Overview

This article delineates best practices for lab managers to excel in trace metal analysis, underscoring the critical nature of adhering to established standards, employing advanced analytical techniques, and committing to continuous improvement. By outlining essential protocols—such as the utilization of certified reference materials and sophisticated methods like ICP-MS—it emphasizes the necessity of regular staff training and stringent quality control measures. These elements are vital for ensuring accurate and reliable results in laboratory settings.

To effectively master trace metal analysis, lab managers must prioritize compliance with industry standards. This compliance not only fosters credibility but also enhances the overall quality of laboratory outputs. Advanced analytical techniques, including ICP-MS, are indispensable in achieving precise measurements, making their integration into standard practices essential. Furthermore, the commitment to continuous improvement through regular training and quality control cannot be overstated, as it directly impacts the reliability of results produced.

In conclusion, the mastery of trace metal analysis hinges on a structured approach that incorporates compliance, advanced techniques, and ongoing development. By embracing these best practices, lab managers can significantly elevate the quality of their laboratory operations, ensuring that they not only meet but exceed industry expectations.

Introduction

Mastering trace metal analysis is essential for laboratories striving to uphold the integrity and reliability of their results. As environmental regulations tighten and the demand for precise measurements escalates, lab managers encounter the challenge of implementing best practices that not only comply with established standards but also enhance operational efficiency.

What strategies can be employed to navigate the complexities of trace metal analysis while ensuring high-quality outcomes and regulatory compliance? By addressing these questions, laboratories can position themselves at the forefront of scientific excellence.

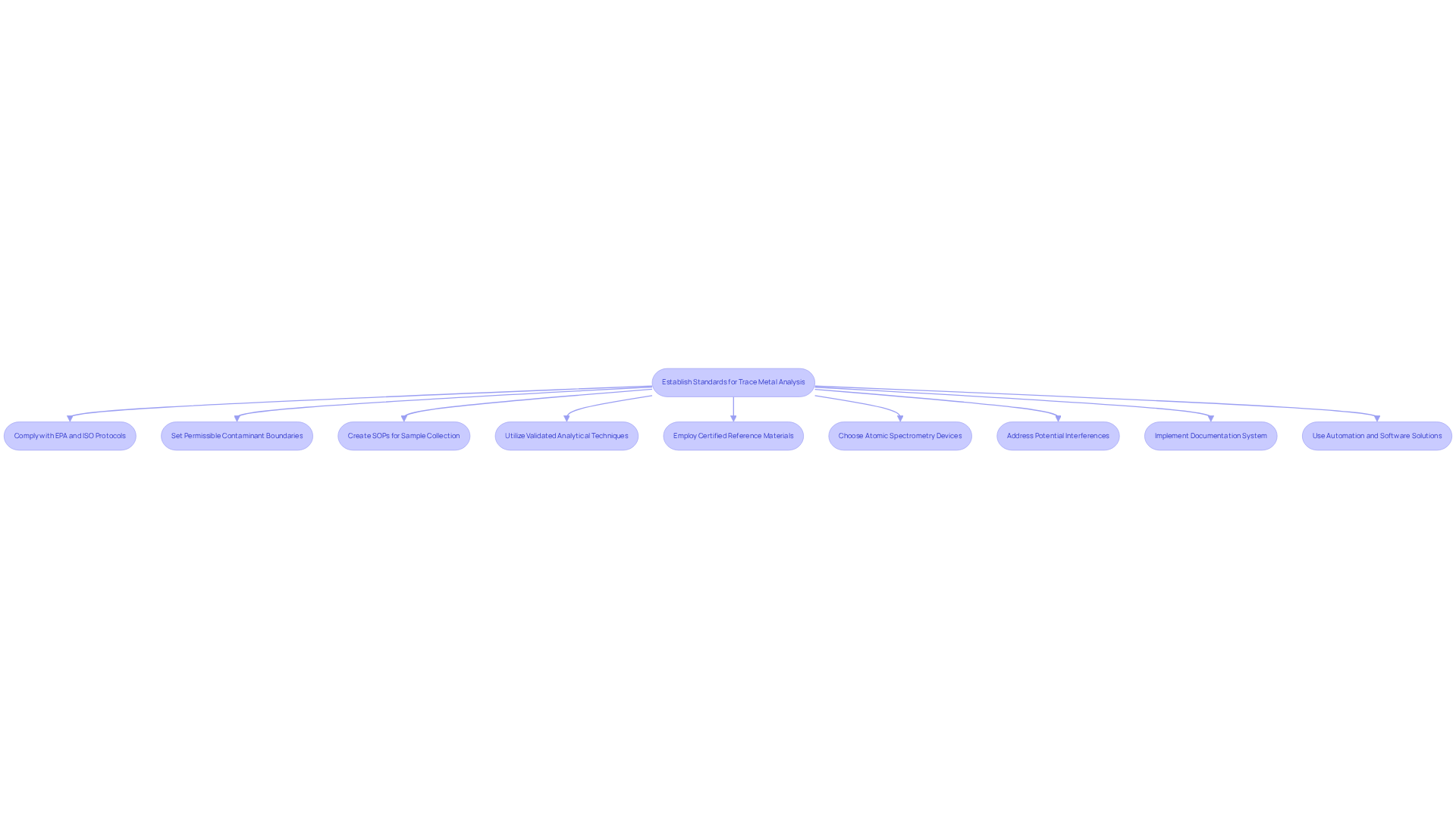

Establish Standards for Trace Metal Analysis

To establish effective criteria for assessing minor elements, facilities must comply with protocols outlined by acknowledged entities such as the EPA and ISO. This compliance entails:

- Establishing permissible boundaries for contaminants

- Creating standard operating procedures (SOPs) for sample collection

- Utilizing validated analytical techniques, including specific EPA methods such as 200.7 and 200.9

The utilization of certified reference materials (CRMs) is crucial for method validation, ensuring analytical accuracy, and enhancing the reliability of results.

Moreover, facilities should consider the choice of atomic spectrometry devices, as their efficiency can significantly influence the outcomes of minor element evaluations. It is essential to remain aware of potential interferences—whether physical, chemical, or spectral—that may compromise the accuracy of results. Implementing a robust documentation system is vital for tracking compliance with these standards, thereby maintaining quality control and facilitating audits.

Furthermore, employing automation and sophisticated software solutions can streamline the evaluation process, ultimately improving operational efficiency. By adhering to these optimal methods, facilities can enhance their elemental examination capabilities and guarantee dependable outcomes. This commitment to high-quality scientific practices not only elevates the standard of analysis but also fosters trust and credibility in the results produced.

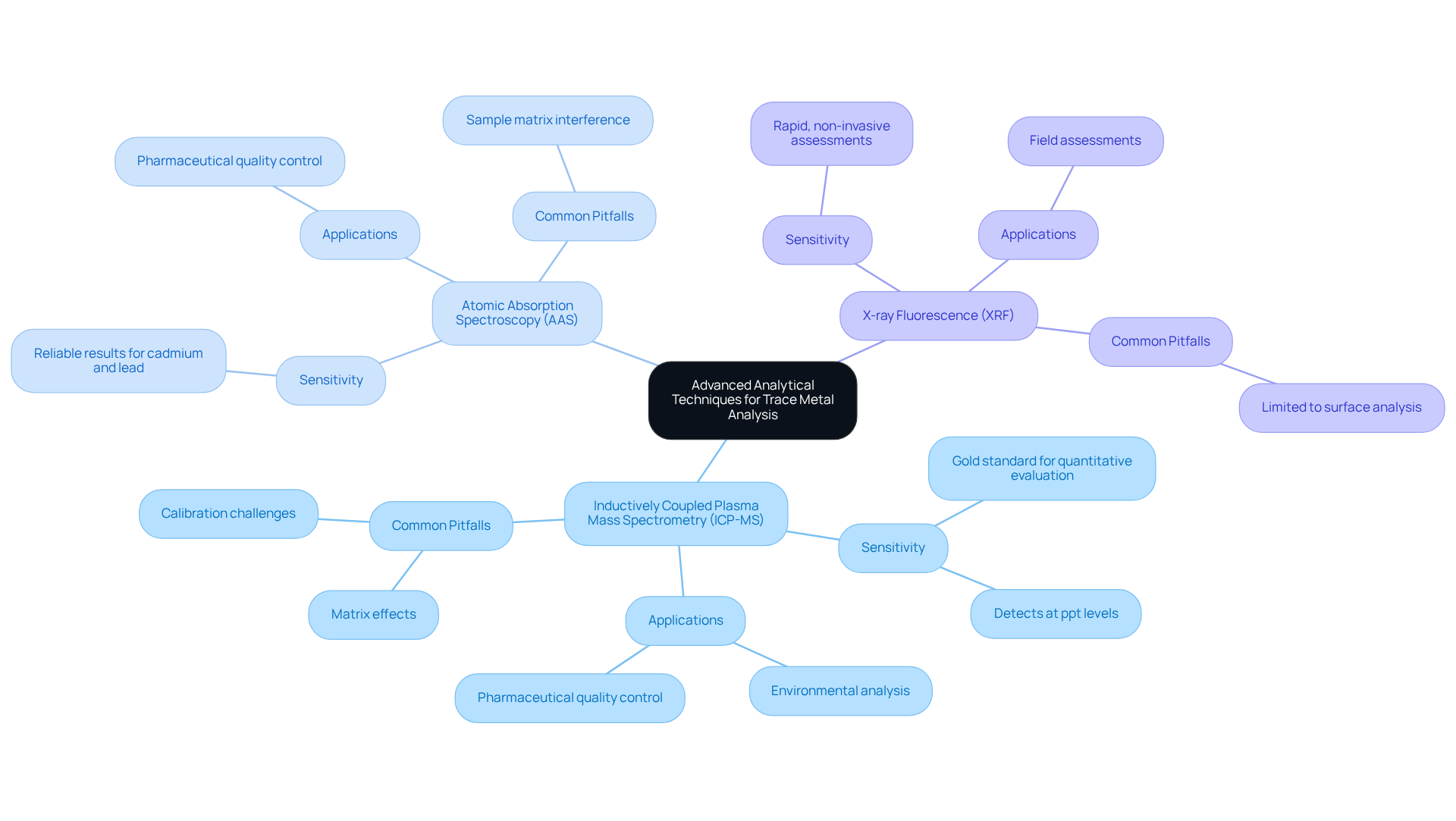

Implement Advanced Analytical Techniques

To enhance trace metal analysis, facilities must implement advanced analytical methods such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectroscopy (AAS), and X-ray Fluorescence (XRF). These techniques are renowned for their remarkable sensitivity and specificity. Notably, ICP-MS can detect substances at parts per trillion (ppt) levels, making it particularly suitable for both environmental and pharmaceutical applications. Recent advancements in ICP-MS technology have significantly improved its sensitivity and interference removal capabilities, establishing it as the gold standard for quantitative evaluation in testing environments.

AAS has also proven effective in trace metal analysis, yielding reliable results for various elements, including cadmium and lead, which are crucial in ensuring pharmaceutical quality control. Meanwhile, XRF complements these methods by offering rapid, non-invasive assessments that further enhance the analytical capabilities of the facility.

To maximize the effectiveness of these techniques, regular training for staff is imperative. This training ensures that personnel are not only adept at operating the equipment but also skilled in troubleshooting potential issues that may arise during analysis, thus preserving the integrity and accuracy of results.

Moreover, it is essential to recognize common pitfalls associated with these techniques, such as matrix effects and calibration challenges. Awareness of these issues can prevent misapplications that might compromise data quality. By prioritizing the implementation of advanced analytical methods and investing in staff training, facilities can significantly improve their processes for trace metal analysis.

Maintain Quality Control and Regulatory Compliance

To ensure robust quality control, facilities must implement a comprehensive QA/QC program that encompasses:

- Regular instrument calibration

- Active participation in proficiency testing

- Systematic audits of analytical procedures

This structured approach is vital for maintaining high standards in laboratory settings. Establishing a meticulous tracking system for documenting all quality control measures is essential. For instance, employing control charts enables facilities to oversee analytical performance efficiently, aiding in the detection of trends and variations from anticipated outcomes.

Furthermore, staying informed about regulatory changes and adhering to standards set by organizations such as the EPA and ISO is critical for maintaining operational integrity. This commitment not only enhances data quality but also ensures compliance with industry regulations, ultimately safeguarding the reliability of the trace metal analysis process.

![]()

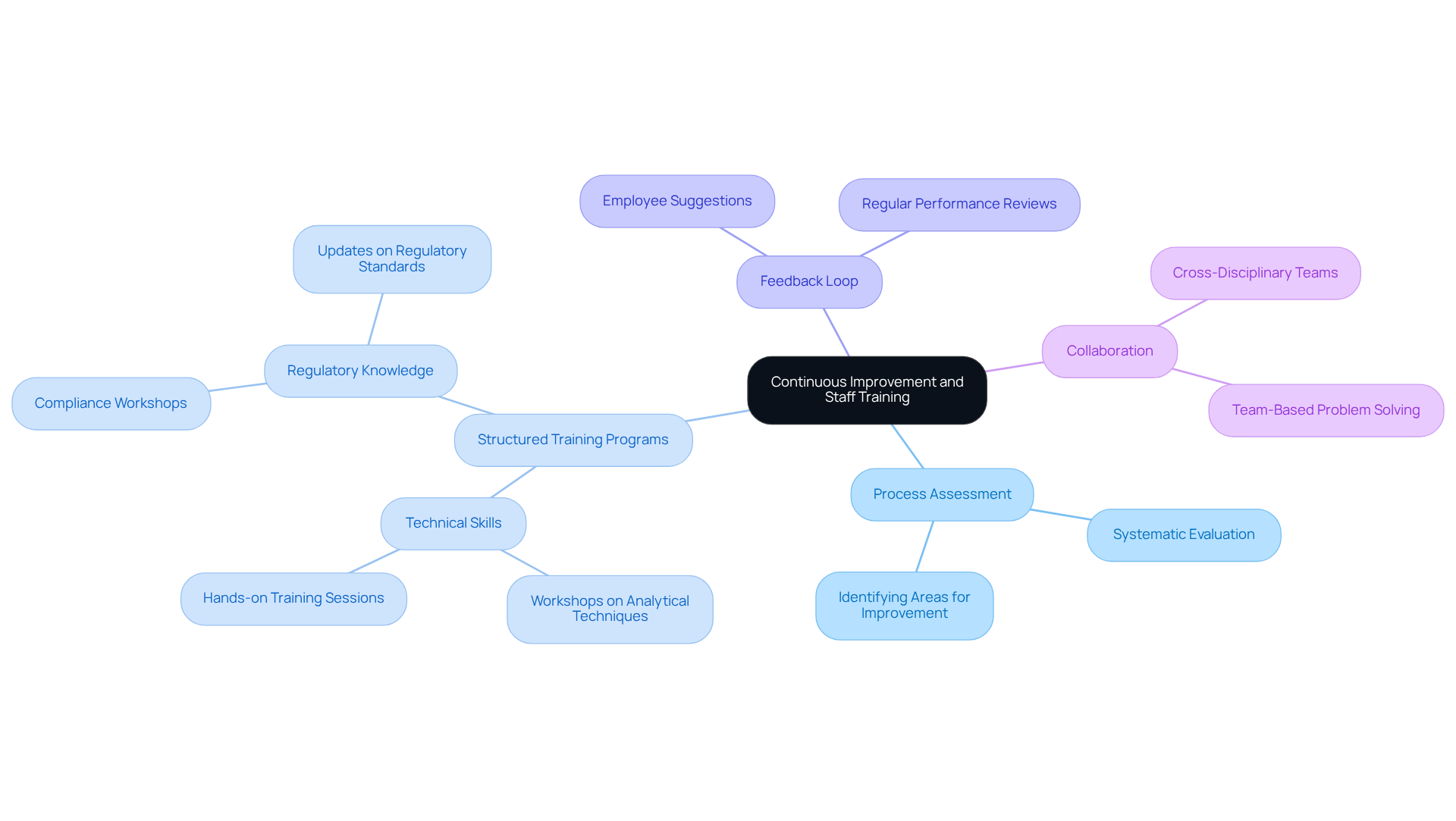

Foster Continuous Improvement and Staff Training

To achieve operational excellence, facilities must prioritize continuous enhancement by systematically assessing processes and actively seeking input from personnel. Implementing a structured training program that encompasses both technical skills and regulatory knowledge is crucial. For instance, workshops focused on the latest analytical techniques and compliance requirements empower staff to enhance their performance and adapt to evolving standards.

Furthermore, establishing a feedback loop allows employees to propose improvements, fostering a collaborative environment that not only encourages innovation but also significantly enhances overall laboratory performance. This proactive approach aligns with the best practices necessary for mastering the field of trace metal analysis and ensuring high-quality outcomes.

Conclusion

Establishing effective trace metal analysis practices is essential for laboratories striving for accuracy and reliability in their results. By adhering to established standards and implementing advanced analytical techniques, facilities can significantly enhance their capabilities in detecting and quantifying trace metals. These best practices not only ensure compliance with regulatory requirements but also foster trust within the scientific community and among stakeholders.

This article underscores the importance of:

- Creating robust standard operating procedures

- Utilizing validated analytical methods

- Maintaining a rigorous quality control program

It emphasizes the necessity for continuous staff training and the adoption of advanced technologies such as ICP-MS and AAS, which are critical for achieving precise results. Furthermore, cultivating a culture of continuous improvement through feedback and innovation can lead to enhanced laboratory performance.

In summary, the significance of mastering trace metal analysis cannot be overstated. Laboratories must prioritize these best practices to ensure high-quality outcomes, maintain compliance with industry standards, and ultimately contribute to the broader goal of environmental safety and public health. By committing to excellence in trace metal analysis, facilities not only elevate their operational standards but also play a pivotal role in safeguarding the integrity of scientific research and its applications.