Overview

This article examines the essential relationship between pH and temperature in pharmaceutical laboratories, highlighting their crucial roles in preserving drug stability and effectiveness. It details how specific pH levels can enhance solubility, while fluctuations in temperature may accelerate degradation. Such insights underscore the necessity for meticulous monitoring and strict adherence to regulatory standards to safeguard product quality and ensure patient safety.

Introduction

Mastering the intricate relationship between pH and temperature is essential for ensuring the efficacy and safety of pharmaceutical products. These two factors play a pivotal role in the stability of active ingredients, influencing everything from solubility to degradation rates. As the pharmaceutical industry grapples with the challenges of maintaining optimal conditions, laboratories must effectively monitor and control these variables to safeguard drug quality and patient health. Exploring best practices and innovative technologies reveals not just the complexities of this relationship but also the critical steps necessary for successful pharmaceutical development.

Understand pH and Temperature Fundamentals

pH quantifies the acidity or alkalinity of a solution on a scale from 0 to 14, with 7 representing neutrality. Values below 7 indicate acidity, while those above signify alkalinity. Temperature, measured in degrees Celsius or Fahrenheit, directly impacts the kinetic energy of molecules, thereby influencing reaction rates and solubility. In drug laboratories, the pH and temperature relation is crucial for maintaining optimal conditions that ensure the effectiveness and stability of formulations.

For instance, certain antibiotics and hormones can break down and lose their effectiveness if not kept in the right pH environment. This underscores the necessity for precise measurement and control. Regulatory standards, such as those outlined by the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), dictate specific pH levels for certain medications to ensure product quality and safety.

Case studies, like 'Preventing pH-Induced Degradation' and 'Use of Buffer Systems in Formulations,' have demonstrated that controlled environments—including temperature and humidity—greatly prolong the shelf life of unstable compounds. This emphasizes the significance of the pH and temperature relation as factors in drug development. As Michael Luo states, 'Precise pH measurements are essential in the drug industry,' highlighting the necessity for strict pH management.

In conclusion, the rigorous control of pH and environmental conditions is not merely a procedural detail; it is a cornerstone of pharmaceutical efficacy and safety.

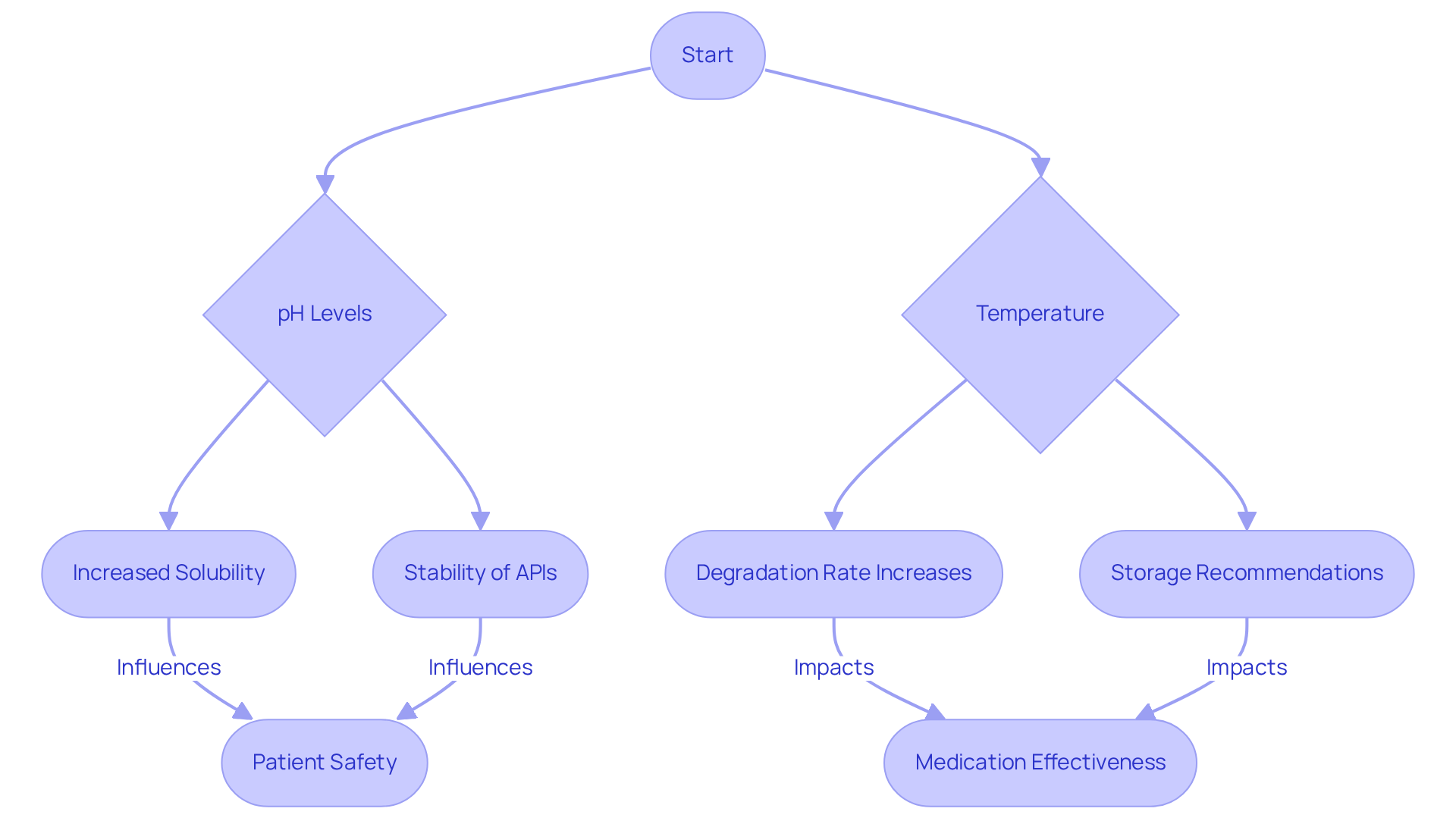

Assess the Impact of pH and Temperature on Pharmaceutical Processes

The pH of a solution is crucial in determining the solubility and stability of active medicinal ingredients (APIs). Research demonstrates that certain substances achieve enhanced solubility at specific pH levels, which directly influences their bioavailability. Conversely, temperature plays a significant role in the degradation of pharmaceuticals; a modest increase of 10°C can double the rate of chemical reactions, including those leading to drug degradation.

Numerous medications, particularly liquid and injectable forms, are sensitive to temperature fluctuations, with improper storage potentially compromising their effectiveness. Case studies reveal that only three antibiotics—Benzylpenicillin, Cefoxitin, and Flucloxacillin—maintain stability in extreme heat conditions exceeding 93°F, while most should be stored in regulated indoor environments between 68°F and 77°F.

This underscores the necessity for stringent monitoring of the pH and temperature relation within pharmaceutical settings to preserve product integrity and ensure patient safety. Recent studies further emphasize the importance of durability testing, focusing on heat, humidity, and light exposure, to predict medication performance throughout their shelf life.

By adhering to established guidelines, such as ICH Q1A(R2), manufacturers can effectively navigate the complexities of drug stability across varying climates, ultimately safeguarding patient health.

Implement Best Practices for Monitoring and Adjusting pH and Temperature

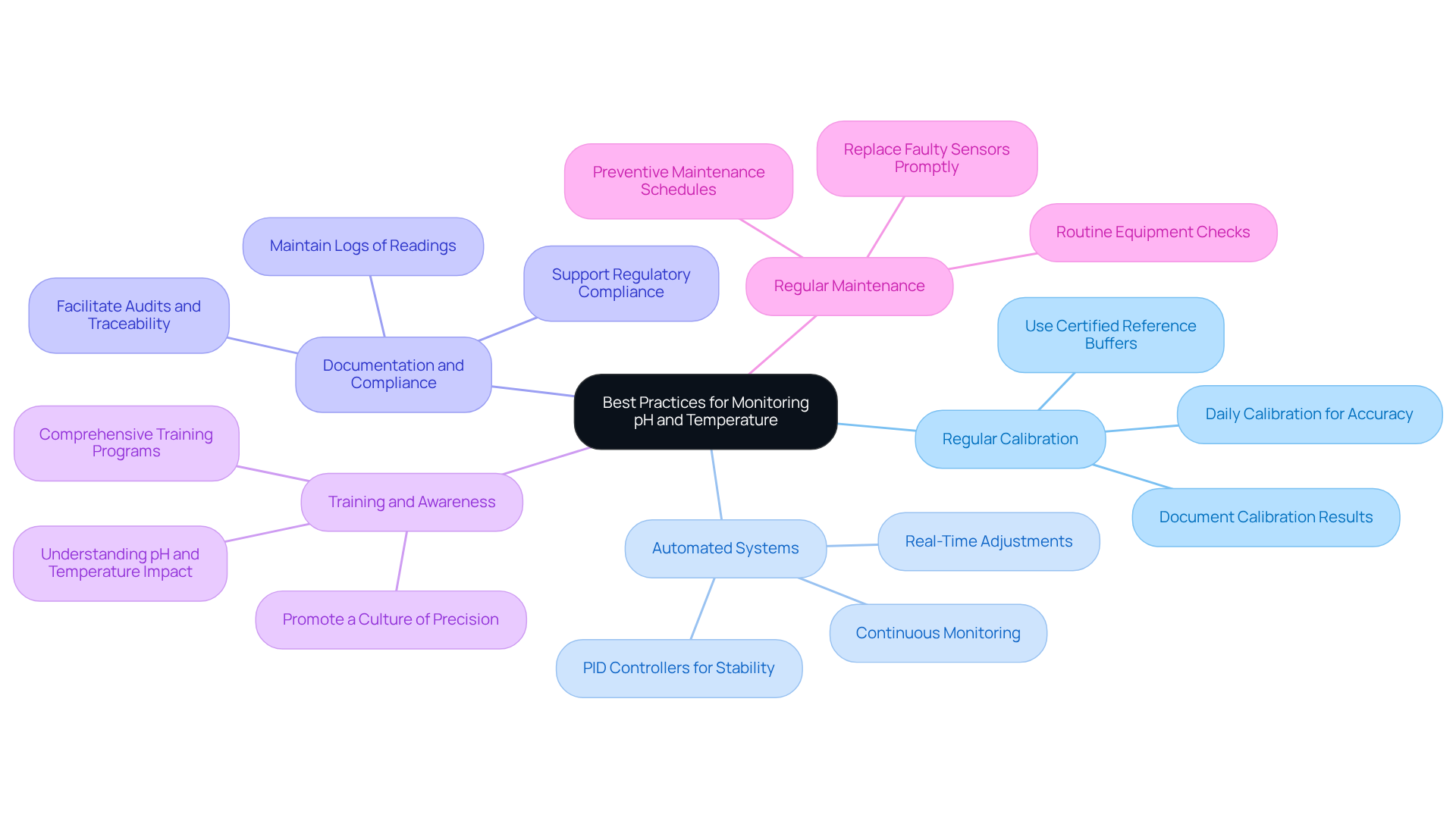

To effectively monitor and adjust pH and temperature in pharmaceutical labs, it is essential to adopt best practices that ensure precision and reliability:

-

Regular Calibration of Instruments: Regular calibration of pH meters and thermal sensors against certified reference buffer solutions is crucial for maintaining accuracy. This practice is vital for reliable measurements, particularly in pharmaceutical applications where precision is paramount.

-

Implementing automated systems allows for continuous monitoring and real-time adjustments regarding the pH and temperature relation. These systems significantly mitigate human error and ensure consistent environmental conditions, which are critical for drug stability and quality. For instance, PID controllers can make real-time adjustments based on deviations from set targets, thereby enhancing process control.

-

Documentation and Compliance: Maintaining thorough logs of pH and heat readings, modifications made, and any deviations from standard operating procedures is essential. This documentation supports regulatory compliance and quality assurance, facilitating audits and enhancing traceability in laboratory operations.

-

Training and Awareness: Comprehensive training for laboratory personnel on the significance of pH and heat control, as well as the proper use of monitoring equipment, is imperative. Understanding the pH and temperature relation and its impact on drug stability fosters a culture of precision in the lab.

-

Regular Maintenance of Equipment: Scheduling routine maintenance for pH meters and climate control devices ensures proper operation and precise readings. This proactive approach can prevent equipment failure and minimize costly downtime.

Case Studies: The implementation of automated systems has demonstrated significant improvements in laboratory efficiency. For example, laboratories utilizing the ARCHITECT 4000 clinical chemistry analyzer have reported enhanced productivity, achieving a maximum throughput of up to 800 tests per hour while maintaining high confidence in clinical results. Such systems not only streamline operations but also ensure compliance with stringent regulatory standards.

The advantages of automation include automated pH and temperature relation control systems that provide numerous benefits, such as improved accuracy, reduced variability, and enhanced compliance with Good Manufacturing Practices (GMP). By integrating these systems, pharmaceutical labs can achieve greater consistency in their processes, ultimately leading to higher quality products.

Conclusion

The relationship between pH and temperature is fundamental to ensuring the efficacy and safety of pharmaceuticals. Mastering these parameters transcends mere technical requirements; it is an essential practice that underpins drug stability and performance. A thorough understanding of how pH influences the solubility and stability of active ingredients, alongside the critical role temperature plays in chemical reactions, is vital for pharmaceutical labs striving for excellence.

Key insights from the article underscore the importance of precise pH management and temperature control:

- Regular calibration of instruments

- Implementation of automated monitoring systems

- Adherence to regulatory standards

These are crucial steps in maintaining the integrity of pharmaceutical products. Case studies reveal that neglecting these factors can lead to significant degradation of medications, highlighting the necessity for rigorous monitoring and best practices.

Ultimately, the significance of pH and temperature management extends beyond laboratory procedures; it is a matter of patient safety and product quality. By prioritizing these aspects, pharmaceutical manufacturers can enhance their processes, ensure compliance with industry standards, and ultimately deliver safer, more effective medications to the market. Embracing these best practices will not only safeguard drug stability but also foster a culture of precision and accountability within the pharmaceutical industry.