Overview

The article examines the critical importance of mastering molecular weight cutoff (MWCO) filters for laboratory applications. By understanding their specifications and selecting the appropriate type based on specific needs, researchers can significantly improve their work.

Proper selection of MWCO filters is essential, as it directly impacts filtration efficiency and the reliability of results in processes such as protein purification and desalting. This necessity is supported by detailed explanations of various filter types and their specific applications, ensuring that practitioners can make informed decisions.

Ultimately, the effective use of MWCO filters not only enhances laboratory outcomes but also fosters confidence in the scientific process.

Introduction

Molecular weight cutoff (MWCO) filters are crucial to the efficiency of laboratory filtration processes, as they determine which molecules are retained and which are permitted to pass through.

With the increasing demand for precise and reliable results in applications such as protein purification and desalting, it is essential for researchers to understand how to select and troubleshoot these filters effectively.

However, given the varying specifications and potential performance challenges, how can one ensure the right filter is chosen for their specific needs?

This article explores the intricacies of MWCO filters, providing insights into their selection, application, and common troubleshooting strategies to enhance laboratory outcomes.

Understand Molecular Weight Cutoff (MWCO)

Molecular weight cutoff filters are a critical factor in filtration processes, defining the molecular weight at which a membrane retains larger molecules while allowing smaller ones to pass through. Expressed in Daltons (Da), the molecular weight cutoff is essential for applications such as protein purification, desalting, and concentration. Selecting molecular weight cutoff filters with the appropriate specifications is crucial for effective protein purification; it ensures that target proteins are retained while smaller impurities are eliminated.

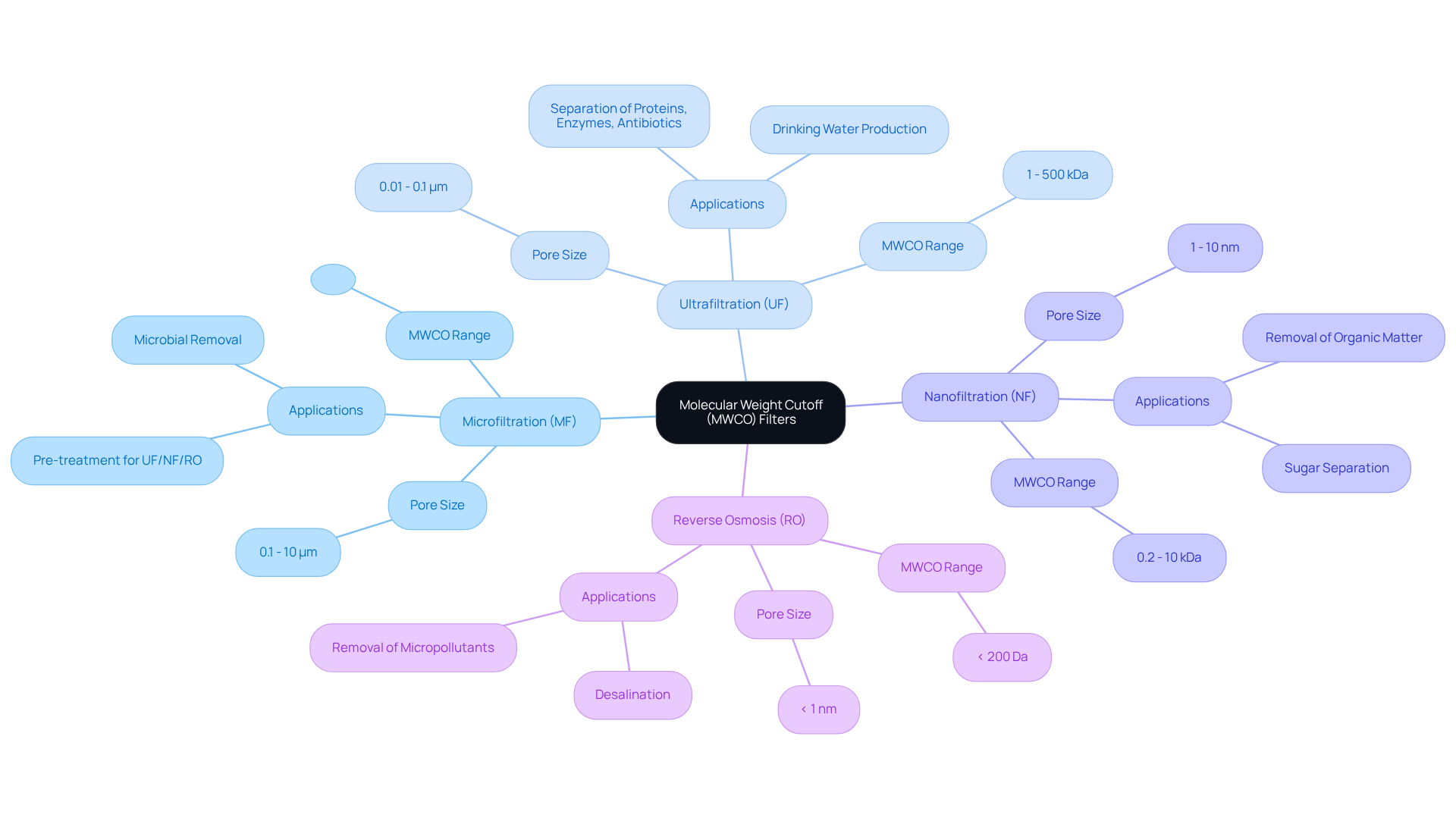

Membranes can be categorized into four distinct types based on their MWCO or pore size:

- Microfiltration (MF): With a MWCO greater than 100 kDa and a pore size ranging from 0.1 to 10 µm, MF is suitable for microbial removal and serves as a pre-treatment step for other filtration processes.

- Ultrafiltration (UF): This category features a molecular weight cutoff between 1 and 500 kDa, with a pore size of 0.01 to 0.1 µm, making it ideal for separating proteins, enzymes, and antibiotics, as well as for producing drinking water.

- Nanofiltration (NF): NF has a molecular weight cutoff of 0.2 to 10 kDa, effectively removing organic matter and separating sugars.

- Reverse Osmosis (RO): With a molecular weight cutoff of less than 200 Da and a pore size under 1 nm, RO is utilized for desalination and the removal of micropollutants.

Understanding these values is paramount for applications involving proteins, nucleic acids, small compounds, and the use of . For instance, proteins typically require molecular weight cutoff filters that retain them while allowing smaller substances, such as salts and solvents, to pass through. Additionally, it is essential to recognize that the method for determining molecular weight cutoff is not standardized, which may lead to variations in rejection rates among membranes from different suppliers. This precision in filtration not only enhances the efficiency of laboratory processes but also bolsters the reliability of results in pharmaceutical applications.

Determine Application Requirements for MWCO Selection

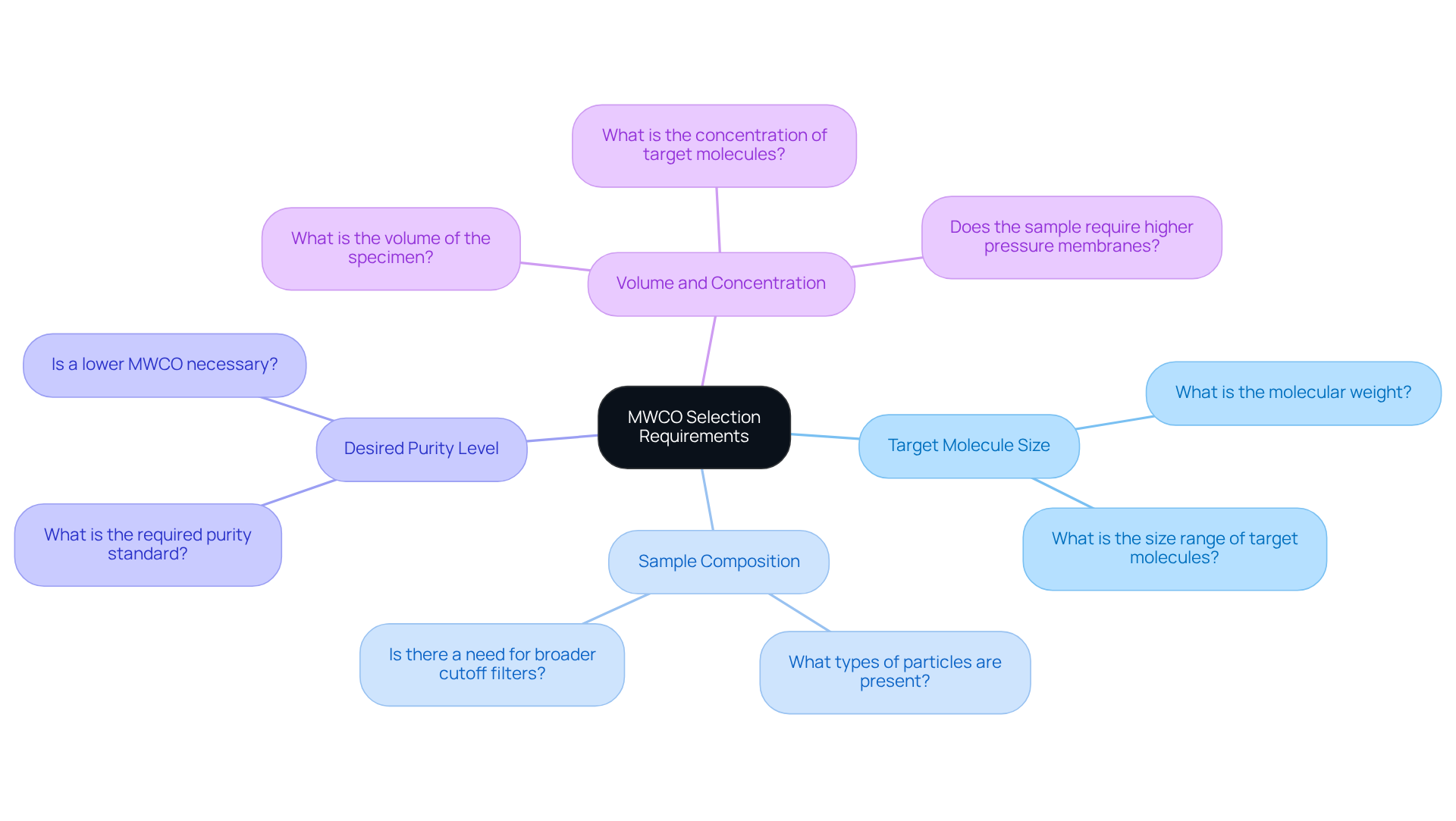

To select the appropriate membrane cutoff device, it is essential to first identify the specific application at hand. Begin by considering the following critical factors:

- Target Molecule Size: Ascertain the molecular weight of the molecules you aim to retain or eliminate. This determination will guide you in selecting a membrane with the appropriate molecular weight cutoff filters.

- Sample Composition: Evaluate the composition of your sample. If it contains a variety of particles, a filter with broader molecular weight cutoff filters may be necessary to accommodate all components effectively.

- Desired Purity Level: Define the purity level required for your application. Higher purity standards may necessitate using molecular weight cutoff filters with a lower MWCO to ensure that larger, unwanted substances are adequately retained.

- Volume and Concentration: Take into account the volume of your specimen and the concentration of the target molecules. Larger volumes might require membranes that facilitate increased flow rates, whereas concentrated samples may need membranes capable of withstanding higher pressures.

By meticulously assessing these factors, you will be equipped to make an informed decision regarding the membrane that best fulfills your laboratory needs.

Troubleshoot Common MWCO Filter Issues

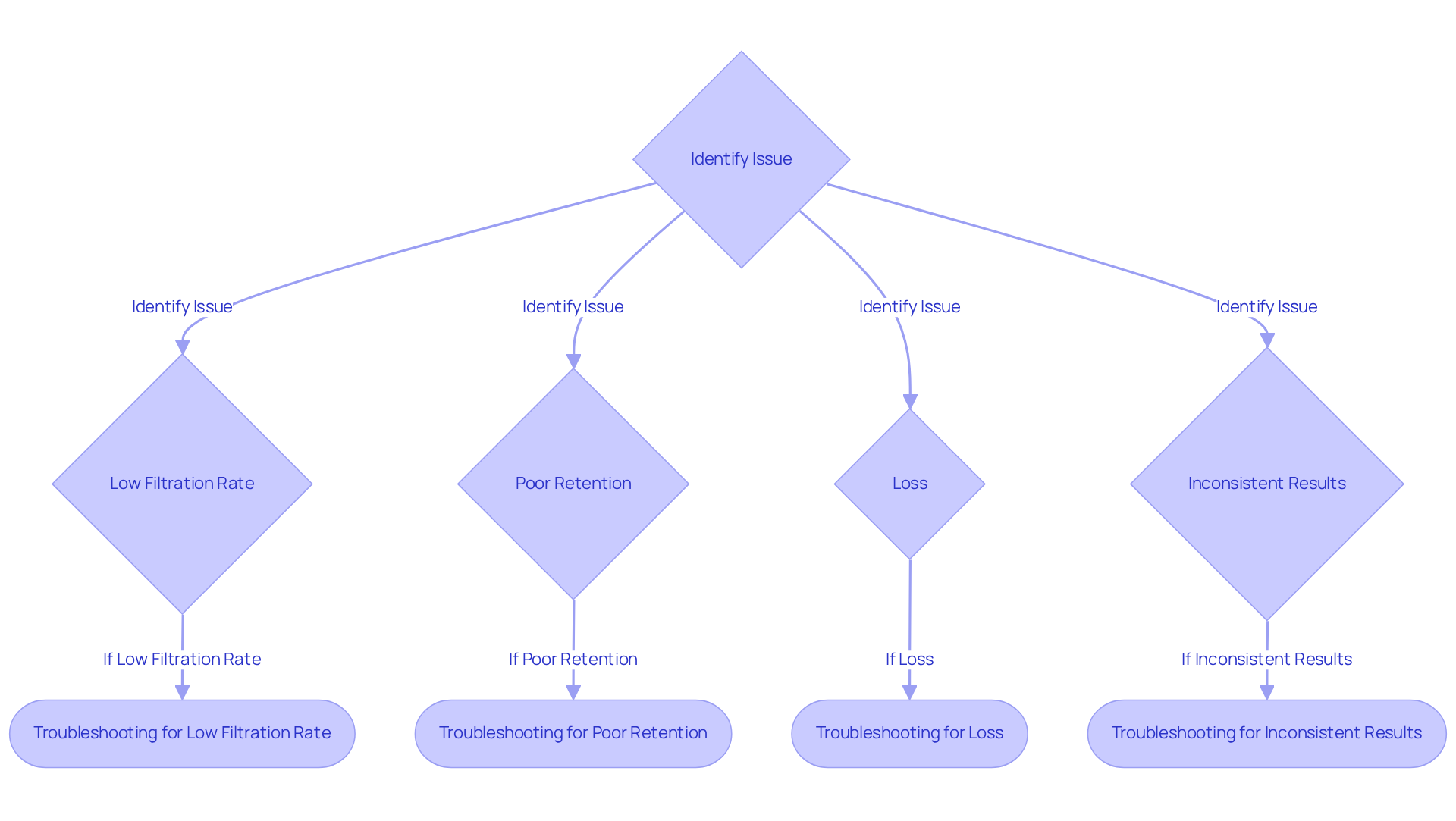

When utilizing membrane separation devices, several typical challenges may arise. Effective troubleshooting strategies are essential for overcoming these obstacles:

- Low Filtration Rate: A slower-than-expected filtration rate often indicates clogging. To mitigate this issue, ensure that the screening device is appropriate for your sample type and consider pre-screening larger particles to prevent early blockage. Adhering to regular cleaning protocols is crucial, as membranes that have not been cleaned can lead to significant reductions in flow rates. Additionally, filtration may slow if membranes have remained uncleaned for an extended period.

- Poor retention occurs when larger molecules unexpectedly pass through the membrane, making it vital to confirm that the selected molecular weight cutoff filters are suitable for your application. Transitioning to a membrane with can enhance retention rates; however, caution is warranted, as selecting a membrane with an excessively small cutoff can prolong the concentration process and reduce flow rates. Ideally, MWCO membranes should be three to six times smaller than the molecular weight of the solute being retained.

- Loss: Considerable loss may occur due to improper screen positioning or leaks. Ensure that the screen is correctly set up and verify compatibility between your specimen and the screen material. If the device has been used multiple times, assess its potential for clogging or leakage, as MWCO systems may begin to leak after 2-3 uses and should be disposed of after a maximum of three applications.

- Inconsistent Results: Variability in experimental outcomes can stem from inconsistent specimen preparation, filter handling, or storage conditions. Standardizing these variables is crucial for achieving reliable results. Furthermore, factors such as sample concentration and composition can significantly influence filtration efficiency, with samples below 1 mg/mL passing through more easily than those exceeding 10 mg/mL.

By proactively addressing these potential issues, you can significantly enhance the reliability and efficiency of your laboratory processes.

Conclusion

Molecular weight cutoff (MWCO) filters are essential in laboratory filtration processes, providing effective separation of molecules based on size. Understanding the various types of membranes and their specific applications empowers researchers to make informed decisions, enhancing the efficiency and reliability of experiments, particularly in protein purification and desalting.

This article has shared key insights into the classification of MWCO filters, underscoring the importance of selecting the appropriate membrane according to application requirements. Common troubleshooting strategies for addressing performance issues were also discussed. Factors such as target molecule size, sample composition, desired purity level, and volume significantly influence the choice of membrane, and recognizing these can profoundly impact experimental outcomes. Furthermore, strategies for overcoming challenges like low filtration rates and inconsistent results were emphasized, highlighting the necessity for meticulous attention to detail in laboratory settings.

The significance of molecular weight cutoff filters cannot be overstated. As laboratories continue to advance in research and development, the understanding and effective utilization of MWCO filters will be crucial. Researchers are urged to remain informed about current trends and advancements in filtration technologies, ensuring they are equipped to achieve optimal results in their applications.