Overview

Mastering the centrifuge tube filter requires careful selection based on several key factors:

- Material compatibility

- Pore size

- Volume capacity

- Application specificity

- Temperature limits

Understanding these criteria is crucial for optimizing laboratory processes and ensuring reliable experimental results. Without proper selection, the risk of contamination or inefficiency increases significantly. Therefore, it is imperative to consider these elements thoroughly to enhance the effectiveness of laboratory operations.

Introduction

Centrifuge tube filters are essential instruments in laboratory environments, facilitating the efficient separation and purification of samples that are critical for achieving accurate research outcomes. It is vital for laboratory professionals to comprehend the different types of filters available and their specific applications to optimize their workflows effectively.

However, the process of selecting the appropriate centrifuge tube filter can present numerous challenges, including considerations of:

- Material compatibility

- Pore size

- Cost

Navigating these complexities is crucial to ensure not only effective filtration but also the preservation of valuable samples.

Understand Centrifuge Tube Filters: Types and Applications

Centrifuge tube membranes are indispensable in laboratory environments, particularly for the separation and purification of samples. Various types of centrifuge tube filters are tailored for specific applications:

- Spin-X® Centrifuge Tube Screens: Leveraging centrifugal force, these devices excel at rapidly processing small volumes, making them ideal for applications such as cell culture media and protein solutions. Their design facilitates efficient sample processing, thereby enhancing laboratory workflow. The recommended G-force for these devices is 5000 xg, which ensures effective protein concentration.

- Positive Pressure Devices: Operating under positive pressure, these units are suitable for larger volumes and time-sensitive applications. They are frequently employed in clinical settings for specimen preparation, where speed and efficiency are paramount.

- Vacuum Screens: Designed for use with vacuum systems, these devices adeptly manage larger quantities and are commonly utilized in environmental testing and microbiology. Their ability to maintain specimen integrity during filtration renders them a reliable choice for various testing tasks.

- Specialized Devices: Certain devices are engineered for specific requirements, such as sterile separation or the removal of particulates from biological specimens. Understanding these distinctions is crucial for selecting the appropriate device based on your laboratory's needs.

The advantages of Spin-X® centrifuge tube filters include their rapid separation capabilities and high recovery rates, which are vital for efficient specimen processing. In practical applications, these devices have proven effective in cell culture, where preserving sample integrity is critical. Laboratory professionals emphasize the importance of selecting the right screen to ensure accurate results and prevent contamination, highlighting that proper filtration methods are essential for successful experimental outcomes.

Furthermore, it is imperative to wear suitable personal protective equipment (PPE) when handling centrifuge tubes to ensure safety within the workspace. By familiarizing yourself with these varieties of centrifuge tube devices, you can make informed decisions that align with your facility's specific requirements and the characteristics of your specimens. Remember, reusing centrifugal separation units is inadvisable, as it can lead to diminished filtration efficiency and potential specimen contamination.

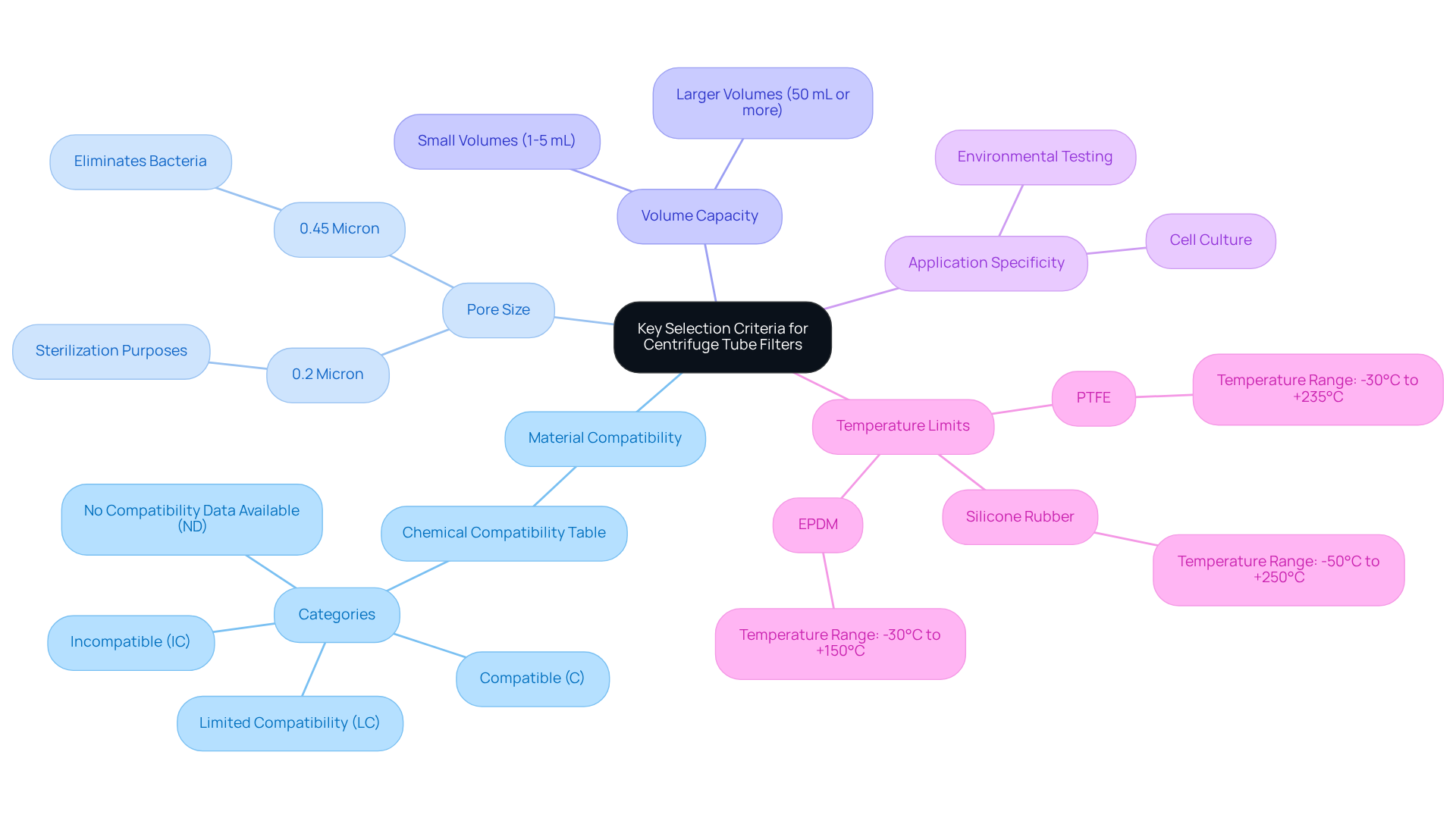

Evaluate Key Selection Criteria for Centrifuge Tube Filters

When selecting a centrifuge tube filter, it is essential to consider several key criteria to ensure optimal performance and reliability in laboratory processes.

- Material Compatibility: Verifying that the medium aligns with the samples being processed is essential. Various membranes differ in chemical compatibility, and certain solvents can deteriorate plastic barriers. Therefore, specific membrane types are required to uphold integrity and performance. Consulting a chemical compatibility table, which categorizes materials as Compatible, Limited Compatibility, Incompatible, or No Compatibility Data Available, can help avoid experimental failures due to incompatibility.

- Pore Size: The pore size of the membrane is crucial as it dictates which particles can pass through. For example, a 0.45-micron screen effectively eliminates bacteria, while a 0.2-micron membrane is necessary for sterilization purposes. Understanding the specific needs of your application will guide the selection of the appropriate pore size.

- Volume Capacity: Assessing the volume of the sample that requires processing is vital. Screens are available for various capacities, from small volumes (1-5 mL) to larger ones (50 mL or more), ensuring that the selected screen meets the demands of your experimental setup.

Different screens display various separation rates. If time efficiency is crucial, choose devices designed to deliver quicker filtration rates, thus improving the overall workflow in your laboratory.

- Application Specificity: Some screening tools are tailored for specific applications, such as cell culture or environmental testing. Choosing a screen that matches your intended use is essential to ensure precise and trustworthy outcomes.

- Temperature Limits: Consider the temperature limits of the membrane materials. For example, PTFE has of -30°C to +235°C, silicone rubber ranges from -50°C to +250°C, and EPDM can withstand temperatures from -30°C to +150°C. This information is crucial for ensuring that the device can operate effectively under the conditions of your experiment.

By carefully assessing these criteria, including the significance of material compatibility and temperature limits, you can select a centrifuge tube filter that not only enhances the efficiency of your laboratory processes but also bolsters the reliability of your experimental results.

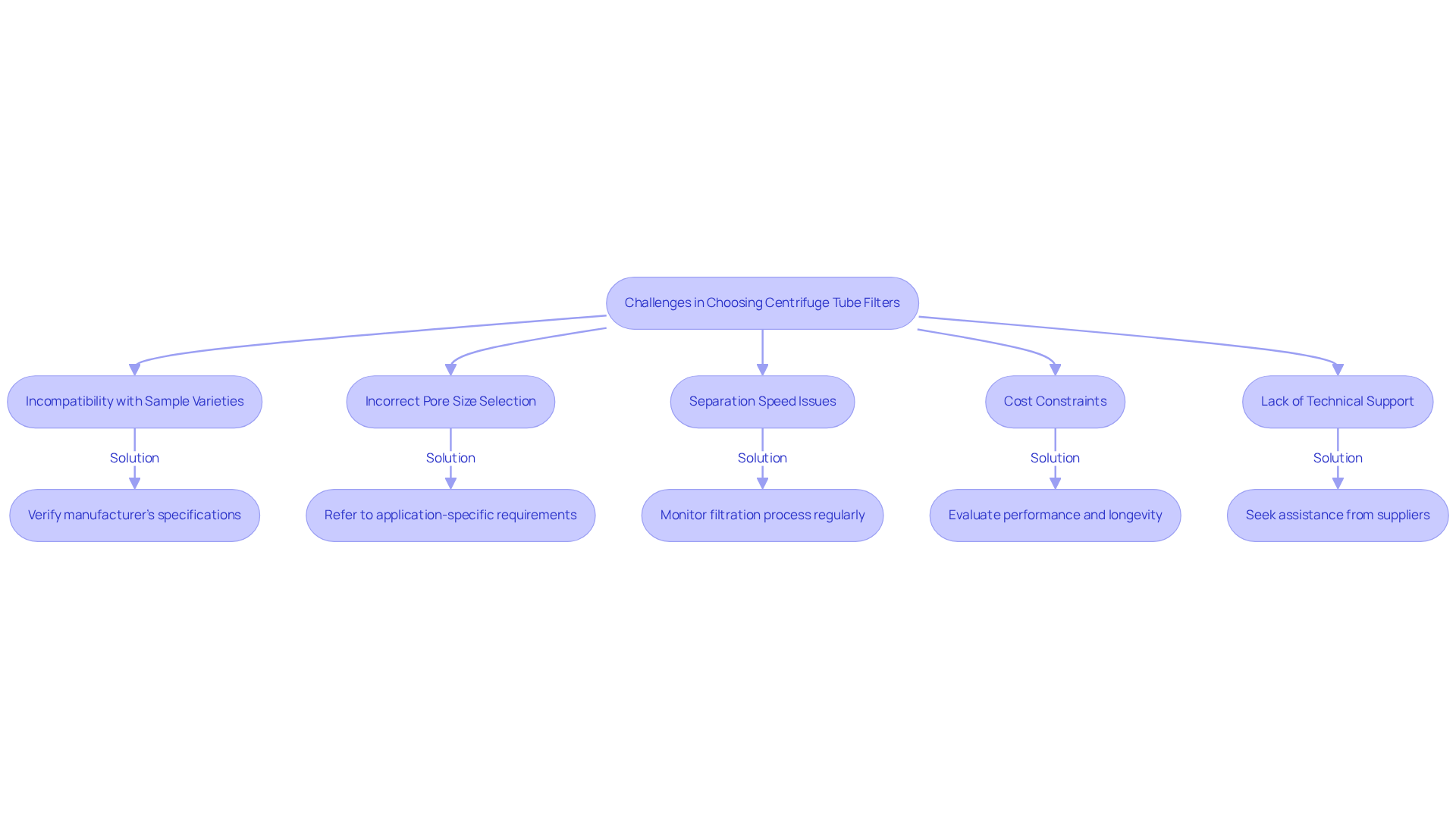

Identify Common Challenges and Solutions in Choosing Filters

Selecting the appropriate centrifuge tube filter can present several challenges. Understanding these common issues and their effective solutions, including the use of a centrifuge tube filter, is essential for optimizing laboratory operations.

- Incompatibility with Sample Varieties is a prevalent concern. Choosing a strainer that does not align with the specimen's chemical properties can lead to significant issues. Always verify the manufacturer's specifications regarding material compatibility to avoid adverse reactions that may compromise the integrity of your samples.

- Another critical issue is Incorrect Pore Size Selection. Using a centrifuge tube filter that has an unsuitable pore size can result in contamination or the loss of vital sample components. To mitigate this risk, refer to application-specific requirements and literature, ensuring that the pore size of the centrifuge tube filter aligns with your separation objectives. For instance, a pore size of 0.22 microns is ideal for eliminating bacteria, whereas smaller dimensions are necessary for mycoplasma separation.

- Separation Speed Issues can also arise, with slow separation rates potentially indicating clogging or an inappropriate pore size. Regular monitoring of the filtration process is crucial. If delays occur, consider transitioning to systems designed for higher flow rates or employing a centrifuge tube filter as a pre-filtration technique to remove larger particles, thereby extending the lifespan of the primary device.

- Cost Constraints are another factor to consider. While may carry a higher price tag, evaluating their performance and longevity can reveal cost-effective alternatives. Investing in a slightly more expensive device may reduce the frequency of replacements, ultimately saving money. For example, utilizing a centrifuge tube filter with a 0.5-micron high-capacity prefilter can extend the lifespan of a 0.22-micron sterilizing unit by three times, as evidenced in practical applications. Moreover, CPF devices have demonstrated greater than 7-log removal efficiency when tested with specific organisms, underscoring their effectiveness.

- Finally, the Lack of Technical Support can complicate the selection process. Seeking assistance from suppliers or manufacturers can alleviate this challenge. Many companies offer technical support and resources to help you make informed decisions, ensuring that you choose options that meet your specific needs. For instance, a client experiencing early clogging of their sterilizing device improved their process by implementing a 0.5-micron high-capacity PES prefilter, significantly enhancing the lifespan of their equipment.

By recognizing these challenges and implementing the suggested solutions, you can streamline your selection process for the centrifuge tube filter, thereby enhancing the efficiency and reliability of your laboratory operations.

Conclusion

Selecting the right centrifuge tube filter is not merely a procedural step; it is a cornerstone of laboratory operations that profoundly influences the quality and reliability of experimental results. By understanding the diverse types of centrifuge tube filters and their specific applications, laboratory professionals can make informed decisions that enhance workflow efficiency and uphold sample integrity.

Key considerations in the selection process encompass:

- Material compatibility

- Pore size

- Volume capacity

- Application specificity

- Temperature limits

Each of these factors is pivotal in ensuring that the selected filter aligns with the unique demands of the laboratory's work. Furthermore, awareness of common challenges—such as compatibility issues, incorrect pore sizes, and separation speed—can significantly mitigate potential problems and streamline the selection process.

Ultimately, mastering the intricacies of centrifuge tube filter selection not only enhances laboratory efficiency but also fortifies the integrity of valuable samples. By adhering to best practices and seeking technical support when necessary, laboratory professionals can navigate the complexities of this selection process with confidence, ensuring that their experiments yield accurate and reliable outcomes.