Overview

The article presents a compelling overview of ten significant benefits associated with the use of magnetic stirrer bars in laboratory environments. It underscores their critical role in enhancing precision, efficiency, and consistency across a variety of applications. By detailing how these instruments improve sample preparation, reaction outcomes, and diagnostic accuracy, the article establishes magnetic stirrer bars as indispensable tools for achieving high-quality results in both scientific research and industrial processes. This emphasis on their importance not only captures attention but also builds interest in their practical applications, generating a desire for laboratories to incorporate these essential instruments into their workflows.

Introduction

In the realm of scientific research and laboratory practices, precision and consistency are not merely important; they are paramount. Magnetic stirrer bars have emerged as indispensable tools across diverse fields, including:

- Pharmaceuticals

- Environmental testing

These devices enable researchers to achieve uniform mixing and reliable results, enhancing the efficiency of sample preparation and chemical synthesis. Moreover, they play a crucial role in:

- Quality control

- Educational settings

As laboratories increasingly embrace advanced technologies, the integration of magnetic stirrers is revolutionizing workflows and improving outcomes. This transformation is driving significant advancements in:

- Healthcare

- Environmental monitoring

- Nanotechnology

This article explores the multifaceted applications of magnetic stirrer bars, underscoring their vital role in enhancing accuracy, efficiency, and innovation within modern scientific practices.

JM Science Magnetic Stirrer Bar: Integrated Process Monitoring for Precision

JM Science magnetic agitation rods are engineered with integrated process monitoring capabilities, allowing for real-time observation of blending conditions. This feature is essential for applications requiring precise control over reaction parameters, such as temperature and viscosity.

Equipped with advanced sensors, these mixing rods deliver critical data that significantly enhances reproducibility and reliability in experimental outcomes. In high-stakes laboratory environments, the capacity to monitor blending conditions in real time not only boosts operational efficiency but also supports informed decision-making, ultimately leading to improved resource allocation and superior research results.

For example, predictive analytics in pathology management has demonstrated that real-time data can streamline workload planning and optimize throughput, highlighting the significance of such technology in contemporary laboratories.

As Still noted, 'Usually, there’s a bit of back and forth between the lab and the LIS software developer before the design is finalized and added to the lab’s production environment,' emphasizing the vital role of real-time data in laboratory processes.

Moreover, real-time analytics empower labs to make informed decisions that positively influence their financial operations. The case study titled 'Predictive Analytics in Pathology Management' illustrates how integrated process monitoring can enhance managerial decision-making by forecasting incoming case types and optimizing resource allocation.

As laboratories increasingly adopt integrated process monitoring, the impact on precision and accuracy in blending processes becomes evident, positioning magnetic stirrer bars from JM Science as indispensable assets for achieving exceptional results.

HPLC Applications: Enhancing Sample Preparation with Magnetic Stirrer Bars

In HPLC sample preparation, magnetic stirrer bars are crucial for ensuring thorough blending of solvents and analytes, which is essential for achieving consistent chromatographic results. Uniform blending facilitates the dissolution of solid samples and the homogenization of mixtures, significantly enhancing the efficiency of sample preparation. This process not only improves analytical performance but also reduces variability in results, a critical factor for laboratories striving for precision in their analyses.

Expert insights underscore that effective blending is directly correlated with the reliability of chromatographic outcomes. Chromatographers assert that uniform mixing can lead to more reproducible results, thereby enhancing the overall quality of analytical data. Statistics reveal that laboratories employing a magnetic stirrer bar in their HPLC sample preparation experience a notable improvement in the uniformity of their analyses. Practical applications of the magnetic stirrer bar demonstrate its efficiency across various laboratory environments. Case studies indicate that laboratories adopting these tools have successfully minimized sample preparation errors, resulting in more accurate quantification of non-volatile and semi-volatile components in liquid samples. Notably, Thermo Fisher Scientific has obtained green lab certification for over 50 facilities, illustrating a commitment to sustainability that aligns with the effective methods facilitated by mixing rods.

As the scientific community continues to prioritize efficiency and accuracy, the role of mixing rods in enhancing chromatographic analyses remains indispensable. Furthermore, laboratories worldwide employ HPLC to identify and quantify non-volatile and semi-volatile chemical components in liquid samples, reinforcing the significance of reliable sample preparation methods. Consequently, the integration of mixing rods not only enhances analytical accuracy but also contributes to the broader objective of reducing the environmental impact of laboratory activities.

Pharmaceutical Formulation: Utilizing Magnetic Stirrer Bars for Consistent Mixing

In pharmaceutical formulation, rotating implements are indispensable for achieving uniform blending of active ingredients and excipients. This uniformity is critical for ensuring that each dosage form meets stringent quality standards and delivers therapeutic efficacy. Magnetic stirrer bars offer a gentle yet effective mixing action, which is particularly advantageous for preventing the degradation of sensitive compounds. Such capability is essential for ensuring homogeneity in formulations, a vital factor for regulatory compliance and patient safety.

The market for stirring rods, especially those equipped with pivot rings, constitutes approximately 45% of the overall market share, underscoring their popularity in demanding applications within the pharmaceutical and chemical sectors. As the need for precision in processes escalates—particularly for high-viscosity liquids or sensitive tasks—the use of agitation bars becomes increasingly vital. A recent case study titled 'Market Share of Magnetic Stirrer Bars With Pivot Ring' highlights the growing demand for these precision tools, emphasizing their role in maintaining quality and consistency in pharmaceutical formulations.

Real-world examples further underscore the effectiveness of using a magnetic stirrer bar in pharmaceutical applications. Research indicates that consistent blending significantly influences the quality of dosage forms, ensuring active ingredients are evenly distributed throughout the formulation. As articulated by a pharmaceutical scientist, "Maintaining consistency in blending is crucial for achieving optimal results in drug formulations." This commitment to precision not only elevates product quality but also reinforces compliance with industry standards, ultimately contributing to enhanced patient outcomes.

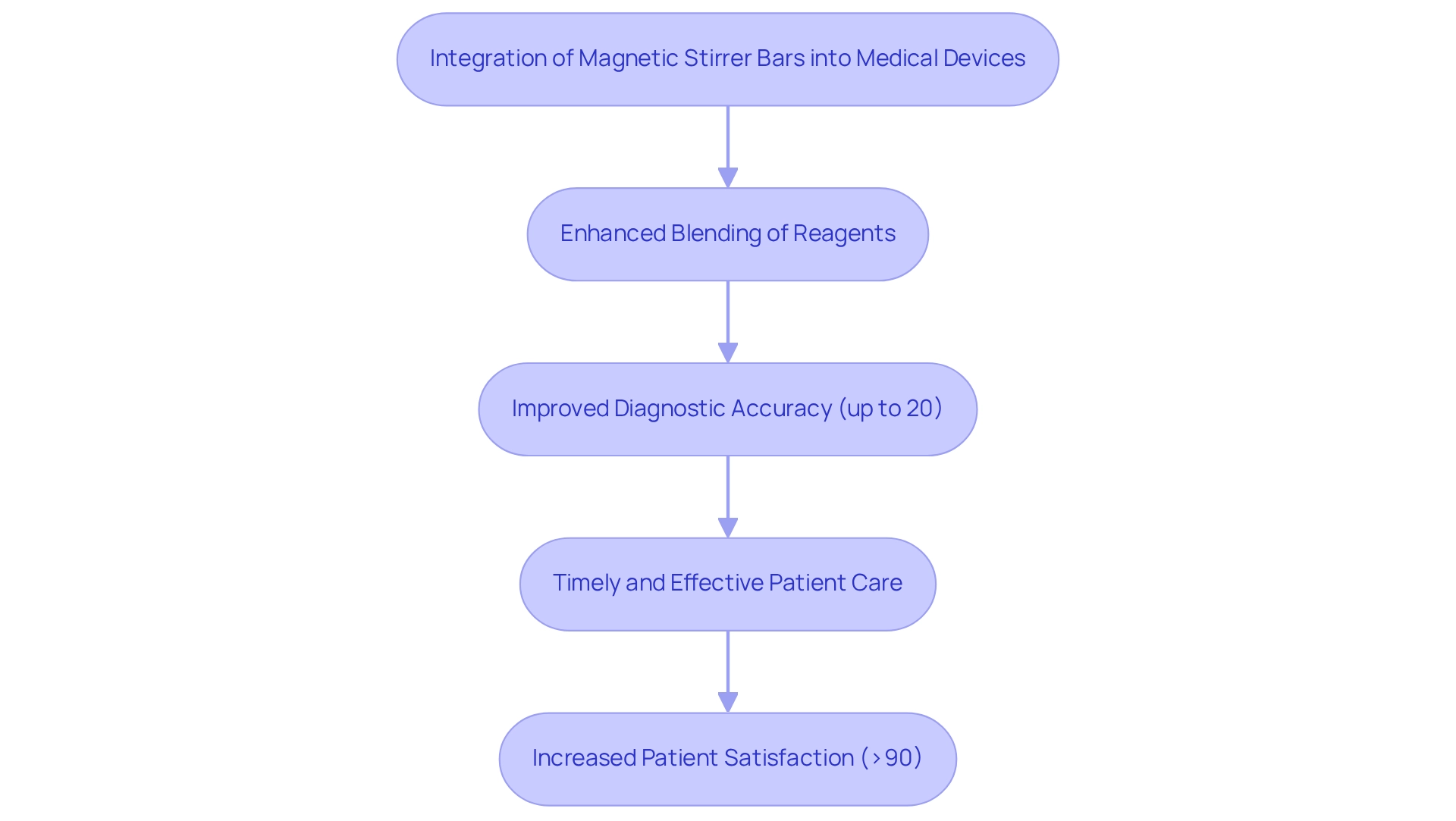

Remote Patient Monitoring: Leveraging Magnetic Stirrer Bars in Medical Devices

Magnetic rods are increasingly being integrated into medical devices for remote patient monitoring, particularly in applications that require the precise blending of reagents for diagnostic tests. By ensuring consistent and uniform blending of samples, these devices significantly enhance the accuracy of test outcomes, which is vital for timely and effective patient care.

Research indicates that regular agitation using a magnetic stirrer bar can lead to improvements in diagnostic accuracy, with some studies suggesting enhancements of up to 20% in result reliability, underscoring the importance of this technology in clinical settings. The integration of magnetic stirrer bar agitation devices into remote patient monitoring tools exemplifies the innovative adaptation of laboratory technologies to improve healthcare outcomes.

Practical applications include the use of a magnetic stirrer bar in devices that monitor vital signs and analyze blood samples, as accurate reagent blending is essential for reliable diagnostics. This relevance is amplified by the projected substantial growth of the remote patient monitoring market, with an expected compound annual growth rate of approximately 20% from 2023 to 2028. Such growth signifies a rising demand for efficient monitoring solutions, further elevating the significance of the magnetic stirrer bar.

Healthcare professionals have noted the positive impact of these technologies on diagnostic precision. Notably, the University of Pittsburgh Medical Center reported a patient satisfaction rate exceeding 90% following the implementation of remote patient monitoring systems that featured advanced blending technologies. This feedback highlights the critical role that consistent agitation with a magnetic stirrer bar plays in enhancing patient care and diagnostic reliability, showcasing how effective laboratory solutions can lead to improved healthcare outcomes.

As the healthcare sector continues to evolve, the incorporation of magnetic stirrer bars in medical devices not only boosts diagnostic test accuracy but also aligns with the broader objective of delivering high-quality patient care. Pharmaceutical lab managers should consider how these devices can be incorporated into their remote monitoring solutions to address challenges related to diagnostic accuracy and patient satisfaction. This innovative approach illustrates the potential for laboratory instrumentation to drive advancements in healthcare, ultimately benefiting both patients and healthcare providers.

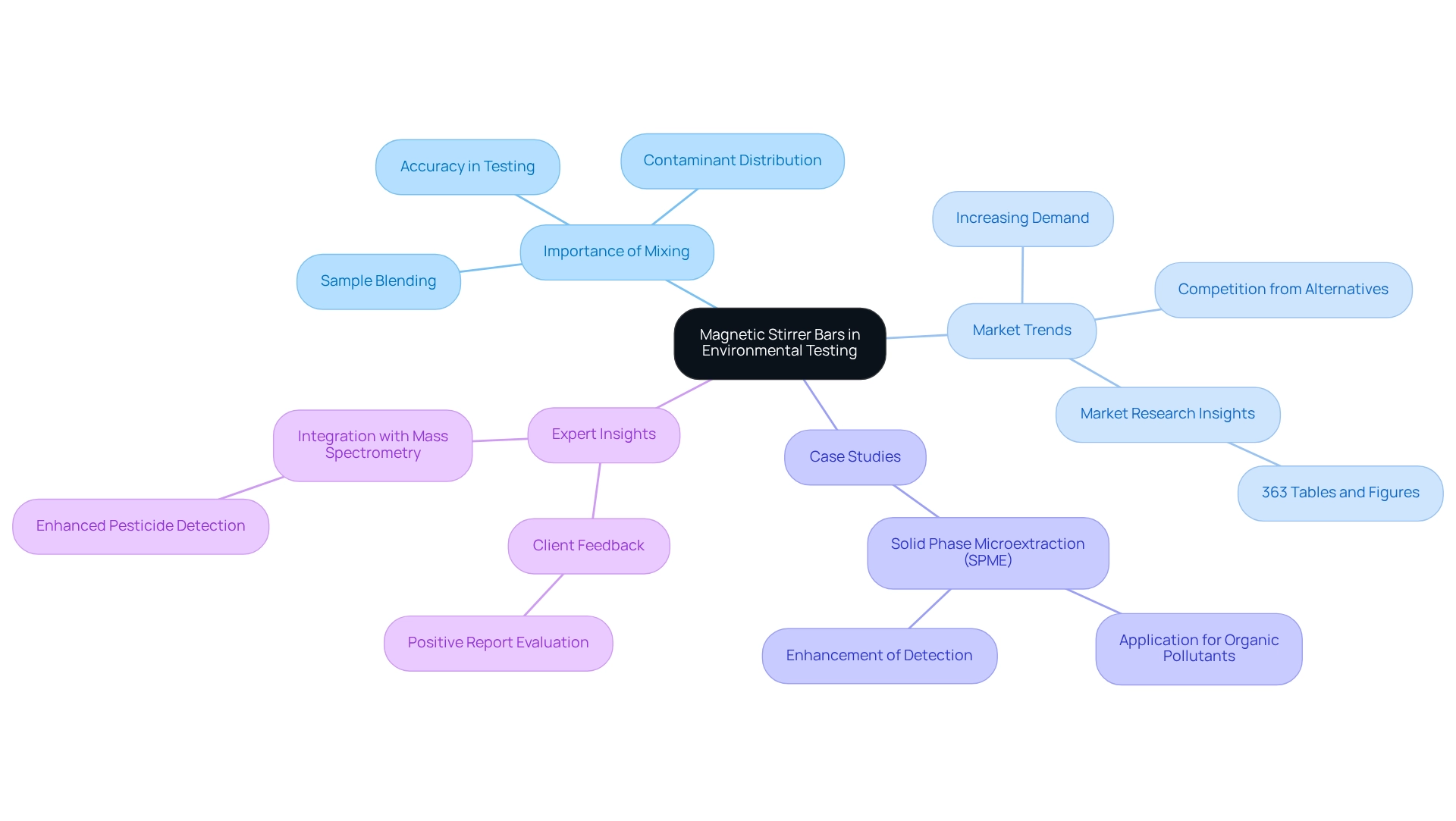

Environmental Testing: Ensuring Accuracy with Magnetic Stirrer Bars

In environmental testing, the utilization of agitation bars is essential for obtaining precise sample blending, particularly for water and soil evaluations. Thorough mixing ensures that contaminants are evenly distributed, which is crucial for obtaining representative samples and reliable test results. By employing electromagnetic mixers, laboratories can significantly enhance the accuracy of their analyses, thereby improving environmental monitoring and ensuring adherence to regulatory standards.

Recent trends from 2025 indicate a growing demand for high-end mixing devices, driven by their expanding applications and competition from alternative technologies. This trend is reflected in a comprehensive market research report, which includes 363 tables and figures detailing the effectiveness and versatility of these instruments.

A significant case study on solid phase microextraction (SPME) for organic contaminants illustrates the practical application of mixing rods in environmental laboratories. The research emphasizes that SPME, when paired with stirring, enhances the identification of pesticides and other pollutants, underscoring the importance of precise blending in environmental examination. This connection highlights the role of stirring rods in improving the detection capabilities of laboratories.

Experts in the field assert that effective blending not only enhances sample representativeness but also plays a vital role in the accuracy of environmental testing. As one client noted, "The report is excellent and has a good amount of data, and our team is extremely happy with the information provided." As the landscape of environmental observation evolves, the incorporation of sophisticated blending methods, such as those offered by specific tools, will remain crucial in obtaining dependable and useful data.

Educational Laboratories: Teaching Science with Magnetic Stirrer Bars

The magnetic stirrer bar is an indispensable tool in educational laboratories, providing students with invaluable hands-on experience in mixing and reaction processes. By utilizing these devices, students can directly observe key chemical principles, such as solubility and reaction kinetics, in real-time. This practical engagement with theoretical concepts deepens understanding and equips students with familiarity in using critical laboratory equipment, essential for their future careers in scientific fields.

Studies indicate that incorporating mixers in educational environments significantly enhances student learning outcomes. For instance, case studies reveal that students who engage with mixing technology demonstrate a superior understanding of complex chemical reactions compared to traditional teaching methods. The market segmentation of mixers showcases various types, including hot plate devices and multi-position devices, each tailored for specific educational applications, thereby enhancing the content's relevance.

Moreover, educators underscore the necessity of hands-on experience in science education, highlighting that it fosters a deeper connection to the material and promotes active participation in the learning process. As one educator aptly noted, "Hands-on experience is crucial; it transforms theoretical knowledge into practical skills that students will carry into their careers."

Statistics show that mixers with a magnetic stirrer bar are particularly effective for extended procedures, such as protein dialysis, making them suitable for a range of educational applications. The ability to conduct experiments requiring precise blending not only bolsters theoretical understanding but also cultivates essential laboratory skills. Therefore, mixing rods are not merely instruments for blending; they play a pivotal role in shaping the next generation of scientists by enhancing the educational experience in chemistry labs.

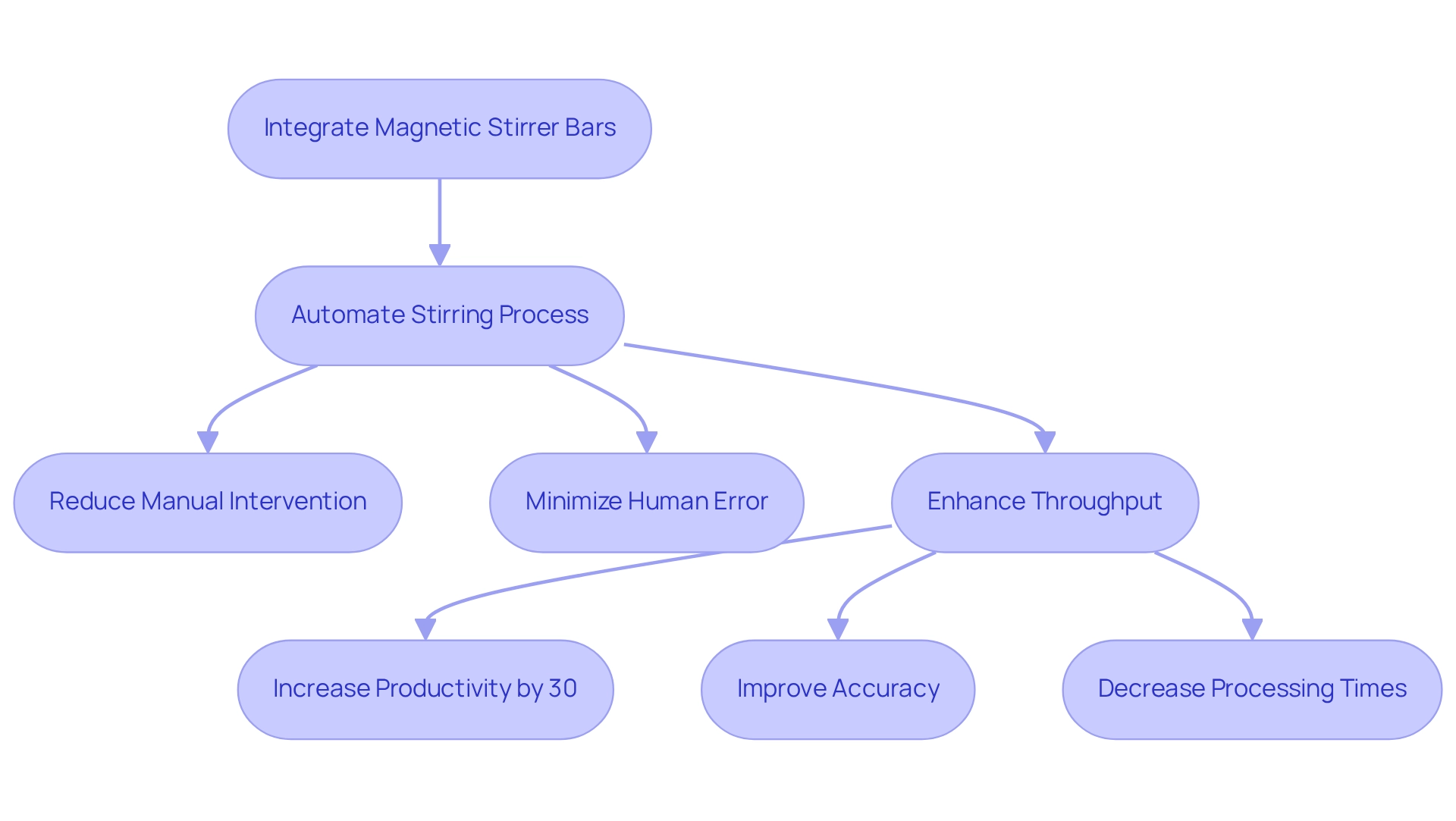

Automation in Laboratories: Integrating Magnetic Stirrer Bars for Enhanced Efficiency

Incorporating mixing rods into automated laboratory systems significantly enhances operational efficiency. By automating the stirring process, laboratories can reduce manual intervention, thereby minimizing human error and enhancing throughput. This is particularly advantageous in high-volume environments, such as pharmaceutical manufacturing and clinical laboratories, where the need for consistent and reproducible results is critical. Automated systems with mixers streamline workflows, allowing scientists to focus on data analysis and interpretation rather than routine tasks. Furthermore, studies indicate that automation can lead to a 30% increase in laboratory productivity, underscoring the importance of these tools in modern scientific practices.

The investment for such automation is approximately USD 3340, a consideration for lab managers as they balance cost with analytical quality, patient safety, and clinical service needs. Real-world applications demonstrate that laboratories using a magnetic stirrer bar have reported enhanced accuracy and decreased processing times, emphasizing its role in improving overall laboratory effectiveness. A case study titled 'Commitment to Innovation in Scientific Instrumentation' from JM Science Inc. illustrates how the integration of these technologies has led to significant advancements in laboratory operations. Moreover, laboratory managers have observed that automation not only improves efficiency but also enables a more concentrated approach to essential tasks, further supporting the significance of the magnetic stirrer bar in contemporary laboratories.

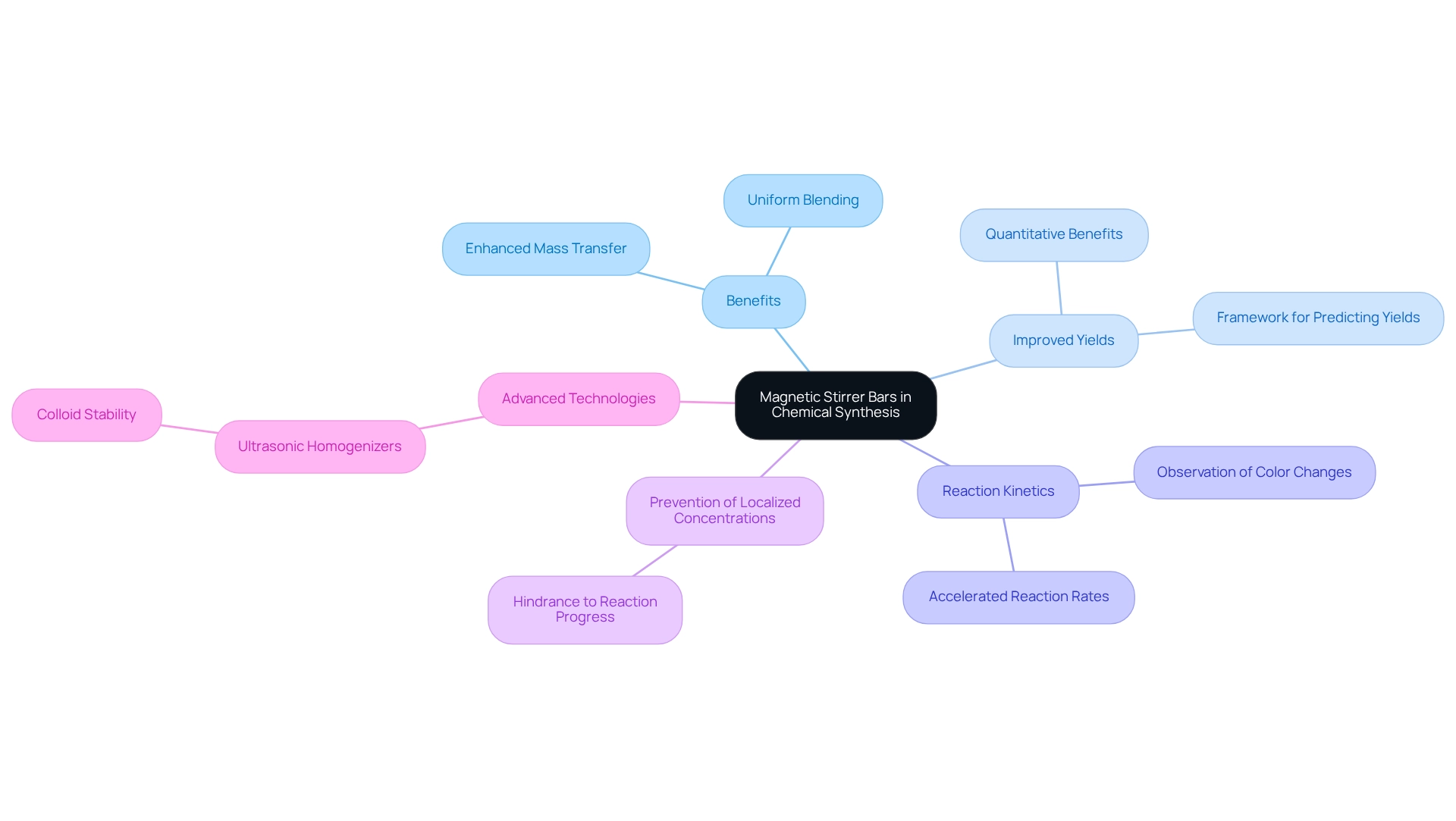

Chemical Synthesis: Facilitating Reactions with Magnetic Stirrer Bars

In chemical synthesis, the use of a magnetic stirrer bar is indispensable as it facilitates thorough blending of reactants essential for optimal reaction conditions. This uniform blending significantly enhances mass transfer and reaction kinetics, ultimately leading to improved yields and accelerated reaction rates. As highlighted, 'stirring is essential in a reaction to ensure uniform incorporation, enhance reaction rates, prevent localized concentrations, and facilitate the observation of color changes to indicate reaction completion.'

By providing a regulated mixing environment, these devices empower chemists to efficiently create new compounds and formulations, making them crucial instruments in both research and industrial applications. The importance of stirring cannot be overstated; it not only aids in achieving uniform integration but also prevents localized concentrations that could hinder reaction progress.

Numerous studies have demonstrated that the use of magnetic stirrer bars leads to significant improvements in reaction yields, highlighting their importance in laboratory settings. For instance, research has aimed to develop a framework for predicting yields in reactions sensitive to blending, emphasizing the quantitative benefits of effective combining.

Moreover, the integration of advanced stirring technologies, such as ultrasonic homogenizers, enhances colloid stability and mixing efficiency, showcasing ongoing innovations in this field. These advancements illustrate how the magnetic stirrer bar and related technologies significantly enhance reaction outcomes in practical applications.

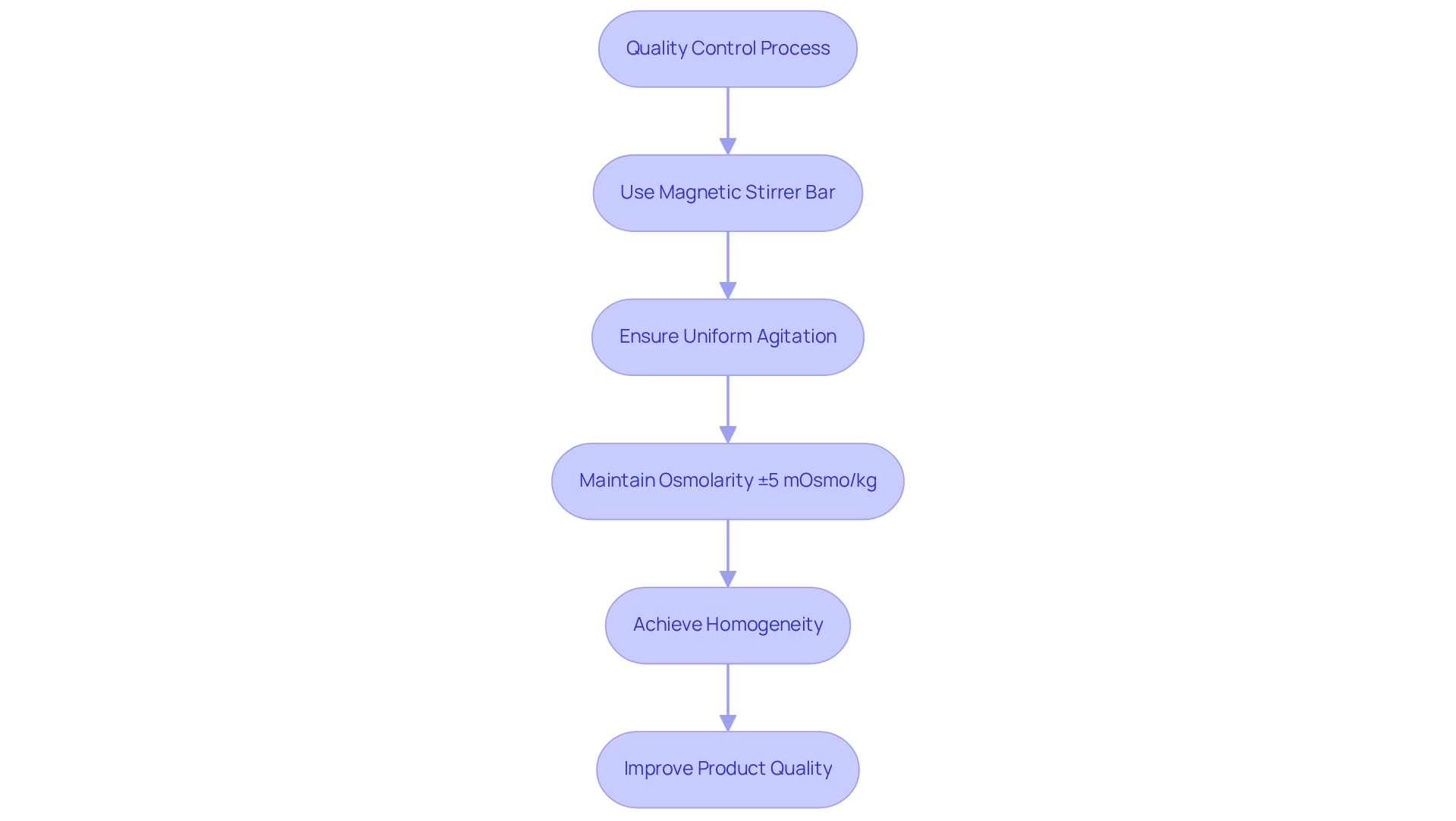

Quality Control: Ensuring Consistency with Magnetic Stirrer Bars

The quality control processes in laboratories and manufacturing environments rely on essential instruments such as the magnetic stirrer bar. They facilitate uniform agitation of samples during testing, which is critical for upholding the integrity of quality evaluations. This consistency is not merely procedural; it is vital for compliance with regulatory standards, ensuring that products are both safe and effective. For example, maintaining osmolarity within ±5 mOsmo/kg is crucial for achieving homogeneity in solutions, directly influencing product quality.

Practical applications demonstrate that the use of mixers significantly enhances the reliability of test outcomes. Quality assurance professionals assert that consistency in testing is paramount for accurate assessments. Naveenganesh Muralidharan, senior manager of the MSAT team, states, "Our article serves as a guide to implementing a scientific and risk-based approach to mixing validation, supporting continuous improvement of biomanufacturing processes." This highlights the indispensable role of the magnetic stirrer bar in quality control workflows, optimizing procedures, and contributing to improved product quality.

Case studies further illustrate the versatility of mixing rods in developing effective quality control practices. Continuous advancements in blending techniques have proven to enhance the efficacy of biomanufacturing processes, underscoring the importance of these tools in achieving high-quality standards. By ensuring comprehensive and consistent agitation, the magnetic stirrer bar ultimately bolsters the safety and effectiveness of laboratory products, making it indispensable in modern scientific practices.

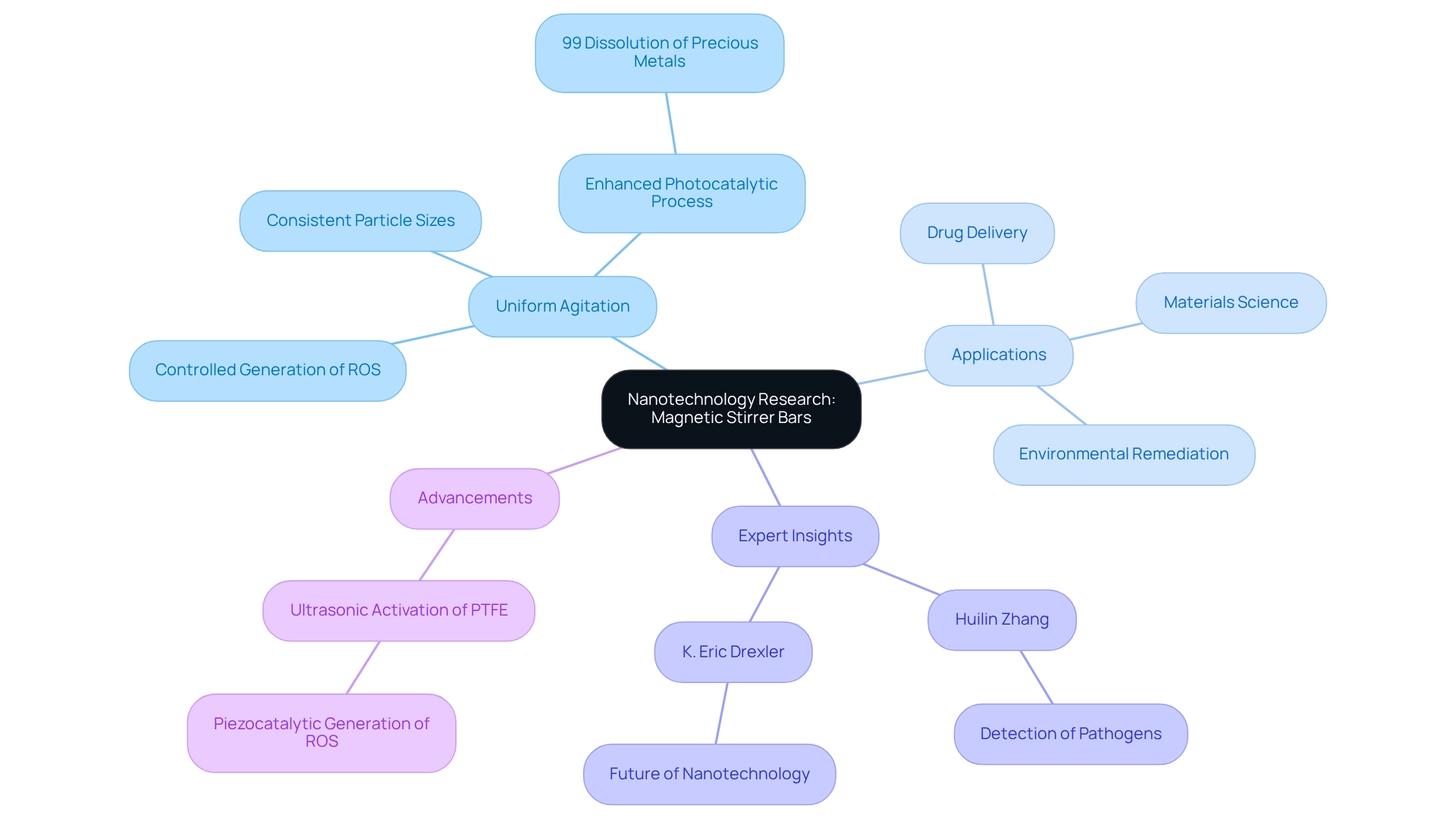

Nanotechnology Research: Utilizing Magnetic Stirrer Bars for Advanced Applications

In the realm of nanotechnology studies, ferromagnetic rods play an indispensable role in the precise blending of nanoscale substances and solutions. Their ability to provide uniform agitation is critical for achieving consistent particle sizes and distributions, which directly impact the performance of nanomaterials across diverse applications. For example, research indicates that uniform agitation can significantly enhance the photocatalytic process, facilitating the selective retrieval of precious metals with over 99% dissolution from waste sources. This remarkable effectiveness is primarily due to the mixing rods' capacity to maintain a homogenous mixture, ensuring optimal interaction among all components during the reaction.

Furthermore, mixing devices are essential for the synthesis and characterization of nanomaterials, driving advancements in vital fields such as drug delivery, materials science, and environmental remediation. Recent studies underscore the ultrasonic activation of PTFE, illustrating how innovative blending techniques, empowered by the effective agitation provided by magnetic stirrer bars, can achieve the controlled generation of reactive oxygen species (ROS) at rates exceeding those of current piezoelectric catalysts. This underscores the critical importance of effective blending in the development of novel materials that address contemporary challenges in environmental and biomedical applications.

Expert insights further reinforce the significance of uniform agitation in nanotechnology. Huilin Zhang emphasizes that precise mixing is vital for the detection of specific pathogens, asserting that uniformity in sample preparation can determine the success of various applications. Moreover, K. Eric Drexler's assertion that the future of nanotechnology will hinge on the instruments available highlights the essential role of mixing rods in advancing the field. As nanotechnology continues to evolve, the role of magnetic stirrer bars in ensuring consistent and reliable results remains crucial.

Conclusion

The exploration of magnetic stirrer bars has highlighted their essential role across various scientific disciplines, underscoring their impact on precision, efficiency, and innovation in laboratory practices. In fields ranging from pharmaceuticals to environmental testing, these tools enhance sample preparation and ensure consistent mixing, which is vital for achieving reliable and reproducible results. The integration of advanced technologies, such as real-time monitoring and automation, further emphasizes the transformative potential of magnetic stirrers in modern laboratories.

In pharmaceutical formulation, the consistent mixing provided by magnetic stirrer bars is crucial for maintaining product quality and therapeutic efficacy. Similarly, in environmental testing, accurate sample mixing ensures that analyses reflect true contaminant levels, aiding compliance with regulatory standards. The benefits extend to educational laboratories, where hands-on experience with these devices cultivates the next generation of scientists, enhancing their understanding of fundamental scientific principles.

As the demand for efficiency and accuracy grows, magnetic stirrer bars are becoming increasingly vital in applications such as chemical synthesis, quality control, and nanotechnology research. Their ability to facilitate optimal mixing conditions not only improves operational workflows but also supports better decision-making in critical areas like healthcare and environmental monitoring. Ultimately, the continued adoption of magnetic stirrer bars will drive advancements across scientific fields, reinforcing their indispensable role in achieving superior research outcomes and fostering innovation.