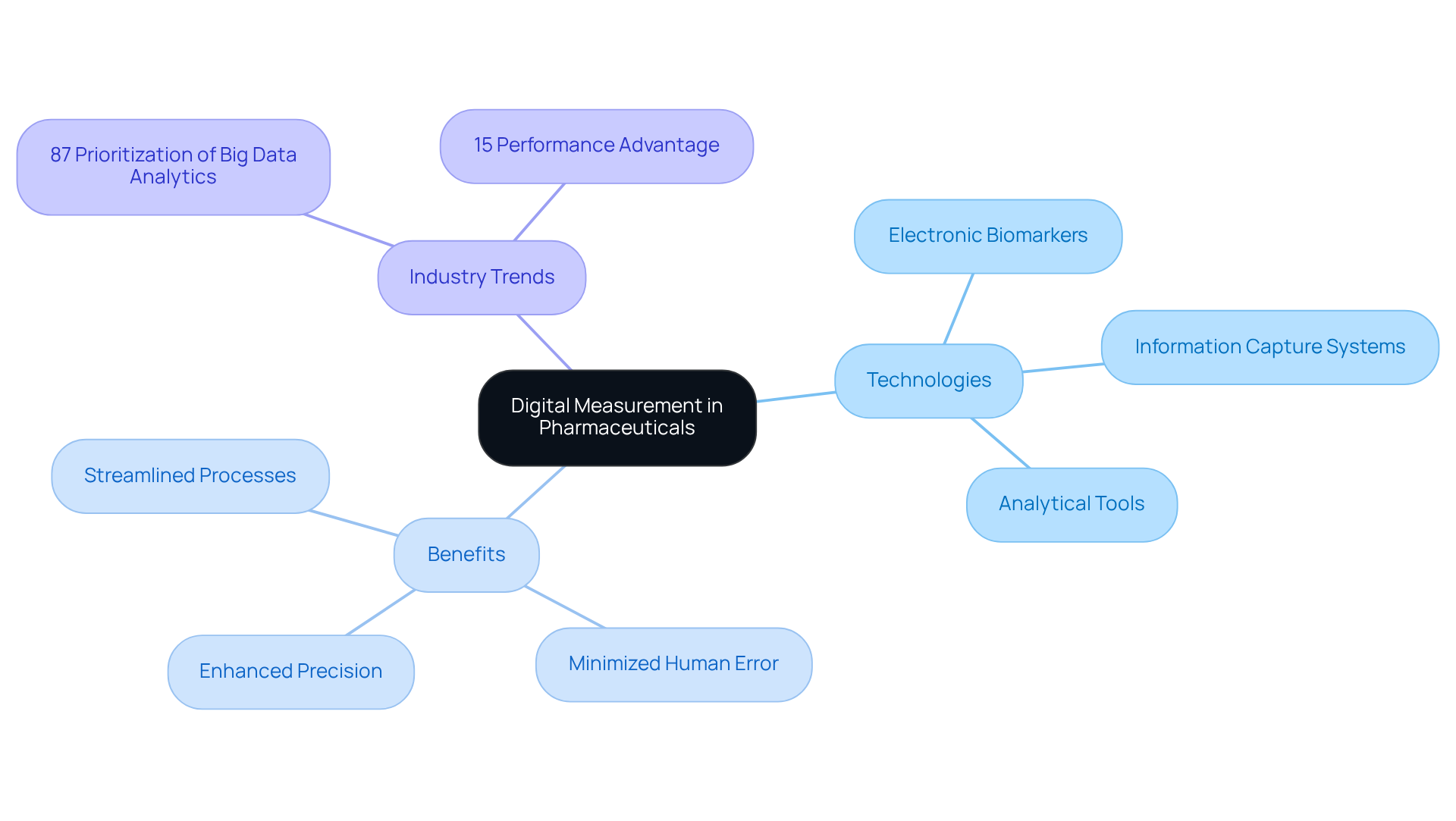

Digital assessment in the pharmaceutical domain represents a pivotal shift towards the integration of electronic instruments and technologies for collecting, analyzing, and interpreting information pertinent to drug development and laboratory activities. This innovative approach encompasses the implementation of electronic biomarkers, sophisticated information capture systems, and advanced analytical tools, all of which deliver real-time insights into critical parameters such as drug efficacy, patient adherence, and safety monitoring. By embracing electronic assessment methods, pharmaceutical laboratories can significantly enhance precision, minimize human error, and streamline operational processes.

This transformation yields not only more reliable outcomes in drug development and clinical trials but also aligns with prevailing industry trends, as evidenced by the fact that 87% of pharmaceutical executives prioritize big data analytics. Furthermore, firms equipped with advanced analytics capabilities outperform their peers by an average of 15% across vital performance metrics. This underscores the essential role of incorporating electronic assessment into laboratory practices, establishing a clear imperative for organizations aiming to maintain a competitive edge in the pharmaceutical landscape.

Implement Best Practices for Accurate Digital Measurements

To achieve accurate digital measurement, pharmaceutical labs must implement essential best practices that ensure precision and compliance with industry standards.

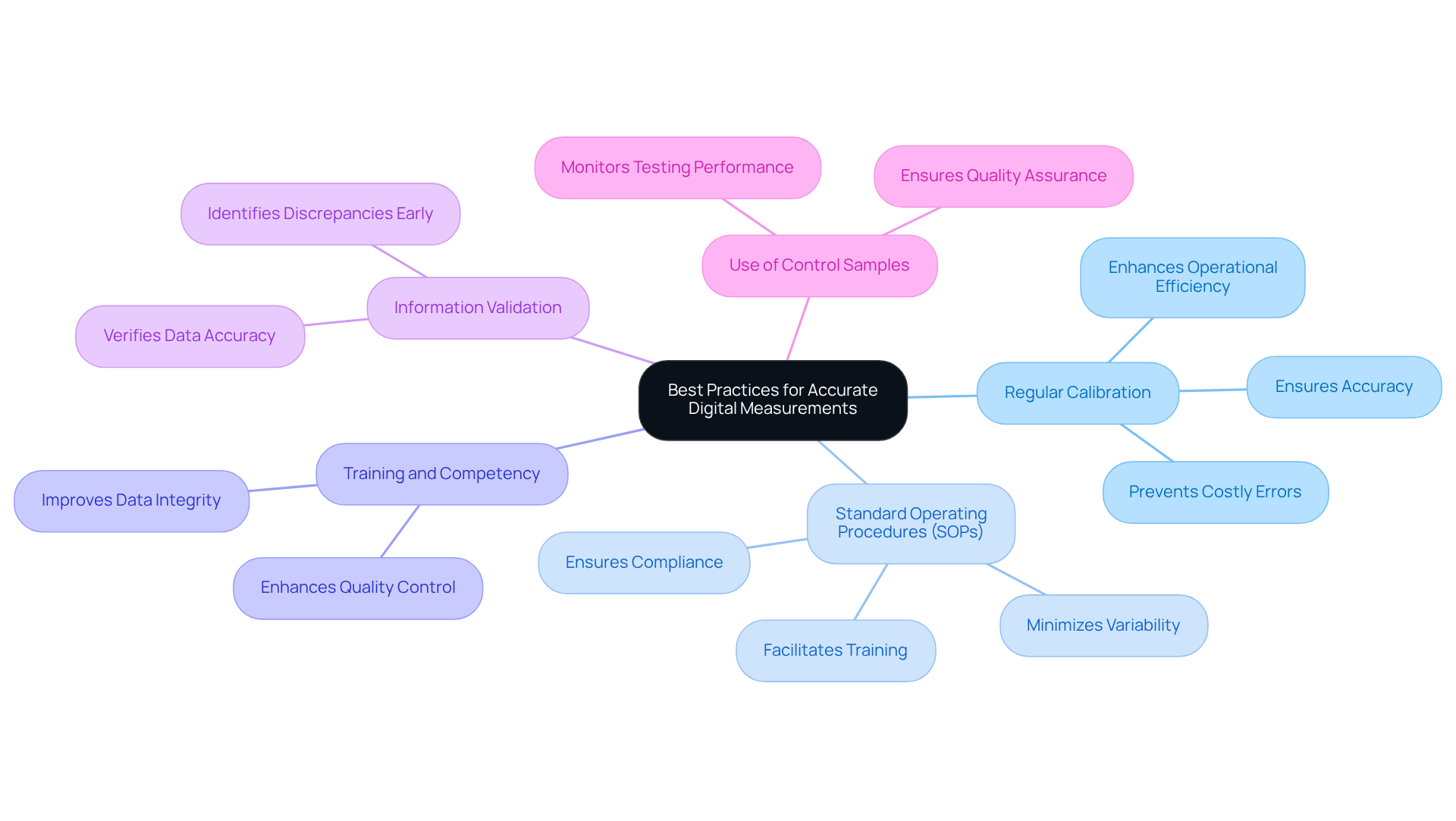

- Regular Calibration: It is imperative that all testing instruments undergo regular calibration in accordance with manufacturer specifications to uphold accuracy. Routine calibration not only prevents unnecessary resource consumption and expenses associated with repeated testing due to erroneous readings but also significantly enhances operational efficiency.

- Standard Operating Procedures (SOPs): Developing and adhering to comprehensive SOPs for all assessment processes is crucial. These procedures should clearly outline each step to minimize variability and errors. Inadequately written SOPs can lead to severe repercussions, such as the need to repeat studies, incurring additional costs. SOPs establish a foundation for consistent practices, ensuring that all personnel adhere to the same protocols, which is vital for regulatory compliance.

- Training and Competency: Comprehensive training for laboratory staff on the use of digital measurement is essential, along with understanding the importance of data integrity. Staff members who are well-trained are more likely to produce accurate results and maintain high standards of quality control, thereby reinforcing the lab's credibility.

- Information Validation: Implementing robust information validation protocols is necessary to verify the accuracy and reliability of collected data prior to analysis. This critical step aids in identifying discrepancies early in the process, ensuring that only validated data informs decision-making.

- Use of Control Samples: Incorporating control samples into experiments is vital for monitoring the performance of testing systems and detecting deviations from expected results. Control samples are instrumental in ensuring ongoing quality assurance and enhancing the reliability of laboratory outputs.

By adhering to these best practices, pharmaceutical laboratories can significantly enhance their accuracy in assessments, thereby supporting compliance with industry standards and improving overall operational efficiency.

Navigate Regulatory Standards for Digital Measurement

Pharmaceutical laboratories must navigate a complex landscape of regulatory criteria when implementing electronic gauging technologies. Understanding key considerations in digital measurement is vital for compliance and operational success.

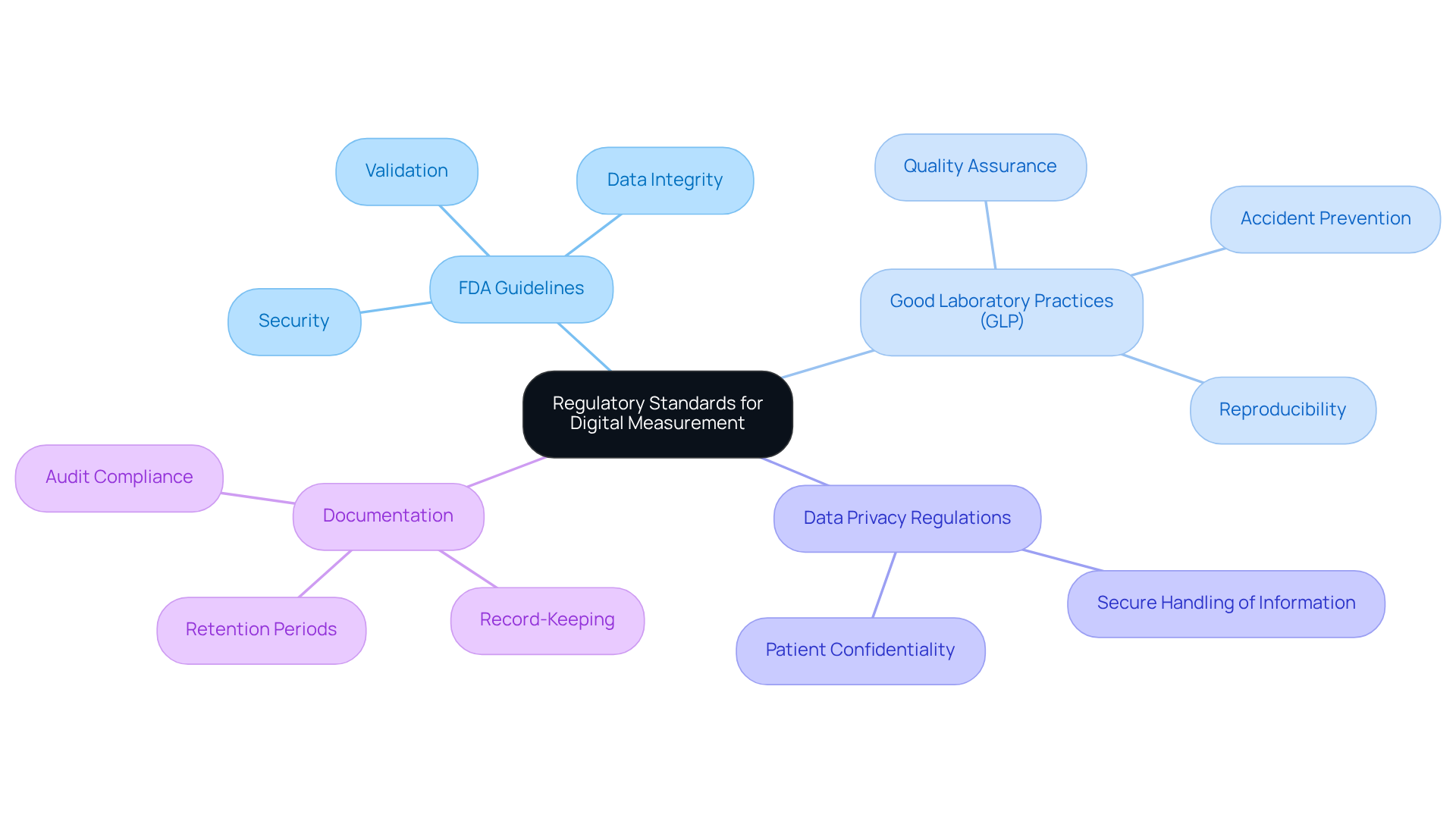

- FDA Guidelines: Familiarity with the FDA's guidance on electronic health technologies is essential. This guidance outlines requirements for data integrity, security, and validation, ensuring that electronic assessment tools meet the necessary standards for clinical investigations through digital measurement. This is particularly relevant concerning sections of the Federal Food, Drug, and Cosmetic Act and the Public Health Service Act, which frame the regulatory environment.

- Good Laboratory Practices (GLP): Adherence to GLP standards is critical for all electronic evaluation processes. GLP emphasizes the importance of quality and reliability in laboratory information, guaranteeing that digital measurement results are reproducible and trustworthy. Laboratories that comply with GLP not only enhance their operational efficiency but also bolster the credibility of scientific research. Neglecting GLP can result in accidents, environmental contamination, and invalidated research, underscoring the high stakes involved in maintaining these standards.

- Data Privacy Regulations: Awareness of data privacy laws, such as HIPAA, is crucial when managing patient information in digital contexts. These regulations govern the secure handling of sensitive information, ensuring that patient confidentiality is upheld throughout the evaluation process.

- Documentation: Comprehensive documentation of all assessment processes, calibrations, and validations is imperative. This meticulous record-keeping not only demonstrates compliance during audits but also reinforces the integrity of the information collected. Such diligence is critical for regulatory approval and public trust in scientific findings. Records must be retained for at least five years after the results of a nonclinical laboratory study are submitted to the FDA, highlighting the significance of thorough documentation practices.

Leverage Innovative Tools for Enhanced Measurement Accuracy

To enhance accuracy in digital measurement, pharmaceutical labs must leverage innovative tools that can significantly transform their operations.

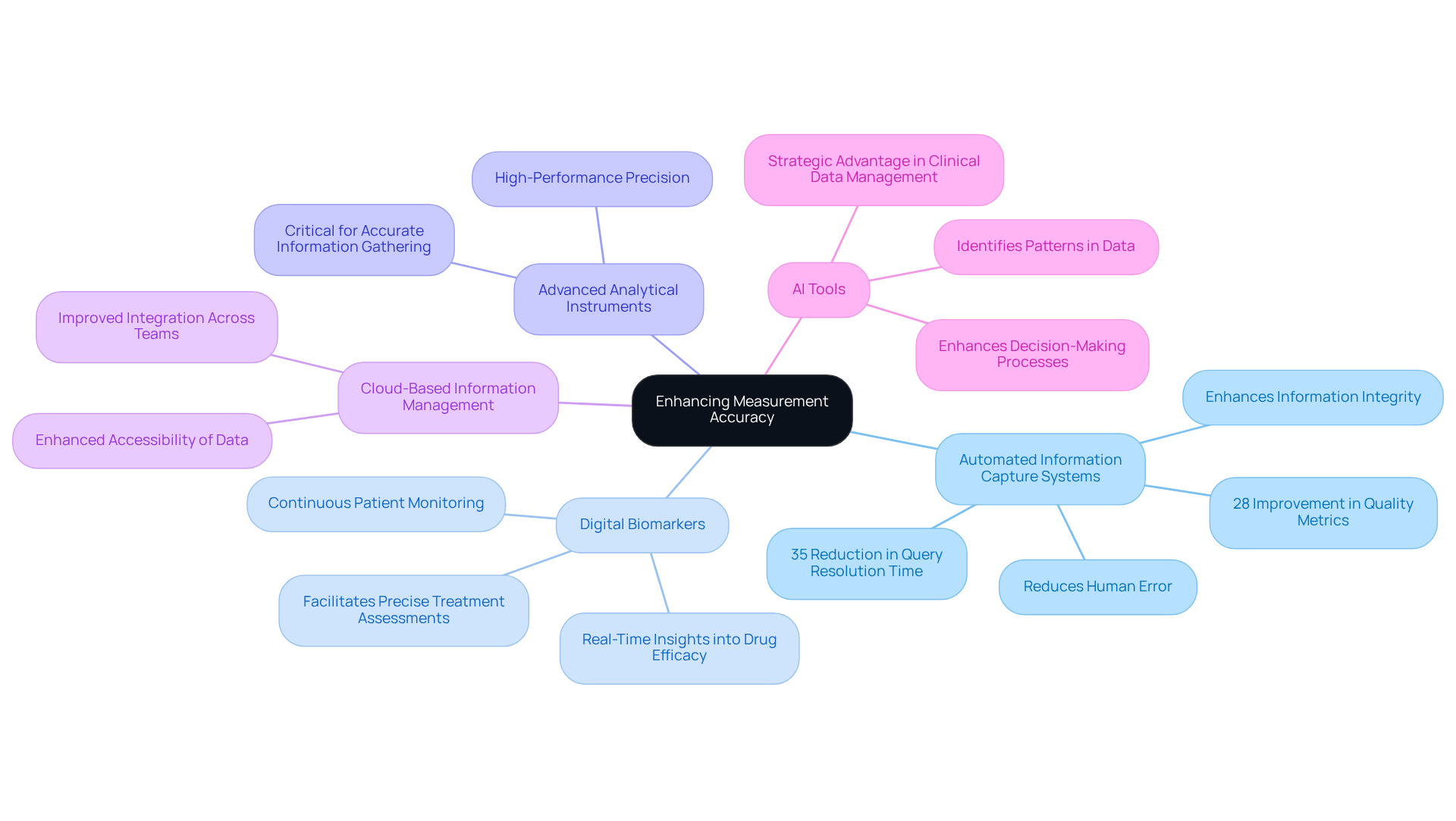

- Automated Information Capture Systems: By implementing electronic information capture (EIC) systems, labs can automate the collection of digital measurement data. This advancement not only reduces the risk of human error but also enhances information integrity. Clinical trials that have adopted AI-driven information management solutions have experienced a remarkable 35% reduction in query resolution time and a 28% improvement in quality metrics.

- Digital Biomarkers: The utilization of digital biomarkers allows for continuous monitoring of patient responses, providing real-time insights into drug efficacy and safety. These biomarkers capture dynamic changes in health, thereby facilitating more precise assessments of treatment effects and enhancing clinical decision-making.

- Advanced Analytical Instruments: Investing in high-performance analytical instruments, such as mass spectrometers and chromatographs, is essential for achieving superior precision and reliability. These tools play a critical role in accurate information gathering and analysis through digital measurement, which are vital for effectively assessing drug performance.

- Cloud-Based Information Management: Embracing cloud-based platforms for information storage and analysis enables improved integration and accessibility across research teams. This approach fosters collaborative initiatives and significantly enhances the effectiveness of information handling systems in clinical trials.

- Artificial Intelligence (AI) Tools: Exploring AI-driven analytics can help identify patterns and anomalies in measurement data, thus enhancing decision-making processes. The integration of AI within clinical data management has evolved into a strategic advantage, positively affecting cost efficiency and regulatory success.

Conclusion

Digital measurement has emerged as a transformative force in the pharmaceutical industry, reshaping how laboratories collect and analyze data critical to drug development and clinical trials. By integrating advanced electronic tools and methodologies, pharmaceutical labs can achieve greater accuracy, enhance operational efficiency, and ultimately improve patient outcomes. This evolution not only aligns with industry trends but also establishes a competitive advantage for organizations that prioritize digital measurement in their practices.

The article highlights several key components essential for mastering digital measurement. These include the implementation of best practices such as:

- Regular calibration

- Adherence to Standard Operating Procedures (SOPs)

- Comprehensive training for staff

- Use of innovative tools like automated information capture systems and digital biomarkers

Furthermore, navigating regulatory standards, including FDA guidelines and Good Laboratory Practices (GLP), is crucial for ensuring compliance and maintaining the integrity of laboratory results. Together, these elements create a robust framework that supports accurate and reliable data collection.

As the pharmaceutical landscape continues to evolve, embracing digital measurement is not merely advantageous—it's imperative for success. Laboratories are encouraged to invest in cutting-edge technologies and cultivate a culture of precision and accountability. By doing so, they can enhance their operational capabilities and contribute to the broader goal of improving drug development processes and patient care. The significance of digital measurement in pharmaceuticals cannot be overstated; it is a vital component that drives innovation and excellence in the industry.