Overview

This article emphasizes the effective utilization of filter centrifuge tubes, outlining the essential steps for preparation, execution of centrifugation, and troubleshooting common issues. Understanding the various membrane types and their specific applications is critical. Adhering to established protocols and settings is paramount for achieving reliable results in laboratory processes involving these tubes. By recognizing these factors, laboratory professionals can enhance their experimental outcomes and ensure precision in their work.

Introduction

Filter centrifuge tubes are essential instruments in laboratory environments, meticulously engineered to separate mixture components based on density with remarkable efficiency. Mastering their application not only enhances sample clarity but also guarantees precise outcomes in critical procedures such as protein concentration and nucleic acid purification.

However, the complexities involved in selecting the appropriate membrane type and pore size, alongside adherence to rigorous preparation and centrifugation protocols, can present significant challenges even for experienced professionals.

How can one effectively navigate these intricacies to maximize the performance of filter centrifuge tubes and circumvent common pitfalls?

Understand Filter Centrifuge Tubes

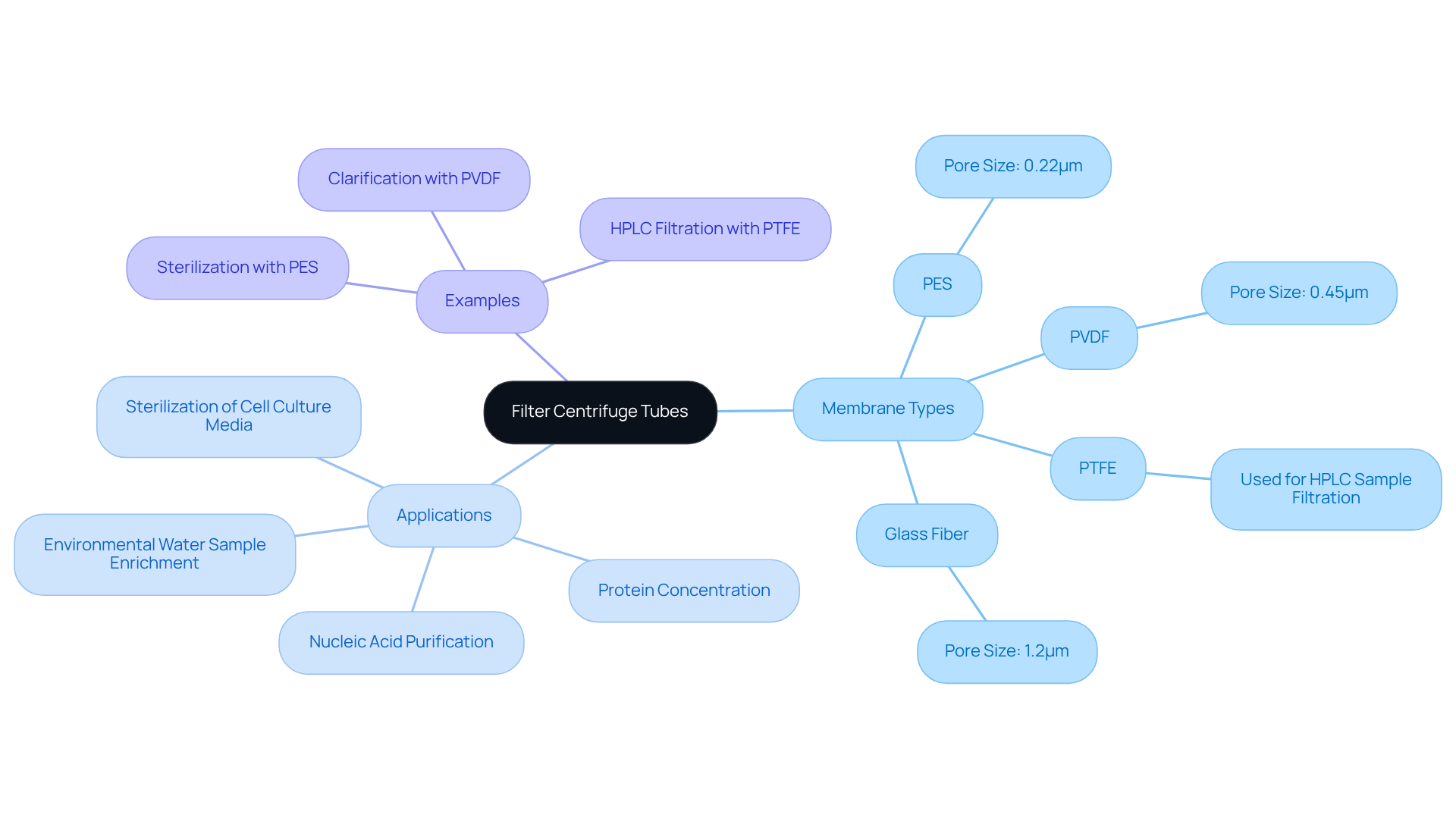

Filter centrifuge tubes are indispensable laboratory instruments specifically engineered to separate mixture components based on density. These conduits feature embedded membranes that facilitate liquid flow while effectively capturing larger particles. A thorough understanding of the various types of membranes, such as polyethersulfone (PES) and nylon, along with their respective pore sizes, is crucial as these factors directly influence filtration efficiency and suitability for diverse sample types.

Common applications of filter centrifuge tubes include:

- Protein Concentration: Utilizing membranes with specific pore sizes to concentrate proteins from solutions.

- Nucleic Acid Purification: Using filter centrifuge tubes that are designed to selectively filter nucleic acids while eliminating contaminants.

Using filter centrifuge tubes is essential for ensuring clarity in samples by removing unwanted particulates.

For example, PES membranes with a pore size of 0.22μm are recommended for sterilizing cell culture media, while PVDF membranes with a 0.45μm pore size are optimal for protein solution clarification. Additionally, verifying membrane integrity through a bubble point test is vital for ensuring effective filtration. The laboratory spin devices market is projected to reach USD 2,541.2 million by 2030, underscoring the increasing importance of this technology in laboratory settings. Understanding these membrane characteristics will significantly enhance your proficiency in utilizing separation vessels effectively within laboratory environments.

Prepare for Use

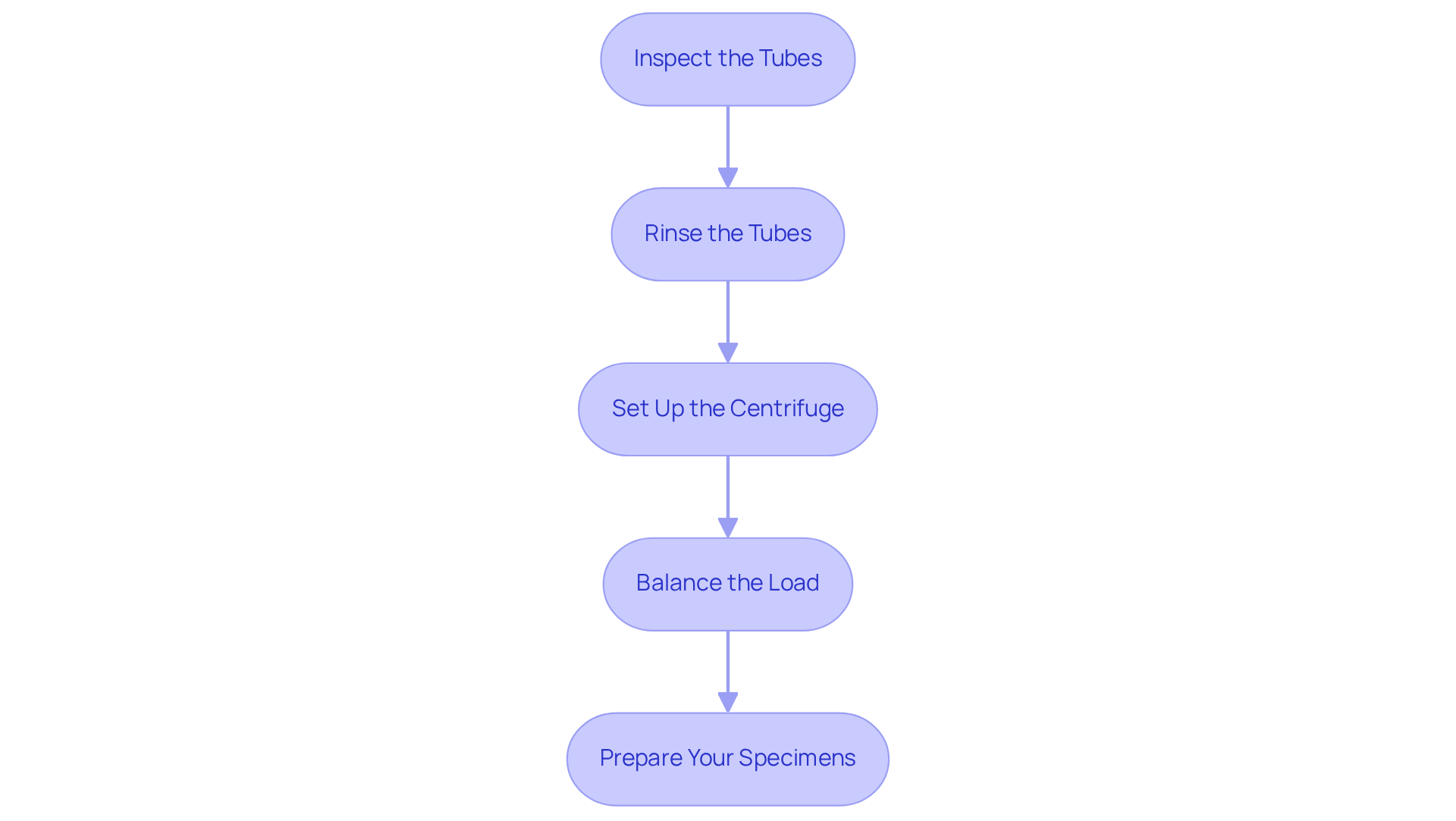

Before utilizing filter centrifuge tubes, it is essential to adhere to the following preparation steps:

- Inspect the Tubes: Begin by checking for any visible damage or defects. Ensure that the filter centrifuge tubes are clean and free from impurities, as this is vital for maintaining the integrity of your samples.

- Rinse the Tubes: Rinse the tubes thoroughly with deionized water or an appropriate buffer to eliminate any residual substances from manufacturing. This step is crucial in preventing contamination of your samples stored in filter centrifuge tubes.

- Set Up the Centrifuge: Confirm that the centrifuge is clean and properly calibrated. It is important to verify that the rotor is correctly installed and that the filter centrifuge tubes fit securely in the slots of the rotor.

- Balance the Load: When using multiple tubes, ensure they are balanced by positioning tubes of equal volume and mass opposite each other in the rotor. This practice prevents damage to the apparatus and ensures uniform processing of samples.

- Prepare Your Specimens: Depending on your application, prepare your specimens by diluting or mixing them as necessary before transferring them into the separating containers. This preparation is key to achieving accurate results.

Execute the Centrifugation Process

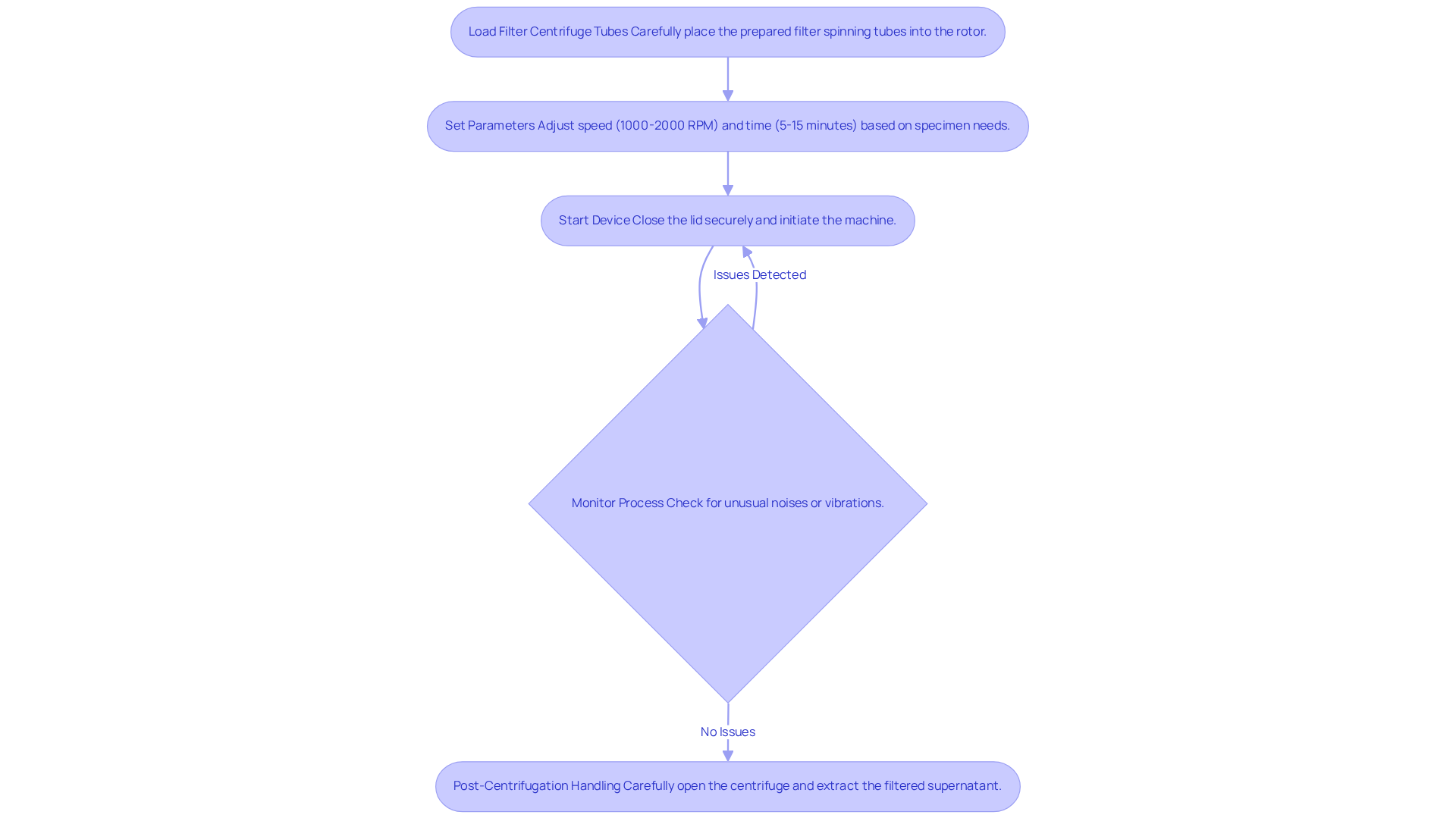

To execute the centrifugation process effectively, follow these essential steps:

- Load the filter centrifuge tubes: Carefully place the prepared filter spinning tubes into the rotor. Ensure they are secure and balanced to prevent any disruption during operation.

- Set the Parameters: Adjust the spinning device settings according to the specific needs of your specimens. Common parameters include:

- Speed: The optimal centrifuge speed for processing blood samples typically ranges from 1000 to 2000 RPM or 100 to 150 g. Refer to the manufacturer's guidelines for specific recommendations based on your sample type.

- Time: Set the duration for centrifugation, generally between 5 to 15 minutes. It is advisable to start with a shorter time and increase as needed based on the results observed.

- Start the Device: Close the lid securely and initiate the machine. Monitor the process closely to ensure there are no unusual noises or vibrations, which could indicate an imbalance or malfunction.

- Post-Centrifugation Handling: Once centrifugation is complete, carefully open the centrifuge and remove the containers. Use a pipette to extract the filtered supernatant from the filter centrifuge tubes without disturbing the pellet or filter membrane, ensuring the integrity of your specimen.

Understanding the impact of RPM and time settings on sample processing is crucial. Improper settings can lead to incomplete separation and unreliable results. As Lauren Davis, a clinical biochemist, emphasizes, "It is essential to avoid under- or over-centrifugation, as it can affect the quality of the separated serum and lead to inaccurate test results." Following standardized protocols not only enhances the quality of the separated serum but also ensures consistent outcomes across different laboratory analyses. Furthermore, various kinds of rotors, such as swing-out or fixed-angle designs, demand specific speed and time adjustments for optimal separation, which must be considered during the spinning process.

Troubleshoot Common Issues

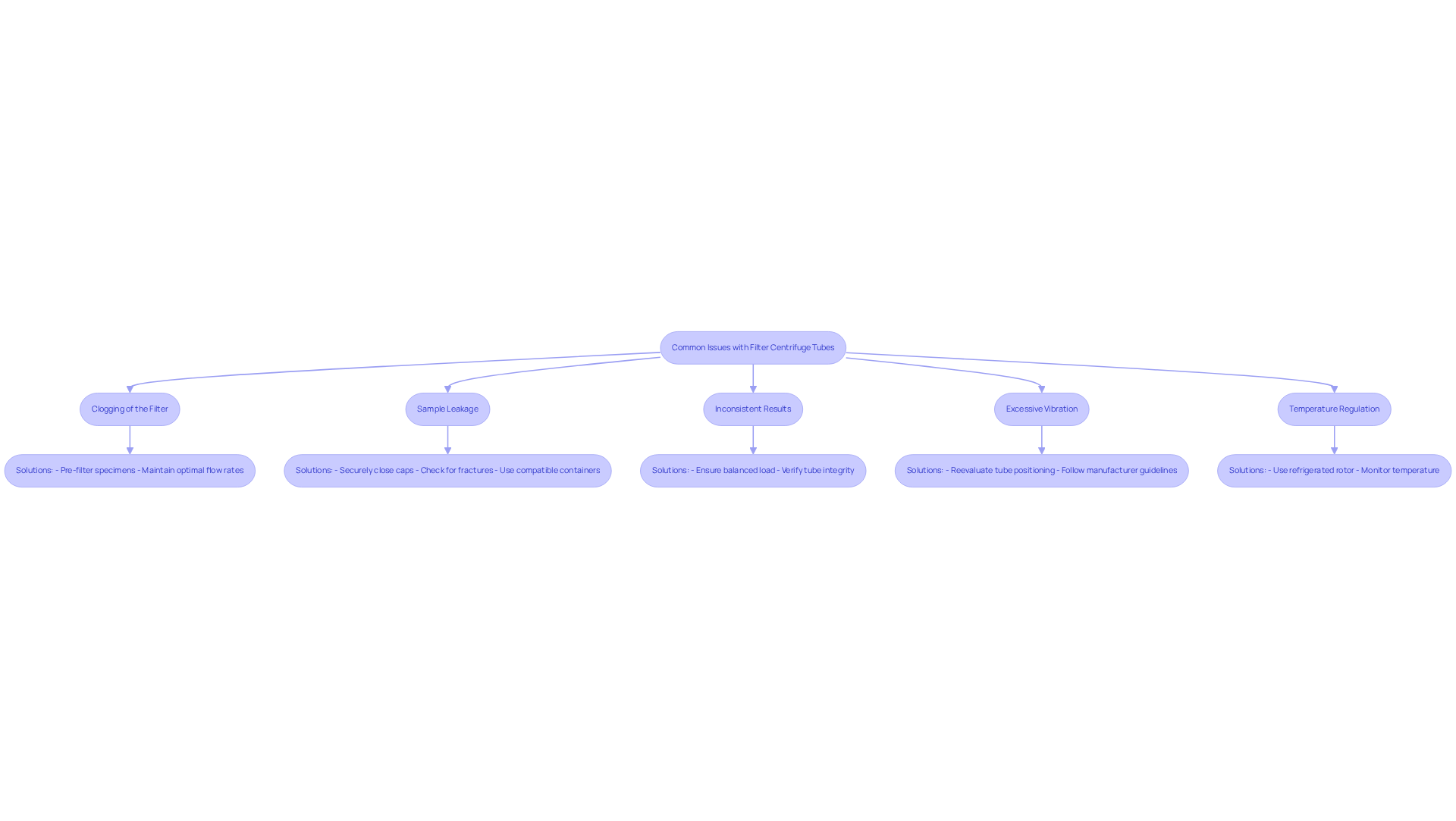

Common issues encountered when using filter centrifuge tubes include:

-

Clogging of the Filter: Clogging can significantly impede the filtration process, leading to delays or complete stoppage. To mitigate this issue, it is recommended to pre-filter specimens using a larger pore size filter before employing the spinning container. This proactive step helps maintain optimal flow rates and prevents bottlenecks during centrifugation. As Amanda Harris, a certified phlebotomist, states, understanding the speed restrictions for centrifuge containers is essential to ensure the safety of laboratory staff and the quality of the materials being processed.

-

Sample Leakage: Securely closing the caps before centrifugation is crucial to prevent leakage. If leakage occurs, it is important to examine the tubes for fractures or verify that the sealing mechanisms are functioning properly. Utilizing suitable containers that are resistant to the solvents in your specimens can also reduce the risk of leakage. The material of the tube, whether plastic or glass, influences its capacity to endure high speeds, making it vital to use compatible containers for safety and accurate outcomes.

-

Inconsistent Results: Variability in results can stem from several factors, including an unbalanced load in the centrifuge or inappropriate settings for the sample type. It is essential to ensure that the tubes are undamaged and that the load is evenly distributed within the rotor to achieve consistent outcomes. A case study on factors affecting maximum velocity restrictions for spinning containers underscores the importance of understanding these limits to guarantee safe and efficient usage.

-

Excessive Vibration: Unusual vibrations during centrifugation often indicate an unbalanced load. Reevaluating the positioning of the tubes and ensuring they are uniformly arranged can assist in resolving this issue, facilitating smoother operation and reducing wear on the equipment. Adhering to manufacturer guidelines and best practices is crucial to avoid accidents and ensure accurate laboratory results.

-

Temperature Regulation: For specimens sensitive to temperature changes, employing a refrigerated rotor or closely monitoring the temperature throughout the process is essential. This practice helps prevent sample degradation and ensures the integrity of the results. Regular inspections for wear and adherence to proper mounting procedures can also improve the reliability of laboratory equipment.

Addressing these common issues proactively can enhance the efficiency and reliability of laboratory processes that involve filter centrifuge tubes.

Conclusion

Mastering the use of filter centrifuge tubes is essential for achieving reliable results in laboratory settings. These specialized instruments not only enhance the clarity of samples but also play a pivotal role in various applications, such as protein concentration and nucleic acid purification. Understanding the different membrane types and their specific characteristics is crucial for selecting the right filter centrifuge tube for any given task, thereby ensuring optimal filtration efficiency.

The article outlines several key steps for effectively using filter centrifuge tubes:

- Preparation and execution of the centrifugation process

- Troubleshooting common issues

Emphasizing the importance of:

- Inspecting tubes

- Balancing loads

- Setting appropriate centrifuge parameters

can significantly impact the quality of results. Additionally, being proactive about potential issues, such as clogging and sample leakage, is vital for maintaining the integrity of laboratory processes and ensuring consistent outcomes.

Ultimately, the effective use of filter centrifuge tubes transcends mere protocol adherence; it embodies best practices that enhance laboratory efficiency and accuracy. By implementing the insights and recommendations discussed, laboratory professionals can elevate their filtration processes, ensuring that their results are both reliable and reproducible. The growing market for laboratory spin devices underscores the increasing significance of mastering these techniques, making it imperative for practitioners to stay informed and adept in the use of filter centrifuge tubes.