Overview

This article addresses essential practices for optimizing laboratory performance with 1.5 mL microcentrifuge tubes. It emphasizes the importance of:

- Material selection

- Handling techniques

- Storage conditions

- Compatible accessories

By highlighting the advantages of polypropylene over polystyrene—specifically in terms of durability and chemical resistance—it outlines best practices for minimizing contamination. Additionally, it recommends specific storage and organizational accessories that enhance both efficiency and sample integrity. Understanding these factors is crucial for any laboratory aiming to maintain high standards in their operations.

Introduction

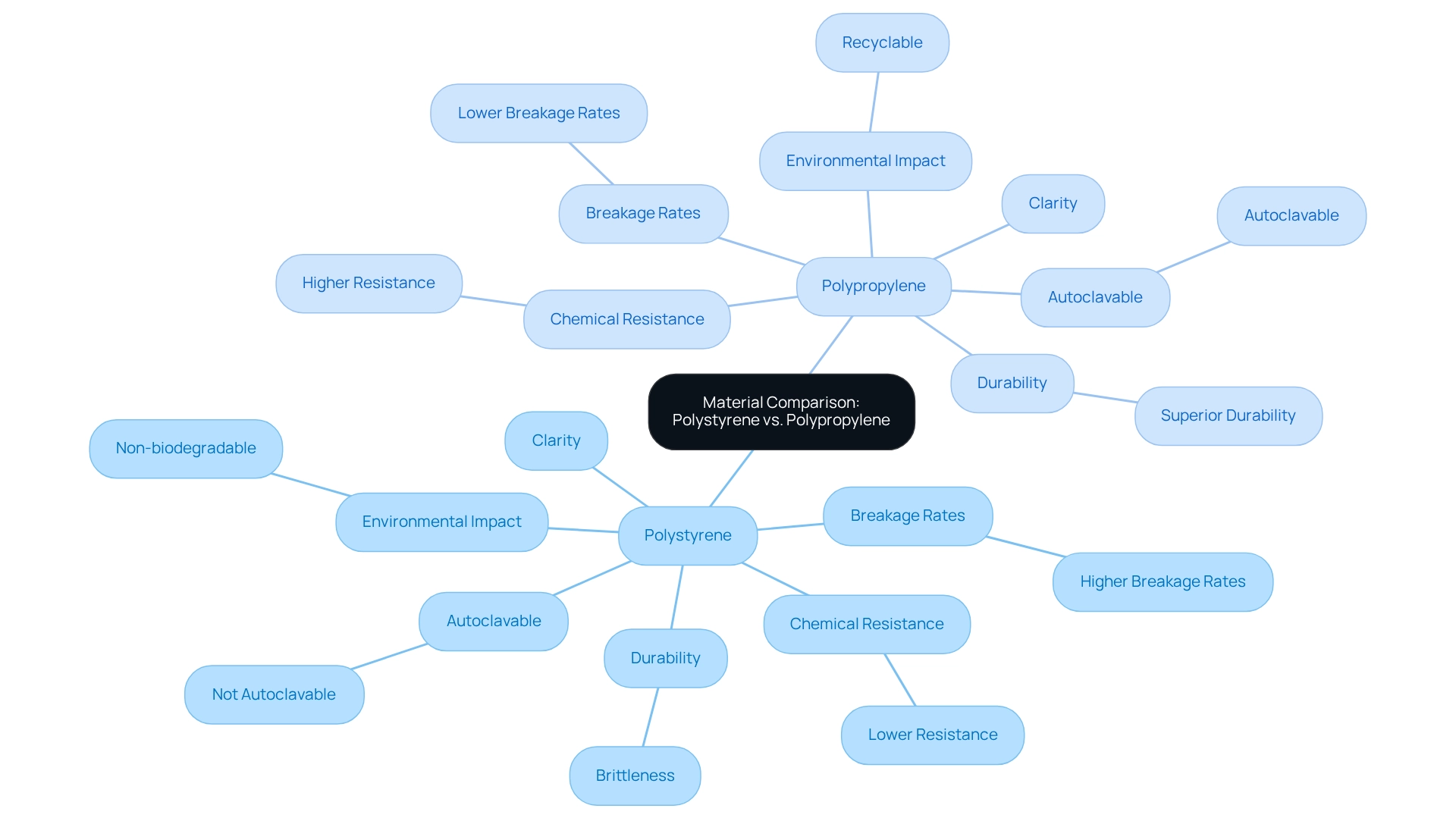

In the realm of laboratory work, the selection of materials and techniques plays a pivotal role in determining the reliability and accuracy of results. Understanding the distinctions between polystyrene and polypropylene in 1.5 mL microcentrifuge tubes is essential for making informed decisions. Polystyrene, while offering clarity for visual inspection, presents limitations in chemical resistance and durability that can hinder its effectiveness in various applications. Conversely, polypropylene stands out as a robust alternative, capable of withstanding higher stress and providing superior chemical resistance, thus becoming the preferred choice in numerous laboratory settings.

Beyond material selection, the implementation of proper handling techniques and optimal storage conditions is crucial in minimizing contamination risks and preserving sample integrity. By utilizing compatible accessories, laboratories can further enhance operational efficiency, ensuring that each step in the experimental process is executed with precision. This article explores these vital aspects, equipping researchers with the knowledge necessary to optimize their laboratory practices.

Choose the Right Material: Polystyrene vs. Polypropylene

When selecting between polystyrene and polypropylene for 1.5 mL microcentrifuge tubes, several critical factors warrant careful consideration.

Polystyrene is renowned for its clarity, facilitating easy visual inspection of samples. However, it exhibits lower chemical resistance and higher breakage rates under stress, making it less suitable for long-term storage or use in harsh chemical environments. Its brittleness and inadequate chemical resistance limit applications requiring autoclaving, as it cannot withstand high temperatures and pressures. Furthermore, it is important to note that polystyrene is non-biodegradable and can persist for centuries, raising significant environmental concerns regarding its use.

In contrast, polypropylene offers superior durability and resistance to a broader spectrum of chemicals, establishing itself as the preferred choice for most laboratory applications. These containers can withstand greater centrifugation forces, significantly decreasing the chance of breakage and maintaining the integrity of samples during processing. Additionally, polypropylene cylinders are autoclavable, which is essential for preserving sterility in sensitive experiments. Recent advancements in polypropylene production have further enhanced its performance, making it an even more dependable choice for scientific settings.

Studies indicate that polypropylene tubes demonstrate lower breakage rates compared to , particularly in high-stress applications. Expert opinions consistently favor polypropylene for its versatility and robustness in various research environments. As Neel Daphtary, President of Chemtech International, observes, "Selecting the appropriate material is crucial for guaranteeing the dependability of test results."

In summary, while polystyrene may be beneficial for uses where visibility of the specimen is crucial, polypropylene is typically recommended for 1.5 mL tubes due to its strength, chemical resistance, and capacity to uphold sterility, making it the best option for most research applications. Furthermore, considerations of cost and recyclability should also influence the decision-making process when choosing between these two materials, as they play a significant role in sustainability within the lab.

Implement Proper Handling Techniques to Avoid Contamination

To minimize contamination risks when handling 1.5 mL microcentrifuge tubes, it is essential to follow these best practices:

- Use Gloves: Always wear disposable gloves to prevent oils and contaminants from your skin from transferring to the samples. Studies indicate that improper handling techniques can lead to significant contamination rates in laboratory settings, with only 6 of successfully removing an average of 95% of the original data. This underscores the necessity of this practice.

- Avoid Contacting the Interior: Never touch the inside of the container or the cap. Utilize sterile methods when transferring specimens to maintain a contamination-free environment. This is crucial, as errors in specimen processing can lead to misdiagnoses, illustrated by a case involving a 12-year-old girl where contamination could have skewed results. Clearly label each of the 1.5 mL tubes with relevant information such as specimen name, date, and experiment details. This practice not only helps in monitoring specimens but also lowers the risk of mix-ups, which can jeopardize experimental integrity.

- Work in a Clean Area: Conduct all specimen handling in a designated clean area, preferably within a laminar flow hood, to minimize exposure to airborne contaminants. Applying this technique is essential, as research experiments have demonstrated that environmental factors can significantly influence sample integrity over time.

As P. C. J. Aspden observed, "Application of Total Quality Management concepts to testing requires that the total process, including preanalytical and postanalytical phases, be managed to reduce or, ideally, eliminate all defects within the process itself." By adhering to these techniques, laboratories can significantly reduce contamination risks, thereby ensuring the reliability and accuracy of their results.

Optimize Storage Conditions for Sample Integrity

To ensure the integrity of samples stored in , implementing best practices is essential.

- Temperature Control: Biological samples must be stored at specific temperatures to prevent degradation. Typically, of -20°C or -80°C is advised. Research indicates that at 37°C, the apparent persistence length of DNA can reach a maximum of 10.7 ± 0.3 nm, underscoring the importance of cooler conditions for maintaining sample integrity. Furthermore, a case study titled "Mechanisms of DNA Flexibility and Bending" reveals that increased flexibility at elevated temperatures can aid in genome compaction and organization, further accentuating the need for stringent heat control.

- Avoid Fluctuations: It is crucial to minimize temperature variations by utilizing dedicated freezers or refrigerators. Regular access to storage units can lead to fluctuations that jeopardize sample integrity. Studies have shown that these fluctuations can significantly impact the compaction and bending of DNA, which is vital for preserving its structural integrity.

- Humidity Control: Monitoring humidity levels is equally important to prevent errors caused by dry heat. Implementing humidity control measures enhances the reliability of stored items and mitigates degradation risks.

- Use Proper Containers: Storing tubes in robust, labeled containers or racks prevents physical damage and facilitates easy access. This organization not only safeguards specimens but also contributes to a clean and efficient workspace.

- Limit Exposure to Light: To protect light-sensitive materials, use opaque containers or store them in dark environments to prevent photodegradation. Expert recommendations highlight that light exposure can cause substantial changes in material composition, further emphasizing the necessity for careful storage methods. As noted by B. Chatelain, addressing pre-analytical concerns is vital for preserving specimen integrity in testing environments.

By adhering to these guidelines, research facilities can enhance the longevity and reliability of their specimens, ensuring they remain suitable for analysis and experimentation.

Utilize Compatible Accessories for Enhanced Efficiency

To optimize the use of 1.5 mL microcentrifuge tubes, several key accessories can significantly enhance laboratory efficiency.

- Tube Racks: Implement tube racks specifically designed for 1.5 mL tubes to maintain organization and accessibility. This approach reduces the risk of spills and mix-ups during experiments, ultimately optimizing workflow. Laboratories that have embraced rack systems report a significant decrease in time spent on collection and arrangement, resulting in enhanced productivity.

- Adapters: Utilize adapters that allow 1.5 mL tubes to fit into larger centrifuge rotors. This versatility enables the processing of different sizes of specimens without the need for multiple centrifuges, thereby maximizing equipment usage. The correlation between the number of computer entry steps and total process times highlights the efficiency improvements associated with using such accessories.

- Labeling Systems: Invest in durable labeling systems that can endure extreme temperatures and conditions. High-quality labels ensure that identification remains intact and legible throughout both storage and processing phases, which is crucial for maintaining data integrity. As noted by Michael Talbert from the University of Oklahoma College of Medicine, effective organization in specimen handling is crucial for reducing errors and enhancing laboratory operations.

- Sealing Devices: Utilize sealing devices or caps that effectively prevent evaporation and contamination, particularly for delicate specimens. This is vital for preserving sample integrity during long-term storage.

Incorporating these accessories not only boosts efficiency but also enhances the overall quality of experimental outcomes. Furthermore, the application of in clinical settings has demonstrated that recognizing non-value-added activities can result in enhanced efficiency and optimization of processes. This practical example underscores the importance of using compatible accessories for 1.5 mL tubes in enhancing laboratory performance.

Conclusion

Selecting the appropriate materials and techniques for laboratory work is essential for ensuring the accuracy and reliability of experimental results. The comparison between polystyrene and polypropylene for 1.5 mL microcentrifuge tubes underscores the significance of material properties in laboratory environments. While polystyrene provides clarity for visual inspection, its limitations in chemical resistance and durability render polypropylene the preferred choice for most applications. Polypropylene's robustness, superior chemical resistance, and autoclavability greatly enhance sample integrity and reliability.

Proper handling techniques, including the use of gloves and the maintenance of a clean working environment, are critical in minimizing contamination risks. These best practices are vital for preserving sample integrity and ensuring accurate results. Furthermore, optimizing storage conditions—such as controlling temperatures and humidity—plays a significant role in preventing sample degradation, highlighting the necessity for meticulous laboratory protocols.

Incorporating compatible accessories, such as tube racks and labeling systems, can significantly enhance operational efficiency and streamline workflows in laboratory settings. By focusing on these critical aspects, laboratories can not only improve their experimental outcomes but also foster a culture of precision and reliability in their research practices. Ultimately, the combination of material selection, handling techniques, storage conditions, and the use of appropriate accessories establishes the foundation for successful laboratory operations, empowering researchers to achieve their objectives with confidence.