Overview

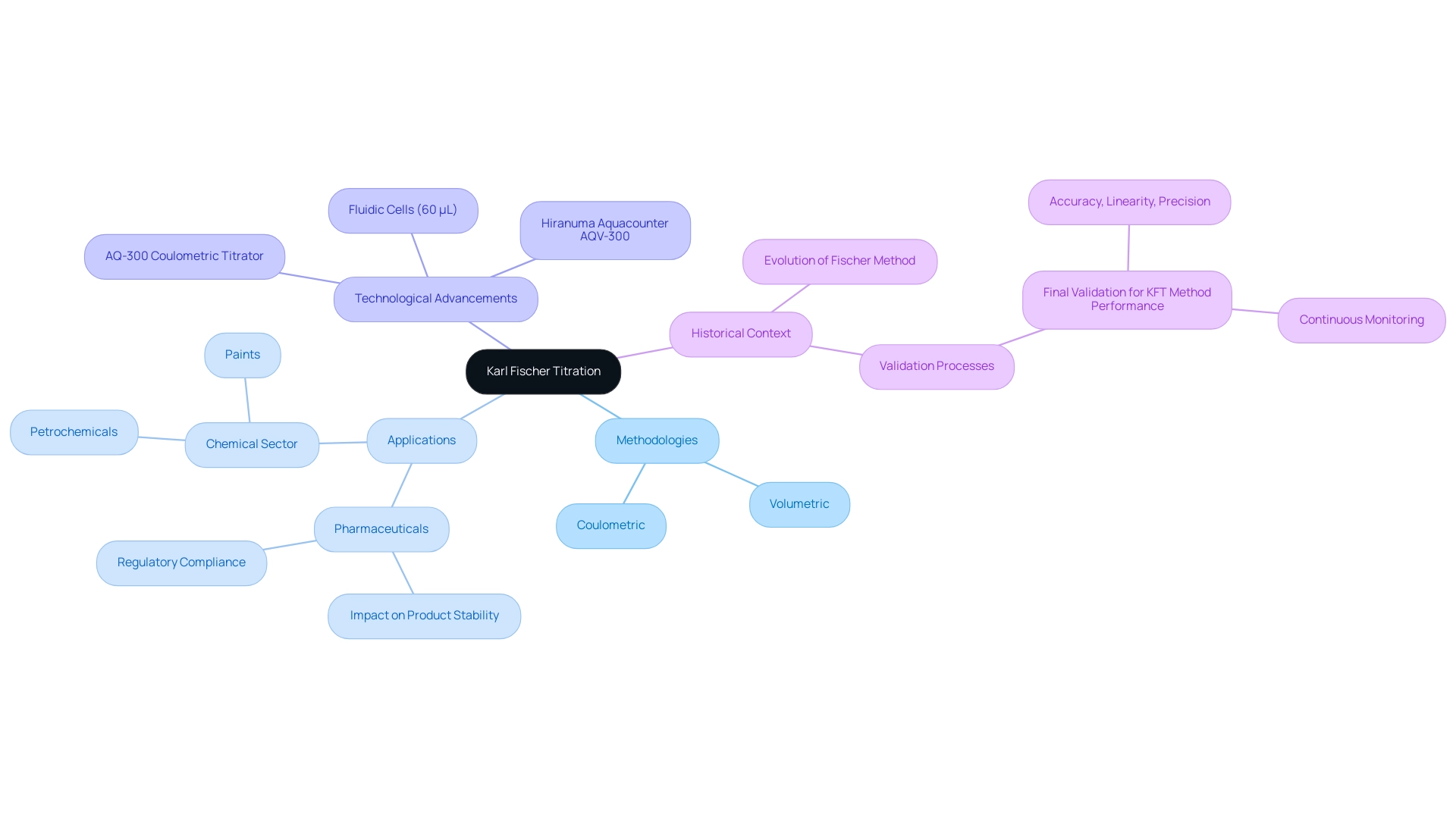

A KF titrator stands as a specialized instrument pivotal in Karl Fischer titration, a precise method for gauging moisture content across diverse samples. This measurement is crucial for industries including pharmaceuticals, food, and chemicals. The article delineates its essential role, detailing methodologies such as volumetric and coulometric titrations, alongside technological advancements that underscore the significance of accurate moisture analysis. Such precision is vital not only for product quality but also for regulatory compliance, ensuring that industry standards are met effectively.

Introduction

In the realm of analytical chemistry, moisture content analysis is a critical factor influencing product quality across various industries. Among the myriad techniques available, Karl Fischer titration stands out as a cornerstone method, renowned for its precision in determining water levels in diverse samples—from solids to liquids and gases.

This article delves into the intricacies of Karl Fischer titration, exploring its fundamental principles, methodologies, and significant applications, particularly within the pharmaceutical and chemical sectors. As advancements continue to shape this analytical technique, understanding its evolution and best practices is paramount for laboratory managers striving to uphold product integrity and regulatory compliance.

Join us as we uncover the essential features, pros and cons, and future trends that define the landscape of Karl Fischer titration technology.

Understanding Karl Fischer Titration: The Basics

The Fischer method stands as a fundamental analytical technique, essential for accurately determining moisture content across a diverse range of samples, including solids, liquids, and gases. Developed in the 1930s by Karl Fischer, this method leverages a chemical reaction between iodine and water, facilitating precise quantification of water content. The execution of this process can be achieved through two primary methodologies: volumetric and coulometric.

Each method is tailored for specific sample types and humidity levels, underscoring the necessity for laboratory managers to grasp their applications. The significance of the Fischer method in water content analysis is paramount, particularly within the pharmaceutical sector, where water levels critically influence product stability and effectiveness. Advanced technologies such as the AQ-300 Coulometric Fischer Titrator and the Hiranuma Aquacounter AQV-300 Volumetric Titrator exemplify cutting-edge solutions in humidity measurement, ensuring compliance with the Japanese Pharmacopoeia and suitability tests for drugs, including the kf titrator for precise moisture analysis. Recent advancements in Fischer titration technology have markedly enhanced the precision and effectiveness of water content measurements, with contemporary instruments featuring fluidic cells designed for inline measurements with a volume of just 60 μL.

This innovation allows for rapid evaluation without compromising accuracy, addressing the increasing demand for reliable water content assessment in pharmaceuticals. Historically, the evolution of the Fischer method has been profound, with continuous research and validation processes reinforcing its robustness. A notable case study titled "Final Validation for Further Verification of KFT Method Performance" illustrates the significance of method performance characteristics established during development. This study validated the method's accuracy, linearity, and precision, establishing a baseline for ongoing monitoring and potential enhancements post-implementation.

The findings highlight the crucial role of rigorous validation in sustaining the reliability of moisture analysis methods. Beyond pharmaceuticals, Fischer analysis is extensively utilized in the chemical sector, including industries such as petrochemicals and paints, where it plays a vital role in preserving product quality by detecting minute levels of water that could lead to deterioration and spoilage. Laboratories increasingly rely on the Fischer method to uphold product integrity and comply with regulatory standards. JM Science Inc. exemplifies this commitment to innovation by consistently updating its product offerings, including high-performance liquid chromatography (HPLC) solutions and innovative medical devices, while fostering strong relationships with leading manufacturers.

This dedication ensures that laboratories have access to the latest advancements in humidity evaluation technology. Ultimately, the integration of the kf titrator method into laboratory practices signifies a steadfast commitment to precision and quality in moisture analysis, rendering it an indispensable tool for laboratory managers across various industries. As B. H. articulated in their manuscript, the evolution of this method reflects an ongoing commitment to enhancing analytical capabilities within the scientific community.

Types of Karl Fischer Titration: Volumetric vs. Coulometric

Karl Fischer analysis is fundamentally categorized into two distinct methodologies: volumetric and coulometric techniques. Volumetric analysis entails the addition of a titrant with a known concentration to the sample until the endpoint is reached, typically indicated by a color change. This method proves particularly effective for samples with higher water content, ranging from 0.1% to 100%.

Conversely, coulometric analysis generates iodine in situ through an electrochemical reaction, making it ideal for samples with low water content, often below 1%. The choice between these two techniques primarily hinges on the water content present in the sample and its specific characteristics.

Recent research underscores the advantages of each method across various applications. For instance, volumetric analysis is frequently employed in high humidity samples, where its straightforward approach facilitates precise water content measurement. In laboratory settings, volumetric analysis is preferred for its reliability in handling samples with water content exceeding 0.1%, while coulometric analysis is favored for its sensitivity in low humidity scenarios.

Statistics indicate that volumetric analysis remains a preferred option in laboratories, particularly for samples with humidity levels surpassing 1%. Meanwhile, coulometric methods are gaining traction due to their accuracy in low humidity contexts. Notably, at a flow rate of 3 L/min, bubble diameter increases from 0.0046 mm at 1052.5 m/s to 0.0074 mm at 9222 m/s, illustrating the effectiveness of measurement techniques in practical applications. Industry specialists emphasize the importance of selecting the appropriate method based on the specific analytical needs, with many advocating for volumetric techniques in routine water content assessments due to their established precision.

Lauri Jalukse observes, "A high-accuracy Winkler method has been developed for the determination of dissolved oxygen concentration," underscoring the critical nature of precision in measurement techniques.

Case studies further exemplify the practical applications of these methodologies. For example, in a study on gas phase extraction utilizing a drying oven, the InMotion Autosampler KF Oven demonstrated the efficacy of volumetric analysis in examining multiple samples simultaneously, thereby optimizing workflows in water content determination processes. This method is particularly advantageous for samples that cannot be directly introduced into a measurement vessel, such as those that may react with the Karl Fischer reagent or release water gradually.

In summary, understanding the distinctions between volumetric and coulometric analysis techniques is crucial for laboratories aiming to achieve accurate water content evaluations. The current market reflects a balanced distribution between both methods, with KF titrators commanding a significant share due to their versatility and reliability across various applications. JM Science Inc. distinguishes itself through its commitment to quality, customer support, and innovation, ensuring that laboratories have access to superior titration solutions tailored to their needs.

Applications of KF Titrators in Moisture Analysis

KF titrators serve a pivotal role in industries where water content is a critical parameter. In the pharmaceutical sector, precise humidity analysis is essential for ensuring the stability and efficacy of drug formulations. Research indicates that even slight variations in humidity levels can significantly impact drug stability, potentially leading to efficacy issues.

For instance, residual humidity can result in light scattering and variations in near-infrared (NIR) absorption, both of which are crucial for preserving product integrity. As noted in the International Journal of Pharmaceutics, "Residual humidity might cause light scattering and NIR absorption in signal variation."

In the food sector, humidity levels directly influence product quality, shelf life, and safety. Accurately determining water content in baked goods, dairy products, and oils is vital for adhering to quality standards and ensuring consumer safety. Notably, as the number of tableting runs increases, the temperature of tablets gradually rises due to heat transfer from compression tools to powder particles. This temperature increase complicates water analysis if not monitored accurately, underscoring the necessity for precise measurement techniques.

The KF titrator is also extensively utilized in the chemical industry for quality control of both raw materials and finished products, ensuring compliance with stringent regulatory requirements. A recent case study employing K-fold cross-validation validated a calibration model for water content prediction, confirming its effectiveness across various tablet batches. This systematic approach enhances the reliability of water content evaluation, which is vital for maintaining product quality.

As of 2025, the applications of KF titrators in the pharmaceutical sector continue to expand, reflecting a growing emphasis on the importance of humidity assessment in both pharmaceuticals and food manufacturing. Key sectors employing the KF titrator for water content evaluation include:

- Pharmaceuticals

- Food and beverage

- Chemical manufacturing

All recognize the significant impact of water levels on product quality and safety. Real-world examples underscore the effectiveness of KF analysis in determining water content in food products, highlighting its essential role in ensuring adherence to safety standards and enhancing overall product quality.

Moreover, advancements in humidity measurement technologies, such as inline scan collection processes that take under 2 seconds, are improving the efficiency and precision of water content determination.

Pros and Cons of Karl Fischer Titration

The Fischer method is widely acknowledged for its remarkable precision and specificity in measuring water content, establishing itself as the gold standard in humidity evaluation. This method can detect water content levels as low as 0.001%, making it indispensable in industries that demand rigorous quality control. A recent study demonstrated that Fischer's method surpassed other analytical techniques in cellulose water content assessment, highlighting its dependability in essential applications.

The research provides statistically-backed information on the precision of analytical methods for cellulose moisture assessment, emphasizing the necessity for additional exploration.

Despite its benefits, significant restrictions are associated with Karl Fischer analysis. The process can be time-consuming, particularly in manual volumetric analysis, which may hinder efficiency in high-throughput environments. Additionally, meticulous sample preparation is essential to prevent contamination, which can compromise results.

The safety risks posed by the reagents utilized in the KF titrator necessitate stringent safety measures during handling, as real-world examples illustrate these challenges. In a case study involving Fourier-transform Infrared Spectroscopy (FT-IR) evaluation, researchers encountered difficulties in determining water content due to the inherent complexities of sample preparation and the potential for reagent interference. Such challenges emphasize the necessity for continuous improvement and innovation in humidity analysis techniques.

Therefore, this study offers a systematic comparison between various analytical techniques, emphasizing the significance of understanding the strengths and weaknesses of each approach.

Moreover, while volumetric analysis is effective, it is often less time-efficient compared to coulometric methods, which can analyze samples more rapidly and with less reagent consumption. The InMotion Autosampler KF Oven exemplifies this advancement, as it can analyze up to 26 samples simultaneously using gas-phase extraction, simplifying sample preparation and enhancing efficiency. This distinction is vital for laboratories seeking to enhance their workflows while ensuring precision.

In summary, while the Fischer method remains a powerful instrument for moisture assessment, comprehending its limitations and challenges is crucial for effective application in laboratory environments.

Key Features of Popular KF Titrators

Choosing the appropriate kf titrator necessitates careful consideration of several essential features. The initial decision between volumetric and coulometric titration methods is crucial, as each serves distinct analytical needs. For instance, the Hiranuma Aquacounter AQV-300 Volumetric and AQ-300 Coulometric kf titrators are specifically designed for drug and medicine testing, ensuring compliance with the Japanese Pharmacopoeia.

The detection limits of kf titrators are optimized for precise content measurements, making them suitable for a variety of pharmaceutical applications. Furthermore, ease of use is paramount; contemporary KF titrators are increasingly equipped with automated features that enhance the process, significantly reducing the risk of human error.

In addition to automation, advanced data management capabilities are becoming standard in modern kf titrators. These features facilitate seamless tracking and reporting of results, essential for maintaining compliance and ensuring data integrity in laboratory settings. Moreover, the kf titrator's compatibility with a wide range of sample types and its ability to accommodate varying moisture content levels are critical, providing the versatility needed for diverse applications.

For instance, the AQV-300 features a kf titrator that manages broad sample compatibility, from semi-solids to challenging matrices, with speed and precision.

As laboratories increasingly adopt automated solutions, understanding the key features of the kf titrator empowers lab managers to make informed decisions that enhance operational efficiency and analytical accuracy. This information is current as of June 27, 2023.

Best Practices for Conducting Karl Fischer Titrations

Achieving precise results in Karl Fischer analysis necessitates strict adherence to several best practices. Proper sample preparation is paramount; this may involve dissolving solids in an appropriate solvent or finely dispersing them within the titration vessel. As Alireza Kord, Ph.D., emphasizes, careful sample preparation is essential for dependable water content evaluation.

For instance, when dealing with samples that are insoluble or release water slowly, utilizing an oven to vaporize water can significantly enhance measurement accuracy. This approach is substantiated by a recent case study titled "Karl Fischer Titration Essentials: Verification of Linearity," which discusses the necessity of verifying the linearity of the system involving the KF titrator and oven, particularly for samples that are insoluble or release water slowly.

Regular calibration of the KF titrator is essential, alongside the use of certified standards to verify titrant concentration. This practice not only ensures precision but also aligns with industry standards, which is crucial for laboratories striving for high-quality moisture evaluation. Furthermore, maintaining a controlled environment—free from humidity and contaminants—is vital for obtaining reliable measurements.

Documentation throughout the titration process represents another key aspect. Documenting any deviations from standard procedures assists in troubleshooting and improving future evaluations. Notably, statistics indicate that water content using the modified oven cKFT method can be as low as 0.1% w/w, underscoring the importance of meticulous methodology in moisture analysis.

Additionally, a growing trend for automation in laboratory processes is evident, with various standardized and tailor-made systems being developed to enhance accurate sampling and efficiency. By adhering to these guidelines, laboratories can significantly improve the precision of their analysis results, ultimately contributing to more dependable data in pharmaceutical and chemical applications.

Future Trends in Karl Fischer Titration Technology

The future of Karl Fischer analysis technology stands on the brink of transformative advancements, particularly through automation and data integration. Emerging trends highlight the rise of smart titration systems that leverage artificial intelligence to fine-tune titration parameters, significantly enhancing both accuracy and efficiency. Furthermore, innovations in reagent formulations are paving the way for safer, more environmentally friendly options, aligning with the industry's growing emphasis on sustainability.

Moreover, the integration of advanced data analytics tools is poised to revolutionize the tracking and assessment of water content. These tools will empower laboratories to monitor trends over time, providing critical insights that bolster quality control across various sectors, including pharmaceuticals and food production. As these technologies continue to evolve, they promise to streamline moisture analysis processes, making them not only more efficient but also more reliable. In this context, Kevin's role in transporting samples and supplies allows laboratory staff to focus on value-added activities, illustrating the practical benefits of automation.

Expert predictions indicate that the adoption rates of AI in measurement technology will accelerate, driven by the pressing need for precision in laboratory environments. Real-world examples of AI integration in chemical analysis processes are already emerging, showcasing significant improvements in operational workflows and data accuracy.

Furthermore, the Genera Automatic Scheduling Software by Retisoft exemplifies how lab automation software optimizes laboratory processes, enhancing overall efficiency. Competitive developments in the lab automation market, including product launches and advancements, provide a broader context for these innovations in Fischer technology, particularly with the KF titrator. As the landscape of the KF titrator evolves, laboratories that adopt these innovations will be well-positioned to enhance their analytical capabilities and maintain a competitive edge in the market.

JM Science Inc.'s commitment to quality and customer support further underscores the importance of reliable instrumentation in this evolving field.

Conclusion

Karl Fischer titration remains a pivotal method in analytical chemistry, particularly for moisture content analysis across various industries. Its historical significance, rooted in the precise determination of water levels, has evolved with advancements in technology, making it an indispensable tool for laboratory managers. Understanding the two primary methodologies—volumetric and coulometric titration—enables laboratories to select the most suitable approach for their specific needs, ensuring accuracy and compliance with regulatory standards.

The broad applications of Karl Fischer titrators extend beyond pharmaceuticals to the food and chemical industries, where moisture content directly impacts product quality and safety. By employing rigorous best practices and leveraging modern innovations, such as automated systems and advanced data analytics, laboratories can enhance their moisture analysis capabilities. This commitment to precision not only upholds product integrity but also fosters regulatory compliance, ultimately benefiting the end consumers.

Looking ahead, the future of Karl Fischer titration technology is bright, with trends indicating a shift towards automation and smarter analytical processes. Embracing these advancements will empower laboratories to streamline workflows, improve data accuracy, and maintain a competitive edge in an increasingly demanding market. As the landscape of moisture analysis continues to evolve, the adoption of innovative techniques will be crucial in meeting the challenges of quality control across diverse sectors.