Overview

This article presents essential insights for lab managers on mastering the near-infrared (NIR) spectrum, underscoring its applications, benefits, and challenges within laboratory environments. NIR analysis is pivotal for enhancing efficiency and accuracy across various laboratory applications, including quality control and real-time monitoring. However, lab managers must also confront challenges such as calibration and regulatory compliance to effectively implement NIR technology. By navigating these complexities, they can harness the full potential of NIR analysis, ultimately driving improvements in laboratory operations.

Introduction

Understanding the nuances of Near-Infrared (NIR) spectrum analysis is essential for lab managers aiming to enhance their laboratory's analytical capabilities. This powerful non-destructive technique provides critical insights into the chemical composition of materials, opening doors to innovative applications across diverse industries, including pharmaceuticals and food safety.

However, as the adoption of NIR technologies accelerates, lab managers encounter significant challenges in:

- Calibration

- Data interpretation

- Regulatory compliance

How can they effectively navigate these complexities while maximizing the benefits of NIR spectrum analysis? This inquiry not only highlights the importance of NIR technology but also underscores the need for strategic approaches in laboratory management.

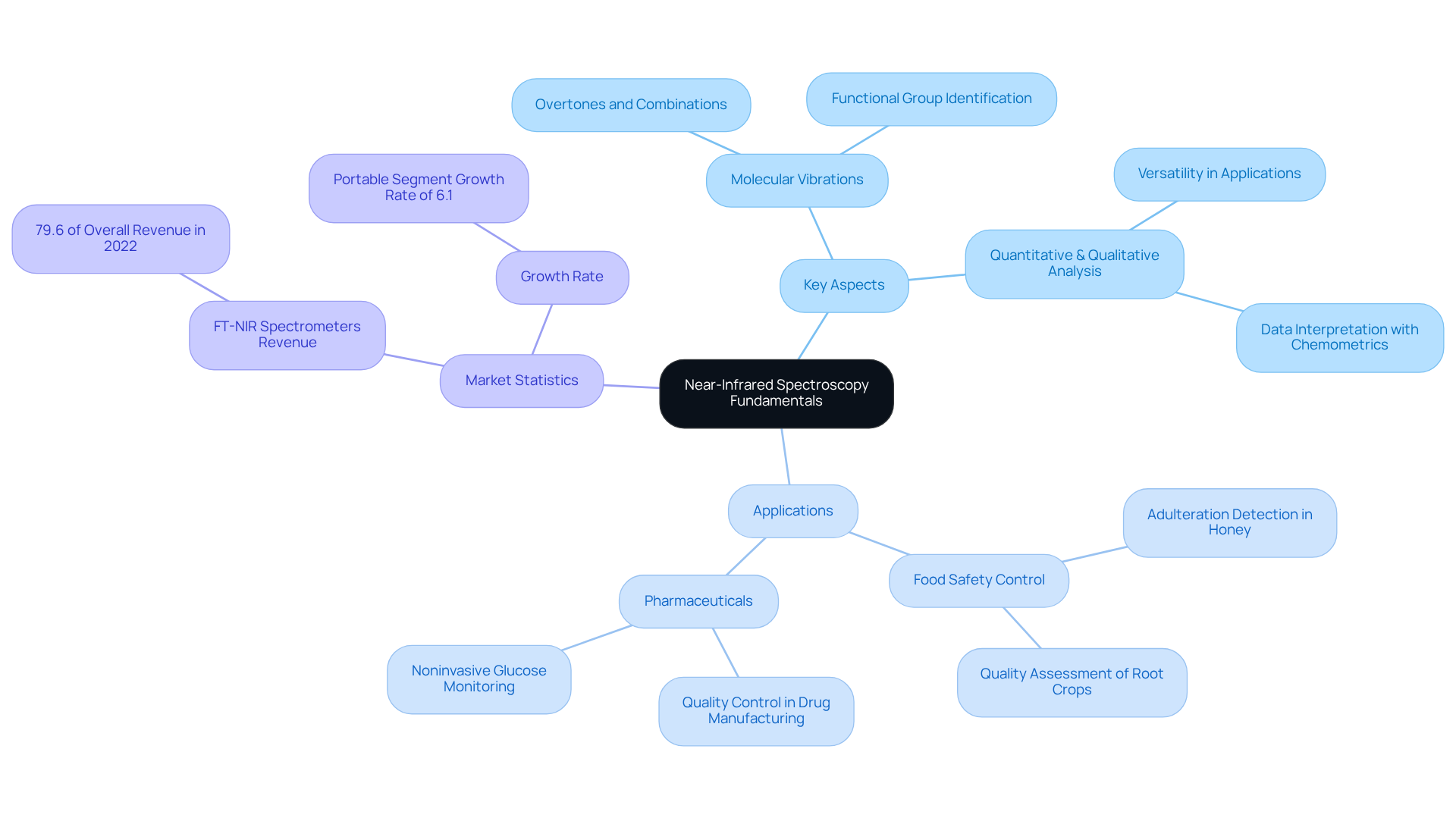

Clarify the Fundamentals of Near-Infrared Spectrum

Near-infrared (NIR) analysis is a non-destructive analytical technique that utilizes light from the NIR spectrum, which typically ranges from 780 nm to 2500 nm. This method is grounded in the absorption of light by molecular vibrations, providing critical insights into the chemical composition of a specimen. The fundamental principles of NIR analysis encompass several key aspects:

-

Molecular Vibrations: NIR spectroscopy effectively measures overtones and combinations of fundamental molecular vibrations, facilitating the identification of functional groups within molecules. This capability is essential for comprehending molecular structures and interactions across various substances. The interaction of NIR light with a sample can result in absorption, transmission, or reflection, and the resulting NIR spectrum serves as a unique fingerprint of the sample's composition. Such interactions are vital for precise identification and characterization.

-

Quantitative and Qualitative Analysis: NIR technology is versatile, enabling both qualitative identification of substances and quantitative examination of specific components. This adaptability makes it suitable for diverse applications in pharmaceuticals, food safety control, and environmental monitoring.

Recent advancements in NIR technology have significantly broadened its applicability. The integration of chemometric models has notably enhanced data interpretation accuracy, particularly within complex matrices. Alyn Baby remarked, 'NIR can be easily incorporated into standard control workflows in food labs,' underscoring its practical relevance. Real-world applications illustrate NIR's effectiveness in detecting adulteration in honey and assessing the quality of root crops, such as potatoes and sweet potatoes, through the analysis of sugar content and moisture levels.

Statistics reveal that FT-NIR spectrometers constituted over 79.6% of the overall revenue in 2022, with the portable type segment projected to experience a growth rate of 6.1% during the forecast period. Understanding these fundamentals is imperative for lab managers aiming to implement NIR spectrum technology effectively, which ensures compliance with regulatory standards and enhances product quality. Furthermore, high-quality reference data is essential for accurate model calibration, highlighting the critical role of data quality in the analytical process.

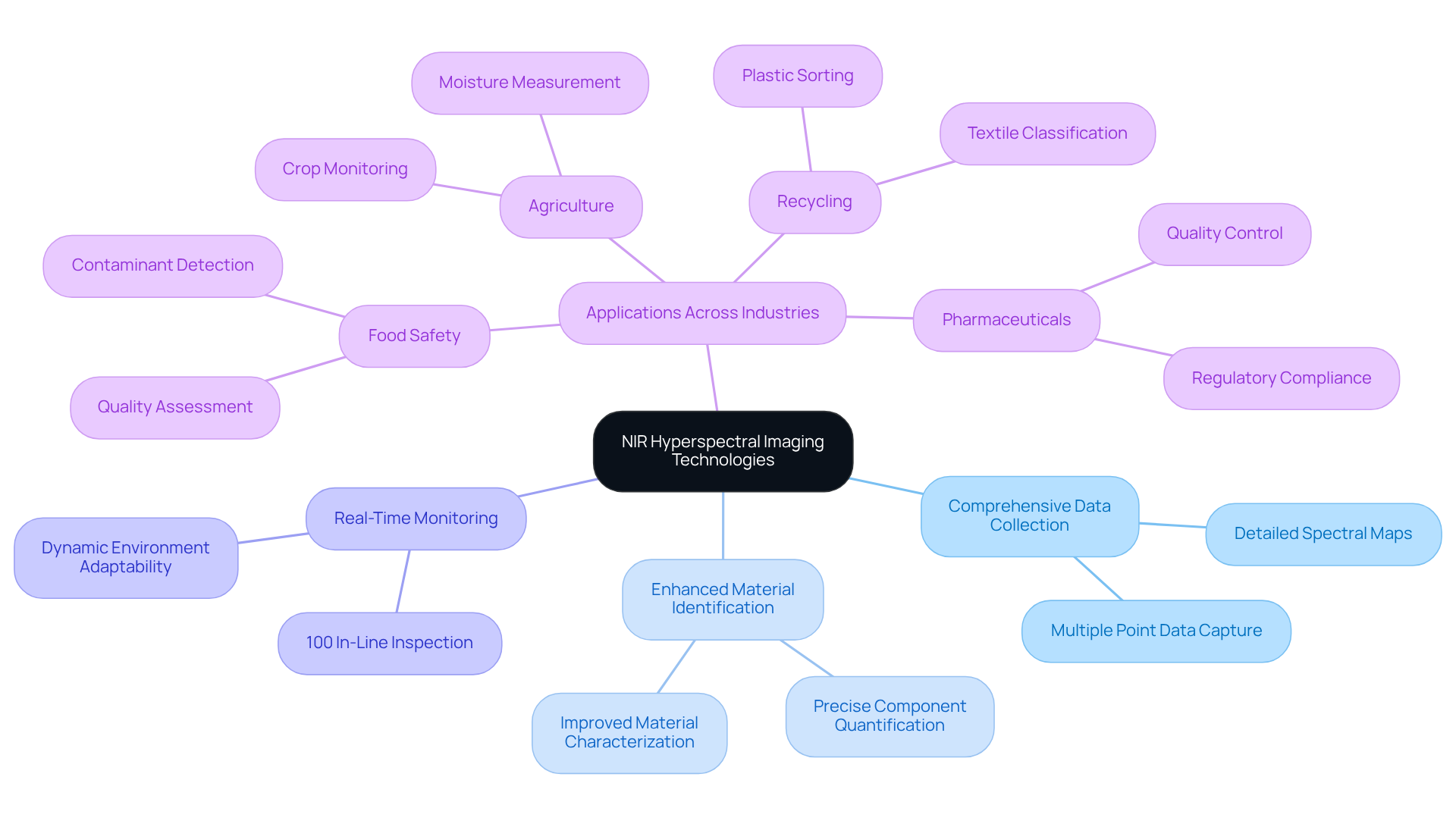

Explore NIR Hyperspectral Imaging Technologies

NIR hyperspectral imaging merges conventional NIR spectrum analysis with cutting-edge imaging techniques, facilitating the acquisition of detailed spectral data across extensive areas. This groundbreaking technology presents several significant advantages:

-

Comprehensive Data Collection: In contrast to traditional NIR spectroscopy, which focuses on a single point, hyperspectral imaging captures data from multiple points concurrently, resulting in a detailed spectral map of the sample. This capability markedly enhances the depth of analysis within the NIR spectrum.

-

Enhanced Material Identification: Through meticulous examination of the NIR spectrum data, lab managers can precisely identify and quantify various components within a sample, thereby improving material characterization and ensuring reliability in results.

-

Real-Time Monitoring: The capacity for real-time analysis is particularly beneficial in dynamic environments, such as production lines or experimental setups where conditions may change rapidly. This feature ensures prompt decision-making and adherence to standards. Notably, NIR spectrum hyperspectral imaging facilitates 100% in-line inspection, thereby enhancing quality standards and reducing waste compared to conventional point spectrometers.

-

Applications Across Industries: NIR hyperspectral imaging utilizes the NIR spectrum and finds applications in diverse sectors, including pharmaceuticals for stringent control, agriculture for efficient crop monitoring, and food safety for contaminant detection. For instance, in the pharmaceutical industry, this technology bolsters the dependability of control processes, ensuring compliance with regulatory standards and enhancing product safety. A case study in pharmaceutical standards control illustrated that the use of NIR spectrum hyperspectral imaging significantly enhanced the reliability of control processes, thereby improving product safety and efficacy.

As industry leaders acknowledge its transformative potential, exemplified by Daniel Carrero, Product Manager of PICVISA, who remarked, "NIR HSI is a game-changer," lab managers are urged to harness these advanced NIR solutions to elevate their laboratory's analytical capabilities.

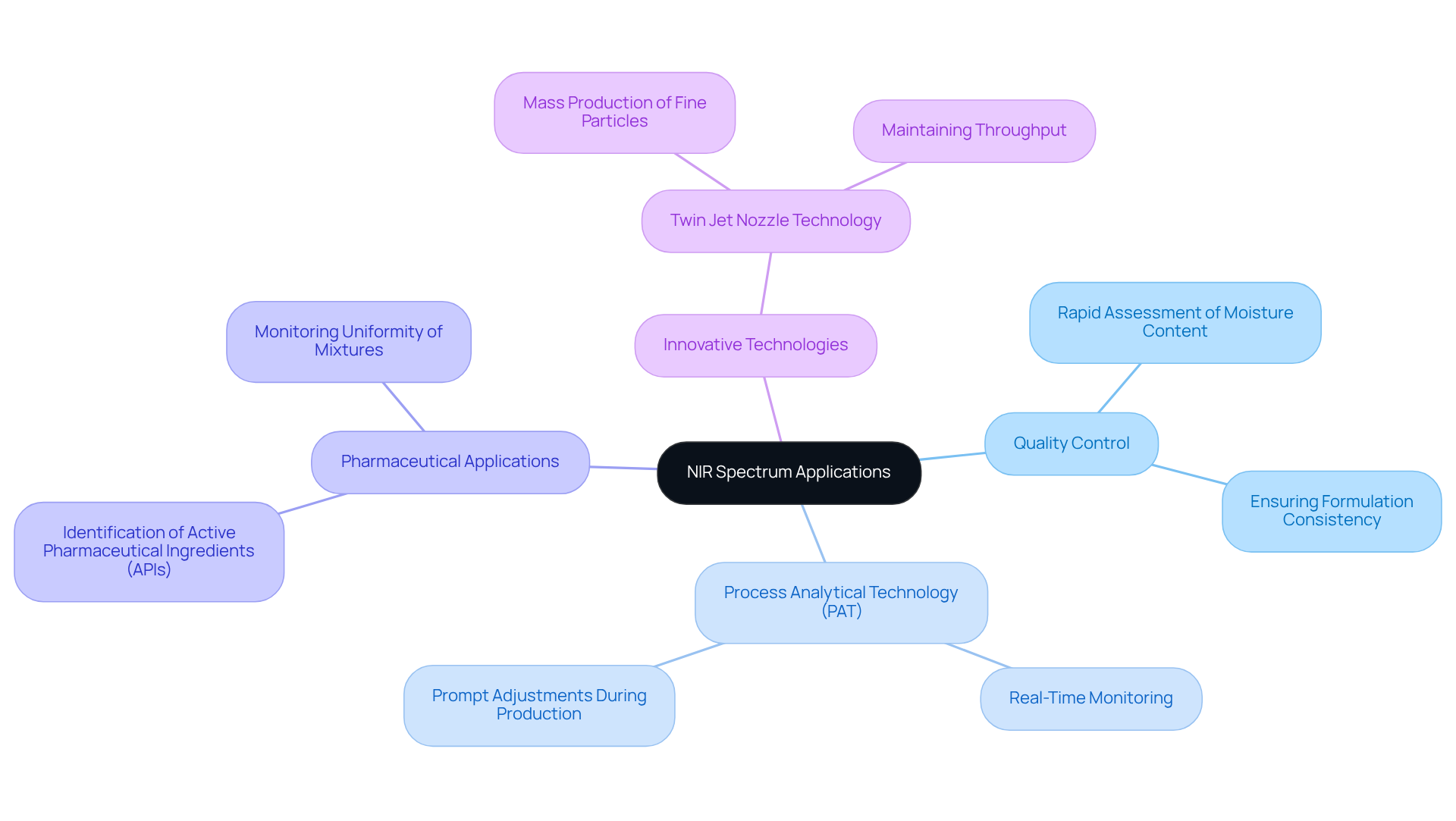

Apply NIR Spectrum in Laboratory Applications

The nir spectrum is crucial in a range of laboratory applications, significantly improving both efficiency and accuracy. Its key applications are as follows:

-

Quality Control: NIR is extensively employed in quality control processes to ensure that raw materials and finished products meet specified standards. For example, it allows for the rapid assessment of moisture content in pharmaceutical powders, thereby ensuring formulation consistency.

-

Process Analytical Technology (PAT): By integrating NIR into PAT, manufacturers can monitor essential characteristics in real-time during production. This capability facilitates prompt adjustments, preserving product standards and compliance.

-

Pharmaceutical Applications: NIR is vital for identifying active pharmaceutical ingredients (APIs) and excipients, as well as for monitoring the uniformity of mixtures during tablet production. This ensures that formulations meet rigorous standards.

-

Innovative Technologies: Recent advancements, such as twin jet nozzle technology, enable the mass production of fine particles measuring 10 μm or smaller without compromising throughput. This innovation enhances the efficiency of pharmaceutical manufacturing processes.

By leveraging the NIR spectrum analysis across these applications, laboratory managers can significantly boost their operational efficiency and product quality, ultimately leading to improved outcomes in pharmaceutical manufacturing.

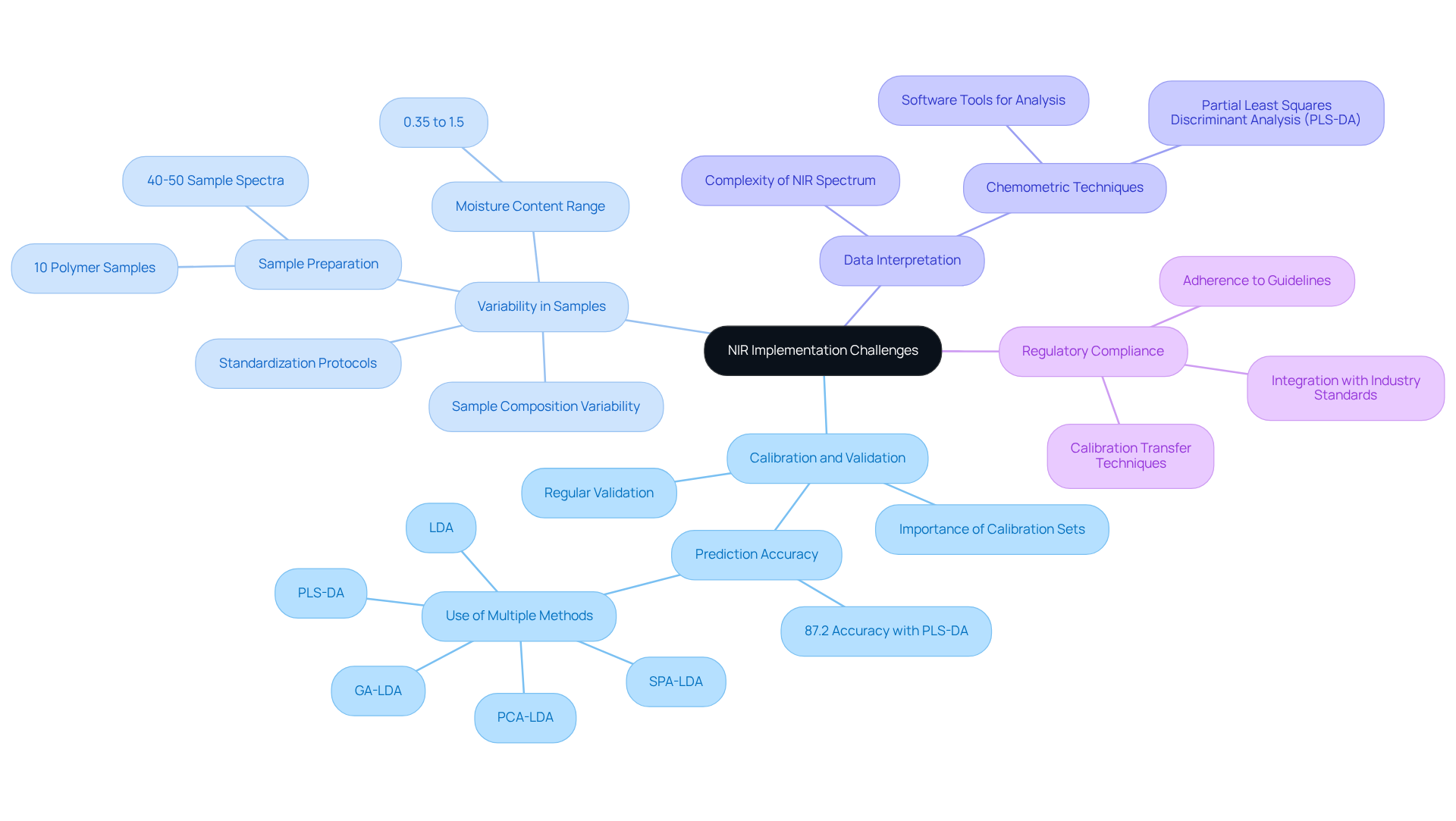

Navigate Challenges in NIR Implementation

Implementing the NIR spectrum spectroscopy in a laboratory setting presents several challenges that are crucial for successful integration.

-

Calibration and Validation: Accurate calibration models are essential for reliable results. Lab managers must ensure that calibration sets accurately reflect the specimens being analyzed. Regular validation of these models is critical, as studies indicate that a well-structured calibration set can achieve prediction accuracies of up to 87.2% in various applications, including the classification of aguardente specimens using methods such as PLS-DA, PCA-LDA, SPA-LDA, GA-LDA, and LDA.

-

Variability in samples, such as variations in composition, temperature, and presentation, can significantly impact the NIR spectrum measurements. Standardizing preparation protocols is vital to address these issues, ensuring uniformity across analyses. For instance, a calibration set for moisture content should encompass items that cover the expected range, typically between 0.35% and 1.5% moisture. A good starting point for a calibration set is approximately 10 polymer samples, with 40-50 sample spectra recommended for a robust prediction model.

-

Data Interpretation: The complexity of the NIR spectrum can pose challenges in its interpretation. Employing chemometric techniques, such as Partial Least Squares Discriminant Analysis (PLS-DA), enhances the extraction of meaningful information from the data. Lab managers should leverage software tools that facilitate data analysis and visualization, thereby improving the accuracy of their interpretations.

-

Regulatory Compliance: In regulated industries, adherence to guidelines for NIR applications is paramount. Lab managers must remain informed about relevant regulations and integrate them into their NIR processes. This includes understanding the necessary calibration transfer techniques and ensuring that all methods align with industry standards.

By proactively addressing these challenges, lab managers can significantly enhance the effectiveness of the NIR spectrum in their laboratories, resulting in improved analytical outcomes and greater confidence in their results.

Conclusion

Mastering the near-infrared (NIR) spectrum is essential for lab managers who seek to enhance analytical capabilities and ensure compliance with industry standards. By grasping the fundamentals of NIR spectroscopy—its principles of molecular vibrations and its dual capacity for qualitative and quantitative analysis—laboratory professionals can leverage this powerful tool to significantly improve product quality and operational efficiency.

The significance of NIR technology is underscored throughout this discussion, highlighting its diverse applications in quality control, process analytical technology, and pharmaceutical manufacturing. The integration of hyperspectral imaging further amplifies the benefits of NIR analysis, facilitating comprehensive data collection, enhanced material identification, and real-time monitoring. Moreover, addressing challenges such as calibration, data interpretation, and regulatory compliance is crucial for the successful implementation of these technologies.

Ultimately, embracing advancements in NIR spectrum technology not only streamlines laboratory processes but also fosters innovation across various industries. By prioritizing the effective application of NIR spectroscopy, lab managers can significantly enhance analytical outcomes, drive product safety, and position their laboratories at the forefront of scientific advancement. The future of laboratory analysis shines brightly with NIR technology, and its potential must be harnessed to achieve excellence in research and production.