Overview

Automated pipettes provide substantial advantages for pharmaceutical laboratories, notably in precision, efficiency, and the reduction of human error. These factors collectively enhance the reliability of experimental outcomes.

Evidence presented in the article indicates a remarkable 30% increase in throughput following the implementation of these systems. Furthermore, automation significantly reduces manual tasks, thereby allowing researchers to concentrate on essential scientific endeavors. This transition not only streamlines laboratory processes but also elevates the overall quality of research.

Introduction

Automated pipettes have emerged as indispensable instruments in pharmaceutical laboratories, fundamentally transforming the execution of liquid handling tasks. By integrating cutting-edge technology, these devices not only enhance accuracy and efficiency but also significantly mitigate the risk of human error—an aspect that can jeopardize critical research outcomes.

As the demand for precision in drug development escalates, a pivotal question arises: how can automated pipetting systems genuinely revolutionize laboratory workflows and guarantee reliable results?

This article explores the extensive benefits of automated pipettes, illustrating how they optimize productivity, enhance accuracy, and ultimately reshape the landscape of pharmaceutical research.

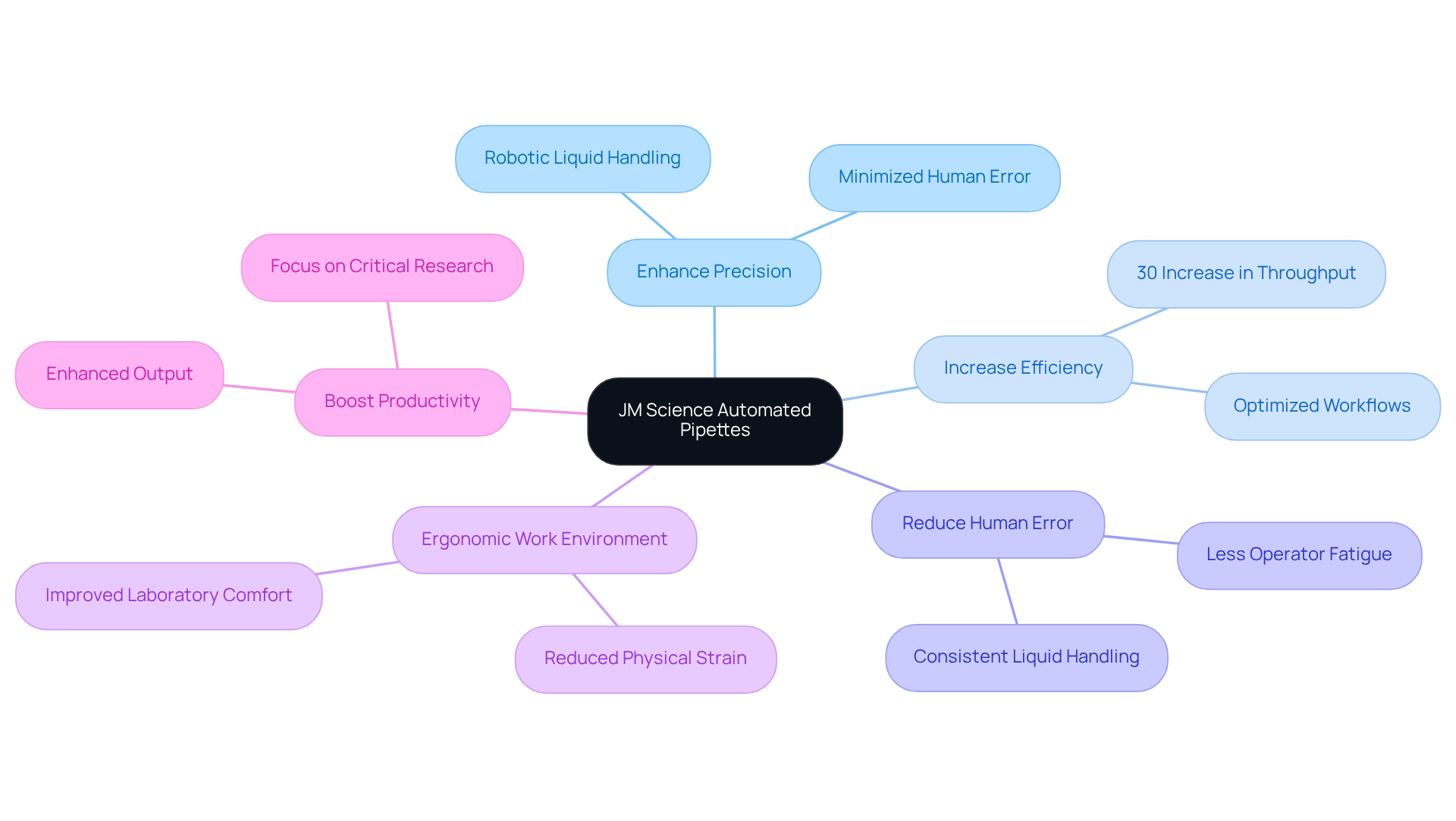

JM Science Automated Pipettes: Enhance Precision and Efficiency in Your Lab

JM Science presents an extensive array of mechanized pipettes expertly engineered to enhance accuracy and efficiency in pharmaceutical environments. These pipettes are meticulously crafted to fulfill the rigorous demands of scientific settings, empowering researchers to achieve precise liquid handling with minimal effort. By harnessing cutting-edge technology, JM Science's automated pipette significantly optimizes workflows, effectively reducing the time allocated to repetitive tasks. This innovation allows scientists to focus on critical research endeavors, ultimately boosting productivity and precision in pharmaceutical research.

A compelling case study underscores the transformative impact of robotic liquid handling technologies on laboratory productivity. In a recent implementation, a pharmaceutical lab reported a remarkable 30% increase in throughput following the integration of JM Science's mechanized pipettes, which effectively minimized human error and enhanced consistency in liquid handling. Laboratory managers have noted that these systems not only elevate accuracy but also reduce the physical strain associated with , fostering a more ergonomic work environment.

Furthermore, insights from lab supervisors emphasize the crucial role of robotic pipetting in achieving superior levels of precision. One manager remarked, "The mechanized pipettes from JM Science have revolutionized our liquid handling processes, enabling us to maintain precision while significantly increasing our output."

As the demand for high-throughput screening and precise liquid handling escalates, JM Science's automated pipette solutions emerge as indispensable instruments for enhancing laboratory efficiency and addressing the stringent requirements of pharmaceutical research.

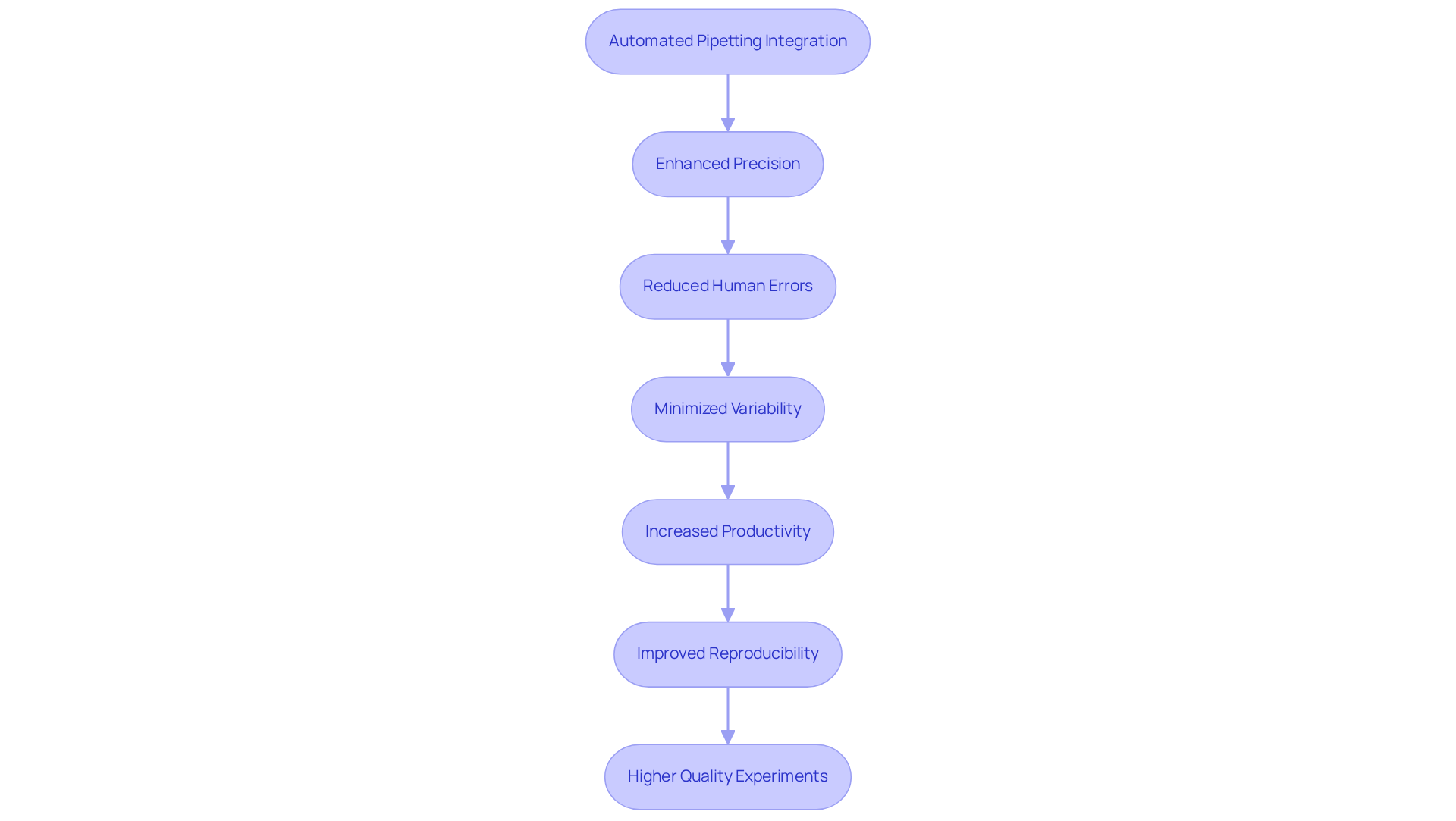

Improved Accuracy: Achieve Consistent Results with Automated Pipetting

Automated pipettes are crucial in enhancing precision and significantly reducing human errors. These advanced systems employ precise mechanisms for aspirating and dispensing liquids, ensuring that the correct volumes are consistently delivered. In pharmaceutical laboratories, where even slight discrepancies can lead to considerable variations in experimental results, this level of accuracy is indispensable.

Research indicates that machine-assisted liquid handling can reduce human errors by up to 50%, thereby minimizing intra- and inter-operator variability. Furthermore, these systems can handle multiple samples simultaneously, greatly boosting productivity in high-throughput environments such as drug discovery and next-generation sequencing. This reliability instills confidence in researchers, ultimately enhancing the reproducibility and quality of their experiments.

As one pharmaceutical researcher noted, "The precision of our results has dramatically improved since we integrated mechanized pipetting into our workflows, allowing us to focus more on scientific discovery rather than manual tasks." Additionally, mechanized solutions mitigate contamination risks through non-contact dispensing technologies, which are vital for maintaining purity in testing procedures.

JM Science's commitment to quality and customer support further bolsters their dedication to providing reliable solutions for scientific challenges. By optimizing workflows and enhancing accuracy, are transforming research methodologies and driving advancements in pharmaceutical studies.

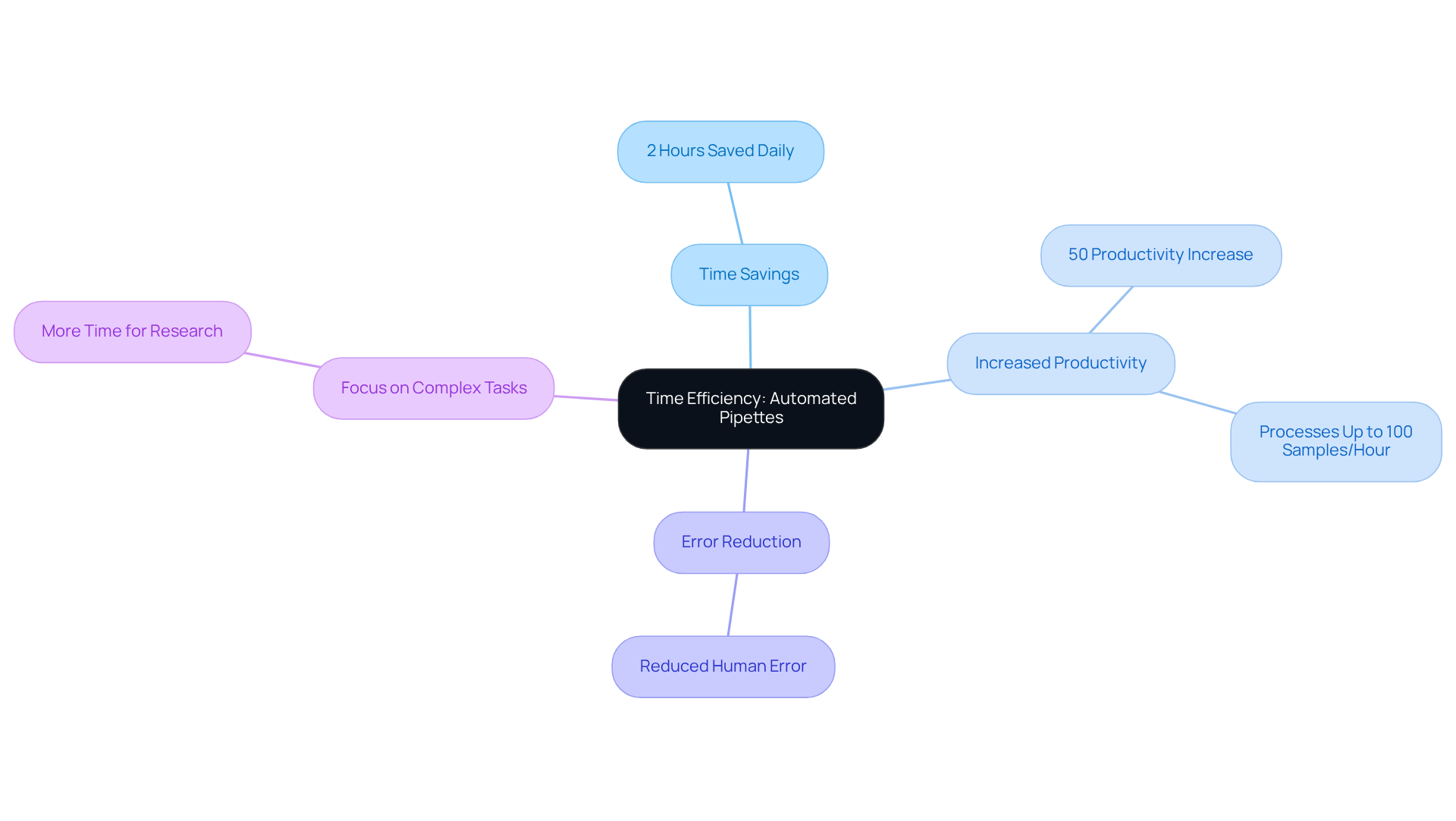

Time Efficiency: Streamline Your Workflow with Automated Pipettes

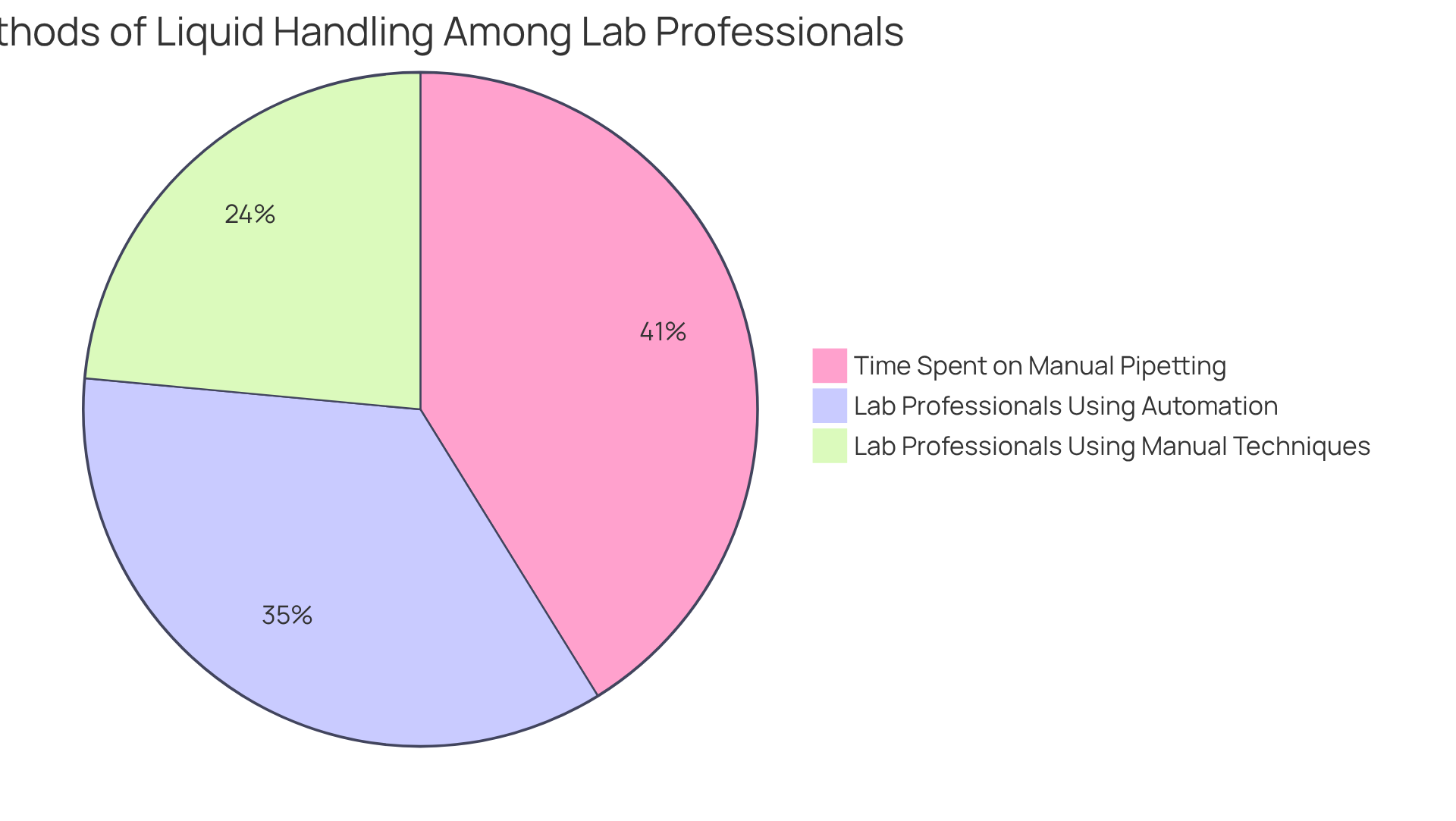

Automated pipettes greatly improve liquid handling tasks, enabling laboratory staff to focus on . By utilizing to automate repetitive liquid handling procedures, these devices drastically reduce the time required for tasks that typically take hours, thereby significantly boosting overall laboratory efficiency.

For instance, researchers generally spend 2 hours daily on liquid handling activities, and laboratories that employ mechanized dispensing equipment report productivity increases of up to 50%. This enhancement enables them to manage more samples in less time. In high-throughput environments, where rapid results are crucial, automated systems can process up to 100 samples per hour, making time efficiency particularly advantageous.

Lab managers have observed that transitioning to automation, such as implementing an automated pipette, not only improves workflow efficiency but also reduces the risk of human error, resulting in more reliable data outcomes. As one lab manager noted, 'The automation of our pipetting tasks using an automated pipette has allowed us to focus on critical research aspects, ultimately improving our throughput and accuracy.'

Another added, "Pipetting automation can help to reduce errors in the lab." This shift towards automation is not merely a trend; it signifies a fundamental transformation in pharmaceutical research, paving the way for faster and more efficient laboratory operations.

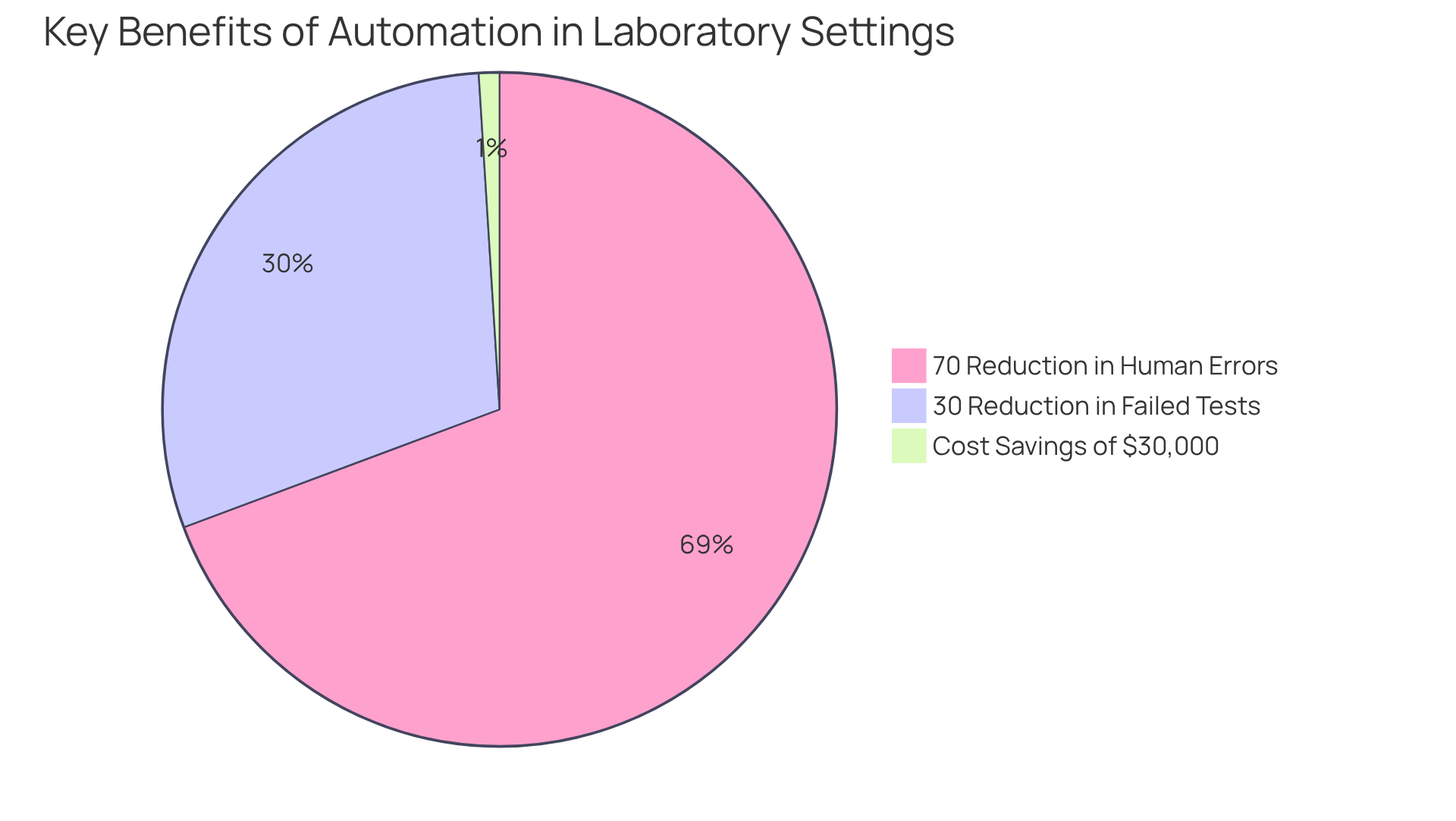

Minimized Human Error: Boost Reliability with Automation

Automated pipette technologies significantly reduce human errors, which are a common issue in manual techniques that can lead to inaccurate volume measurements and cross-contamination. By strictly adhering to standardized protocols, these systems execute each action of the automated pipette with remarkable precision. This reliability is vital in pharmaceutical settings, where the directly influences drug development and patient safety. Notably, automation has been demonstrated to decrease human errors by over 70%, thereby enhancing the accuracy of laboratory results.

A compelling case study revealed that the introduction of robotic processes led to a 30% reduction in failed tests, effectively preventing unnecessary delays in patient diagnosis. Furthermore, pharmaceutical researchers emphasize that the dependability provided by automated pipettes not only improves data quality but also fosters confidence in the findings, which is essential for regulatory compliance and successful product development.

As Dr. Jane Smith, a pharmaceutical scientist, articulated, "The reliability of mechanized systems is crucial for ensuring that our results are both accurate and reproducible, which ultimately impacts patient safety." Additionally, the financial ramifications are considerable, with automation potentially saving laboratories approximately $30,000 annually in labor and error correction costs. As the sector evolves, the integration of an automated pipette in liquid handling processes is becoming increasingly indispensable for maintaining high standards of reliability in experimental results.

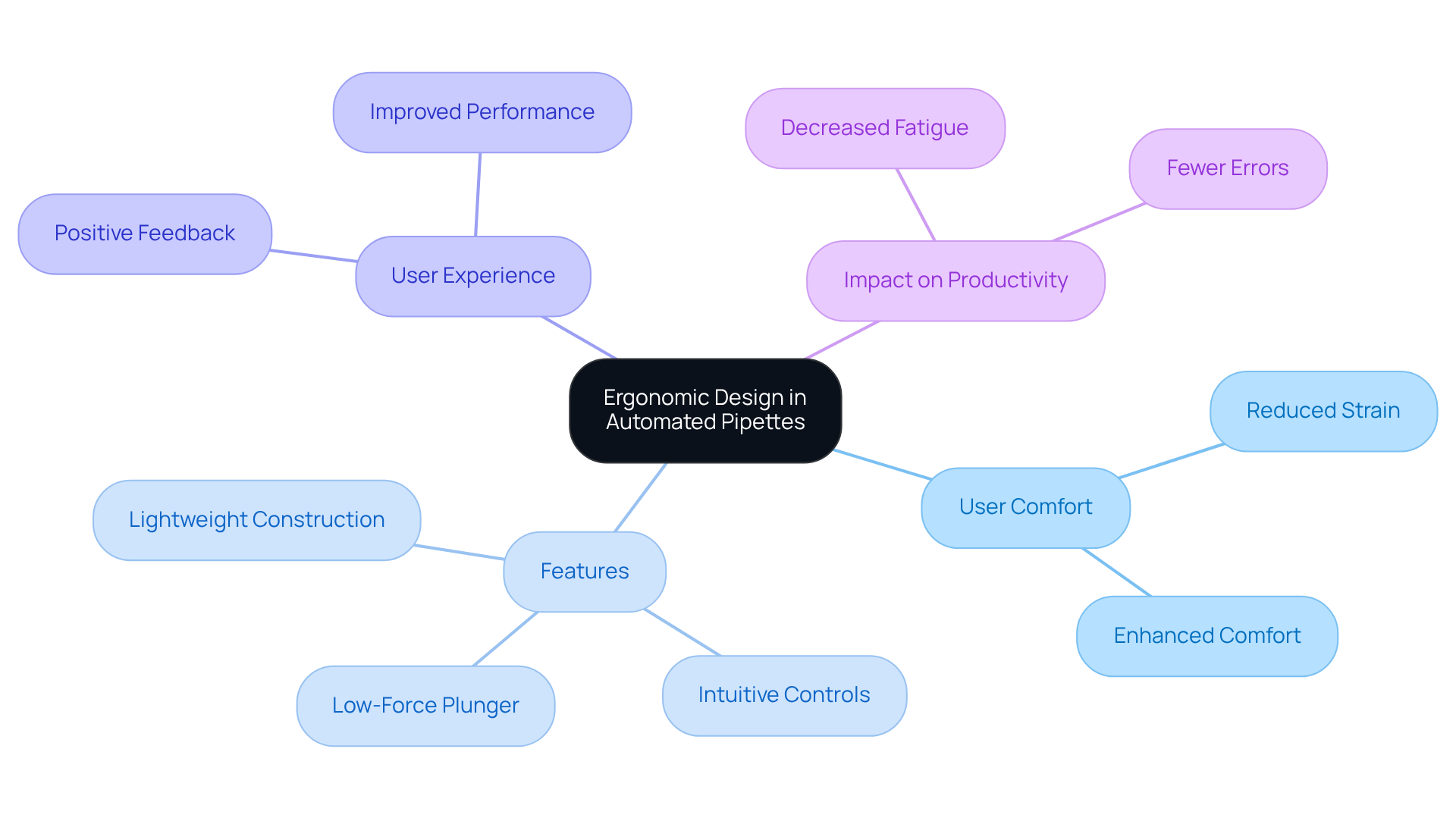

Ergonomic Design: Enhance User Comfort and Reduce Fatigue

The automated pipettes from JM Science are meticulously engineered with a focus on ergonomics. Their lightweight constructions and intuitive controls significantly minimize user strain, addressing a critical need in laboratory settings. Research indicates that in high-intensity environments, staff can spend up to seven hours a day on liquid transfer tasks, with two hours considered a typical standard. This underscores the importance of ergonomic design in maintaining comfort and efficiency. These automated pipettes are designed to mitigate common issues such as wrist strain and arm fatigue, offering a solution that surpasses conventional liquid handling methods. For instance, feature a low-force plunger and an optimal finger rest shape, effectively reducing hand fatigue during prolonged use.

Users consistently report that ergonomic pipettes not only enhance their overall experience in the lab but also lead to improved performance and fewer errors. As Angelo dePalma aptly notes, "The key to avoiding RSI is to assume natural, strain-free posture while conducting experiments." The ali-Q™ 2 aliquoting pipet controller exemplifies this principle, enabling semi-automatic precise multidispenses through its dual dispensing technology, thereby reducing the time spent on repetitive tasks. By prioritizing user comfort, JM Science's pipettes foster a healthier work environment, ultimately enhancing productivity and morale among staff. This emphasis on ergonomic design is vital for promoting a sustainable and efficient workflow, as it directly correlates with decreased fatigue and enhanced accuracy in pipetting tasks.

Versatility: Handle Diverse Liquid Types and Volumes with Ease

JM Science's automated pipettes are highly adaptable instruments, meticulously engineered to handle a diverse array of liquid types and volumes. Their significance in pharmaceutical laboratories cannot be overstated. These devices excel in managing everything from viscous solutions to volatile reagents and delicate biological samples, allowing researchers to customize settings according to specific requirements. For instance, the Myra automatic pipette machine showcases remarkable accuracy, achieving precision levels below 1% for volumes of 2 µL and higher. It also adeptly manages sub-microliter volumes with a mechanized delivery precision of under 10% CV at 1 µL. Such capabilities are essential in environments where a variety of materials are routinely encountered.

Case studies highlight the versatility of across various applications. One study focused on the Myra framework, enabling laboratories to conduct a two-week demonstration, allowing researchers to evaluate its performance in real-world scenarios. Another case study highlighted the critical importance of adaptability in liquid management tools, illustrating how these instruments can be programmed for a broad spectrum of protocols, accommodating the dynamic nature of pharmaceutical research.

Moreover, automated pipette devices are specifically designed to manage various liquids with efficiency. Positive displacement pipettes, for example, are liquid-class agnostic, effectively handling different viscosities without sacrificing accuracy. This versatility not only enhances the reliability of experimental outcomes but also significantly mitigates the risk of cross-contamination, a paramount concern in pharmaceutical labs. By integrating advanced software for monitoring and recording each phase of the liquid handling process, these solutions ensure comprehensive data management, further aiding researchers in their quest for accuracy and effectiveness. Furthermore, automated processes can manage up to 100 samples each hour, making them ideal for high-demand research environments. The ergonomic benefits of these setups also play a crucial role, as they help reduce the risk of repetitive strain injuries (RSI) among laboratory staff. Additionally, considering vendor support and maintenance is essential for ensuring operational efficiency and minimizing downtime.

Integration with LIMS: Improve Data Management and Traceability

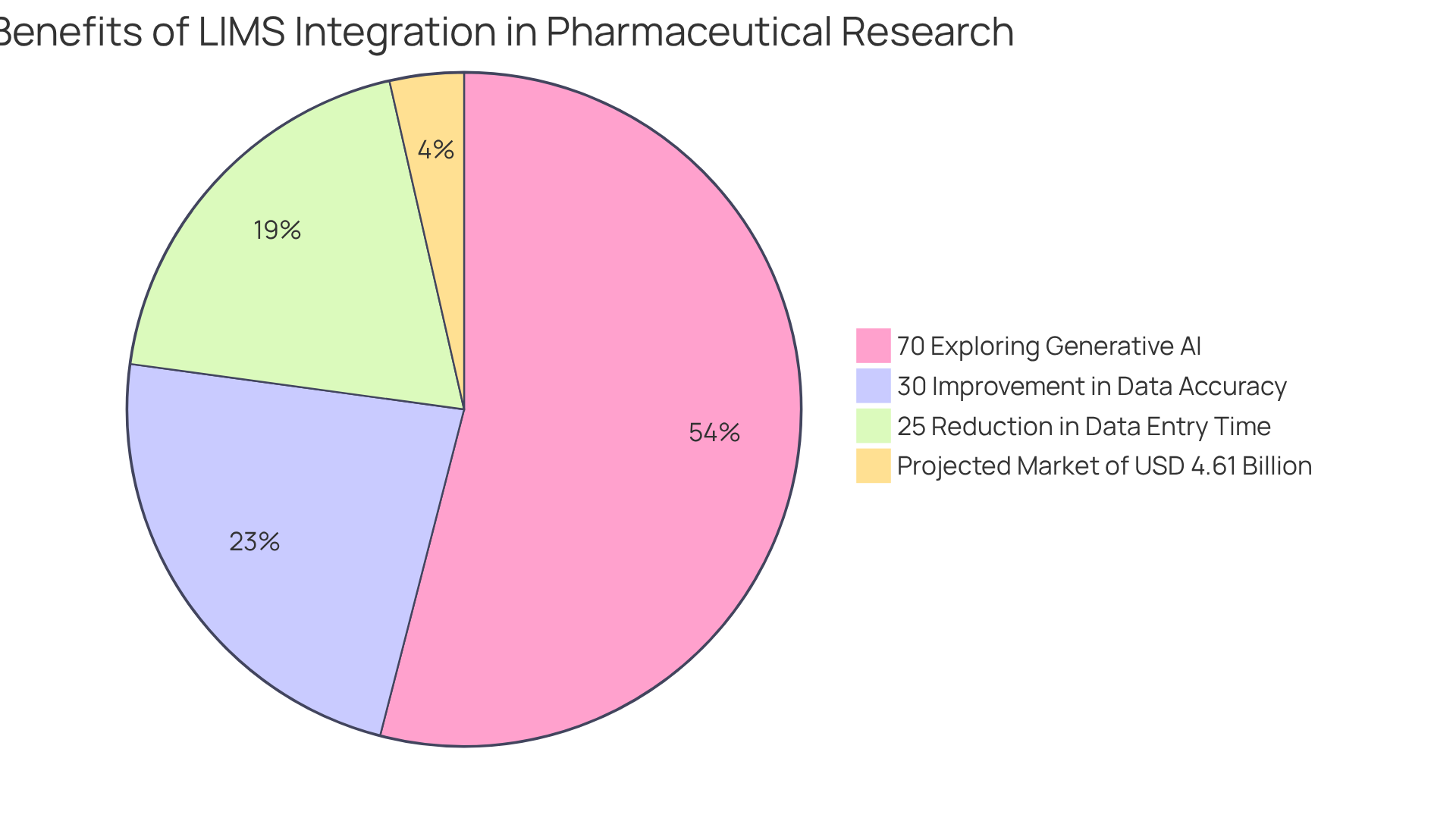

The integration of automated pipette systems with Laboratory Information Management Systems (LIMS) significantly enhances data management and traceability within pharmaceutical research environments. This seamless integration not only facilitates real-time tracking of samples and results but also ensures that all data is accurately recorded and readily accessible. As a result, facilities can maintain strict adherence to regulatory standards, which is essential in the pharmaceutical industry where data integrity is paramount.

Moreover, studies reveal that organizations leveraging LIMS experience an impressive 30% improvement in data accuracy and a 25% reduction in time spent on data entry tasks. Such efficiency streamlines research workflows and elevates the overall quality of research outputs. Current trends indicate that 70% of healthcare organizations are actively exploring generative AI and automation technologies, highlighting a growing recognition of their potential to transform operational processes.

Additionally, is projected to reach USD 4.61 billion by 2032, underscoring the increasing significance of LIMS in the industry. Lab managers have noted that integrating LIMS with automated systems has markedly enhanced data management capabilities. One manager stated, 'The use of an automated pipette in our pipetting processes has drastically improved our data accuracy and compliance, allowing us to focus more on research rather than administrative tasks.'

Adhering to regulations is vital, as emphasized by CDC, WHO, and Thermofisher Scientific, which assert that following standards is crucial for operational processes. This shift towards automation and LIMS integration is not merely a trend; it represents a critical evolution in the pursuit of operational excellence within pharmaceutical facilities.

Cost-Effectiveness: Save on Resources with Automated Solutions

Investing in automated pipette solutions represents a strategic choice for pharmaceutical laboratories seeking to achieve substantial cost savings. These advanced setups significantly reduce the need for consumables, such as pipette tips and reagents, thereby lowering operational costs.

Furthermore, by minimizing the time dedicated to manual tasks, laboratories can enhance their overall productivity and allocate resources more effectively. The precision and efficiency of mechanized processes also play a crucial role in minimizing costly errors, which is essential in high-stakes areas like drug discovery and genomics.

For instance, robotic liquid handling devices can process up to 100 samples per hour, compared to just 10 samples per hour achievable through manual pipetting. The susceptibility of manual preparation to errors often necessitates multiple experiments, highlighting the reliability of solutions such as the automated pipette. This remarkable not only accelerates research timelines but also optimizes budget allocations by reducing labor costs linked to repetitive tasks.

Additionally, implementing automation can enhance assay reproducibility, ensuring consistent results that alleviate the financial repercussions of experimental failures. Automated processes diminish human errors, guaranteeing precise measurements and uniform outcomes across experiments.

Moreover, these systems improve ergonomics by lessening repetitive manual activities, thereby lowering the risk of repetitive strain injuries among research personnel.

In summary, transitioning to an automated pipette signifies a pivotal advancement toward improved efficiency and resource optimization in pharmaceutical research.

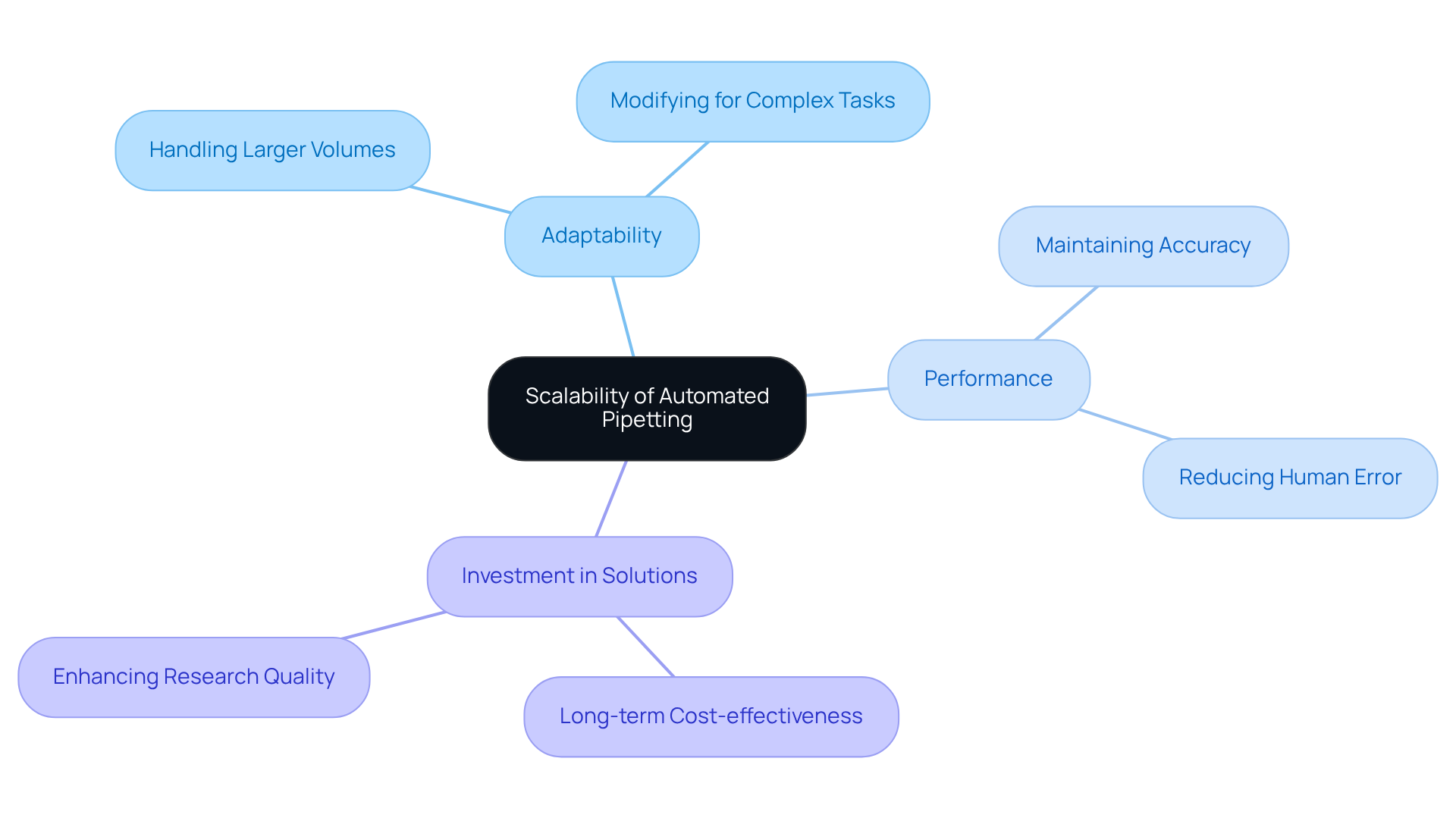

Scalability: Adapt Automated Pipetting to Your Growing Lab Needs

Automated pipette devices are designed with scalability in mind, enabling facilities to adapt to evolving requirements and increasing workloads. As research demands escalate, automated pipette systems can be expanded or modified to handle larger volumes or more complex tasks without sacrificing performance. This inherent scalability ensures that research facilities can maintain effective operations, even as their needs evolve. Ultimately, investing in such as the automated pipette empowers laboratories to meet the challenges of modern scientific inquiry.

Enhanced Reproducibility: Ensure Consistent Results Across Experiments

Automated pipettes are essential for enhancing reproducibility in laboratory experiments. By standardizing liquid handling processes, these systems significantly mitigate variations often resulting from manual sampling techniques. This consistency is particularly crucial in pharmaceutical research, where reproducible results are vital for validating findings and ensuring the reliability of experimental data. Notably, studies reveal that over 60% of lab professionals employ some form of automation for liquid handling, with many indicating that manual liquid transfer can introduce substantial variability in results, even among seasoned researchers. Furthermore, an alarming 70% of lab professionals dedicate over 1 hour daily to manual pipetting tasks, underscoring the time-saving advantages of automation that are critical for lab managers.

The transition to mechanized processes empowers researchers to reliably reproduce experiments, a necessity for drawing robust conclusions. For example, like the I.DOT Liquid Handler, which boasts a dead volume of just 1 μL, have demonstrated improvements in accuracy and efficiency, minimizing human error and enhancing throughput. This not only accelerates drug development processes but also optimizes resource utilization, ultimately leading to more reliable data.

Moreover, the ability of automated processes to maintain uniform quality standards throughout experiments is underscored by the fact that 78% of surveyed lab professionals identified enhancing data quality as a significant challenge in their workflows. Automated solutions specifically address this challenge by ensuring precise measurements and reducing variability. Additionally, these systems are adaptable and can be configured for various protocols and samples, further augmenting their versatility in research environments. By tackling these challenges, automated pipette solutions significantly advance pharmaceutical research, enabling laboratories to meet the rigorous demands of modern scientific inquiry while also achieving cost savings through reduced consumption of pipette tips and reagents.

Conclusion

Automated pipettes have emerged as indispensable tools in pharmaceutical laboratories, revolutionizing liquid handling processes and enabling researchers to achieve exceptional precision and efficiency. By integrating cutting-edge technology, these devices not only streamline workflows but also substantially reduce the likelihood of human error—an essential factor in preserving the integrity of scientific research.

Key benefits of automated pipettes are evident throughout this discussion, including:

- Their capacity to enhance accuracy

- Boost time efficiency

- Minimize human error

- Offer ergonomic solutions for laboratory personnel

The versatility of these systems empowers them to manage a diverse array of liquid types and volumes, while their integration with Laboratory Information Management Systems (LIMS) significantly enhances data management and traceability. Furthermore, the cost-effectiveness of automated pipetting solutions, coupled with their scalability, ensures that laboratories can adapt seamlessly to evolving research demands without sacrificing performance.

The importance of adopting automated pipette technology is paramount. As the pharmaceutical industry progresses, embracing these innovations is vital for laboratories striving to elevate productivity and attain reliable results. Investing in automated solutions not only enhances operational efficiency but also cultivates a safer and more comfortable work environment for researchers. Ultimately, the integration of automated pipetting systems represents a crucial step toward achieving excellence in pharmaceutical research, paving the way for groundbreaking discoveries and improved patient outcomes.