Overview

The article delves into the critical process of selecting and utilizing cryogenic tubes in laboratory environments. It offers in-depth insights into the various types of cryogenic tubes available, the essential considerations for material selection, and the best practices for handling these instruments. Furthermore, the article underscores the importance of adhering to regulatory compliance, highlighting that the proper choice and usage of cryogenic tubes are vital for maintaining specimen integrity and ensuring the safety of laboratory operations.

Introduction

In the realm of scientific research, the preservation of biological samples is paramount. Cryogenic tubes have emerged as indispensable tools in this endeavor. These specialized containers, designed to maintain extremely low temperatures, play a crucial role in various fields, from biobanking to pharmaceuticals, safeguarding the integrity of sensitive materials such as DNA and stem cells.

As the demand for effective sample storage solutions grows, understanding the nuances of cryogenic tubes—including their types, material selection, and best practices for handling—becomes increasingly vital. This article delves into the essential aspects of cryogenic tubes, offering insights into their applications, regulatory compliance, and the latest advancements that ensure the reliability and safety of cryogenic storage in modern laboratories.

Introduction to Cryogenic Tubes: Definition and Applications

Cryogenic tubes serve as specialized containers meticulously engineered to preserve biological materials at extremely low temperatures, typically utilizing liquid nitrogen. These tubes are indispensable across numerous scientific domains, including biobanking, pharmaceuticals, and medical research, where the integrity of specimens is paramount. Their design facilitates the preservation of specimens in a frozen state, effectively thwarting degradation and safeguarding cellular structures.

This capability is vital for the long-term preservation of sensitive materials such as stem cells, DNA, and various biological samples.

The significance of low-temperature storage in medical research cannot be overstated. Recent statistics indicate a marked increase in the utilization of refrigerated containers within biobanking, underscoring a growing recognition of their critical role in maintaining specimen integrity for future investigations. For instance, adhering to standardized protocols during the initial collection of biological specimens is crucial for establishing high-quality biobanks, as highlighted in the recent case study titled 'Design of Specimen Collection for High Quality Biobanking.'

Implementing rigorous protocols ensures that specimens remain viable for examination, which is essential for advancing medical research and therapeutic innovations. Expert insights further underscore the necessity of specialized containers in pharmaceuticals. Researchers assert that these structures not only facilitate the preservation of biological materials but also enhance the reliability of experimental outcomes.

The incorporation of precise measurement tools, such as the Hiranuma Aquacounter AQ-300 Coulometric and AQV-300 Volumetric Karl Fischer titrators from JM Science, is crucial for ensuring compliance with the Japanese Pharmacopoeia in drug testing. As the pharmaceutical sector evolves, the demand for efficient low-temperature preservation techniques is expected to grow, driven by the need for accurate measurement and testing in drug development. By 2025, the importance of low-temperature preservation in pharmaceuticals will be particularly pronounced, as advancements in drug formulation and personalized medicine necessitate robust preservation solutions to maintain material quality.

Practical examples illustrate the effective application of low-temperature containers in pharmaceutical research, where they have been instrumental in preserving essential specimens for clinical trials and drug efficacy studies. Additionally, recent research indicates that hyperbaric oxygen therapy (HBOT) can significantly improve healing rates for , further emphasizing the importance of freezing solutions in medical research environments. Overall, the utilization of cryogenic tubes is indispensable in biobanking and pharmaceuticals, ensuring that invaluable biological samples are preserved for future scientific advancements.

As Professor Hussam Jouhara remarked, 'All authors have read and agreed to the published version of the manuscript,' highlighting the collaborative effort in propelling research forward through dependable storage solutions.

Types of Cryogenic Tubes: A Comprehensive Overview

Cryogenic tubes are available in a diverse array of designs, each meticulously tailored to fulfill specific laboratory requirements. The primary categories include:

- Internally threaded

- Externally threaded

- Self-supporting structures

Internally threaded cylinders are often favored for their superior sealing capabilities, which significantly mitigate the risk of contamination and uphold integrity during preservation.

Conversely, externally threaded cylinders facilitate easier handling and access, rendering them a practical choice for routine laboratory tasks. Self-supporting containers offer distinct advantages for item retention, particularly within rack systems, as they ensure stability and enhance organization. Moreover, many contemporary refrigerated containers are equipped with advanced features such as barcoding, which streamlines identification and tracking—an essential component for laboratories operating at high throughput.

Recent market analyses reveal a burgeoning preference for specific container designs among laboratories, with internally threaded vessels gaining prominence due to their reliability in preserving specimen conditions. Notably, Europe is projected to exhibit a consistent compound annual growth rate (CAGR) in the low-temperature pipeline market, underscoring the increasing demand for efficient low-temperature storage solutions.

Expert insights indicate that the choice between internally and externally threaded pipes often hinges on the particular applications and workflows of the laboratory. For example, laboratories prioritizing secure sealing for volatile samples may gravitate towards internally threaded options, whereas those emphasizing efficiency and ease of use might opt for externally threaded designs.

The competitive landscape of is marked by fierce competition, with established companies like Leica Biosystems and Cryomech Inc. vying for market share through product innovation. Innovations in continue to emerge, with manufacturers developing tubes that not only meet rigorous performance standards but also improve usability. This includes advancements in materials that withstand extreme temperatures and designs that optimize space within low-temperature containment systems.

As the market evolves, laboratories are encouraged to stay informed about the latest innovations to ensure they select the most suitable low-temperature solutions for their specific needs. Aditi Shivarkar, an expert in packaging market research, underscores the significance of reliable storage solutions in laboratory environments, noting that the right selection can profoundly influence operational efficiency. Additionally, ongoing geopolitical tensions, such as the Russia–Ukraine war, have disrupted supply chains, impacting the availability of cryogenic tubes and highlighting the necessity for laboratories to adapt to contemporary challenges.

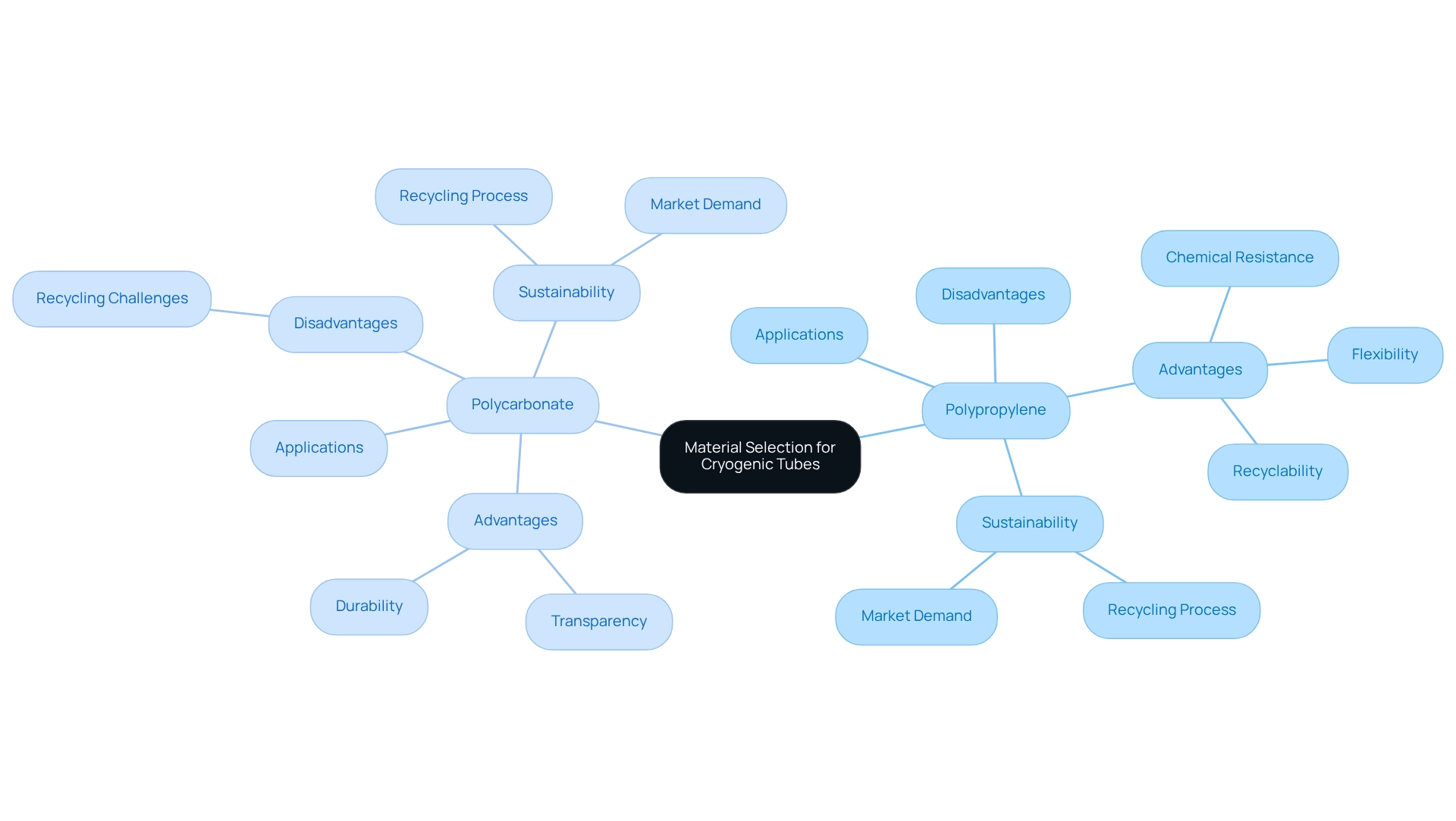

Material Selection for Cryogenic Tubes: What You Need to Know

Cryogenic tubes play a vital role in preserving biological specimens at extremely low temperatures, and the choice of material significantly impacts their efficacy. Typically, these tubes are made from polypropylene or polycarbonate, each presenting unique advantages. Polypropylene is often favored for its remarkable chemical resistance, flexibility, and capacity to endure thermal stress without becoming brittle.

Conversely, polycarbonate is noted for its superior transparency and durability, making it suitable for applications where visibility of the contents is crucial. When selecting materials for cryogenic tubes, it is essential to consider the specific requirements of the specimens being stored. For instance, materials that are sensitive to temperature fluctuations may benefit from the stability of polypropylene, while those requiring visibility could be better served by polycarbonate. Additionally, potential chemical interactions between the specimen and the cryogenic tube material must be assessed to ensure compatibility and maintain the specimen's integrity.

Recent expert opinions underscore the importance of material selection in low-temperature applications, particularly with regard to cryogenic tubes. Materials scientists assert that polypropylene's recyclability and lower energy production requirements render it a more sustainable option compared to polycarbonate, which encounters recycling challenges due to contamination and higher energy demands. A case study on sustainability and recycling reveals that polycarbonate recycling is less prevalent because of these elevated energy needs, indicating a diminished demand for recycled polycarbonate relative to polypropylene.

Moreover, it is noteworthy that less than 1% of the polypropylene produced globally is recycled, underscoring the urgent need for in laboratory settings. Practical examples illustrate the performance differences between polypropylene and polycarbonate containers. In laboratory environments, polypropylene containers have demonstrated superior durability under harsh conditions, while polycarbonate vessels are preferred for applications necessitating transparent observation of materials. As of 2025, the market continues to evolve, with polypropylene gaining traction as a more widely adopted choice due to its advantageous properties and recyclability.

Ultimately, the impact of material selection on the low-temperature performance of cryogenic tubes is paramount. Laboratories must meticulously evaluate the characteristics of both polypropylene and polycarbonate to ensure optimal preservation and integrity, aligning their choices with the specific demands of their research and operational goals. As highlighted by materials scientists, the benefits of polypropylene over polycarbonate in terms of sustainability and performance position it as a compelling choice for contemporary laboratory applications.

Best Practices for Handling and Using Cryogenic Tubes

When managing cryogenic containers, it is imperative to wear appropriate personal protective equipment (PPE), including cryogenic tubes, cryogenic gloves, and face shields, to safeguard against frostbite and other injuries. Direct contact with liquid nitrogen must be strictly avoided, and care should be taken to ensure cryogenic tubes are not overfilled, allowing for material expansion during freezing. Gradual thawing of samples is recommended to prevent thermal shock, which can compromise the integrity of the samples.

Regular training on is crucial for all laboratory personnel. Statistics reveal that 79.8% of individuals involved in laboratory accidents lacked adequate training on safety measures. By implementing comprehensive training programs, laboratories can significantly mitigate the risks associated with low-temperature storage. For example, the Data Ownership Safety Architecture (DOSA) has shown promise in enhancing laboratory safety by securely encrypting and sharing data related to incidents. This approach improves monitoring and response capabilities while maintaining privacy.

Safety officers emphasize the necessity of PPE in extremely low-temperature environments, noting that proper equipment is not merely a suggestion but a requirement for compliance with safety standards. Richard Palluzi states, "This Commentary discusses the most common safety issues observed in a variety of academic and industrial research laboratories over the author’s 45-plus year career," highlighting the importance of vigilance in laboratory safety. Furthermore, the tragic case of a chemist who died from exposure to x-ray radiation serves as a sobering reminder of the critical nature of safety in laboratory settings.

Additionally, the historical incident involving a graduate student killed in a chemical explosion within a household refrigerator in Illinois in 1940 underscores the potential dangers linked to improper material handling. By adhering to these best practices and ensuring ongoing education, laboratories can cultivate a safer working environment while effectively managing materials in cryogenic tubes at extremely low temperatures.

Thermal Management in Cryogenic Applications: Techniques and Considerations

For efficient thermal management in low-temperature applications, laboratories must prioritize the use of insulated holding units and implement regular temperature monitoring practices. Dewar flasks, specifically designed for extreme temperature preservation, are essential in maintaining low temperatures while minimizing nitrogen loss, which is vital for preserving the integrity of substances. Additionally, the use of thermal blankets or extra insulation significantly enhances temperature consistency, ensuring that specimens remain within the necessary parameters.

Routine examination of the seals and closures on refrigeration containers is crucial to prevent heat transfer, which can jeopardize preservation conditions. Laboratory managers emphasize that consistent temperature monitoring is vital; as one noted, 'The integrity of our samples relies heavily on our ability to maintain precise temperature control.' This proactive strategy not only safeguards valuable materials but also aligns with current best practices in low-temperature preservation.

By 2025, for cryogenic tubes have advanced, with many laboratories adopting cutting-edge technologies to enhance thermal management. Case studies underscore the successful application of these techniques, showcasing facilities that have effectively utilized Dewar flasks and other insulated containers to bolster their low-temperature preservation capabilities. Furthermore, it is essential for laboratories to remain cognizant of safety protocols and personal protective equipment (PPE) requirements during filling operations at cryogen fill stations, particularly when handling cryogenic tubes, as these practices are critical for maintaining a safe working environment. Facilities categorized as level 2 or higher must also ensure that proper signage and warning information are posted, as outlined in the case study 'Signage and Safety Postings for Cryogenic Facilities.'

By adhering to these best practices and safety protocols, laboratories can ensure the safety and effectiveness of their low-temperature materials while mitigating risks associated with low-temperature preservation.

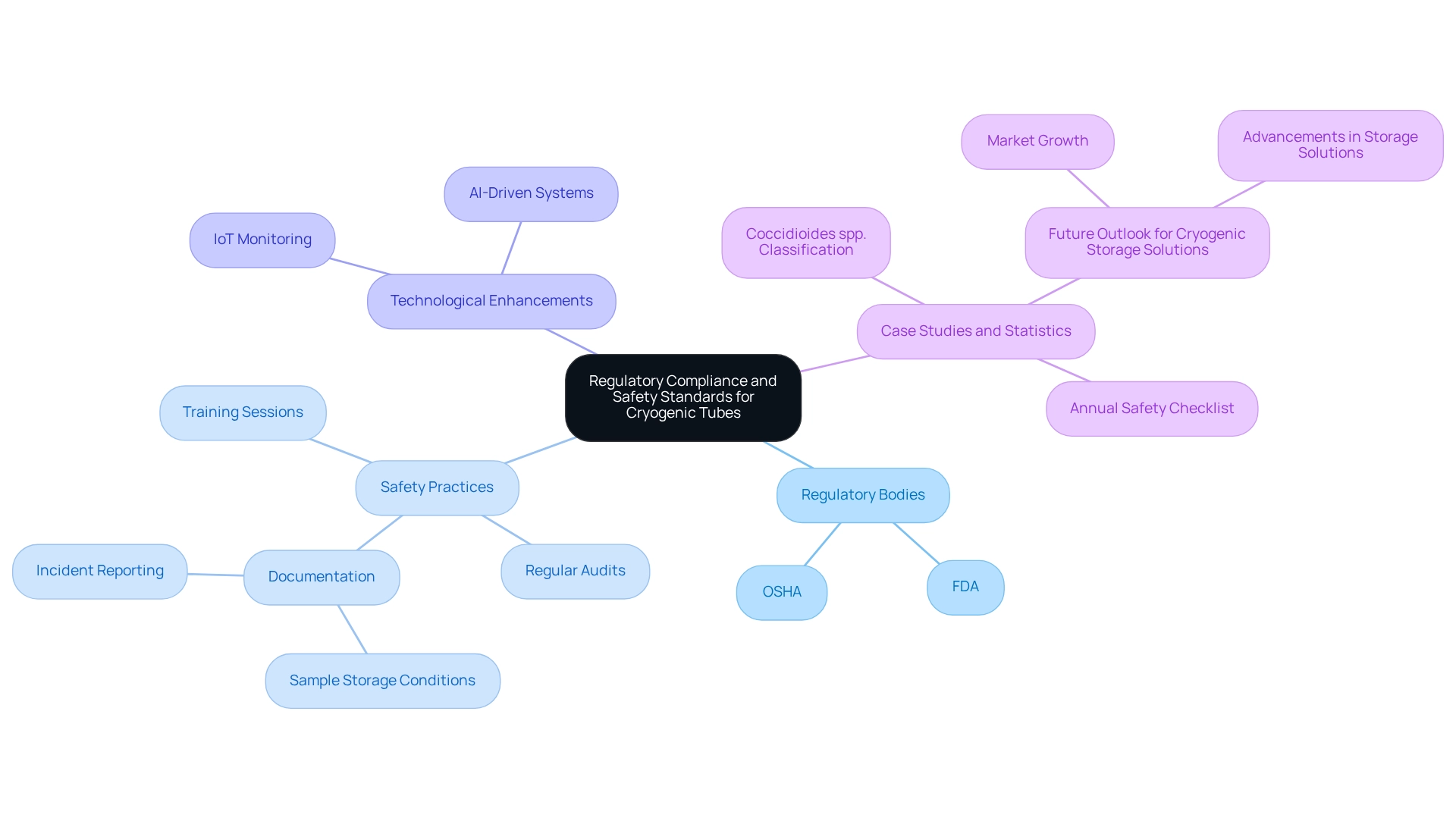

Regulatory Compliance and Safety Standards for Cryogenic Tubes

Laboratories are mandated to adhere to stringent regulatory standards when utilizing cryogenic tubes, particularly those set forth by the FDA and OSHA. These regulations cover safe handling practices for materials at extremely low temperatures, including the proper use of cryogenic tubes, accurate labeling, and meticulous documentation of sample storage conditions. To ensure adherence to these safety protocols, it is imperative for laboratories to conduct regular audits and training sessions for their personnel.

As Vince McLeod, a senior industrial hygienist, notes, 'Adhering to FDA and OSHA standards is essential for reducing risks linked to extremely low temperature materials.' Maintaining detailed records of all frozen materials is crucial. This includes documenting their preservation conditions and any incidents that may arise, which not only aids in regulatory compliance but also enhances overall safety within the laboratory environment.

Compliance officers assert that following FDA and OSHA standards is vital for mitigating risks associated with the use of cryogenic tubes and extremely low-temperature materials. A recent case study highlighted the effective implementation of these standards in a leading pharmaceutical laboratory, showcasing and adherence rates.

As of 2025, the FDA has updated its guidelines on low-temperature preservation, underscoring the necessity for laboratories to stay informed about evolving regulations. Statistics reveal that laboratories actively applying these guidelines report elevated compliance rates, substantially lowering the risk of safety incidents. Furthermore, the classification of Coccidioides spp. as a select agent requiring registration with the CDC/U.S. Department of Agriculture emphasizes the significance of regulatory compliance in laboratory environments.

Expert opinions suggest that integrating advanced monitoring technologies, such as IoT and AI-driven systems, can further enhance compliance and safety in managing cryogenic tubes, ensuring that laboratories meet both regulatory standards and best practices in low-temperature storage.

Moreover, implementing an annual safety checklist tailored to specific biosafety risks can assist laboratories in effectively maintaining compliance and safety standards. Clinical microbiology guidelines for monomorphic yeasts and the handling of molds in a BSC also provide relevant context for safety practices concerning low-temperature materials.

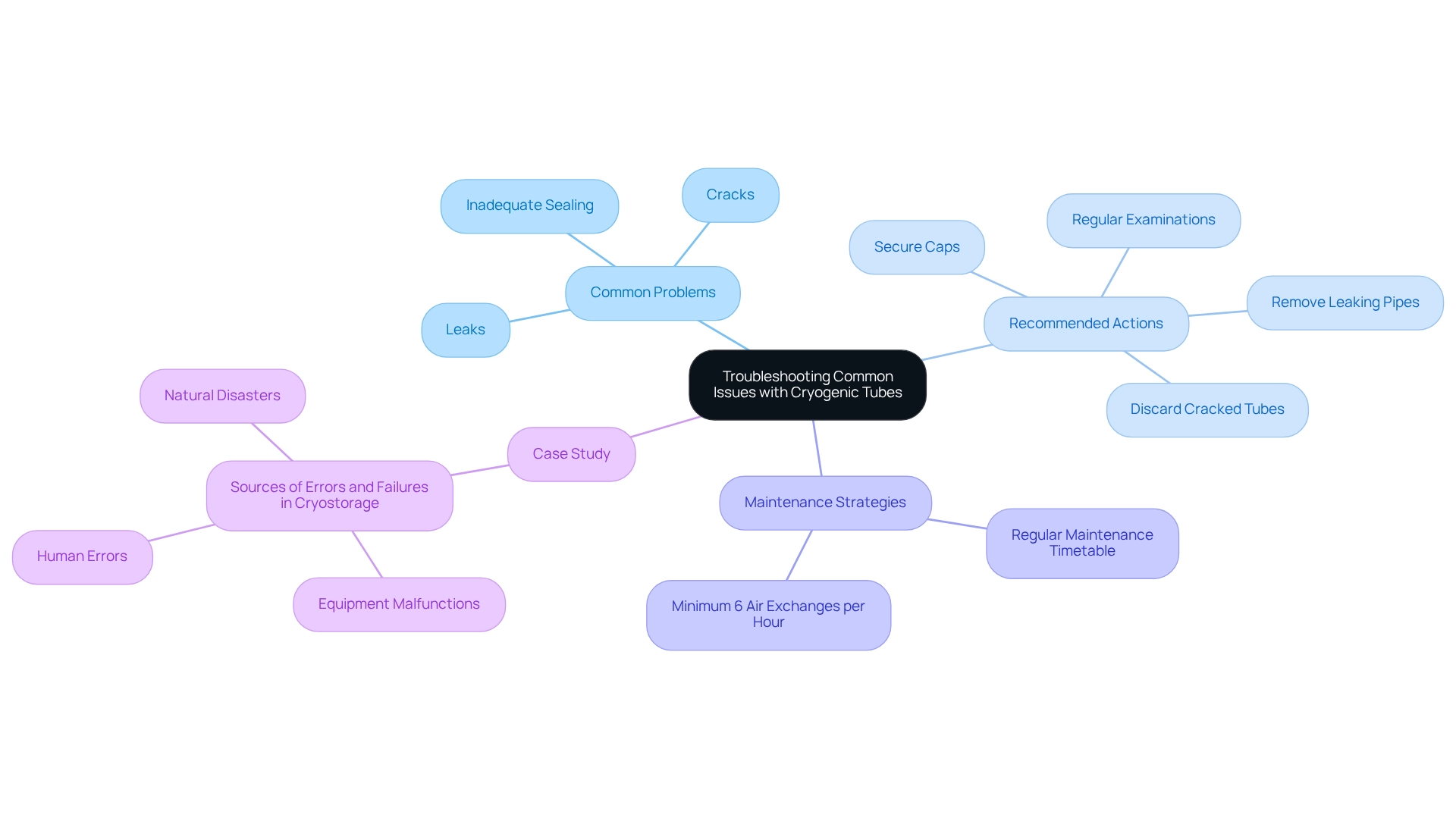

Troubleshooting Common Issues with Cryogenic Tubes

Common problems associated with cryogenic tubes, such as leaks, cracks, and inadequate sealing, can significantly undermine the integrity of specimens. To effectively troubleshoot these issues, it is essential to conduct regular examinations of the pipes for any signs of damage, including visible cracks or discoloration. Moreover, ensuring that caps are securely tightened is crucial in preventing leaks.

If a pipe is suspected of leaking, it should be promptly removed from the reserve to minimize the risk of contamination to other specimens. In cases where cracks are identified, the affected cryogenic tube must be discarded to maintain the integrity of the cryopreserved samples. Implementing a proactive maintenance strategy is vital; establishing a regular maintenance timetable for refrigerated systems can help identify potential problems before they escalate. Statistics indicate that routine upkeep can reduce the occurrence of common issues by as much as 30%, thereby enhancing the reliability of low-temperature preservation.

Additionally, it is recommended that refrigerated chambers maintain a minimum of six air exchanges per hour to ensure optimal conditions for the preservation of materials. A case study titled "Sources of Errors and Failures in Cryostorage" highlights various sources of errors that can arise in cryostorage practices, including equipment malfunctions and human errors. This emphasizes the necessity for robust policies and protocols to minimize errors and ensure the integrity of cryopreserved samples. Laboratory technicians stress that thorough record-keeping and traceability of cryopreserved specimens are essential components of quality management systems, particularly in IVF practices.

As Hussam Jouhara from notes, sustaining ideal conditions is crucial for the reliability of solutions involving cryogenic tubes. By addressing these common issues and implementing effective troubleshooting methods, laboratories can significantly enhance the reliability of their low-temperature storage systems.

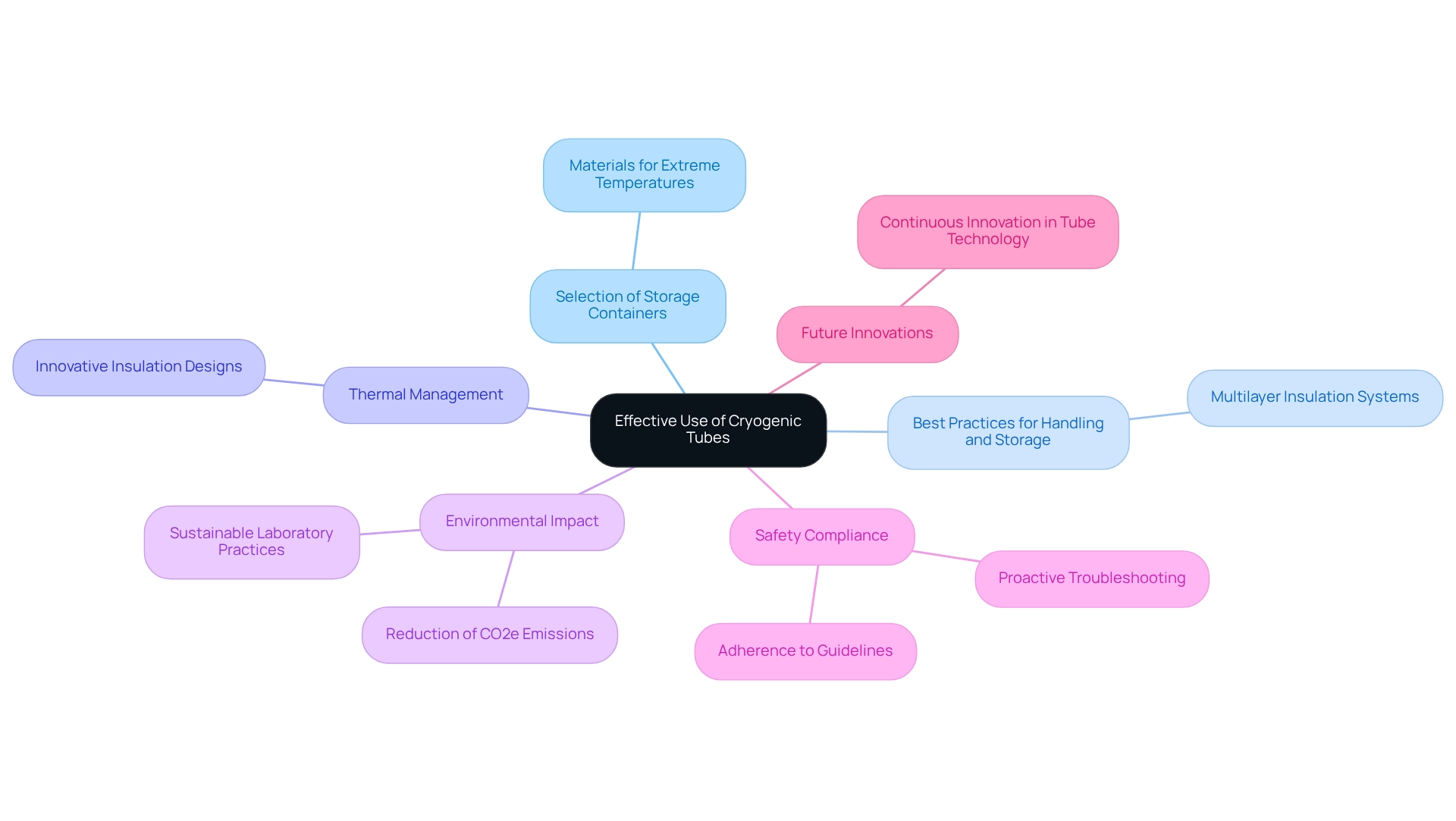

Summary and Key Takeaways for Effective Use of Cryogenic Tubes

Selecting the appropriate storage container is essential for optimizing laboratory efficiency and preserving specimen quality. Laboratories must evaluate various types of cryogenic tubes, emphasizing materials capable of enduring extreme temperatures, typically between −110˚C and −160˚C, while ensuring sample viability. Best practices for handling and storage are imperative; for example, employing multilayer insulation systems can significantly improve thermal performance, as highlighted by recent benchmark data from Cryostat-100, which demonstrates superior results in high vacuum conditions.

Effective thermal management is critical. Research reveals that innovative insulation designs can yield considerable environmental benefits, such as a reduction of 0.257 metric tons of CO2e over 20 years for a single unit. As stated, 'Thermal insulation plays a significant role in most low-temperature systems,' underscoring its vital role in sustaining optimal conditions.

This aligns with the increasing demand for sustainable laboratory practices, where environmentally-friendly vials and tubes are gaining popularity, allowing companies to secure a competitive edge.

Safety compliance is paramount. Laboratories must adhere to stringent guidelines to ensure the secure storage of low-temperature substances. Proactive troubleshooting of common challenges, such as inadequate sealing or temperature fluctuations, can avert material degradation and enhance the reliability of low-temperature storage solutions.

Recent research highlights the effectiveness of refrigeration containers in preserving biological samples, with data indicating that proper application can significantly extend sample lifespan. Industry leaders assert that the future of low-temperature tube technology hinges on continuous innovation and sustainability, paving the way for improved laboratory practices. By adhering to these guidelines, laboratories can boost operational efficiency and safeguard the safety and integrity of their cryogenic tube storage systems.

Conclusion

Cryogenic tubes are indispensable instruments in the preservation of biological samples, serving a critical function across various scientific domains, including biobanking and pharmaceuticals. Their capacity to sustain extremely low temperatures is vital for preserving sensitive materials such as DNA and stem cells, which is essential for the advancement of medical research. This article underscores the necessity of selecting the appropriate type of cryogenic tube, taking into account factors such as design, material, and optimal handling practices to enhance sample preservation and laboratory efficiency.

Material selection holds significant importance, with polypropylene and polycarbonate providing unique advantages tailored to specific laboratory requirements. Implementing best practices, such as the use of personal protective equipment and ongoing training, is crucial for safe handling. Furthermore, effective thermal management techniques—like employing insulated storage containers and conducting regular temperature monitoring—are vital for maintaining the integrity of samples.

Adhering to regulatory standards established by organizations such as the FDA and OSHA is imperative to mitigate risks associated with cryogenic materials. Laboratories must remain vigilant regarding evolving regulations and adopt proactive troubleshooting strategies to resolve common issues, including leaks and cracks in cryogenic tubes.

In conclusion, the proficient use of cryogenic tubes significantly bolsters the reliability of sample storage, ensuring the preservation of valuable biological specimens for future research. As the demand for innovative and sustainable laboratory practices escalates, the integration of advanced cryogenic storage solutions will be pivotal in shaping the future of scientific inquiry. By adhering to established guidelines and embracing new technologies, laboratories can safeguard the safety and integrity of their cryogenic storage systems, ultimately contributing to advancements in health and medicine.