Overview

The article "Selecting and Utilizing a Micro Centrifuge: An Expert's Guide" provides an authoritative overview of the essential factors involved in selecting and effectively employing micro centrifuges within laboratory environments. It underscores the necessity of choosing the appropriate micro centrifuge to optimize performance and ensure precise results. This guide is enriched with insights into various types of micro centrifuges, critical considerations for selection, best operational practices, and the latest technological advancements that bolster efficiency and reliability in scientific research.

Introduction

In the realm of scientific research and clinical diagnostics, microcentrifuges stand as indispensable instruments, fundamentally transforming laboratory sample processing. These compact devices, capable of spinning at remarkable speeds, enable the precise separation of components based on density, making them vital in disciplines such as molecular biology, biochemistry, and environmental testing. As technological advancements continue to enhance their capabilities, it becomes essential to understand the various types of microcentrifuges, their applications, and the best practices for operation. This knowledge is crucial for optimizing laboratory workflows. From selecting the appropriate model to troubleshooting common issues, this comprehensive exploration highlights the pivotal role microcentrifuges play in modern laboratories, ensuring accuracy and efficiency in a fast-paced scientific landscape.

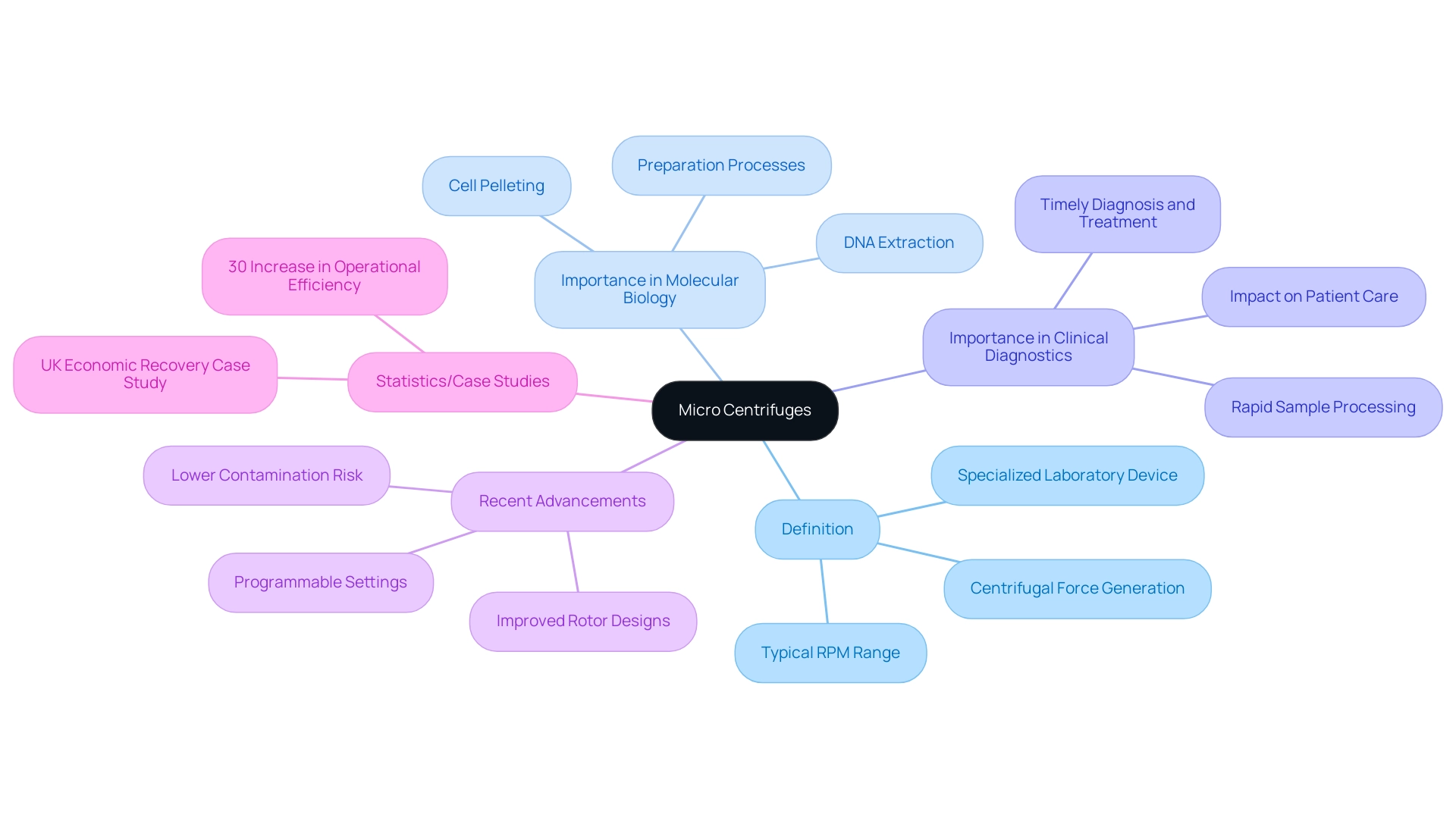

Understanding Micro Centrifuges: Definition and Importance

A small centrifuge is a highly specialized laboratory device designed to rotate specimens at remarkable velocities, typically ranging from 6,000 to 20,000 RPM. This rapid rotation generates substantial centrifugal force, effectively separating components within a mixture according to their density. Micro centrifuges play a pivotal role across various scientific disciplines, including molecular biology, biochemistry, and clinical diagnostics. They are essential for processes such as DNA extraction, cell pelleting, and preparation, where precision and speed are paramount.

Recent advancements in micro centrifuge technology have led to enhanced performance features, including programmable settings and improved rotor designs that optimize specimen separation. These innovations not only enhance efficiency but also lower the risk of contamination, which is critical in clinical diagnostics. In molecular biology, the ability to quickly and accurately isolate nucleic acids can significantly impact the outcomes of experiments and research.

The importance of micro centrifuge devices in clinical diagnostics cannot be overstated. They facilitate rapid processing of samples, essential for timely diagnosis and treatment. Case studies have shown that facilities utilizing advanced micro centrifuge technology can improve turnaround times for critical tests, thereby enhancing patient care. Furthermore, expert opinions highlight that the reliability of micro centrifuges directly correlates with the accuracy of diagnostic results, underscoring their vital role in healthcare settings. As Daniel Zaga noted, "The role of the micro centrifuge in clinical diagnostics is crucial, as it ensures that results are both timely and accurate."

Statistics from 2025 indicate that facilities equipped with modern micro centrifuge machines report a 30% increase in operational efficiency, showcasing their significance in streamlining workflows. Additionally, a recent case study on the United Kingdom's economic recovery illustrates how advanced research technologies, including the micro centrifuge, contribute to improved efficiency and patient care outcomes. As the demand for precise and rapid diagnostic tools continues to grow, the role of micro centrifuges in both research and clinical environments remains indispensable, solidifying their status as essential instruments in the scientific community.

Types of Micro Centrifuges: Features and Applications

Microcentrifuges are indispensable tools in laboratory environments, with various types specifically designed for distinct applications.

- Micro centrifuge: These versatile instruments are widely utilized in laboratories for routine tasks. They support various rotor configurations, making them suitable for spinning microtubes and PCR plates, which are critical in molecular biology and genetic research.

- Refrigerated micro centrifuges are engineered for temperature-sensitive materials, maintaining low operational temperatures to prevent degradation. This feature is particularly vital in medical diagnostics, where preserving the integrity of biological specimens is crucial for accurate results.

- Compact and portable, micro centrifuges are ideal for quick spins and small sample volumes. Their lightweight design proves particularly advantageous in fieldwork or smaller laboratory settings where space is at a premium.

- High-speed micro centrifuge devices are designed for applications requiring high g-forces, making them essential for separating cellular components in molecular biology. Their capability to achieve rapid speeds significantly enhances efficiency in processing.

The global research equipment market is poised for notable expansion, with a forecasted compound annual growth rate (CAGR) of 3.68% from 2025 to 2033. This growth is propelled by rising demands for molecular diagnostic applications and technological advancements, with market value expected to increase from approximately USD 1.94 billion in 2024 to USD 2.70 billion by 2034. Notably, the COVID-19 pandemic has accelerated the use of testing devices in blood banks and biopharmaceutical companies for critical processes like specimen preparation and medication manufacturing.

As one industry expert noted, "The sudden outbreak of the COVID-19 pandemic has led to the increasing utilization of centrifuge by blood banks and biopharmaceutical enterprises for preparing samples, harvesting cells, producing drugs in bulk, etc."

In pharmaceutical laboratories, the reliability and efficiency of micro centrifuges have been underscored in case studies for their application in routine analyses. Laboratory managers emphasize the importance of selecting the right micro centrifuge based on specific application needs, with many opting for models that offer a balance of performance and versatility. JM Science Inc. is committed to consistently refreshing its product range and fostering strong partnerships with leading manufacturers, ensuring that facilities have access to the latest technologies and solutions.

As of 2025, the market share for various types of micro centrifuges indicates a growing preference for high-speed and refrigerated models, driven by their advanced features and applications in both research and clinical settings.

The latest models of micro centrifuges in 2025 are equipped with enhanced functionalities, including programmable settings and improved energy efficiency, catering to the evolving requirements of research facilities. As the landscape of scientific instrumentation continues to progress, staying informed about the latest advancements in small-scale centrifuge technology is essential for optimizing research workflows.

Key Considerations for Selecting the Right Micro Centrifuge

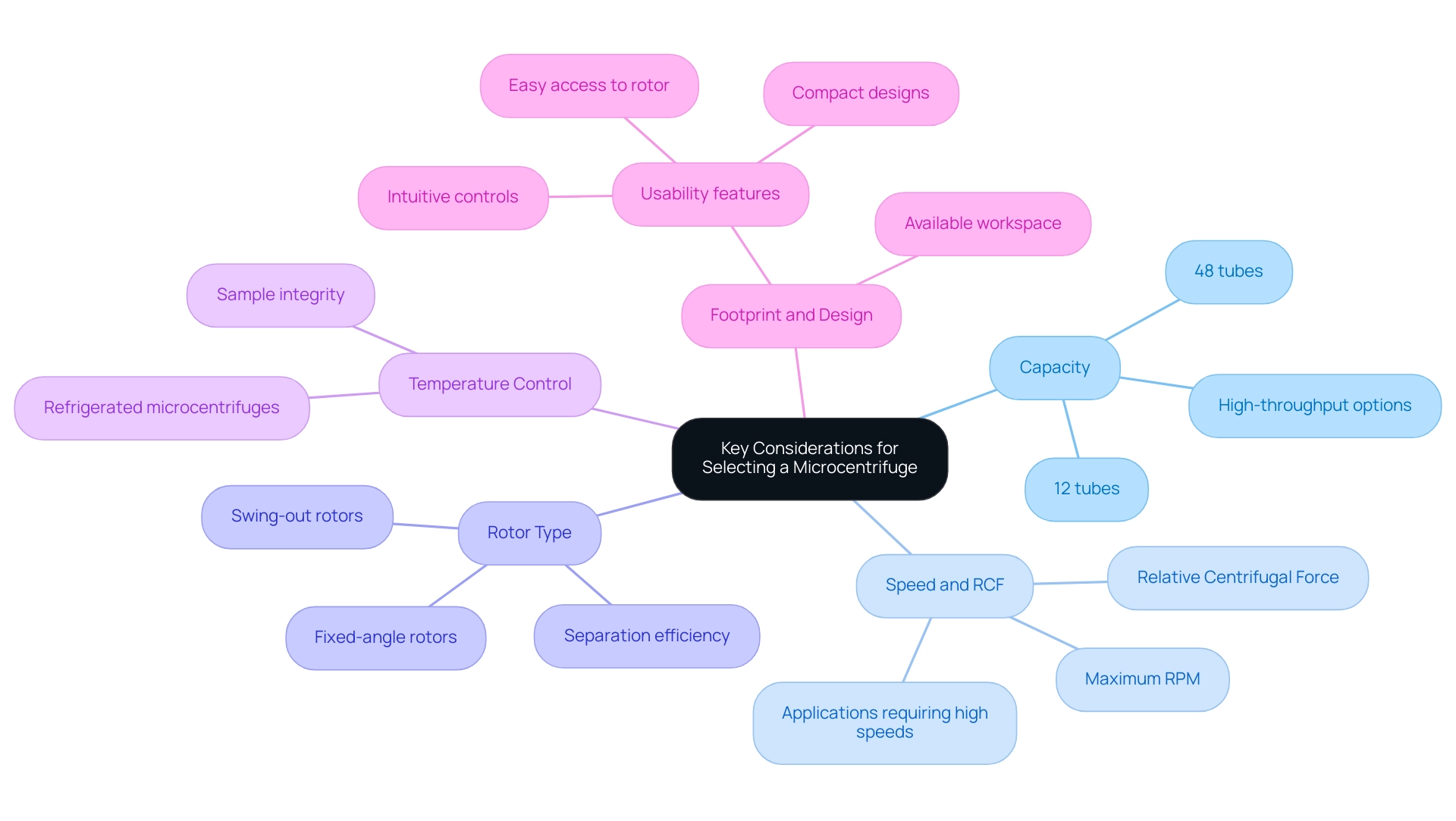

When selecting a microcentrifuge, several critical factors must be considered to ensure optimal performance and suitability for laboratory applications.

- Capacity is paramount; evaluate the quantity of items you need to process simultaneously. Microcentrifuge models typically accommodate between 12 to 48 tubes, with some offering even greater capacity to meet high-throughput demands.

- Next, consider Speed and RCF. Assess the maximum speed (RPM) and relative centrifugal force (RCF) necessary for your specific applications. For instance, protocols such as DNA extraction often require higher speeds to achieve effective separation.

- The Rotor Type is another crucial choice, as it directly impacts separation efficiency based on the types and desired outcomes. Fixed-angle rotors are ideal for pelleting, while swing-out rotors provide better separation for larger volumes. This consideration aligns with JM Science's commitment to continually updating its product offerings to meet the changing requirements of research facilities.

- Furthermore, Temperature Control is essential for sensitive samples, making the selection of a refrigerated microcentrifuge vital to maintain sample integrity and prevent degradation during processing.

- Finally, consider the Footprint and Design. Evaluate the available workspace and the design features that enhance usability. Features such as easy access to the rotor, intuitive controls, and compact designs can significantly improve workflow efficiency.

As the market for lab spin devices is projected to reach an estimated value of USD 1.67 billion by 2025, understanding these selection criteria becomes increasingly important for pharmaceutical facilities aiming to optimize their operations. Additionally, the centrifuge market in Germany is anticipated to expand at a compound annual growth rate (CAGR) of 3.4% from 2025 to 2034, indicating a rising demand for advanced centrifugation solutions. This growth is further supported by market segmentation strategies that focus on research and teaching, allowing companies like JM Science Inc. to tailor their offerings to meet specific customer needs.

Including professional guidance on centrifuge selection can further assist managers in making informed choices. Key considerations include evaluating the average capacity of microcentrifuges, which typically ranges from 12 to 48 tubes, and understanding the importance of rotor type in achieving desired separation results. As Vishakha Agrawal from Expert Market Research states, "At Expert Market Research, we aim to bring you the latest insights and trends in the market."

By tailoring selections to meet specific laboratory needs, stakeholders can enhance their operational efficiency and contribute to overall market growth.

Best Practices for Operating and Maintaining Micro Centrifuges

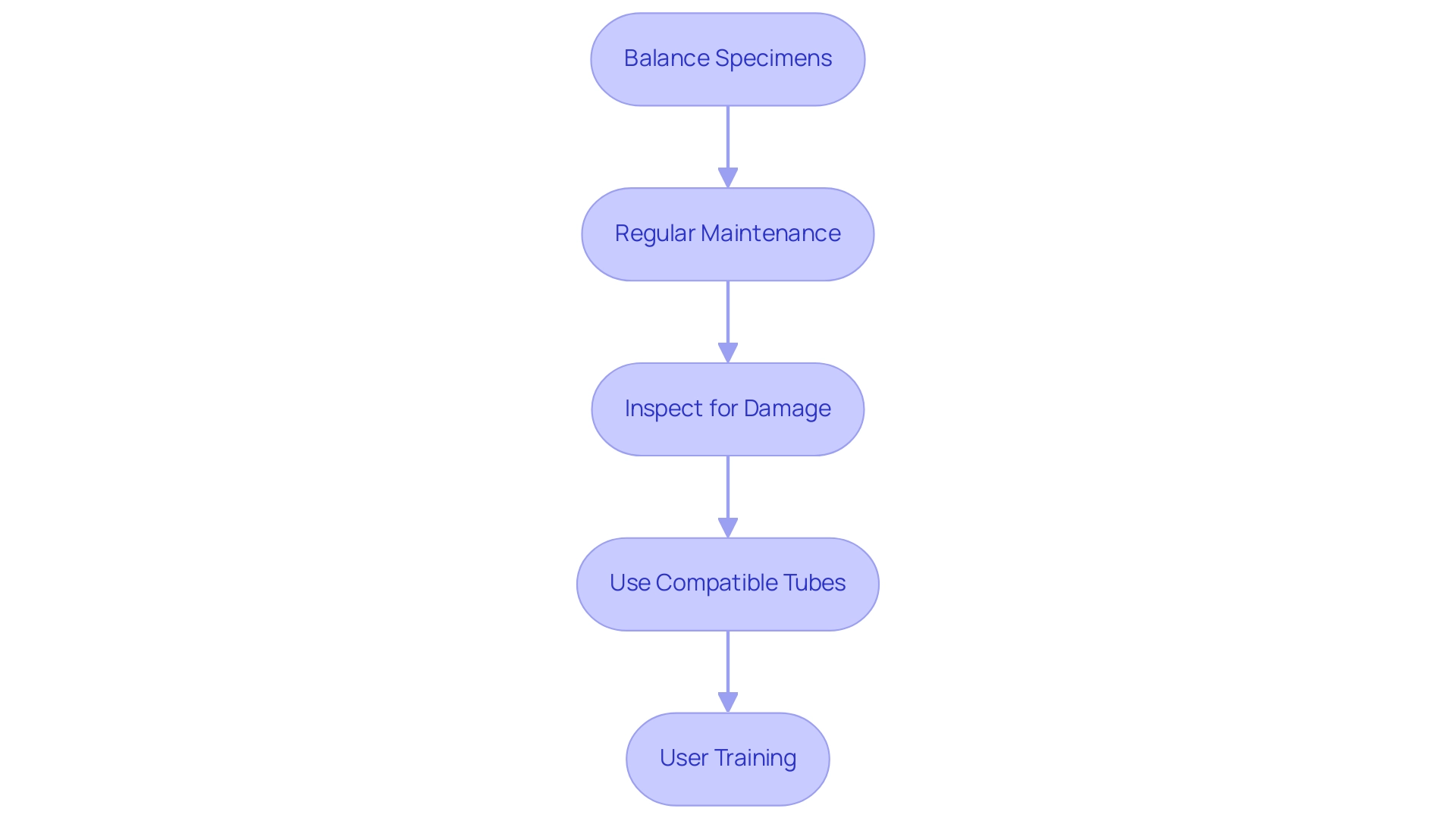

To ensure optimal performance and longevity of your microcentrifuge, it is imperative to adhere to the following best practices:

- Balance Specimens: Always load specimens symmetrically within the rotor. An unbalanced load can lead to excessive vibrations, potentially damaging the equipment and compromising sample integrity.

- Regular Maintenance: Implement a routine cleaning schedule for the rotor and chamber to prevent contamination and mechanical wear. Following the manufacturer's maintenance guidelines is crucial for sustaining performance.

- Inspect for Damage: Prior to each use, thoroughly examine tubes and rotors for any signs of cracks or wear. Immediate replacement of damaged components is essential to ensure safety and reliability during operation.

- Use Compatible Tubes: Choose centrifuge tubes that are specifically designed for your centrifuge model. This guarantees proper sealing and reduces the risk of leaks during centrifugation, which can result in loss or contamination.

- User Training: Provide comprehensive training for all personnel on the correct operation of the microcentrifuge. This includes guidance on loading materials, appropriate speed settings, and adherence to safety protocols to mitigate the risk of accidents.

Understanding the effect of balance on centrifuge performance is essential. For instance, selected Eppendorf rotors have been rigorously tested at temperatures of 135 °C for 20 minutes, demonstrating their reliability under extreme conditions. Furthermore, case studies on the decontamination and sterilization of rotors highlight the importance of proper sterilization methods, such as autoclaving, especially when dealing with potentially hazardous biological or radioactive materials.

As noted in a case study, "Proper sterilization methods are essential for ensuring the safety of personnel and the integrity of samples, particularly when dealing with highly infectious agents."

By adhering to these best practices and maintaining a proactive approach to microcentrifuge operation, facilities can enhance their analytical capabilities and ensure the longevity of their equipment. JM Science Inc. offers a range of high-quality microcentrifuge models and accessories that support these best practices, ensuring that laboratories can operate efficiently and safely.

Troubleshooting Common Issues with Micro Centrifuges

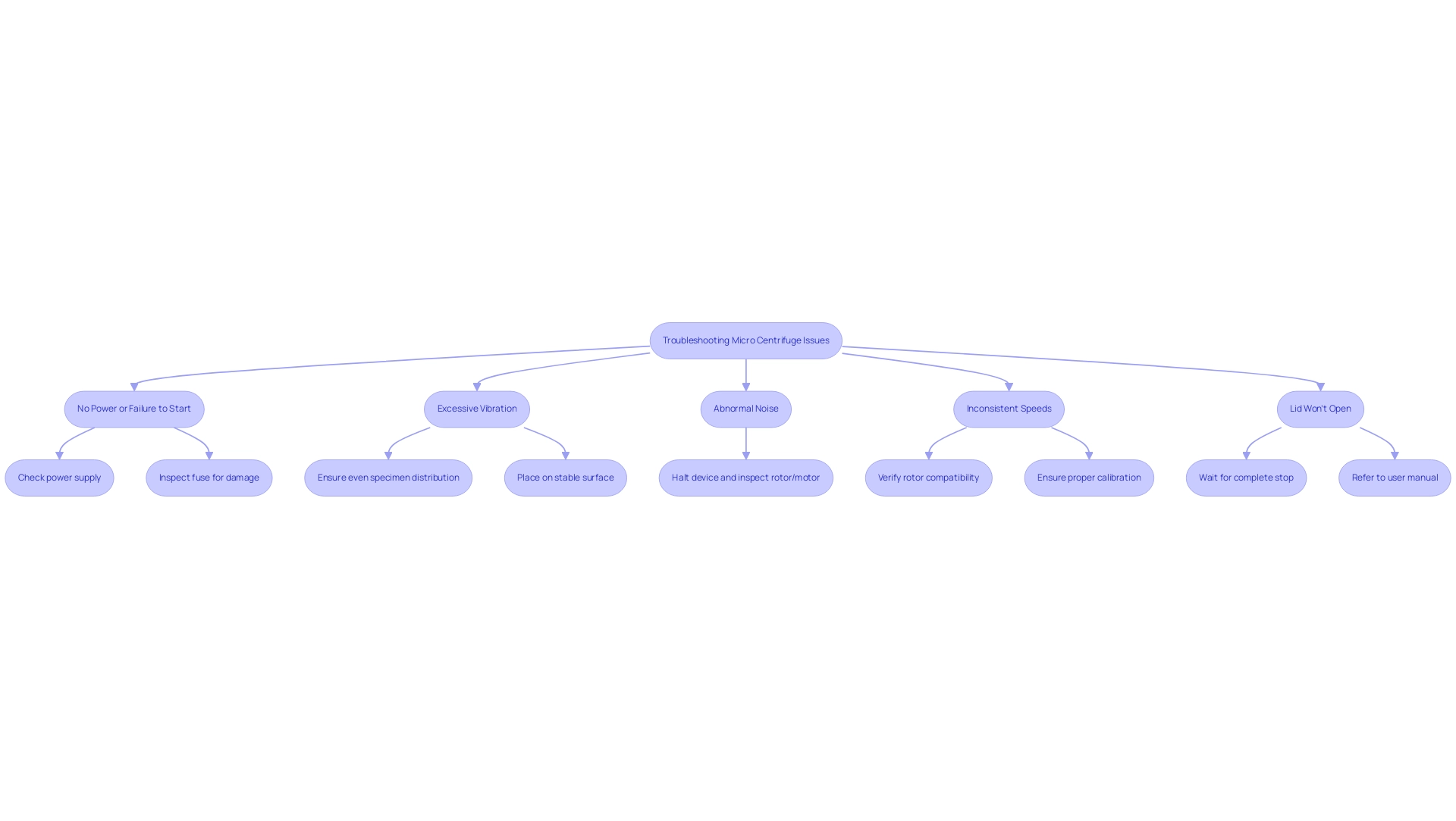

Common issues encountered with microcentrifuges and their troubleshooting steps are critical for maintaining optimal performance in laboratory settings.

- No Power or Failure to Start: Begin by checking the power supply to ensure the unit is plugged in. If the spinning device still does not start, inspect the fuse for any signs of damage or failure.

- Excessive Vibration: Excessive vibration can often be traced back to unbalanced specimens. Ensure that all samples are evenly distributed within the rotor and that the device is placed on a stable, level surface to minimize movement during operation.

- Abnormal Noise: If you hear unusual sounds while the spinning device is running, this may indicate an issue with the rotor or motor. Quickly halt the spinning device and perform a thorough inspection for any visible damage or misalignment.

- Inconsistent Speeds: When a spinning device fails to reach the set speed, it is crucial to verify rotor compatibility with the unit. Additionally, ensure that the device is properly calibrated, as discrepancies can lead to ineffective separation of samples.

- Lid Won't Open: Always wait for the centrifuge to come to a complete stop before attempting to open the lid. If the lid remains stuck, refer to the user manual for specific troubleshooting instructions, as this may indicate a safety mechanism is engaged.

A key point to remember is that the pellet formed in a microcentrifuge is typically off to one side of the tube, and care must be taken when removing the supernatant to avoid dislodging it. Recent statistics indicate that improper handling and maintenance of small centrifuges, including microcentrifuge units, are among the primary causes of issues in research facilities. This underscores the significance of regular training and compliance with operational protocols. Furthermore, case studies from the past year reveal that many facilities have successfully mitigated these common problems through systematic troubleshooting and preventive maintenance practices.

For example, the effect of COVID-19 on the refrigerated centrifuge market has demonstrated how external factors can affect research operations and equipment dependability. As a Senior Research Analyst noted, "I have a proven track record of conducting thorough analyses, distilling key insights, and presenting findings in a way that resonates with diverse stakeholders." By addressing these issues proactively, managers can enhance the reliability and longevity of their centrifuge equipment.

Innovations in Micro Centrifuge Technology: What’s New?

Recent advancements in micro centrifuge technology are revolutionizing research practices and improving operational efficiency. Key advancements include:

- Smart features

- Improved rotor designs

- Energy efficiency

- User-friendly interfaces

- Compact designs

Smart features have become increasingly prevalent in the latest models, which are equipped with programmable settings, real-time monitoring, and automatic shut-off features. These enhancements significantly elevate safety and usability. Innovations in rotor materials and designs have resulted in lighter, more durable options, thereby improving performance and reducing wear and tear over time. Furthermore, new micro centrifuge models are designed to consume less energy while delivering high performance, aligning with the growing emphasis on sustainable practices in research. Modern devices often incorporate intuitive touch screens and easy-to-navigate controls, making them accessible for users of all skill levels and streamlining workflows. Advances in engineering have also led to the creation of more compact models that maximize space without sacrificing performance, making them ideal for facilities with limited real estate.

The global automated microplate centrifuge market is projected to reach a size of $710 million by 2025, with a remarkable Compound Annual Growth Rate (CAGR) of 11.6% from 2025 to 2033. This growth is driven by the increasing demand for rapid diagnostics, the prevalence of chronic diseases, and the expansion of research activities in pharmaceuticals and biotechnology. Notably, the introduction of systems like Thermo Fisher Scientific's DynaSpin Single-Use Centrifuge system exemplifies the trend towards efficiency, reducing waste by 70% compared to conventional systems.

As JM Science continually updates its product offerings and maintains strong relationships with leading manufacturers, it plays a crucial role in ensuring that research facilities have access to the latest innovations. As the market evolves, continuous technological progress and increasing healthcare investments are anticipated to further drive the adoption of smart features in modern micro centrifuges, ensuring that research facilities remain at the forefront of innovation.

The Role of Micro Centrifuges in Modern Laboratories

Micro centrifuges are indispensable tools in contemporary research facilities, facilitating rapid and effective specimen processing across diverse applications. Their ability to separate components based on density is essential in various scientific domains, including:

- Molecular Biology: Micro centrifuges are vital for DNA and RNA extraction, significantly streamlining the preparation of specimens for genetic analysis. This precision enhances result reliability, which is crucial for advancing research in genomics and proteomics.

- In clinical diagnostics, micro centrifuges are pivotal in processing blood specimens within medical laboratories. They enable the isolation of plasma and serum, which are critical for a wide array of diagnostic tests. The rising demand for personalized medicine further emphasizes the significance of these instruments in delivering accurate and timely results.

- Pharmaceutical Research: These devices facilitate drug development by allowing for efficient compound separation during formulation and testing. As pharmaceutical research progresses, the necessity for high-quality micro centrifuge devices becomes increasingly evident, with researchers underscoring their reliability in producing reproducible outcomes. Brian Moore, VP at NICCA USA, Inc., remarked, "The quality of research they have done for us has been excellent," underscoring the importance of dependable instrumentation in research environments.

- Environmental Testing: Micro centrifuges are employed in analyzing soil and water specimens, aiding in pollutant detection and environmental health assessment. Their rapid sample processing capabilities contribute to timely environmental monitoring and compliance with regulatory standards.

- Quality Control: In manufacturing contexts, micro centrifuges ensure product consistency and quality through rigorous testing. This application is particularly crucial in sectors where precision is paramount, such as pharmaceuticals and biotechnology.

Recent advancements in micro centrifuge technology, exemplified by Eppendorf's launch of the Centrifuge 5427 R, reflect the industry's commitment to sustainability while enhancing performance. This model incorporates hydrocarbon cooling, aligning with the growing trend toward environmentally friendly practices in research. Furthermore, the patented compressor technology in the Centrifuge 5418 R minimizes vibrations and safeguards samples, further illustrating technological progress in this field.

As the laboratory centrifuge market continues to expand, propelled by innovations in genomics and proteomics, the role of micro centrifuges remains critical in meeting the evolving demands of researchers and clinicians alike.

Conclusion

Microcentrifuges are undeniably vital to the advancement of scientific research and clinical diagnostics. Their ability to efficiently and accurately separate components based on density has made them indispensable in various fields, including molecular biology, biochemistry, and environmental testing. Understanding the different types of microcentrifuges, from benchtop to high-speed models, allows laboratories to select the right instrument tailored to their specific needs, enhancing operational efficiency and ensuring precise results.

Moreover, adhering to best practices for operation and maintenance is essential for maximizing the longevity and performance of these instruments. Regular inspections, balanced sample loading, and proper training are key to preventing common issues and ensuring reliable results. As technology continues to evolve, innovations such as smart features and energy-efficient designs are setting new standards in laboratory instrumentation, further solidifying the role of microcentrifuges in modern labs.

Ultimately, as the demand for rapid and accurate diagnostics grows, the significance of microcentrifuges in optimizing laboratory workflows cannot be overstated. Embracing advancements in this technology not only enhances research capabilities but also contributes to improved patient care and environmental monitoring. By investing in the right microcentrifuge and adhering to best practices, laboratories can position themselves at the forefront of scientific discovery and innovation, ensuring they meet the challenges of an ever-evolving landscape.