Overview

Peak tailing in HPLC represents a significant challenge in analytical chemistry, primarily arising from interactions between analytes and stationary phases, particularly due to residual silanol groups. This phenomenon can distort chromatographic signals, ultimately compromising data integrity. Understanding the factors that contribute to peak tailing is crucial for any laboratory aiming for accurate results.

The article delves into various elements that exacerbate this issue, offering insights into the optimization of mobile phase conditions, the selection of appropriate columns, and the implementation of effective injection techniques. These strategies are essential for enhancing analytical performance. By addressing these factors, laboratories can ensure the reliability of their results, which is paramount in scientific inquiry.

In conclusion, tackling peak tailing is not merely a technical necessity; it is a vital step toward achieving high-quality analytical outcomes. Laboratories must prioritize the optimization of their methodologies to uphold the integrity of their data and reinforce their commitment to excellence in scientific research.

Introduction

Peak tailing in High-Performance Liquid Chromatography (HPLC) poses a significant challenge for analysts, distorting chromatographic signals and compromising data integrity. Understanding the myriad causes—from chemical interactions with stationary phases to instrumental inconsistencies—provides laboratories with a pathway to enhance their analytical performance. However, the pressing question remains: how can practitioners effectively mitigate these issues to achieve sharper, more reliable chromatograms? This article delves into the causes, implications, and best practices for overcoming peak tailing, equipping readers with the knowledge necessary to improve their HPLC results.

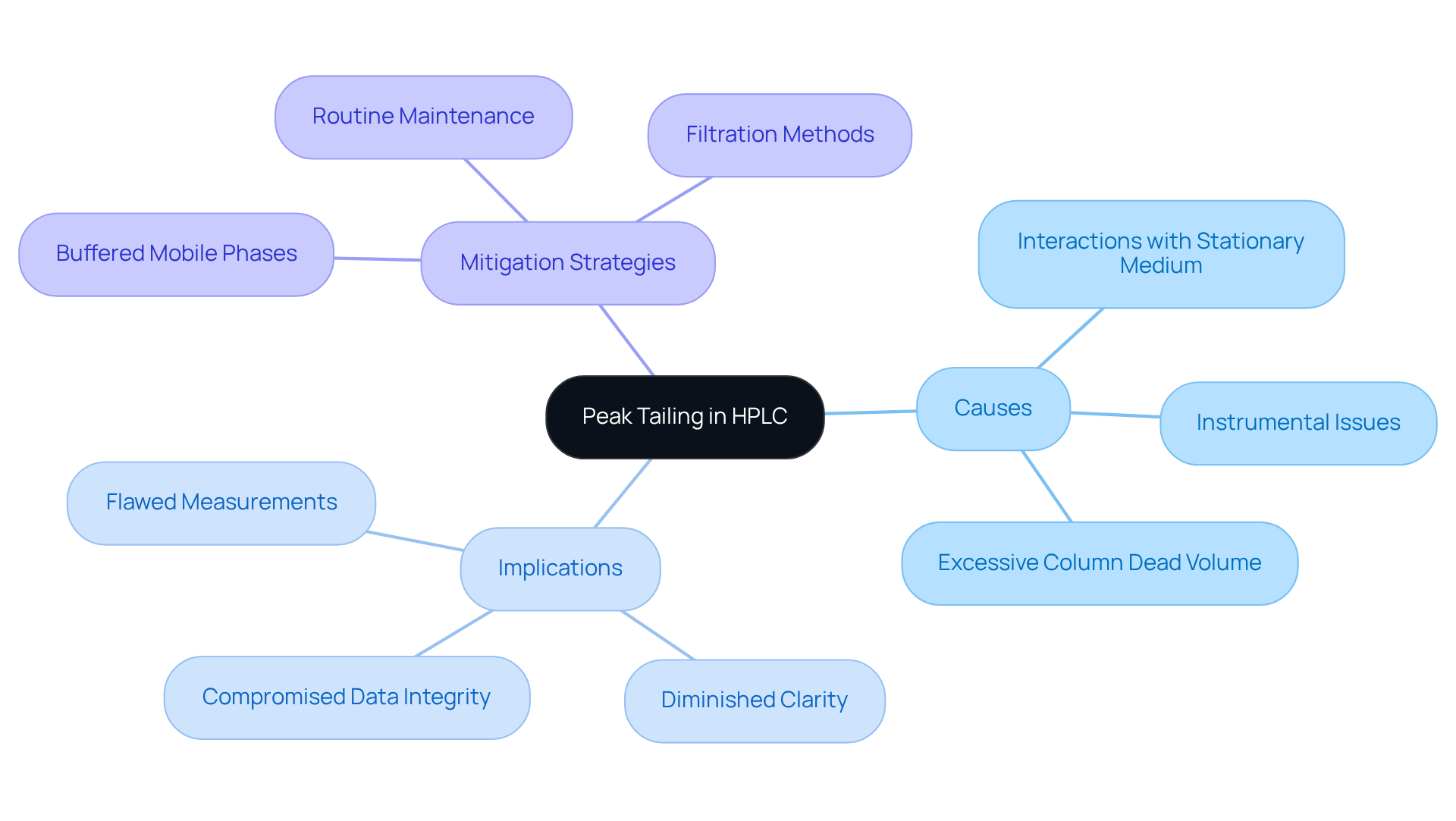

Define Peak Tailing in HPLC: Causes and Implications

Peak tailing HPLC in High-Performance Liquid Chromatography (HPLC) represents a critical distortion of chromatographic signals, characterized by the trailing edge extending beyond the leading edge, resulting in an asymmetric shape. This phenomenon arises from various factors, such as interactions between the analyte and the stationary medium, instrumental issues, and excessive column dead volume. Notably, working close to an analyte's pKa can exacerbate irregular signal shapes due to intensified interactions with silanol groups on the stationary material. To mitigate these interactions, employing buffered mobile phases with a pH between 3 and 7 is essential, as it effectively neutralizes these effects.

The consequences of maximum waste management are significant; they can lead to flawed measurements, diminished clarity, and compromised data integrity. A sensible standard for an acceptable tailing factor (TF) is TF ≤ 2, serving as a benchmark for evaluating maximum performance. In practical terms, chromatographers have observed that trailing effects can result in misinterpretation of results, particularly in complex matrices where analytes may interact unpredictably with the column. For instance, a study highlighted that improper vial cap selection could introduce impurities, exacerbating signal distortion and yielding unreliable data.

Experts emphasize the importance of addressing peak tailing HPLC to enhance analytical performance. Routine maintenance techniques, such as flushing the system with powerful solvents and utilizing high-efficiency equipment, can significantly alleviate these issues. Additionally, employing appropriate filtration methods with 0.22 µm or 0.45 µm filters is crucial to prevent column clogging and maintain performance integrity. By understanding the fundamental causes of maximum trailing, including secondary interactions and mobile phase conditions, laboratories can implement corrective measures that yield clearer, more reliable signals, thereby preserving the integrity of their chromatographic data. Furthermore, utilizing endcapped bonded phases can reduce the amount of unreacted silanols, thereby minimizing distortion. Incorporating guard columns also serves to protect against contaminants, ultimately enhancing overall chromatographic performance.

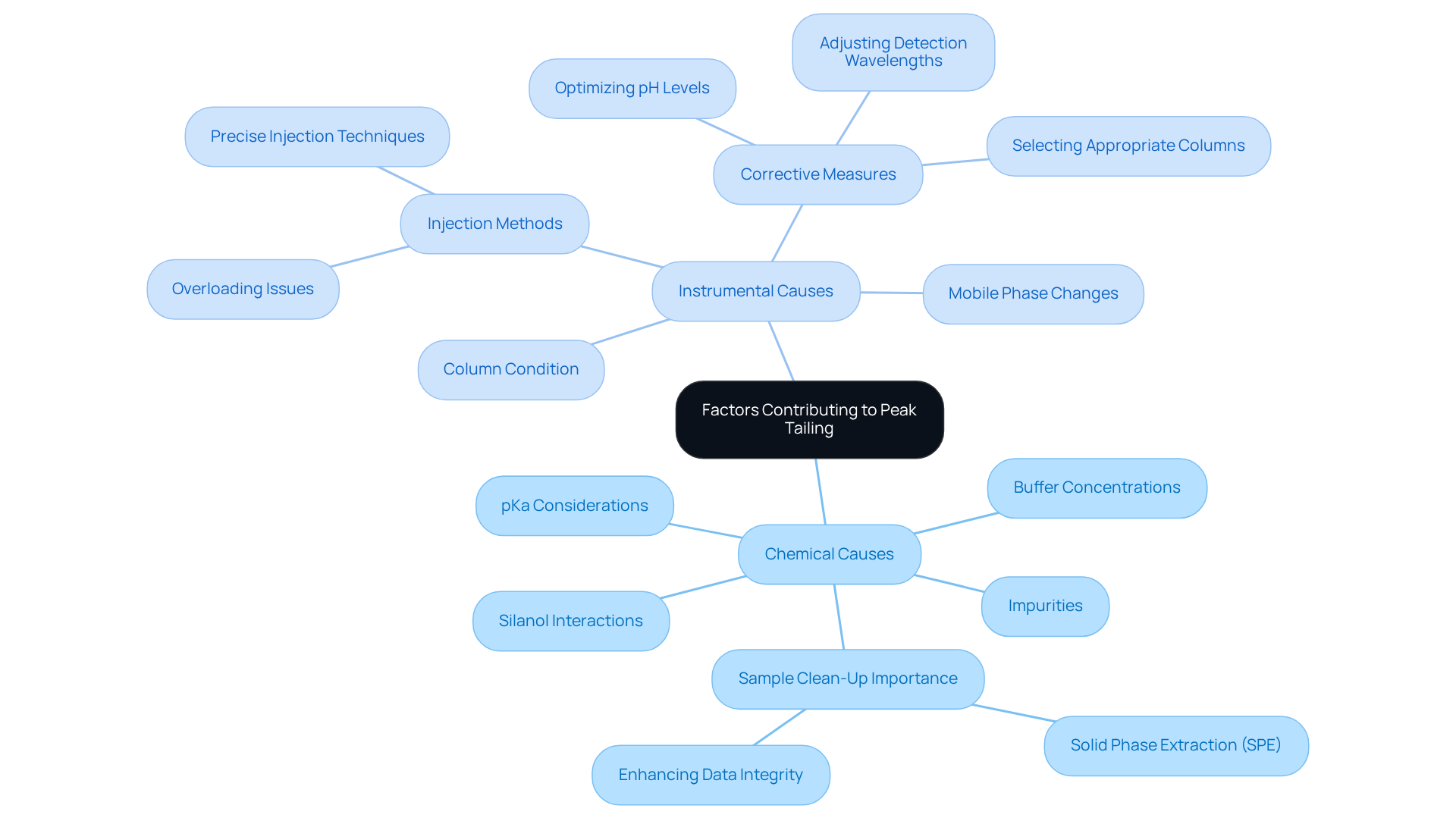

Identify Factors Contributing to Peak Tailing: Chemical and Instrumental Causes

Several factors contribute to peak tailing HPLC, which can be broadly categorized into chemical and instrumental causes.

Chemical Causes: Basic analytes can interact with residual silanol groups on the stationary phase, leading to tailing. This phenomenon is particularly common in reversed-phase chromatography. Operating near the pKa of the analyte can result in inconsistent retention and signal shape. Increasing buffer concentration at mid pH effectively masks silanol interactions, thereby minimizing tailing. Additionally, the presence of impurities or interfering substances can distort peak shapes, underscoring the importance of sample clean-up techniques like Solid Phase Extraction (SPE) to eliminate contaminants that may interfere with analysis. Regular sample cleaning not only enhances data integrity but also prolongs the lifespan of HPLC equipment by preventing contaminants from reaching the chromatography section or detector.

Instrumental Causes: The condition of the HPLC column is crucial; degradation or contamination can lead to uneven flow and retention issues. Consistent upkeep and observation of structural conditions are vital for optimal performance. Moreover, improper sample injection methods, such as overloading the column, can distort the signal. Ensuring precise injection volumes and techniques is essential for maintaining optimal integrity. Changes in the mobile phase can also influence the interactions between the analyte and the stationary phase, resulting in distortion. Employing endcapped or polar embedded HPLC supports can mitigate these effects and improve peak shape. Corrective measures for maximum discharge involve optimizing pH levels, adjusting detection wavelengths, and selecting suitable columns.

By understanding these factors, laboratory staff can take proactive measures to reduce tailing in their analyses, specifically addressing peak tailing HPLC. Sharp, well-defined summits in chromatograms lead to more reliable data and precise quantification, ultimately enhancing data accuracy and the dependability of analytical results. Addressing both chemical and instrumental factors enables laboratories to achieve sharper, well-defined signals, thereby enhancing the overall quality of their chromatographic analyses.

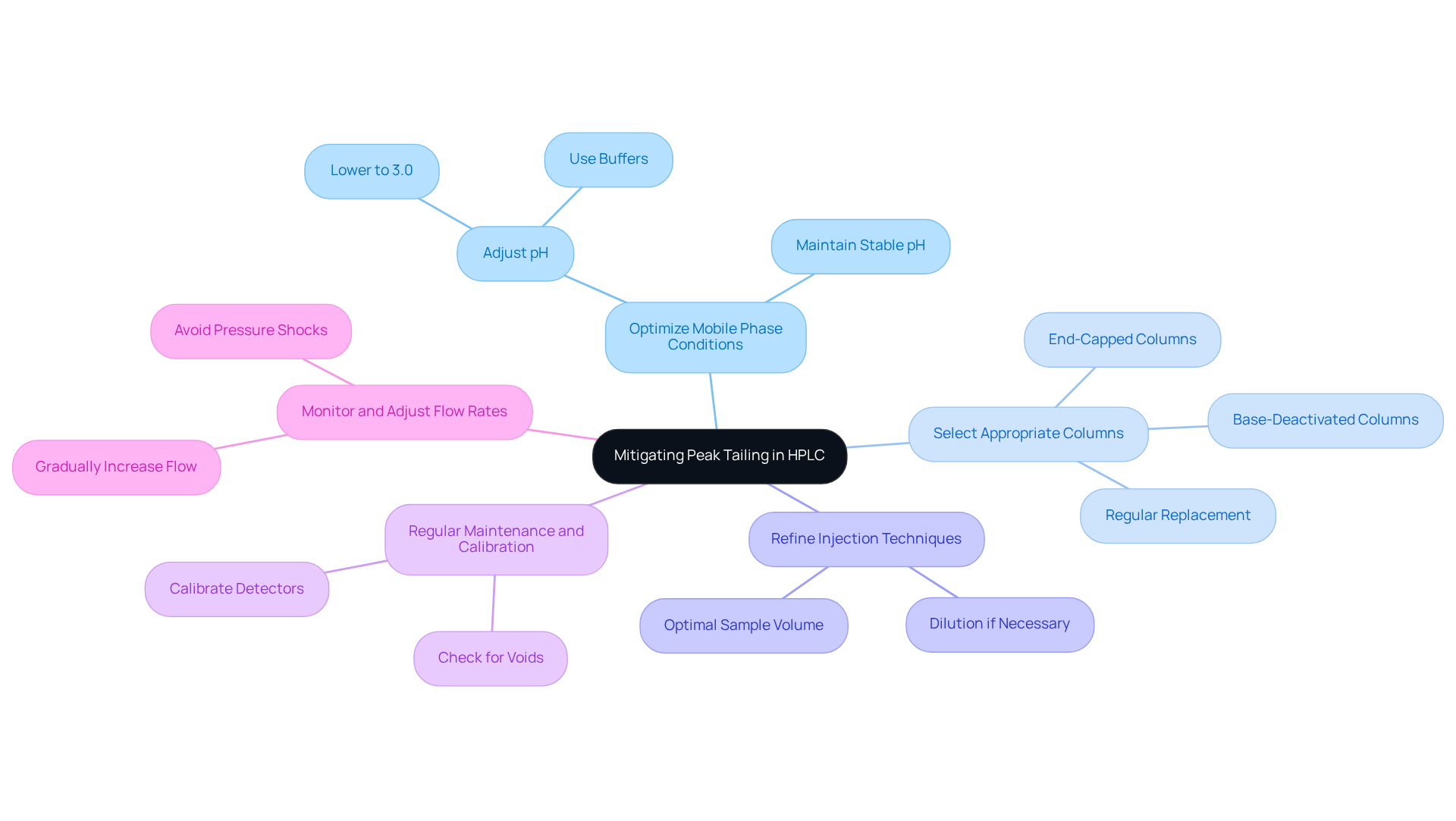

Implement Solutions to Mitigate Peak Tailing: Best Practices and Techniques

To effectively mitigate peak tailing HPLC, laboratories can adopt several best practices and techniques that are essential for achieving optimal analytical performance.

-

Optimize Mobile Phase Conditions: Adjusting the pH of the mobile phase is crucial to minimizing interactions with silanol groups. Operating at a pH below the pKa of the analyte can significantly decrease trailing. For instance, lowering the pH to 3.0 can reduce the asymmetry factor (As) for substances such as methamphetamine to 1.33. Additionally, utilizing buffers helps maintain stable pH levels throughout the analysis, which is vital for ensuring uniform shape profiles and reducing distortion.

-

Select Appropriate Columns: Choosing columns with end-capped or base-deactivated stationary phases is another effective strategy. These columns can diminish secondary interactions that contribute to peak tailing HPLC by approximately 50%, thereby improving peak symmetry. Furthermore, it is important to regularly replace any structures showing signs of degradation or contamination to maintain optimal performance.

-

Refine Injection Techniques: Proper injection techniques are essential. Ensuring that sample volumes fall within the optimal range prevents column overload, which can lead to peak fronting and tailing. If tailing persists, diluting the sample solution is a practical approach to consider.

-

Regular Maintenance and Calibration: Routine maintenance of the HPLC system is necessary to ensure all components function correctly. This includes checking for voids at the column inlet and ensuring proper fittings between tubing and columns to minimize dead volume. Regular calibration of detectors and other instrumentation is also critical for maintaining precision in signal detection, which is essential for reliable analytical results.

-

Monitor and Adjust Flow Rates: Adjusting flow rates can effectively alleviate peak tailing by optimizing the interaction time between the analyte and stationary phase. Gradually increasing flow rates can help avoid pressure shocks that may cause distortion at maximum levels.

By implementing these strategies, laboratories can significantly reduce the occurrence of peak tailing HPLC, which leads to enhanced analytical performance and improved data reliability. While statistics indicate that peaks with an As greater than 1.5 are acceptable for many assays, striving for lower values through these techniques can yield even better results.

Conclusion

Peak tailing in High-Performance Liquid Chromatography (HPLC) presents substantial challenges that undermine analytical accuracy and data integrity. A comprehensive understanding of the causes and implications of this phenomenon is crucial for chromatographers who aspire to enhance their results. By addressing both chemical and instrumental factors, laboratories can implement effective strategies to minimize tailing, thus achieving clearer and more reliable chromatographic signals.

This article explores the various causes of peak tailing, underscoring the critical interactions between analytes and stationary phases, as well as the significance of mobile phase conditions. It emphasizes best practices, including:

- Optimizing pH levels

- Selecting appropriate columns

- Refining injection techniques

- Conducting regular maintenance to mitigate these issues

Each strategy plays a vital role in enhancing analytical performance and ensuring the reliability of results.

Ultimately, tackling peak tailing transcends a mere technical challenge; it represents an essential step in preserving the integrity of chromatographic analyses. Laboratories are urged to adopt these best practices and prioritize routine maintenance to elevate data accuracy and reliability. By doing so, they can markedly improve their analytical outcomes, fostering a deeper understanding of the samples under analysis and upholding the highest standards of quality in laboratory results.