Overview

The article primarily addresses the critical selection and significance of solvent containers within pharmaceutical laboratories, underscoring their essential role in safeguarding chemical integrity and ensuring adherence to regulatory standards. It articulates key criteria for selection, including:

- Chemical compatibility

- Effective sealing mechanisms

- Material considerations

Furthermore, the article elucidates the repercussions of non-compliance, which can significantly jeopardize research integrity and safety. By emphasizing these points, the article not only informs but also prompts action towards the careful selection of solvent containers.

Introduction

In the intricate world of pharmaceutical laboratories, selecting solvent containers transcends mere convenience; it stands as a pivotal factor in preserving the integrity and safety of chemical analyses.

As these laboratories endeavor to uphold rigorous standards, grasping the nuances of container types, materials, and compliance regulations becomes essential.

With a plethora of options at their disposal, how can laboratory managers adeptly navigate the complexities of solvent container selection to mitigate risks and amplify research outcomes?

This guide explores the essential criteria and best practices for mastering solvent container selection, ensuring that every laboratory remains steadfast in its commitment to excellence and safety.

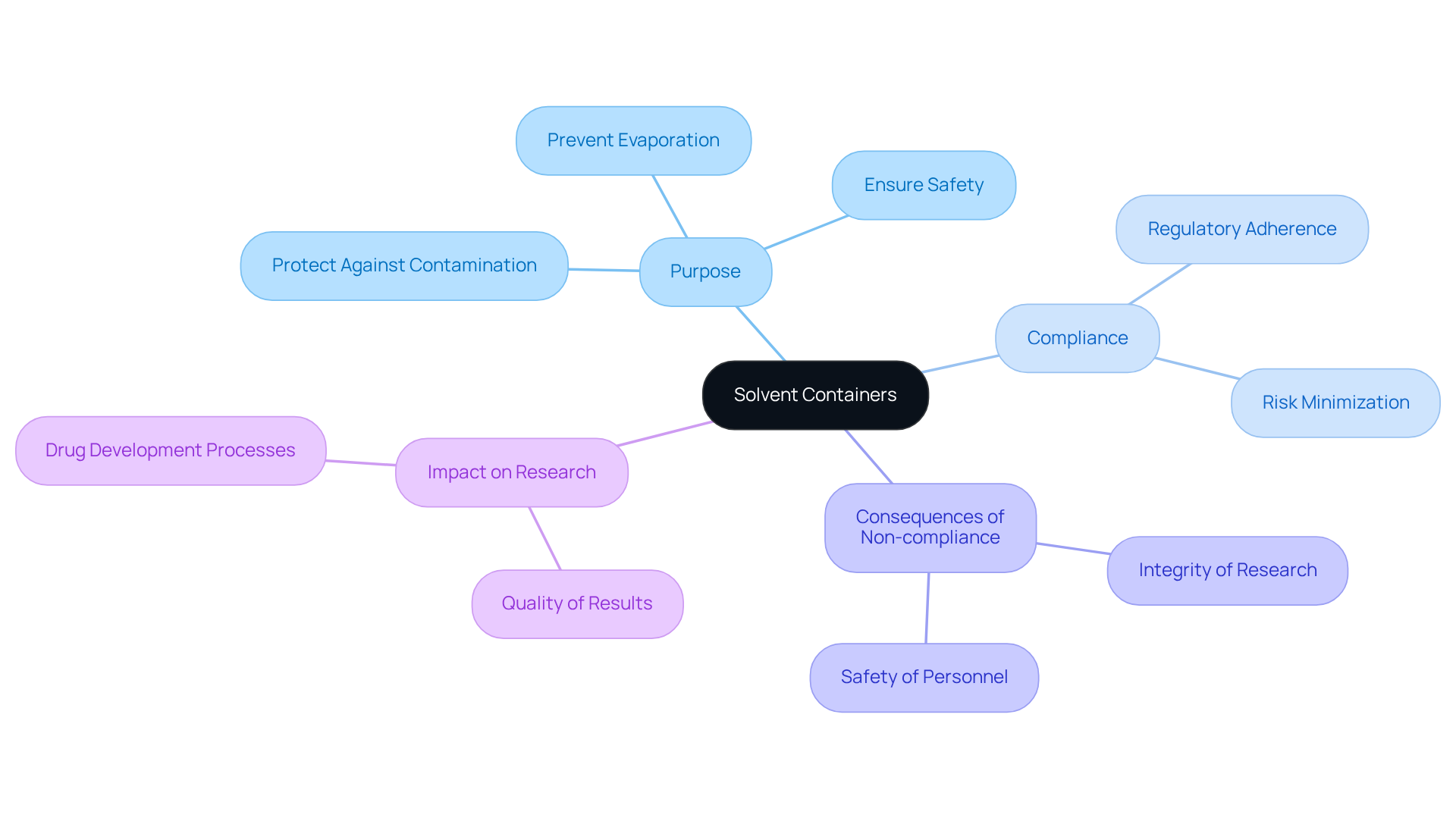

Understand the Purpose of Solvent Containers

Solvent containers are essential vessel units for the storage and management of various solutions utilized in pharmaceutical laboratories. Their primary objective is to , evaporation, and degradation, all of which can jeopardize experimental results. Furthermore, suitable vessels play a critical role in ensuring compliance with regulations by minimizing the risk of leaks and contact with hazardous substances. As Marcus Cato wisely remarked, 'Practice science cautiously,' underscoring the importance of adhering to protective protocols in experimental environments.

Practical examples illustrate that compliance with container regulations is indispensable for maintaining operational standards in research facilities. Non-compliance can lead to severe repercussions, affecting not only the integrity of research but also the safety of laboratory personnel. The impact of contaminants on pharmaceutical research cannot be overstated; tainted substances can yield inaccurate outcomes, undermining the reliability of research findings and potentially obstructing drug development processes. Therefore, selecting the appropriate solvent containers for liquids is vital for preserving the quality and accuracy of scientific endeavors.

In conclusion, solvent containers are critical in pharmaceutical laboratories, providing protection against contamination and evaporation while ensuring compliance with safety regulations. Their significance lies in supporting the integrity of research and fostering the advancement of pharmaceutical innovations.

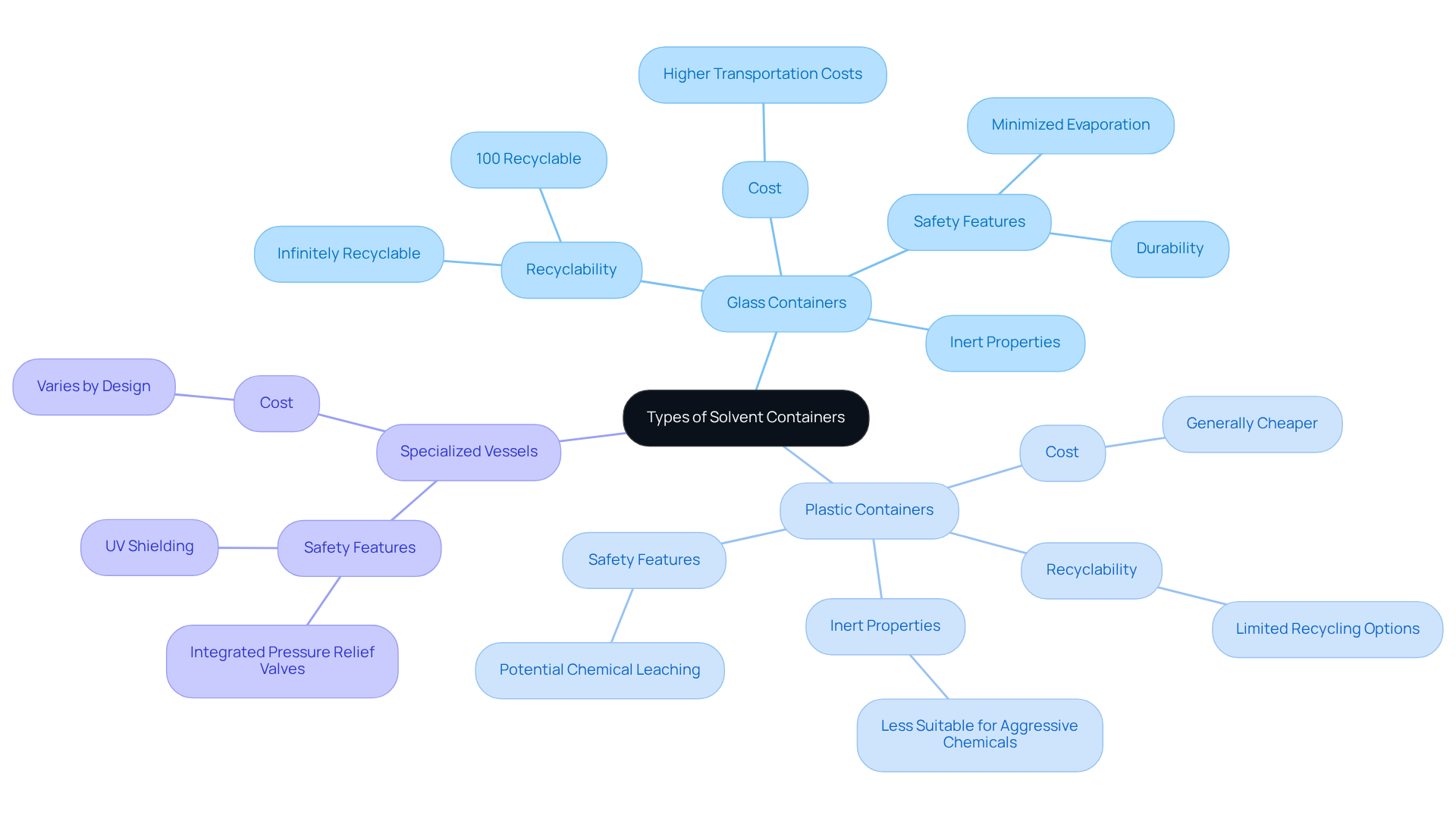

Explore Different Types of Solvent Containers

In pharmaceutical facilities, the selection of solution vessels is crucial for maintaining the integrity of chemical analyses. The primary types of solvent containers include:

- Glass Containers: Renowned for their inert properties, glass containers are ideal for storing organic solvents as they do not react with most chemicals. Their ability to be sealed tightly minimizes evaporation, making them a reliable choice for sensitive applications. Furthermore, glass is 100% recyclable, aligning with sustainability goals in laboratory practices. The fact that glass can be recycled infinitely further supports its environmental advantages.

- Plastic Containers: While lightweight and less fragile than glass, plastic containers are generally suited for less aggressive chemicals. However, they may pose risks due to potential leaching of chemicals, which can compromise the quality of the substances stored within. It's also important to note that plastic solvent containers are generally cheaper than glass, due to large-scale manufacturing, which can be a significant consideration for laboratory managers.

- Specialized Vessels: These vessels are designed for particular chemicals or uses, incorporating improvements like integrated pressure relief valves or UV shielding. Such innovations address the distinct needs of different substances, ensuring optimal performance and safety.

Laboratory managers have recognized the significance of choosing the appropriate solvent container. One manager remarked, "Utilizing specialized glass vessels has significantly enhanced our solvent stability and decreased contamination risks." This sentiment reflects a broader trend in the industry, where glass vessels are increasingly favored for their reliability. Additional insights from other managers indicate a growing preference for glass due to its durability and compliance with stringent regulatory standards.

Market dynamics indicate a growing preference for glass over plastic in laboratory settings. Recent statistics indicate that glass vessels possess a substantial market share, especially in North America, where stringent regulatory standards require high-quality storage solutions. However, it is essential to consider that transportation costs for glass are higher than plastic due to its weight. As pharmaceutical companies face pricing pressures and tighter regulations, the demand for durable and compliant storage options continues to rise, further solidifying glass's position in the market.

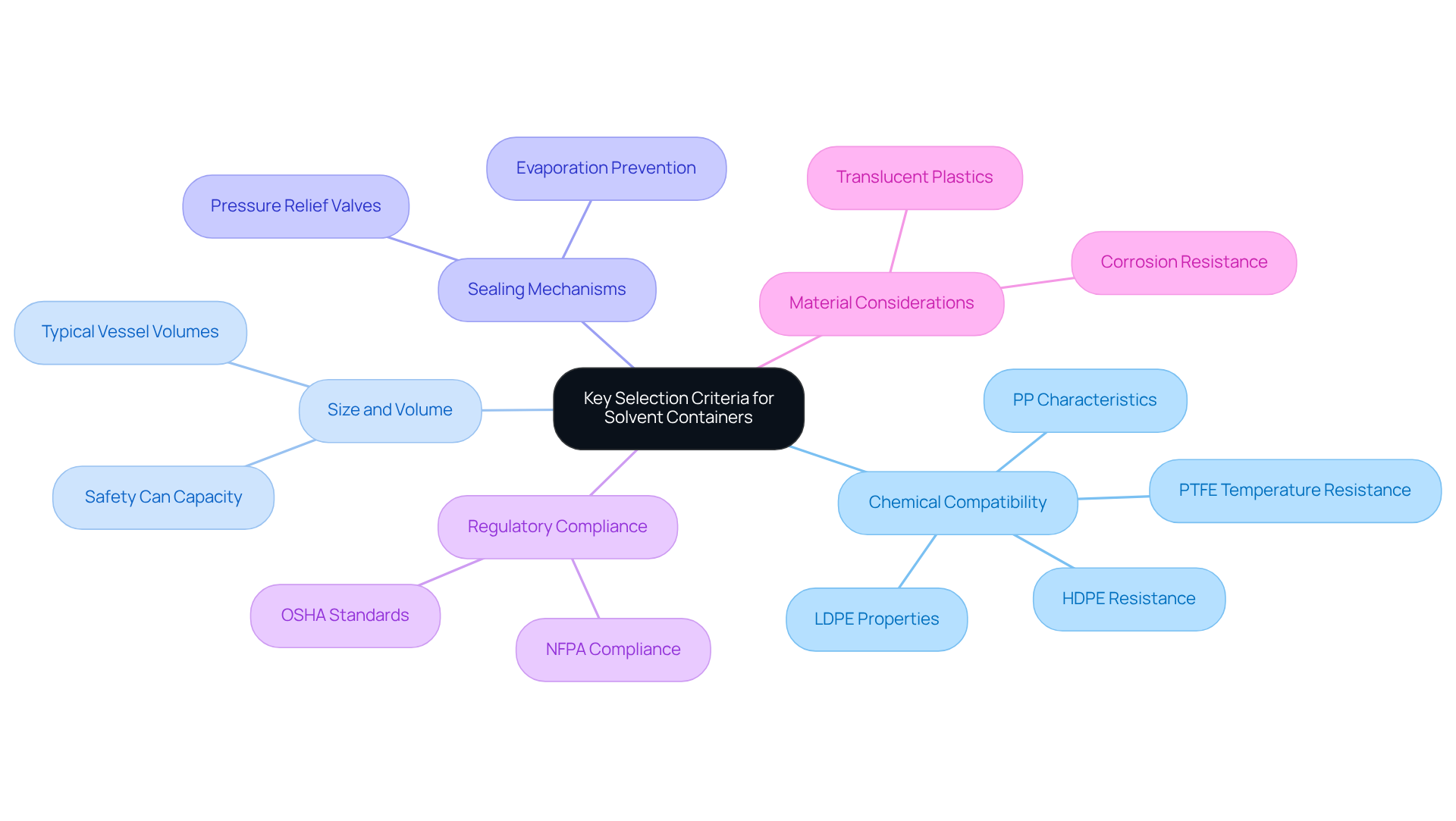

Evaluate Key Selection Criteria for Solvent Containers

When selecting for pharmaceutical labs, several key criteria for solvent container selection must be considered.

- Chemical Compatibility is essential; the container material must be compatible with the solvents being stored. For instance, high-density polyethylene (HDPE) is highly resistant to non-oxidizing acids and hydrocarbons, while polytetrafluoroethylene (PTFE) can withstand temperatures up to 250°C and is resistant to a wide range of chemicals. This compatibility prevents reactions that could lead to contamination or deterioration of both the solvent and its solvent container.

- Next, consider Size and Volume. Choose vessel sizes that correspond with your usage patterns. Safety cans are an example of a solvent container, typically having a maximum capacity of 5 gallons (20 liters), making them suitable for various laboratory applications. Typical volumes of liquid vessels utilized in pharmaceutical laboratories often vary from 1 liter to 20 liters, based on the particular application. Selecting the right size for the solvent container minimizes waste and ensures efficient storage.

- Sealing Mechanisms are crucial to prevent evaporation and contamination. Containers designed as solvent containers equipped with pressure relief valves are particularly important for volatile solvents, as they help manage internal pressure safely.

- Moreover, ensure Regulatory Compliance. Solvent containers must meet applicable health and environmental regulations, with compliance to standards such as OSHA and NFPA being vital for maintaining safe laboratory operations. Current cabinets ought to be marked if they fulfill these standards, ensuring clarity and protection in the lab environment.

- Finally, consider Material Considerations. The chemical compatibility of the substances' storage materials is paramount. In addition to HDPE and PTFE, low-density polyethylene (LDPE) is translucent with high impact resistance and excellent resistance to weak or dilute acids, while polypropylene (PP) is known for its glass-like clarity and flexibility. By thoroughly assessing these standards, pharmaceutical laboratories can improve security and effectiveness in their storage methods.

Implement Best Practices for Using and Maintaining Solvent Containers

To ensure the effective use and maintenance of solvent containers, adhering to best practices that safeguard laboratory integrity and safety is essential.

Labeling: Clearly label all containers with the solvent name, concentration, and date of receipt. This practice significantly reduces the risk of mix-ups and guarantees , which is crucial for maintaining laboratory security and compliance. As Trevor Henderson states, "Proper labeling not only minimizes risks but also fosters a culture of responsibility and compliance within the lab environment."

Storage Conditions: Store vessels in a cool, dry location, away from direct sunlight and heat sources. Inadequate storage can lead to the breakdown of chemicals, impacting their quality and potentially presenting safety risks. Statistics suggest that a substantial proportion of solvent-related incidents arise from vessel failures, with improper storage being a key factor. For instance, solvents stored in high temperatures can degrade more rapidly, leading to hazardous reactions.

Regular Inspections: Conduct routine checks for leaks, cracks, or signs of wear in the vessels. Promptly replacing any damaged vessels is essential to prevent spills and maintain a safe working environment.

Chemical Spill Cleanup Kits: Ensure that chemical spill cleanup kits are readily available in the laboratory. These kits should contain instructions, absorbents, and protective equipment to manage minor spills safely.

Proper disposal requires following local regulations for the disposal of solvent containers and their contents. This ensures environmental safety and compliance with hazardous waste management protocols, which are vital in pharmaceutical settings.

Conclusion

Selecting the appropriate solvent containers is a fundamental aspect of ensuring safety and integrity in pharmaceutical laboratories. These containers not only safeguard against contamination and evaporation but also guarantee compliance with regulatory standards. A meticulous choice of solvent containers bolsters the reliability of research outcomes and fosters advancements in pharmaceutical innovations.

The significance of understanding the various types of solvent containers—ranging from glass to specialized vessels—cannot be overstated. Each type serves distinct purposes, with glass containers frequently favored for their inert properties and recyclability. Key selection criteria include:

- Chemical compatibility

- Size

- Sealing mechanisms

- Regulatory compliance

These are essential considerations for laboratory managers. Furthermore, implementing best practices for labeling, storage, and maintenance is crucial for protecting laboratory environments.

In conclusion, the selection of solvent containers is of paramount importance. By prioritizing the right materials and adhering to best practices, pharmaceutical laboratories can enhance safety, improve operational efficiency, and ultimately contribute to the successful development of pharmaceuticals. A proactive approach in this domain not only protects laboratory personnel but also ensures that scientific endeavors remain uncompromised, paving the way for future innovations in the field.