Overview

PEEK, or polyether ether ketone, stands as a high-performance thermoplastic distinguished by its remarkable strength, chemical resistance, and thermal stability. These attributes render it particularly suitable for applications within the pharmaceutical and aerospace sectors. Notably, this material plays a crucial role in High-Performance Liquid Chromatography (HPLC) systems and medical devices. Its exceptional properties guarantee reliable performance even under extreme conditions. However, it is essential to consider compatibility factors with specific solvents to maximize its effectiveness.

Introduction

Polyether Ether Ketone (PEEK) tubing has emerged as a crucial element in various high-performance applications, particularly within the pharmaceutical and aerospace industries. Its remarkable strength, chemical resistance, and thermal stability position PEEK tubing to not only meet but often exceed the rigorous standards of modern technology.

However, despite these advantages, the selection and application of PEEK tubing present challenges, particularly concerning compatibility with certain solvents and the necessity for meticulous handling. To fully leverage the benefits of this advanced material while avoiding potential pitfalls, it is essential to consider several key factors.

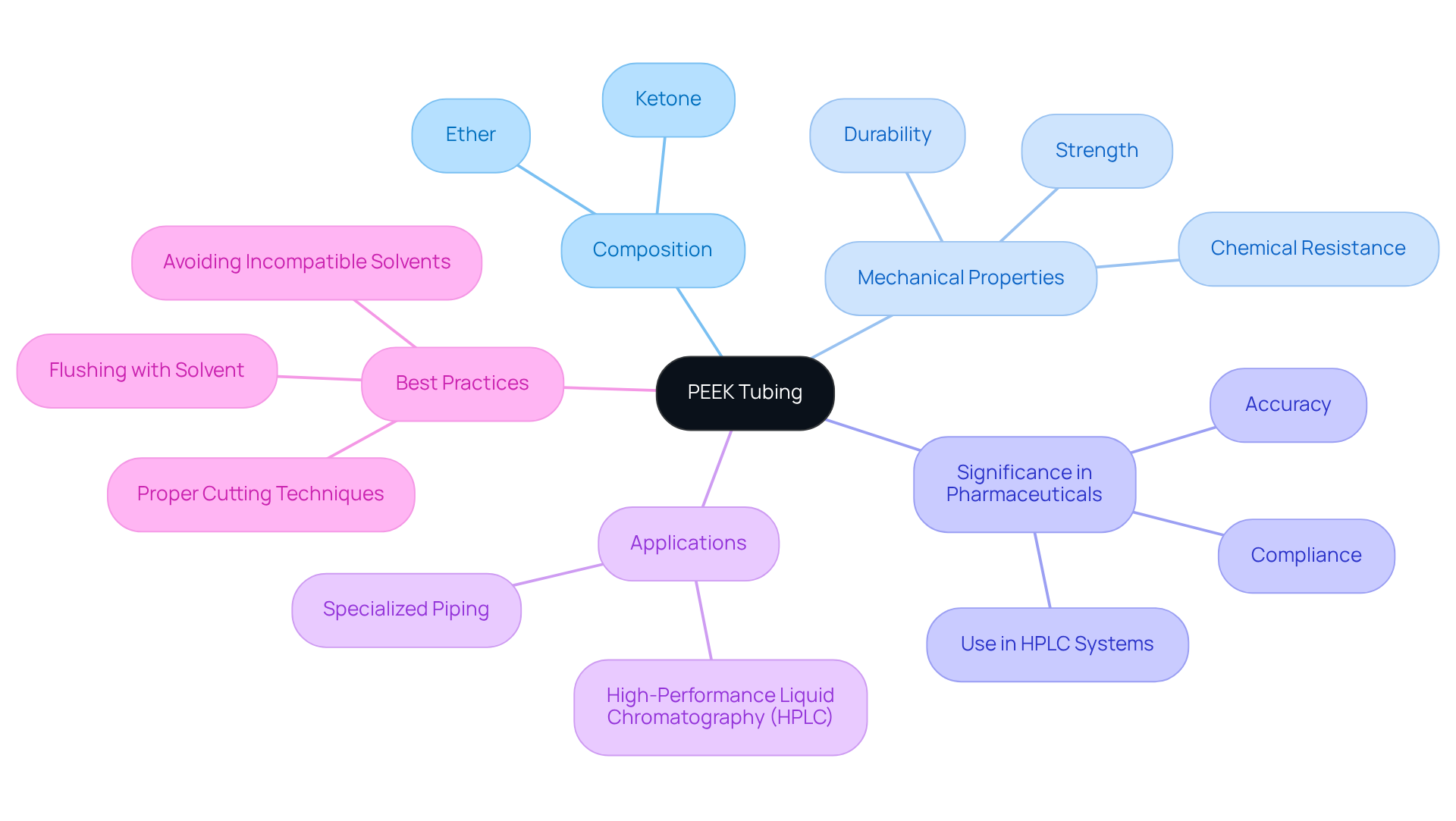

Define PEEK Tubing: Composition and Significance

Polyether Ether Ketone tubing stands out as a high-performance thermoplastic, recognized for its exceptional mechanical and material properties. Composed of repeating units of ether and ketone, this material is celebrated for its strength, durability, and resistance to harsh chemicals and high temperatures. Such attributes render it an ideal choice for applications demanding dependable performance under extreme conditions.

The significance of these materials is particularly pronounced in the pharmaceutical sector, where accuracy and dependability are paramount. Its ability to maintain structural integrity in demanding environments ensures compliance with the rigorous standards required for pharmaceutical applications. For instance, specialized piping is frequently utilized in high-performance liquid chromatography (HPLC) systems, where its compatibility with various solvents enhances analytical capabilities. However, it is essential to note that this type of piping is unsuitable for use with tetrahydrofuran (THF) and chlorinated solvents, as these can compromise its integrity and lead to brittleness.

In laboratory settings, the advantages of employing high-performance polymer pipes extend beyond their chemical resistance. Their convenience and cost-effectiveness position them as a preferred choice among researchers. The polymer can be easily cut to preferred lengths, allowing for customization in diverse applications. Adhering to proper cutting techniques is crucial to avoid blocking the lumen, thereby ensuring optimal performance in HPLC systems. Best practices recommend flushing the pipes with solvent after cutting to eliminate any particulate matter, thus preserving the integrity of the analytical process.

Overall, the distinctive characteristics and adaptability of this material underscore its importance in the pharmaceutical industry, where it plays a vital role in ensuring precise and reliable outcomes in laboratory assessments. This aligns with JM Science Inc.'s commitment to providing high-quality products for chemistry and medical diagnostics, highlighting the significance of specialized materials in achieving accurate results.

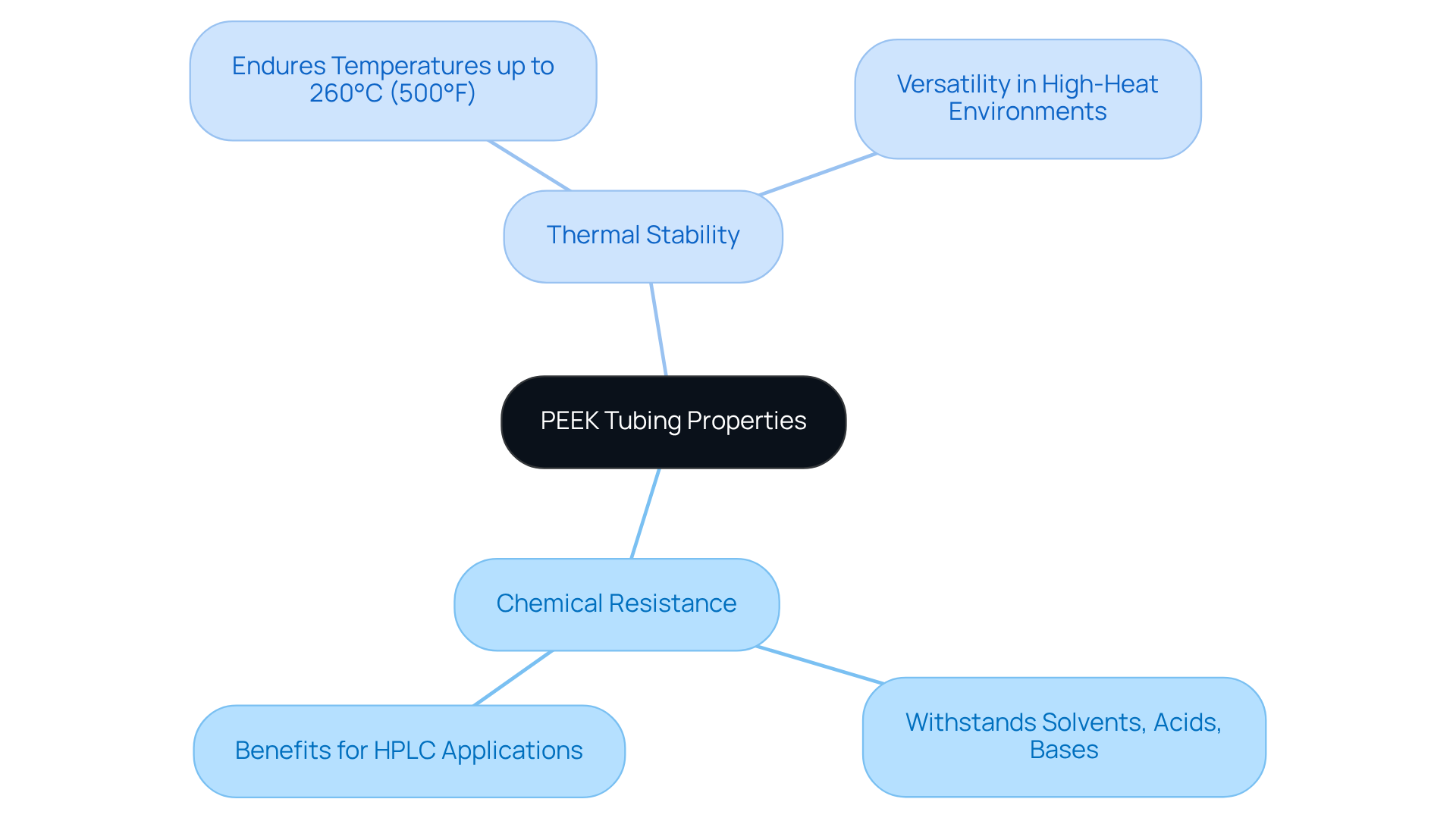

Explore Key Properties of PEEK Tubing: Chemical Resistance and Thermal Stability

This type of plastic exhibits exceptional chemical resistance, allowing it to withstand contact with a wide range of solvents, acids, and bases without deterioration. Such a characteristic proves particularly advantageous in high-performance liquid chromatography (HPLC) applications, where the integrity of the pipes is crucial for achieving precise outcomes. Additionally, this material demonstrates remarkable thermal stability, enduring temperatures up to 260°C (500°F) without compromising its mechanical properties. This thermal resilience ensures that the material can be employed in high-heat environments, thereby enhancing its versatility in both laboratory and industrial settings.

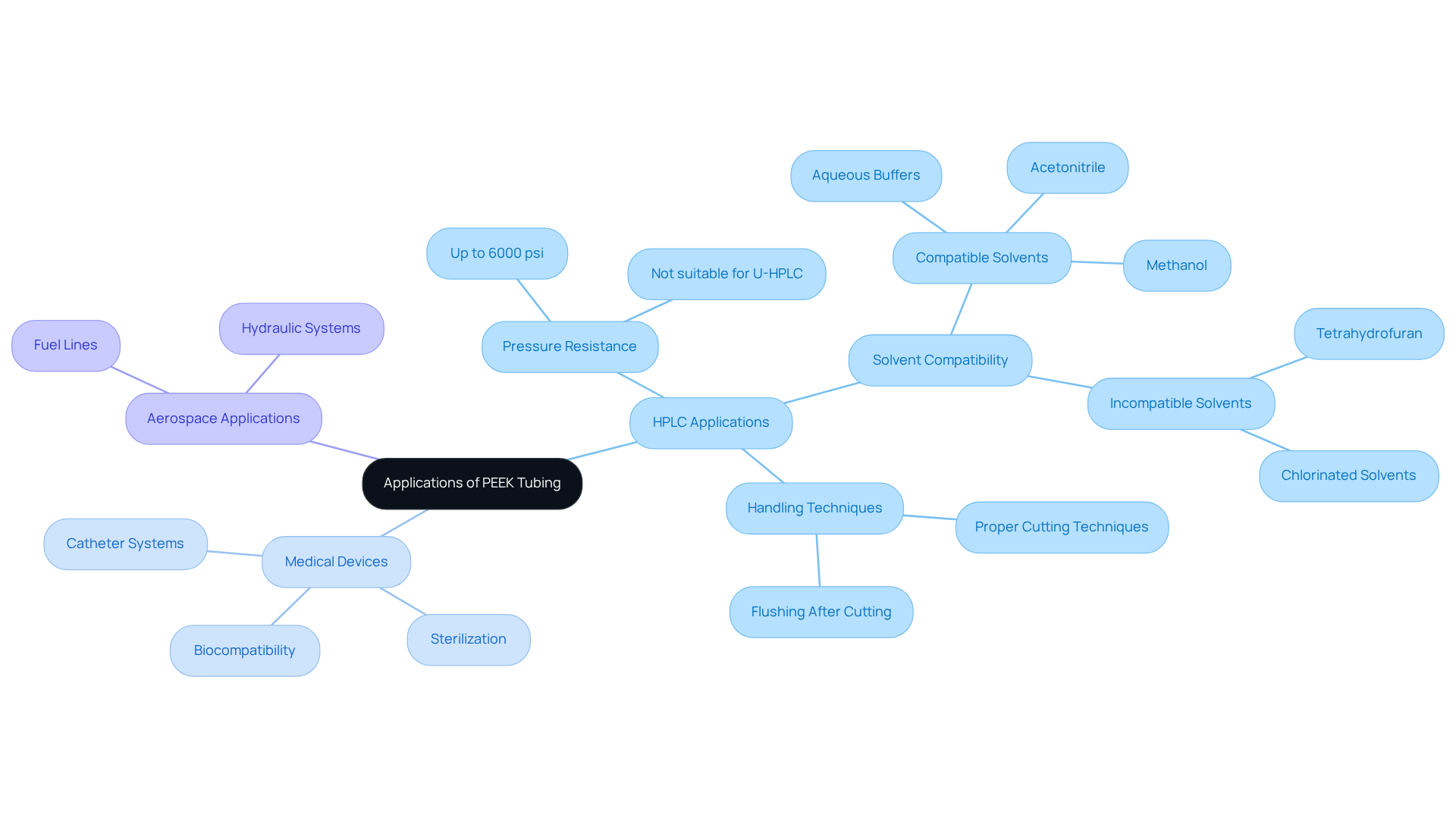

Examine Applications of PEEK Tubing: HPLC and Beyond

Polyether ether ketone material serves as a cornerstone in High-Performance Liquid Chromatography (HPLC) systems, distinguished by its capacity to withstand high pressures—up to 6000 psi—while resisting chemical degradation. However, it is crucial to note that this material is unsuitable for the elevated pressures typical in Ultra-High-Performance Liquid Chromatography (U-HPLC) applications. This consideration is vital for laboratories striving to achieve accurate and reliable analytical results.

Beyond its fundamental role in HPLC, this polymer is increasingly utilized in medical devices, where its biocompatibility and sterilization properties are essential for ensuring patient safety and device effectiveness. For instance, specialized pipes are employed in catheter systems and drug delivery devices, where maintaining the integrity of materials is critical for optimal performance.

Furthermore, it is important to recognize that not all HPLC solvents are compatible with specific plastic pipes; while aqueous buffers, acetonitrile, and methanol are acceptable, tetrahydrofuran and chlorinated solvents are not recommended due to potential brittleness and background issues in LC-MS applications. Proper cutting and handling techniques are imperative to prevent obstruction of the lumen in specialized pipes, and it is advisable to flush a few milliliters of solvent through the pipes after cutting to remove any particles resulting from the cutting process.

In the aerospace sector, polyether ether ketone pipes are favored for fuel lines and hydraulic systems, where they must operate reliably under extreme conditions. Their resistance to harsh chemicals and high temperatures renders them an ideal choice for these demanding applications.

The increasing utilization of specialized materials in healthcare equipment is noteworthy, driven by technological advancements and a heightened focus on patient care. As the industry evolves, the versatility of this material continues to play a pivotal role in innovations within both healthcare and aerospace, underscoring its importance as a high-performance substance across diverse sectors.

Considerations for Selecting PEEK Tubing: Supplier Quality and Customization

Selecting high-performance plastic piping requires a careful assessment of supplier quality, as this choice directly impacts the material's performance and reliability. Reputable suppliers offer comprehensive specifications and certifications that guarantee adherence to industry standards. Evaluating the reputation and transparency of suppliers is essential to mitigate potential risks. Moreover, rigorous quality control measures—such as testing for chemical purity and dimensional accuracy—serve as critical indicators of a supplier's dependability.

Customization options, including diameter, length, and wall thickness, empower users to tailor the material to meet specific laboratory requirements. For example, customized polymer solutions have been effectively integrated into various analytical processes, enhancing operational efficiency and delivering superior results. The versatility of these materials is particularly evident in the oil and gas sector, where personalization plays a vital role.

By emphasizing high-quality, customized peek and peek tubing, laboratories can markedly enhance their analytical capabilities and overall performance.

Conclusion

Polyether Ether Ketone (PEEK) tubing stands out as an essential component in a multitude of high-performance applications, attributed to its remarkable strength, durability, and chemical resistance. This specialized thermoplastic not only fulfills the rigorous demands of industries such as pharmaceuticals and aerospace but also guarantees reliable performance in challenging environments. Its capacity to endure extreme temperatures and pressures renders it indispensable for processes that necessitate precision and integrity.

The article delves into key insights regarding the properties and applications of PEEK tubing. Notable advantages, such as its exceptional chemical resistance and thermal stability, are particularly highlighted in contexts like high-performance liquid chromatography (HPLC) and medical device manufacturing. Furthermore, the significance of selecting reputable suppliers and the advantages of customization are underscored, equipping users to tailor solutions to their specific laboratory and industrial requirements.

In an environment where accuracy and reliability are of utmost importance, the significance of PEEK tubing is paramount. As industries continue to advance, the demand for high-quality materials like PEEK is poised to escalate. Stakeholders are urged to prioritize comprehensive supplier evaluations and consider the unique properties of PEEK tubing to enhance operational efficiency and foster innovation. By embracing these insights, organizations can not only achieve superior analytical results but also pave the way for technological advancements and improved patient care across various sectors.