Overview

The article underscores the critical role of silanization in enhancing the properties and applications of silanized glass within laboratory environments. Silanization is essential, as it generates a hydrophobic surface that significantly reduces solute adsorption. This advancement not only bolsters sample integrity but also improves recovery rates across various analytical and pharmaceutical applications. The article substantiates these claims by detailing the benefits of silanization in preventing contamination and ensuring accurate measurements, ultimately reinforcing the necessity of high-quality scientific instruments in laboratory settings.

Introduction

Silanization stands as a pivotal chemical process that transforms ordinary glass into a highly functional material, essential in laboratory environments. By applying silane compounds, this technique not only enhances the characteristics of glass but also facilitates reduced solute adsorption and improved sample integrity. Yet, a critical question persists: how can researchers fully leverage the advantages of silanized glass while navigating the complexities of its applications and maintenance? This article delves into the properties, applications, and best practices for utilizing silanized glass, providing valuable insights for those aiming to optimize their laboratory results.

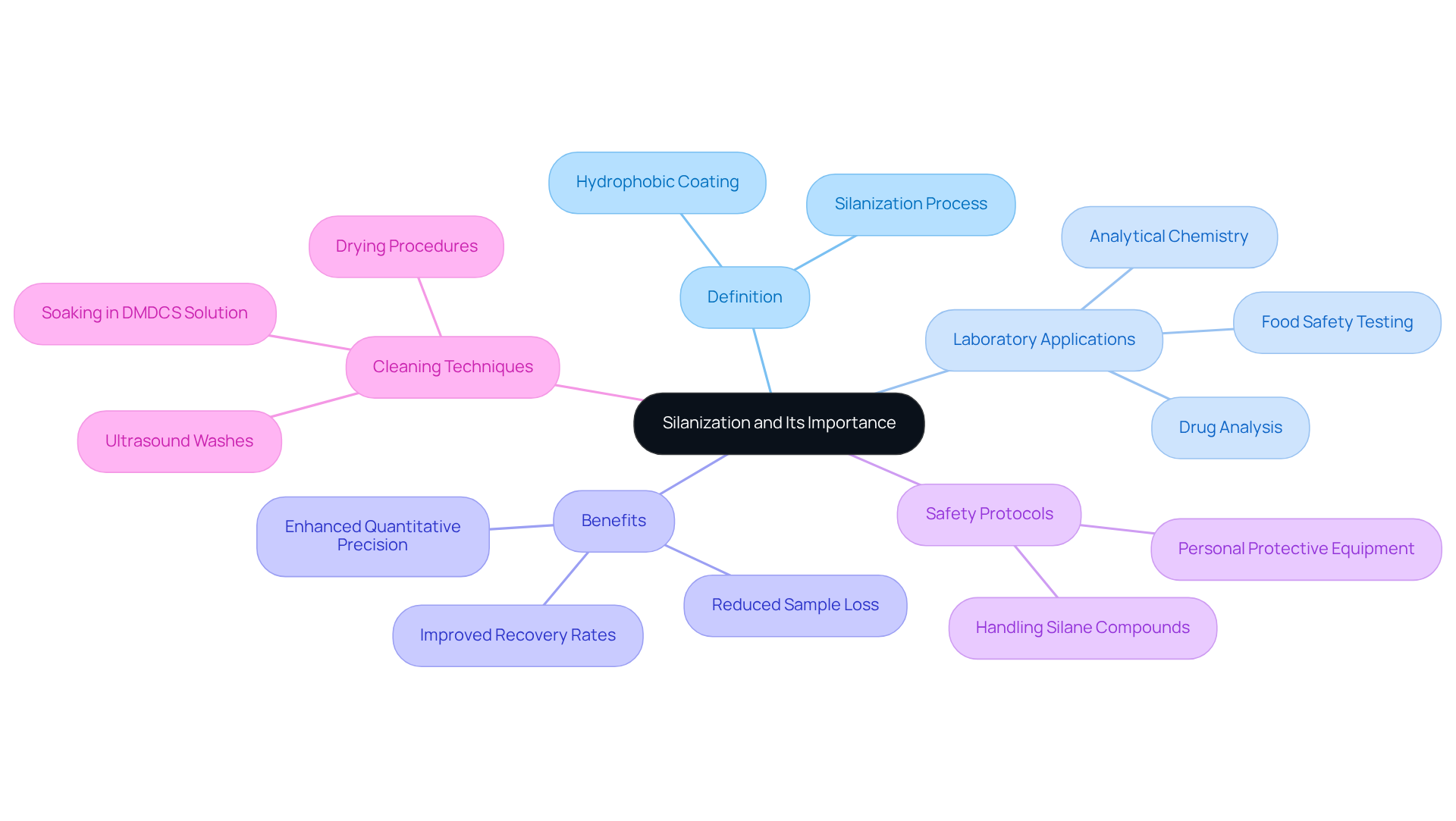

Define Silanization and Its Importance in Laboratory Settings

Silanization, also known as siliconization, represents a transformative chemical process that applies silane compounds to modify the characteristics of materials, particularly to create silanized glass. This treatment effectively replaces hydroxyl groups on the transparent layer with silane groups, resulting in a hydrophobic coating that significantly minimizes solute adsorption.

In laboratory settings, especially within analytical chemistry and pharmaceutical applications, silanized glass is crucial for enhancing the performance of glassware. By preventing sample loss and ensuring precise measurements, this process is vital in preserving the integrity of experimental results. The reduction in surface reactivity of the material not only boosts the reliability of analyses but also contributes to overall laboratory efficiency.

For instance, vials made from silanized glass have shown improved recovery rates and quantitative precision, making them indispensable in applications such as drug analysis and food safety testing. The advantages of silanization extend beyond mere functionality; they are essential in fostering innovation and precision in scientific research.

As Mohammad Hossein Khoeini notes, 'Silanization decreases polar groups and dispersive energy, enhancing the hydrophobicity of the material,' further underscoring its significance in laboratory environments. Moreover, implementing appropriate cleaning techniques, such as ultrasound washes and drying procedures, is critical before silanization to maintain the integrity of the silanized layer.

Additionally, handling silane compounds like dimethyldichlorosilane (DMDCS) necessitates caution due to their reactivity, highlighting the importance of adhering to safety protocols in laboratory practices.

Explore the Properties of Silanized Glass and Their Implications

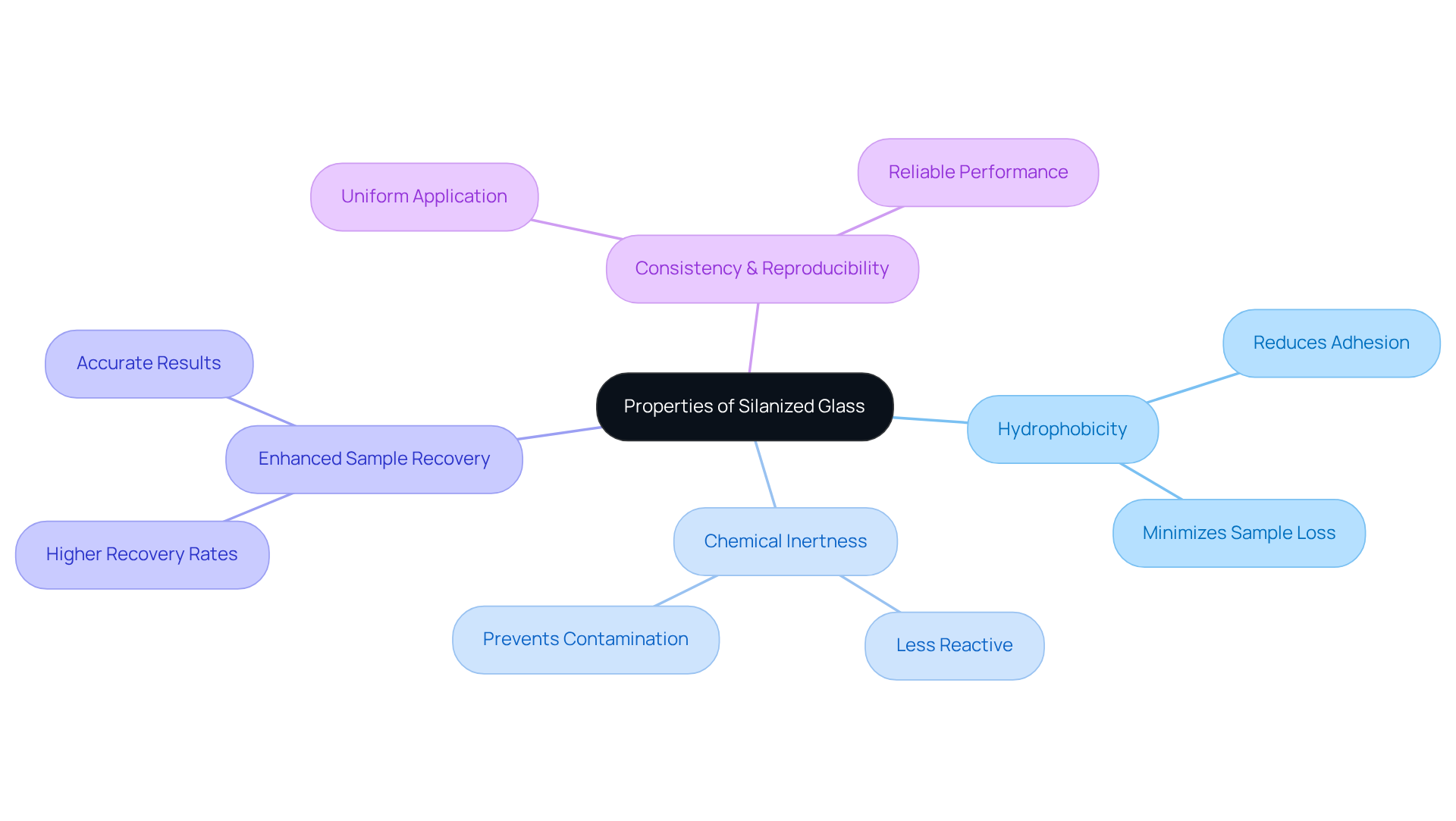

Silanized glass exhibits several pivotal properties that greatly enhance its functionality in laboratory applications.

Firstly, the hydrophobicity of the silane coating creates a hydrophobic layer, which effectively reduces the adhesion of aqueous solutions and minimizes sample loss due to adsorption. This property is crucial for maintaining the integrity of samples during experiments.

Secondly, the chemical inertness of silanized glass renders it less reactive, making silanized glass an ideal choice for storing sensitive compounds without the risk of contamination.

Moreover, silanization facilitates enhanced sample recovery, enabling higher recovery rates of analytes, particularly in trace analysis. This is achieved by preventing the adherence of polar compounds to the surface, thereby ensuring accurate results.

Lastly, the consistency and reproducibility of the silanization process allow for uniform application, guaranteeing reliable performance across batches of glassware, which is essential for experimental validity.

In summary, these properties render silanized glass invaluable tools in various laboratory settings, especially in analytical and pharmaceutical research.

Examine Applications of Silanized Glass in Pharmaceutical and Analytical Laboratories

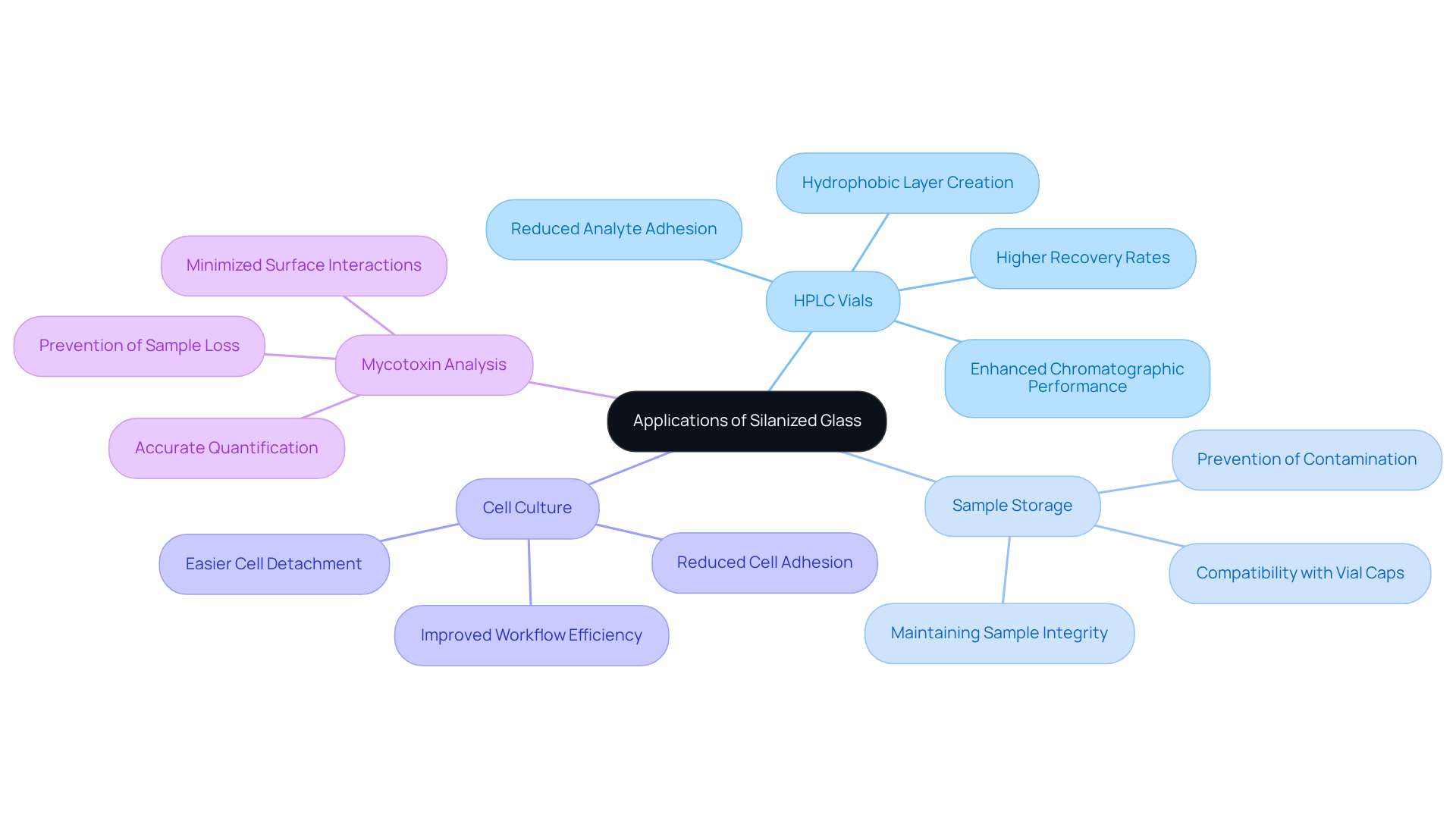

In pharmaceutical and analytical laboratories, silanized glass plays a pivotal role in various applications.

HPLC vials made from silanized glass are indispensable for high-performance liquid chromatography (HPLC), significantly reducing analyte adhesion to the vial walls. This reduction enhances chromatographic performance and accuracy, leading to higher recovery rates and more reliable analytical results. The silanization process effectively masks polar silanol groups on the glass surface, creating a hydrophobic layer that minimizes interactions with highly polar molecules that could compromise data integrity. Typically, a 10% to 40% silane solution is employed, ensuring optimal performance.

Sample Storage: Silanized glass containers are particularly well-suited for storing sensitive samples, including biological fluids and pharmaceuticals. By preventing contamination and degradation, these vials ensure that sample integrity is maintained over time, which is crucial for accurate analysis. Additionally, ensuring compatibility between vial caps and vials is essential to prevent unexpected contamination or sample loss in HPLC.

Cell Culture: In cell culture applications, treated flasks are beneficial as they reduce cell adhesion to the walls. This property facilitates easier cell detachment and transfer, improving workflow efficiency in laboratory settings.

In mycotoxin analysis, the use of silanized glass containers is critical, as preventing sample loss is essential for accurate quantification. Silanization assists in preventing the adsorption of mycotoxins onto the surface, ensuring that the results represent true concentrations instead of losses caused by surface interactions. As Cristina Jaycox pointed out, 'If the mycotoxins adhered to the container instead of passing through the method and being measured at the conclusion of the procedure, then our findings would indicate either a low recovery or a misleadingly low result, all because of unprocessed equipment.'

These applications highlight the versatility and necessity of treated surfaces in preserving the integrity and reliability of laboratory results, making it an essential component in contemporary analytical practices.

Implement Best Practices for Using Silanized Glass in Laboratory Work

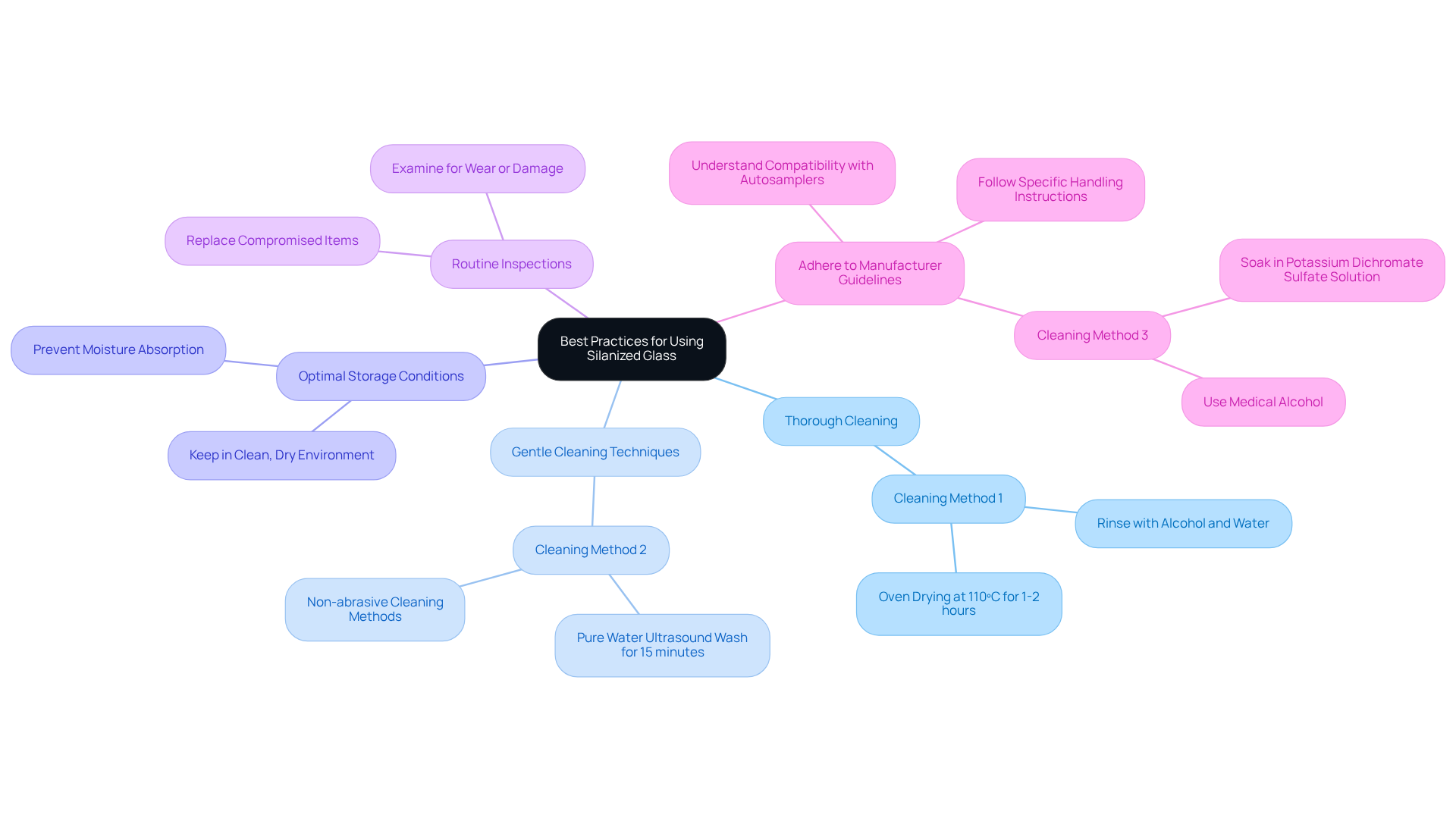

To maximize the effectiveness of silanized glass in laboratory applications, it is essential to adhere to the following best practices:

-

Thorough cleaning is essential: Before use, ensure that silanized glass laboratory equipment is meticulously cleaned to eliminate contaminants that may compromise experimental results. Cleaning Method 1, which involves rinsing with alcohol and water followed by oven drying, is effective in preparing containers for reuse.

-

Gentle Cleaning Techniques: Avoid abrasive materials and harsh chemicals that can damage the silane coating. Instead, opt for non-abrasive cleaning methods to preserve the integrity of the surface. Cleaning Method 2, requiring a pure water ultrasound wash for at least 15 minutes, is a gentle yet effective approach. This method has been demonstrated to effectively clean containers without compromising the silanized glass layer, as highlighted in the case study 'Cleaning Method 2: Water and Air Dry.'

-

Silanized glass is often used in laboratory settings. Optimal storage conditions dictate that silanized glass containers should be kept in a clean, dry environment to prevent moisture absorption, which can degrade the silane layer. Proper storage is essential for preserving the performance of glass items over time.

-

Silanized glass is used in various applications. Routine inspections require regularly examining containers for signs of wear or damage to the silanized glass coating. Replacing compromised items is essential to ensure consistent performance and prevent unexpected contamination during experiments. As noted by Kalvin Chen, utilizing silanized glass surfaces is advised to avoid solute adsorption on the surface, underscoring the significance of preserving the integrity of the equipment.

-

Adhere to Manufacturer Guidelines: Follow specific handling and usage instructions provided by manufacturers to fully leverage the benefits of treated glassware. This includes understanding the compatibility of vials with autosamplers, which is vital for accurate results in HPLC applications. Additionally, consider Cleaning Method 3. Silanized glass is often used in laboratory settings, which involves soaking in potassium dichromate sulfate solution and medical alcohol, as part of a comprehensive cleaning strategy.

By implementing these best practices, laboratory personnel can enhance the longevity and effectiveness of their research outcomes with silanized glass.

Conclusion

Silanized glass serves as a foundational element in laboratory environments, fundamentally transforming interactions between materials and samples while enhancing the reliability of experimental results. The application of silane compounds to glass surfaces creates a hydrophobic layer that minimizes sample loss and contamination, rendering silanized glass an indispensable asset in analytical and pharmaceutical laboratories.

This article explores the critical properties of silanized glass, including its hydrophobicity and chemical inertness, which collectively ensure higher recovery rates and more accurate analyses. It highlights various applications of silanized glass in:

- High-performance liquid chromatography (HPLC)

- Sample storage

- Cell culture

This underscores its versatility and necessity in maintaining sample integrity. Furthermore, best practices for utilizing silanized glass emphasize the importance of proper cleaning, storage, and handling, maximizing its effectiveness and longevity.

Ultimately, the significance of silanized glass in laboratory settings cannot be overstated. By fostering innovation and precision in research, it empowers scientists to achieve more reliable and reproducible results. Embracing the principles of silanization and adhering to best practices will enhance laboratory efficiency and pave the way for breakthroughs in scientific discovery.