Overview

This article examines the critical aspects of selecting and maintaining HPLC tubes, a vital component for optimizing laboratory performance in high-performance liquid chromatography. Understanding the various types of tubes available is essential, as it directly impacts the effectiveness of chromatographic analyses.

Key selection criteria include:

- Material compatibility

- Pressure ratings

These criteria must be meticulously evaluated to ensure optimal performance.

Furthermore, implementing best practices for maintenance is crucial; these practices not only enhance reliability but also improve efficiency in laboratory settings. By adhering to these guidelines, laboratories can significantly elevate their analytical capabilities.

Introduction

Understanding the intricacies of high-performance liquid chromatography (HPLC) is essential for any laboratory striving for excellence in analytical results. The selection and maintenance of HPLC tubes not only influence the efficiency of experiments but also play a pivotal role in ensuring data reliability.

With various types of tubing available and a multitude of factors to consider, laboratory professionals must navigate this complex landscape to achieve optimal performance.

This article delves into the critical aspects of HPLC tube selection and maintenance, offering best practices that can significantly enhance laboratory outcomes while mitigating common pitfalls.

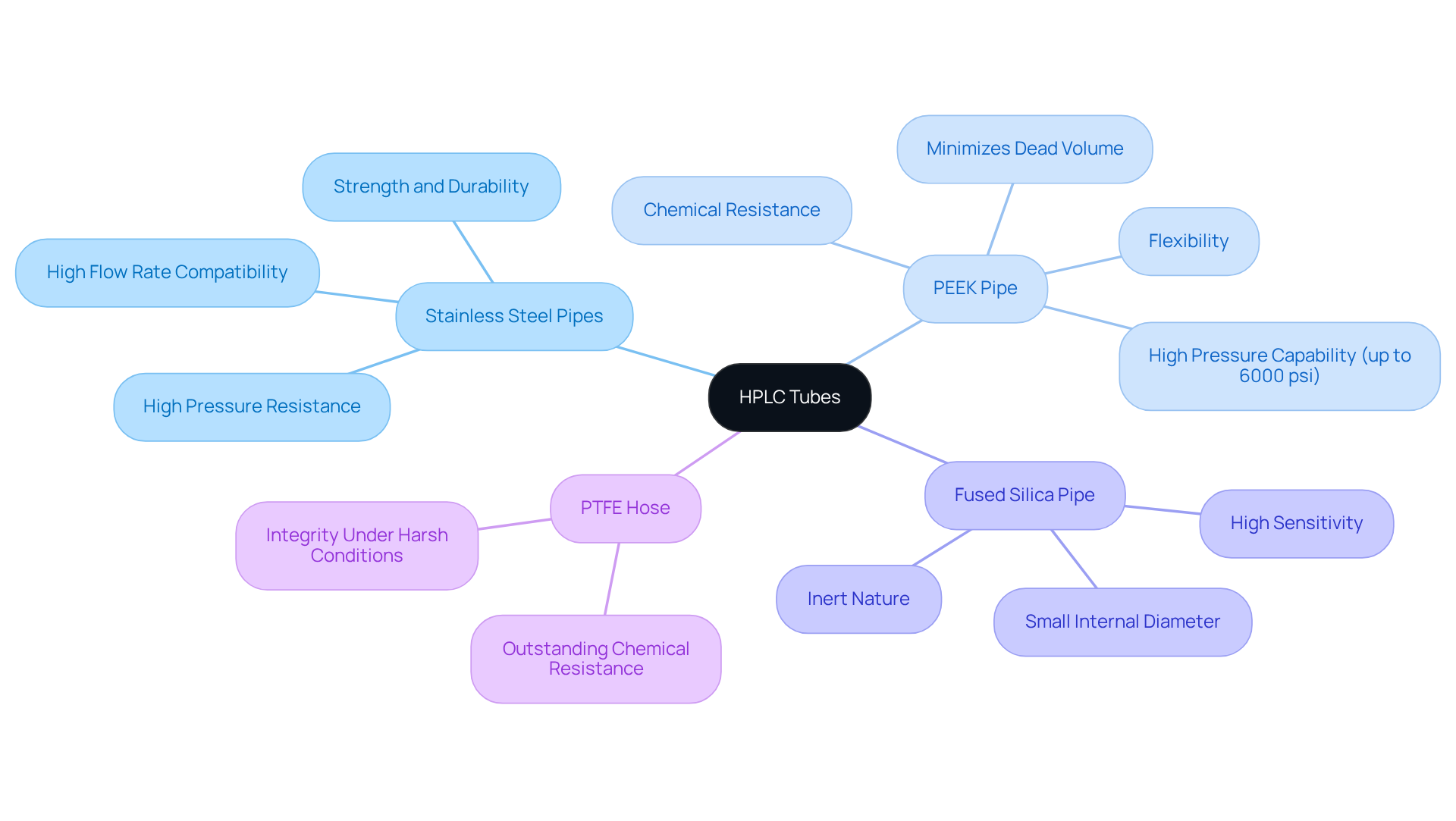

Understand HPLC Tubes: Types and Functions

HPLC tubes are essential components in high-performance liquid chromatography (HPLC) setups, functioning as conduits for both the mobile phase and the sample. Understanding the primary types of HPLC tubes is crucial for optimizing laboratory applications performance.

-

Stainless Steel Pipes are renowned for their strength and ability to endure high pressures. Frequently employed in HPLC systems, the HPLC tube is ideal for applications that demand high flow rates and compatibility with a wide array of solvents. Their reliability in high-pressure environments solidifies their status as a preferred choice among many laboratories.

-

PEEK Pipe, or polyether ether ketone, is celebrated for its exceptional chemical resistance and flexibility. Capable of withstanding pressures up to 6000 psi (400 bar), PEEK is particularly advantageous in scenarios involving aggressive solvents or where minimizing dead volume is essential. As John Dolan, an expert in HPLC troubleshooting, notes, "Another benefit of PEEK is that it can be effortlessly trimmed to any required length with a compact guillotine-like cutter featuring a razor blade."

-

Fused Silica Pipe is predominantly used in capillary HPLC systems due to its small internal diameter, which facilitates high sensitivity in analyses. Its inert nature minimizes sample interaction, ensuring accurate results. This type of pipe is crucial in high-resolution applications where precision is of utmost importance.

-

PTFE Hose, or polytetrafluoroethylene, is recognized for its outstanding chemical resistance, making it a common choice for applications involving corrosive solvents. The HPLC tube's ability to maintain integrity under harsh conditions renders it invaluable in specialized HPLC setups.

A comprehensive understanding of these varieties and their specific roles is instrumental in selecting the appropriate HPLC tube for distinct applications, thereby ensuring optimal performance and reliability in chromatography analyses. Furthermore, it is imperative to consider common pitfalls such as chemical compatibility and the necessity for routine maintenance to avert issues like contamination or wear, which can jeopardize analytical results. By integrating insights from case studies and market share data, lab managers can make informed decisions regarding HPLC connections, ultimately enhancing the efficacy of their laboratory operations.

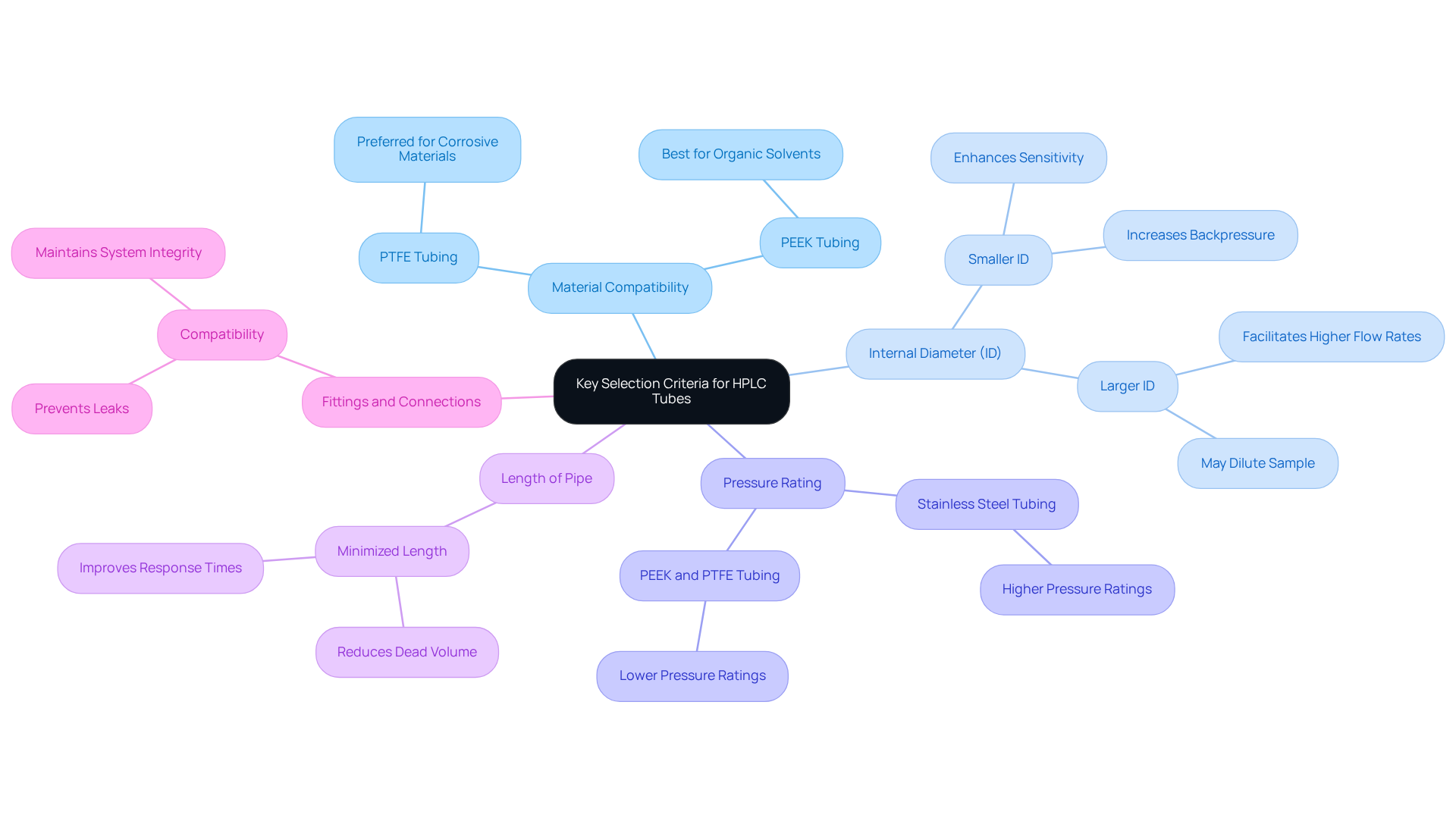

Evaluate Key Selection Criteria for HPLC Tubes

Choosing the appropriate HPLC tube is essential for optimizing performance and guaranteeing reliable results. Evaluating several essential criteria is key to making informed decisions in laboratory settings.

- Material Compatibility is the first consideration. The pipe material must be appropriate for the solvents and specimens under examination. For example, PEEK tubing excels with organic solvents, while PTFE is preferred for corrosive materials, safeguarding the integrity of both the tubing and its contents.

- Next, the Internal Diameter (ID) plays a significant role in influencing flow rates and pressure dynamics. A smaller ID can enhance sensitivity by concentrating the material, though it may also lead to increased backpressure. Conversely, a larger ID facilitates higher flow rates, which can dilute the sample, potentially impacting overall analysis. As highlighted in the case study "Impact of pH and Buffer on Chromatographic Performance," understanding the implications of ID is essential for achieving optimal separation performance.

- The Pressure Rating of the tubing is another critical factor. It is vital that the pipe withstands the pressures generated during HPLC operations. Generally, stainless steel pipes offer higher pressure ratings compared to PEEK or PTFE, making them more suitable for high-pressure applications, especially in advanced chromatographic techniques. As noted by Sarah Lee, "Best practices for instrument troubleshooting and repair include consulting the instrument manual, contacting the manufacturer's technical support, and performing routine maintenance and calibration."

- Additionally, the Length of Pipe should be minimized to reduce dead volume and potential sample loss. Shorter lengths not only help maintain pressure stability but also improve response times, which is critical for achieving accurate and timely results in analytical processes. The case study 'Column Maintenance and Regeneration Techniques' emphasizes that effective maintenance strategies enhance the longevity and performance of chromatography setups.

- Finally, Fittings and Connections must be compatible with the tubing to create secure connections. Appropriate fittings prevent leaks and uphold system integrity, which is essential for steady performance in high-performance liquid chromatography systems.

By thoroughly evaluating these criteria, laboratory experts can make knowledgeable choices when selecting HPLC tubes that are tailored to their specific applications. This careful selection ultimately enhances the reliability and precision of their analyses. Case studies have demonstrated that optimizing these factors can lead to significant improvements in chromatographic performance, underscoring the importance of meticulous selection in laboratory environments.

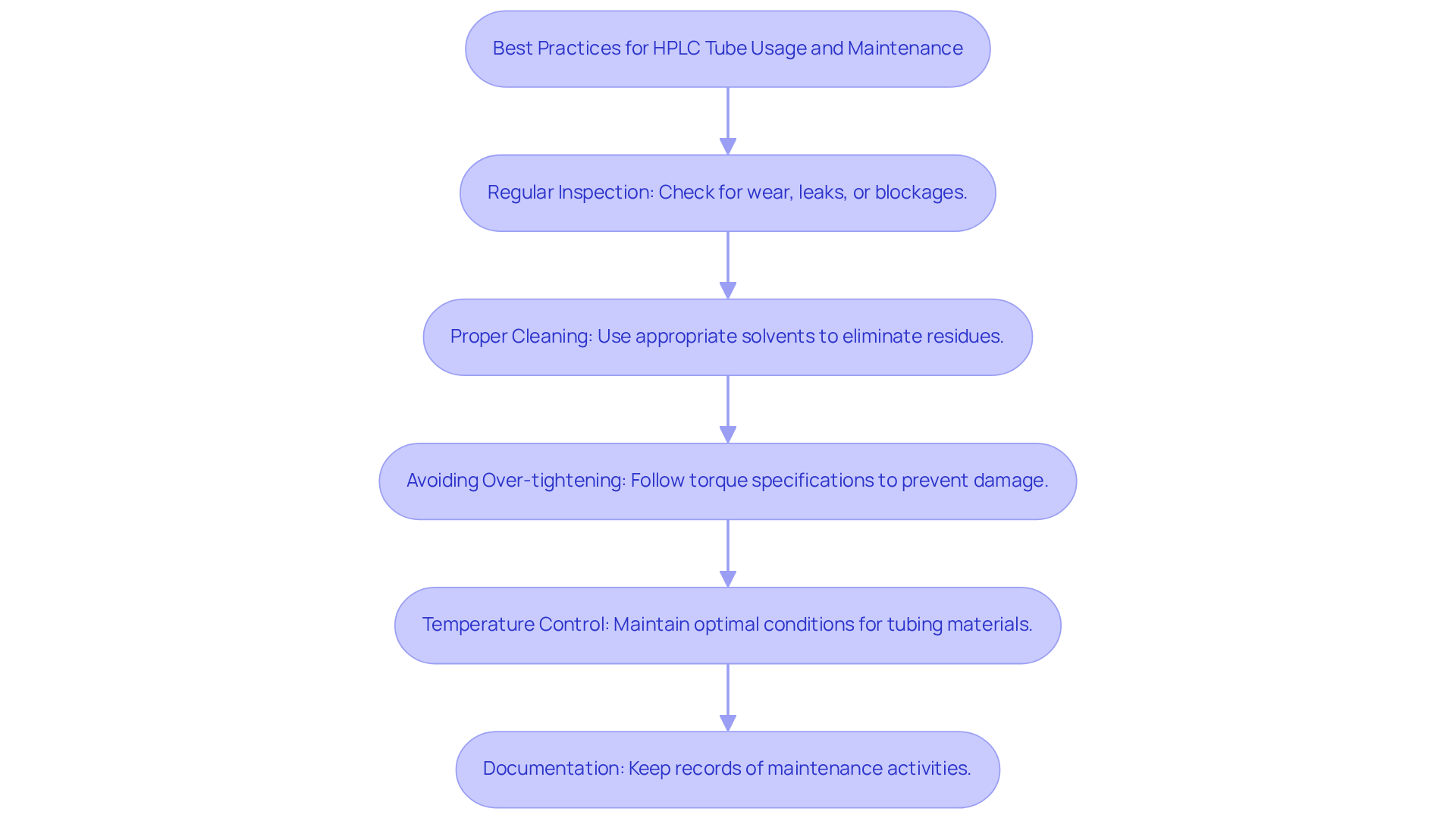

Implement Best Practices for HPLC Tube Usage and Maintenance

To maximize the performance and lifespan of HPLC tubes, implementing the following best practices is essential:

-

Regular Inspection: Conduct frequent checks for signs of wear, leaks, or blockages in the tubing. Early detection of these issues can significantly reduce costly downtime and repairs. A case study illustrates this point, where a pharmaceutical lab reduced downtime by 45% after establishing a comprehensive maintenance schedule. Additionally, neglecting maintenance can lead to substantial costs; for instance, one lab faced $50,000 in annual costs due to equipment failures.

-

Proper cleaning of the HPLC tube involves regularly cleaning it to eliminate residues that could compromise performance. Utilize appropriate solvents tailored to the previous samples analyzed, ensuring that the cleaning process does not introduce contaminants.

-

Avoiding Over-tightening: When connecting fittings, adhere to the manufacturer's suggested torque specifications to prevent damage to the pipe and subsequent leaks. Over-tightening can lead to material fatigue and failure, which can be costly in terms of both repairs and downtime.

-

Temperature Control: Maintain optimal temperature conditions for the conduits, particularly for materials like PEEK and PTFE, which are sensitive to heat. Proper temperature management helps prevent material degradation and extends the tubing's lifespan.

-

Documentation: Maintain detailed records of all maintenance activities, including cleaning schedules and inspection results. This documentation aids in identifying patterns and refining maintenance strategies over time, contributing to enhanced operational efficiency.

Incorporating expert insights, such as the importance of maintaining optimal pressure for maximizing separation efficiency, further emphasizes the significance of regular inspections. By adhering to these best practices, laboratories can significantly improve the reliability and efficiency of their HPLC systems, particularly through the use of an HPLC tube, leading to superior analytical outcomes and reduced operational costs.

Conclusion

Mastering the selection and maintenance of HPLC tubes is vital for achieving optimal performance in laboratory settings. The proper choice of tubing not only enhances the reliability of chromatographic analyses but also ensures that the integrity of samples is maintained throughout the process. Understanding the various types of HPLC tubes—such as stainless steel, PEEK, fused silica, and PTFE—along with their respective strengths and applications, is essential for any laboratory aiming to improve its analytical capabilities.

Key considerations in selecting HPLC tubes include:

- Material compatibility

- Internal diameter

- Pressure rating

- Length

- Fittings

Each of these factors plays a crucial role in determining the effectiveness of the chromatography setup. Furthermore, implementing best practices for tube usage and maintenance, such as:

- Regular inspections

- Proper cleaning

- Temperature control

can significantly extend the lifespan of HPLC tubes and enhance the quality of analytical results.

Ultimately, prioritizing HPLC tube selection and maintenance is not merely a technical necessity; it is a strategic approach that can lead to improved laboratory efficiency and reduced operational costs. By investing time and resources into understanding and optimizing these components, laboratories can ensure they remain at the forefront of analytical excellence, paving the way for more accurate and reliable results in their research endeavors.