Overview

NIR sensors are integral to effective silage quality management, offering real-time data on moisture and nutrient content. This capability allows farmers to optimize their harvesting and feeding strategies, ensuring maximum efficiency. By leveraging NIR technology, farmers can significantly enhance forage quality and livestock productivity.

Informed decision-making based on accurate measurements of key parameters, such as protein levels and moisture content, is essential for achieving these improvements. Ultimately, the implementation of NIR sensors empowers farmers to make strategic choices that lead to better outcomes in their operations.

Introduction

The agricultural landscape is undergoing a rapid transformation, with technology serving as a crucial catalyst for optimizing practices and enhancing productivity. Near-Infrared (NIR) sensors emerge as a groundbreaking tool in silage quality management, providing farmers with unprecedented insights into the nutritional composition of their forage. By leveraging real-time data, these sensors not only enhance feed efficiency but also raise critical questions about the ability of traditional methods to keep pace with such advancements. As farmers strive to refine their feeding strategies, the integration of NIR technology presents both significant opportunities and formidable challenges that warrant thorough exploration.

Explore NIR Sensor Technology and Its Principles

Near-Infrared (NIR) spectroscopy represents a powerful non-destructive analytical technique that leverages the near-infrared region of the electromagnetic spectrum, ranging from approximately 780 nm to 2500 nm, to analyze material composition. NIR devices operate by assessing the absorption and reflection of light by chemical compounds, thereby providing valuable insights into the molecular structure of samples. This technology proves especially beneficial in agriculture, particularly for evaluating moisture content, protein levels, and other critical factors in forage management.

For instance, NIR devices significantly enhance forage quality by delivering real-time information that empowers farmers to make informed decisions regarding feed efficiency and animal welfare. Notably, can process approximately 1 million samples per load, yielding extensive data in comparison to traditional sample analysis methods. Practical applications and case studies have demonstrated that incorporating NIR technology in forage management leads to improved crop yields and increased profitability. By facilitating precise monitoring of feed composition, farmers can optimize their feeding strategies, ensuring livestock receive the highest quality nutrition.

The principles underlying the NIR sensor are based on its ability to analyze material composition swiftly and accurately. As noted, "NIRS has established itself as an ideally suited tool for the quantification of chemical compositions." This capability is crucial for maintaining high-quality feed, as it allows for timely adjustments based on the nutritional needs of the herd. Furthermore, the potential for on-mower NIR data to provide real-time insights can enhance forage quality by adjusting machine settings according to crop conditions. As the agricultural sector increasingly embraces innovative technologies, the NIR sensor emerges as a key instrument for refining forage management practices, ultimately contributing to improved outcomes in livestock production.

Apply NIR Sensors in Silage Quality Assessment

NIR sensors are pivotal in the forage production process, encompassing everything from harvesting to storage. During the harvesting phase, these NIR sensors can be mounted on forage harvesters, facilitating real-time analysis of moisture and nutrient content. This immediate feedback empowers farmers to make informed decisions regarding , ensuring the highest quality feed, ideally around 35% dry matter (DM) to maximize nutritive value.

Furthermore, the NIR sensor technology is instrumental in evaluating the fermentation standards of forage by measuring critical parameters such as pH and volatile fatty acids. Maintaining the functionality of moisture devices is essential for obtaining accurate real-time measurements, thereby enhancing the efficacy of NIR applications.

Additionally, kernel processing is vital for improving starch digestion and utilization by ruminants, which directly impacts feed quality. Case studies demonstrate that the integration of NIR sensors leads to significant improvements in feed management, underscoring their essential role in modern agricultural practices.

Nevertheless, it is crucial to address challenges in monitoring forage quality to achieve optimal results.

Implement NIR Sensors: Setup and Operational Guidelines

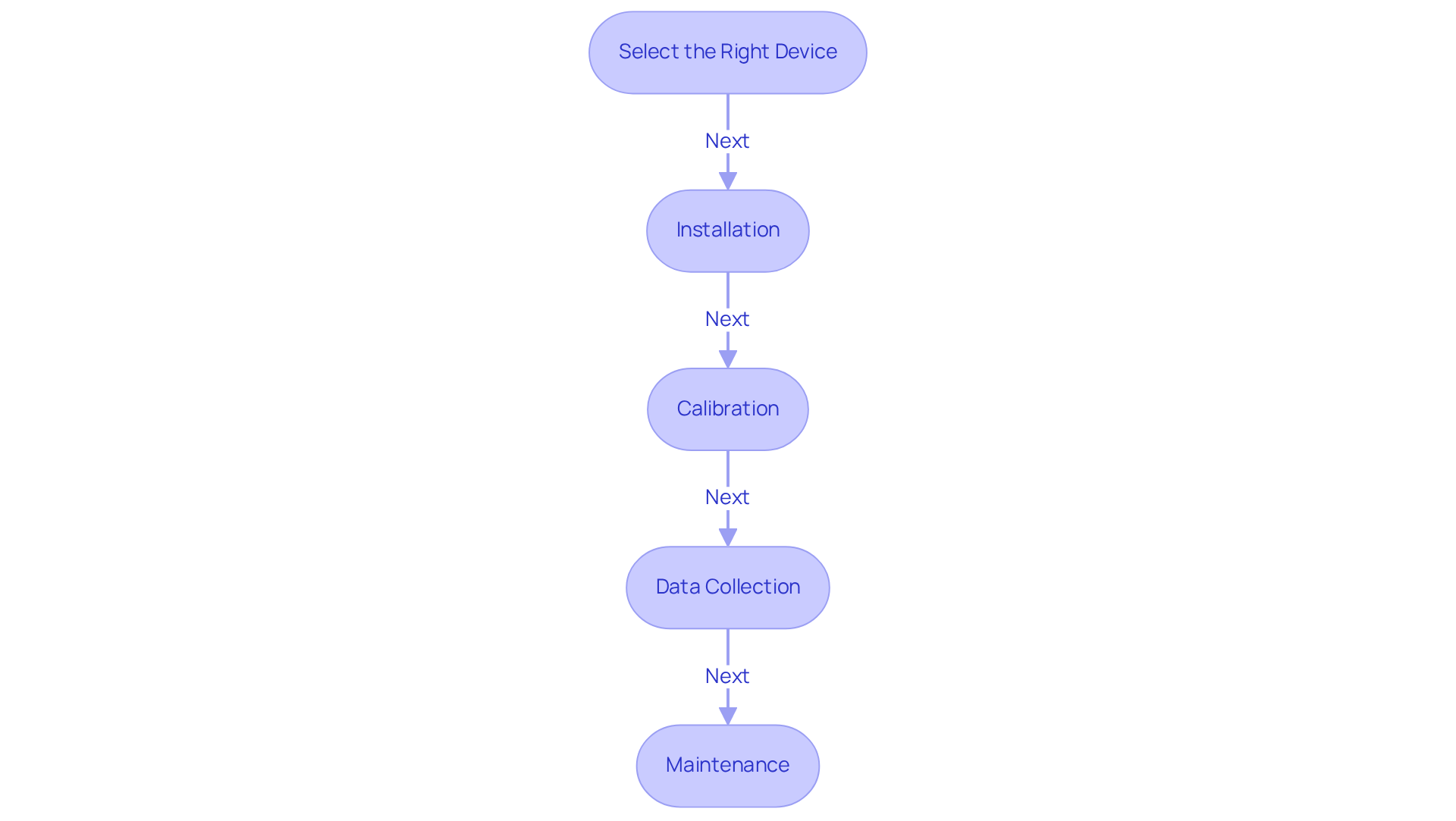

To implement NIR sensors effectively in silage management, it is essential to adhere to the following guidelines:

- Select the Right Device: Choose a NIR sensor tailored to your specific requirements, taking into account factors such as wavelength range and sensitivity. Recent advancements indicate that devices equipped with a NIR sensor can generate approximately 1 million samples per load, significantly enhancing data collection capabilities.

- Installation: Properly mount the device on the forage harvester or within the storage area. Positioning is crucial; ensure the device is aligned to capture precise readings of moisture and nutrient content.

- Calibration: Meticulously follow the manufacturer's calibration instructions. Utilize known standards to verify accuracy, as have demonstrated superior performance, particularly for very wet materials like corn whole plant (CWP). For instance, the average prediction error for crude protein (CP) in CWP is 0.46% DM, showcasing the accuracy of the [NIR sensor technology](https://jmscience.com) in practice.

- Data Collection: Operate the device during harvesting or storage to gather information on critical parameters such as moisture, protein, and starch levels. On-farm NIR sensor systems provide instant results, enabling immediate management decisions that can optimize feeding systems.

- Maintenance: Regularly clean and service the device to ensure consistent performance and longevity. This practice is vital for sustaining the accuracy of readings over time.

By adhering to these optimal methods, users can maximize the advantages of the NIR sensor technology, which leads to enhanced forage management and improved decision-making in agricultural operations.

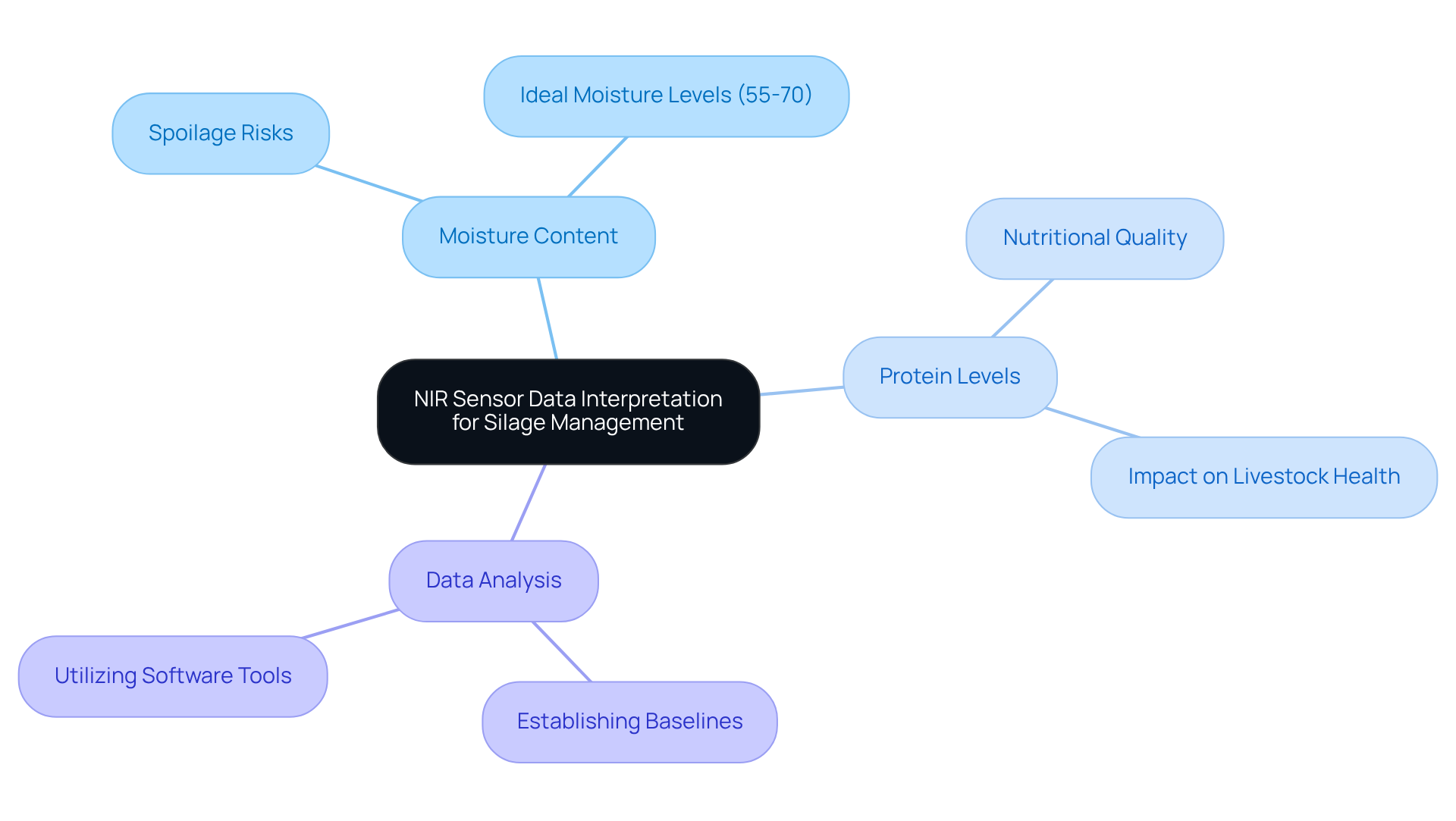

Interpret NIR Sensor Data for Effective Silage Management

Interpreting the NIR sensor data is crucial for optimizing , as it provides insights into key parameters that directly affect fermentation and nutritional value. Moisture content is pivotal; excessive moisture can lead to spoilage, while insufficient moisture can impede effective fermentation. Ideally, fermented fodder should be harvested at a moisture level of 55 to 70 percent to maximize nutrient retention and minimize losses. Protein levels are equally significant, as they directly impact the nutritional quality of feed, influencing livestock health and productivity. Research indicates that forage with can enhance feed efficiency and overall animal performance.

To effectively interpret data from the NIR sensor, farmers must establish baseline values tailored to their specific crops and monitor any deviations over time. Utilizing accompanying software tools can streamline data analysis, enabling farmers to identify trends and make informed decisions regarding feed management strategies. Real-world examples demonstrate that farms employing the NIR sensor technology have successfully improved their silage quality by adjusting harvesting practices based on moisture and protein data. This ultimately leads to enhanced livestock productivity and reduced feed costs.

Conclusion

The integration of Near-Infrared (NIR) sensor technology into silage quality management marks a transformative approach for farmers seeking to enhance feed efficiency and livestock health. By leveraging the capabilities of NIR sensors, agricultural professionals gain real-time insights into the nutritional composition of forage, facilitating timely and informed decision-making that optimizes both crop yields and profitability.

Key insights discussed throughout the article include:

- The operational principles of NIR sensors

- Their applications during harvesting and storage phases

- The significance of accurate data interpretation

Monitoring critical parameters such as moisture and protein content not only ensures high-quality feed but also directly impacts livestock performance. Furthermore, practical guidelines for effectively implementing NIR sensors are outlined, emphasizing the importance of proper device selection, calibration, and maintenance to maximize the technology's benefits.

As the agricultural sector evolves, embracing innovative technologies like NIR sensors becomes essential for sustainable and efficient farming practices. By adopting these advanced tools, farmers can elevate their silage management strategies, resulting in improved animal productivity and reduced costs. The future of agriculture lies in the hands of those willing to harness the power of data and technology, making the implementation of NIR sensors a crucial step toward achieving excellence in forage management.