Overview

This article underscores the critical importance of mastering the scale-up calculator in pharmaceutical research, a vital tool for transitioning from laboratory-scale processes to larger production scales without compromising product quality. It elaborates on essential concepts such as geometric and dynamic scaling, providing practical steps and tools for effectively utilizing a scale-up calculator. The emphasis on accurate calculations is paramount, as they are integral to achieving successful drug development outcomes. By understanding and implementing these concepts, researchers can significantly enhance their production efficiency and product integrity.

Introduction

In the intricate realm of pharmaceutical research, transitioning from laboratory experiments to large-scale production presents numerous challenges. Mastering the scale-up calculator is crucial for researchers who seek to maintain critical parameters such as flow rates and concentrations throughout this complex process. As the demand for precision in drug development escalates, how can researchers effectively leverage these tools to navigate potential pitfalls and secure successful outcomes? This guide explores the importance of scale-up calculations, providing insights and practical steps designed to empower researchers in their pursuit of excellence in pharmaceutical production.

Understand Scale-Up Calculations in Pharmaceutical Research

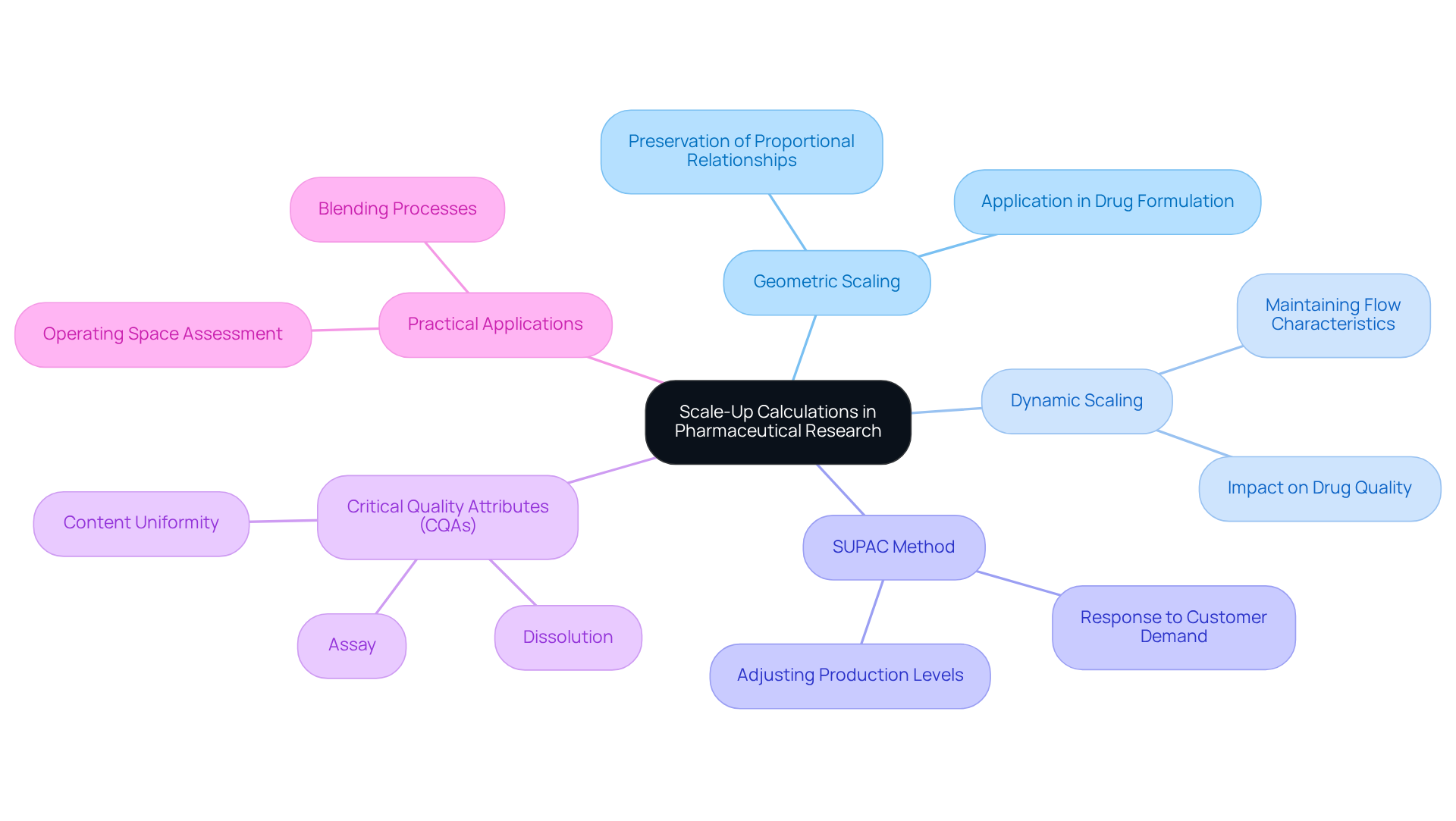

The scale up calculator assessments are pivotal in drug research, facilitating the transition from laboratory-scale processes to larger production scales. These computations are essential for maintaining critical parameters such as flow rates, concentrations, and reaction times. For instance, when progressing from a small-scale experiment to a pilot plant, it is imperative to replicate the same conditions to ensure the product's quality and efficacy. Key concepts include:

- Geometric scaling, which preserves proportional relationships between dimensions

- Dynamic scaling, which emphasizes maintaining similar flow characteristics

Moreover, the SUPAC method underscores the importance of utilizing a scale up calculator to adjust production levels according to customer demand, further emphasizing the necessity of growth assessments in drug development. As noted by industry specialists, understanding these principles is crucial for effectively implementing growth assessments in research initiatives, particularly in 2025, where precision in scaling can significantly impact drug development outcomes. Practical applications of these computations, such as research on blending processes and assessing variations in operating space through the developed DEM model, highlight their importance in ensuring consistency and reliability in drug manufacturing, ultimately leading to successful product launches.

Additionally, critical quality attributes (CQAs) such as assay, dissolution, and content uniformity must be considered to guarantee effective expansion processes. By grasping these concepts, researchers can navigate the complexities of drug development, ensuring that assessments using a scale up calculator are not merely procedural but integral to achieving excellence in pharmaceutical production.

Identify Tools for Scale-Up Calculations

In pharmaceutical research, a scale up calculator is among the several essential tools for effective expansion calculations. These tools not only streamline processes but also enhance accuracy and reliability. Here are some recommended options:

-

Liquid Chromatography Scale-Up Calculators: Tools such as the YMC Prep Scale-Up Calculator and those from Agilent significantly facilitate the transition from analytical to preparative chromatography. The YMC Prep Scale-Up Calculator, for example, provides critical parameters like theoretical column volume, required packing material, and flow rates, ensuring consistent results across scales. Notably, the project start to finish time for simulations using this calculator is less than 10 minutes, making it a highly efficient choice for researchers.

-

Process Development Software: Comprehensive solutions like Scale-up Suite and Dynochem enable modeling and simulating process expansion. These platforms allow for real-time adjustments based on experimental data, thereby enhancing accuracy and efficiency in method development. As one industry leader remarked, "It signifies significant assistance for our pilot engineers to get ready for any expansion project!"

-

Excel Spreadsheets: Custom spreadsheets can be designed to execute specific computations relevant to your project, providing flexibility and control over the expansion process. This method enables rapid adjustments and tailored analysis, ensuring that the computations satisfy the distinct requirements of your research.

-

Online Calculators: Websites like Pharma Calculation offer a range of calculators for API expansion, allowing quick evaluations and aiding decision-making in the initial phases of development. Utilizing these online resources can significantly enhance the effectiveness of your growth computations.

Acquainting yourself with these tools, such as a scale up calculator, can greatly improve the accuracy and dependability of your expansion calculations, ultimately leading to more successful results in drug research.

Utilize a Scale-Up Calculator: Step-by-Step Guide

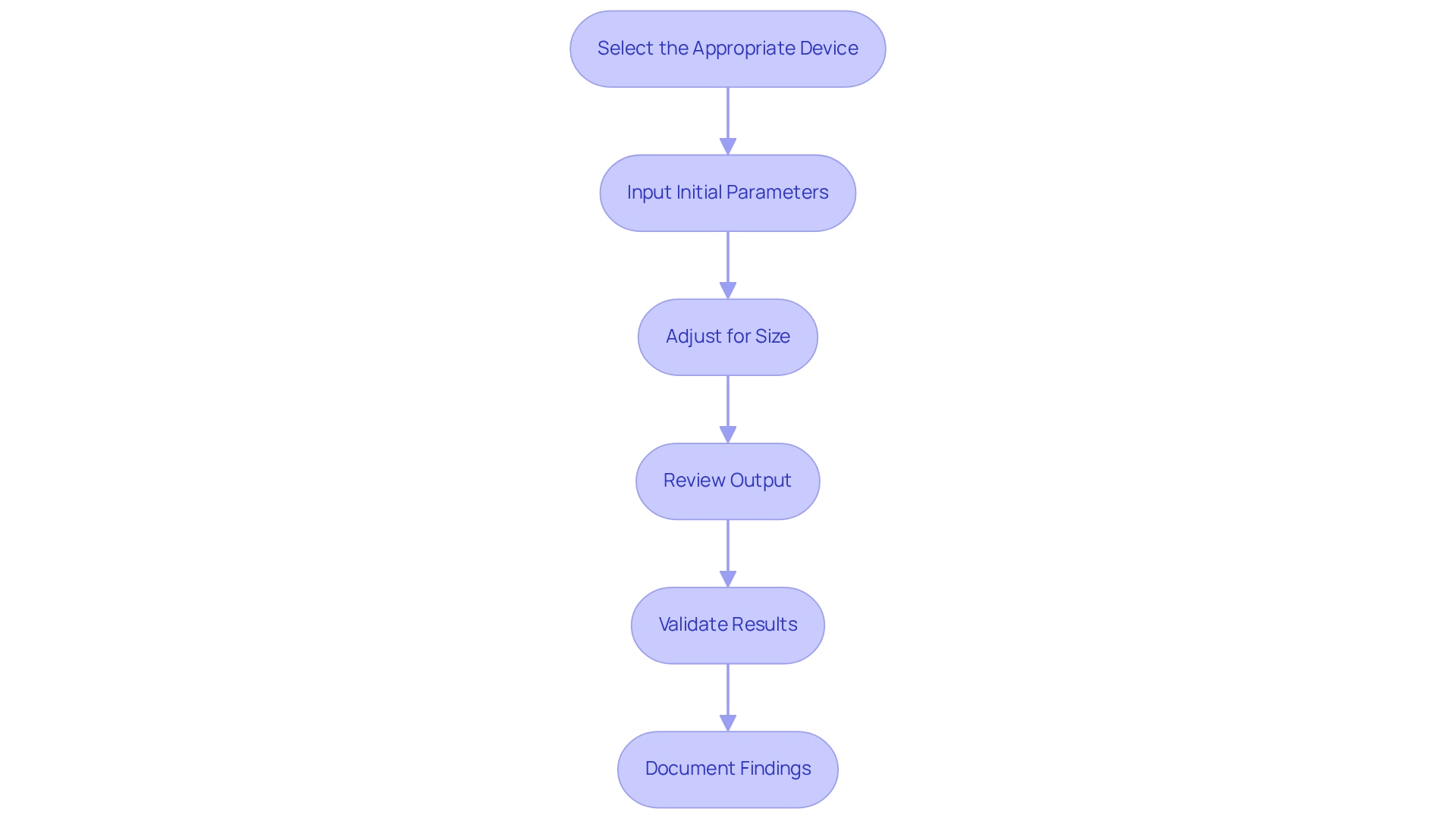

To effectively utilize a scale-up calculator in pharmaceutical research, follow these essential steps:

-

Select the Appropriate Device: Choose a tool tailored to your specific needs, whether for liquid chromatography or general pharmaceutical processes. This initial decision sets the foundation for successful scaling.

-

Input Initial Parameters: Enter parameters from your laboratory-scale experiments, including flow rates, concentrations, and volumes. These elements are critical for accurate scaling and must be precise to ensure reliable outcomes.

-

Adjust for Size: Specify the desired enlargement factor (e.g., 10x, 100x) to determine how the parameters will change. This adjustment is crucial, as it ensures that the modifications reflect the intended production scale.

-

Review Output: Analyze the output provided by the calculator. This will include adjusted flow rates, sample loads, and other essential parameters necessary for successful scale-up. A thorough review of these outputs is vital for informed decision-making.

-

Validate Results: Cross-check the outcomes with theoretical assessments or prior experimental data. Ensuring accuracy and reliability is paramount, as validation is crucial for maintaining product quality. Remember, process validation is an integral part of Good Manufacturing Practice (GMP), providing evidence that a process will consistently produce a product meeting predefined specifications.

-

Document Findings: Maintain a detailed record of the calculations and results for future reference and compliance purposes. This documentation is essential for regulatory adherence and supports the integrity of your research.

By adhering to these steps, you can efficiently utilize a scale-up calculator as a growth measurement tool to enhance your drug research, ensuring that your processes are effective and compliant with industry regulations. Incorporating validated tools in your research is vital, as evidenced by the impact factor of the International Journal of Universal Pharmacy and Bio Sciences, which stands at 4.018. Furthermore, consider insights from experts like Su Bin Yeom, who emphasizes that the fundamental goal of Quality by Design (QbD) is to develop pharmaceutical products that consistently meet healthcare needs.

Troubleshoot Common Issues with Scale-Up Calculators

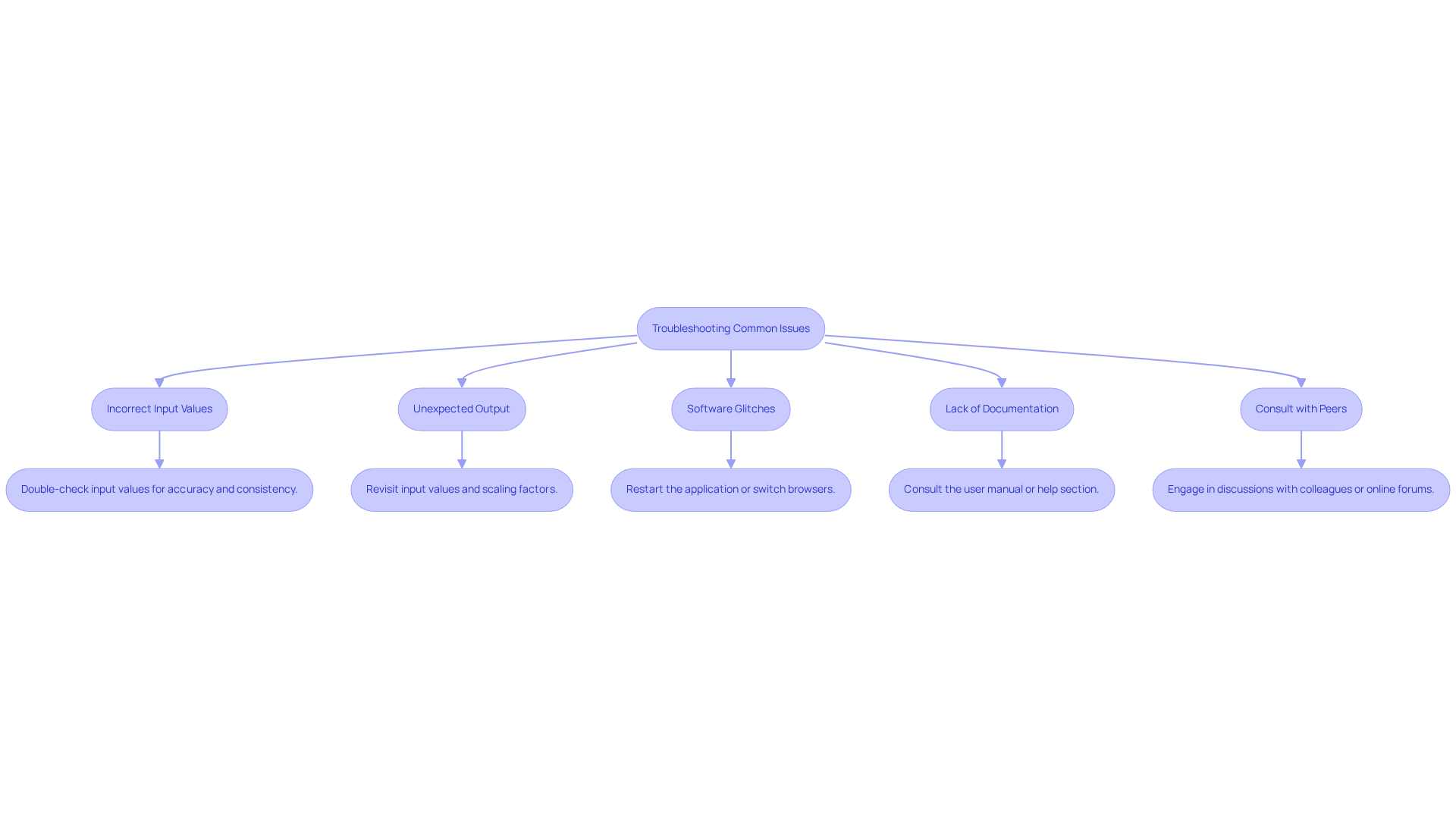

When utilizing expansion assessment tools, you may encounter several common challenges. Understanding how to troubleshoot these issues is essential for effective use.

-

Incorrect Input Values: Begin by double-checking all input values for accuracy. It is crucial to ensure that units are consistent—for instance, distinguishing between mL and L—and that all necessary parameters are included to avoid miscalculations.

-

Unexpected Output: If the output appears unreasonable, revisit your input values and scaling factors. Evaluate whether the scale-up factor is appropriate for your specific process, as this can significantly impact the results.

-

Software Glitches: Should the application software become unresponsive or generate errors, a simple restart of the program may resolve the issue. If the tool is web-based, consider switching to a different browser to enhance performance.

-

Lack of Documentation: If uncertainty arises regarding the interpretation of results, consult the user manual or help section associated with the device. Many tools provide essential guidance on effective usage, which can clarify complex data.

-

Consult with Peers: If problems persist, engaging in discussions with colleagues or seeking advice from online forums can be invaluable. Many professionals share their experiences, offering insights that may help resolve your issues.

By being aware of these common challenges and their corresponding solutions, you can significantly enhance your proficiency in using a scale up calculator.

Conclusion

Mastering the scale-up calculator is essential for advancing pharmaceutical research and ensuring successful drug development. The ability to accurately transition from laboratory-scale processes to larger production scales preserves product quality and significantly enhances the reliability and efficacy of pharmaceutical outputs. By understanding and effectively utilizing scale-up calculations, researchers can navigate the complexities of drug manufacturing with confidence.

Throughout this guide, key concepts such as geometric and dynamic scaling have been highlighted, alongside practical tools and step-by-step methodologies for employing a scale-up calculator. The importance of critical quality attributes and the necessity of thorough documentation and validation processes have also been underscored. These insights collectively reinforce the notion that precision in scaling is not just a procedural requirement but a cornerstone of successful pharmaceutical production.

As the pharmaceutical landscape continues to evolve, embracing the use of advanced tools and methodologies for scale-up calculations becomes increasingly vital. Researchers are encouraged to leverage the insights and techniques discussed to enhance their drug development processes. By prioritizing accuracy and reliability in scaling, the industry can ensure that innovative therapies reach the market efficiently, ultimately benefiting healthcare and patient outcomes.