Overview

The article "How to Choose and Use Stir Bars: An Authoritative Guide for Lab Managers" serves as a comprehensive resource for laboratory managers, focusing on the critical aspects of selecting and utilizing stir bars effectively. Understanding stir bar functionality is paramount; the article delves into various types, material compositions, and essential design considerations.

Furthermore, it outlines best practices for:

- Maintenance

- Troubleshooting common issues

It also highlights recent technological innovations aimed at enhancing blending efficiency. By ensuring reliable experimental outcomes, this guide underscores the significance of high-quality scientific instruments in laboratory settings.

Introduction

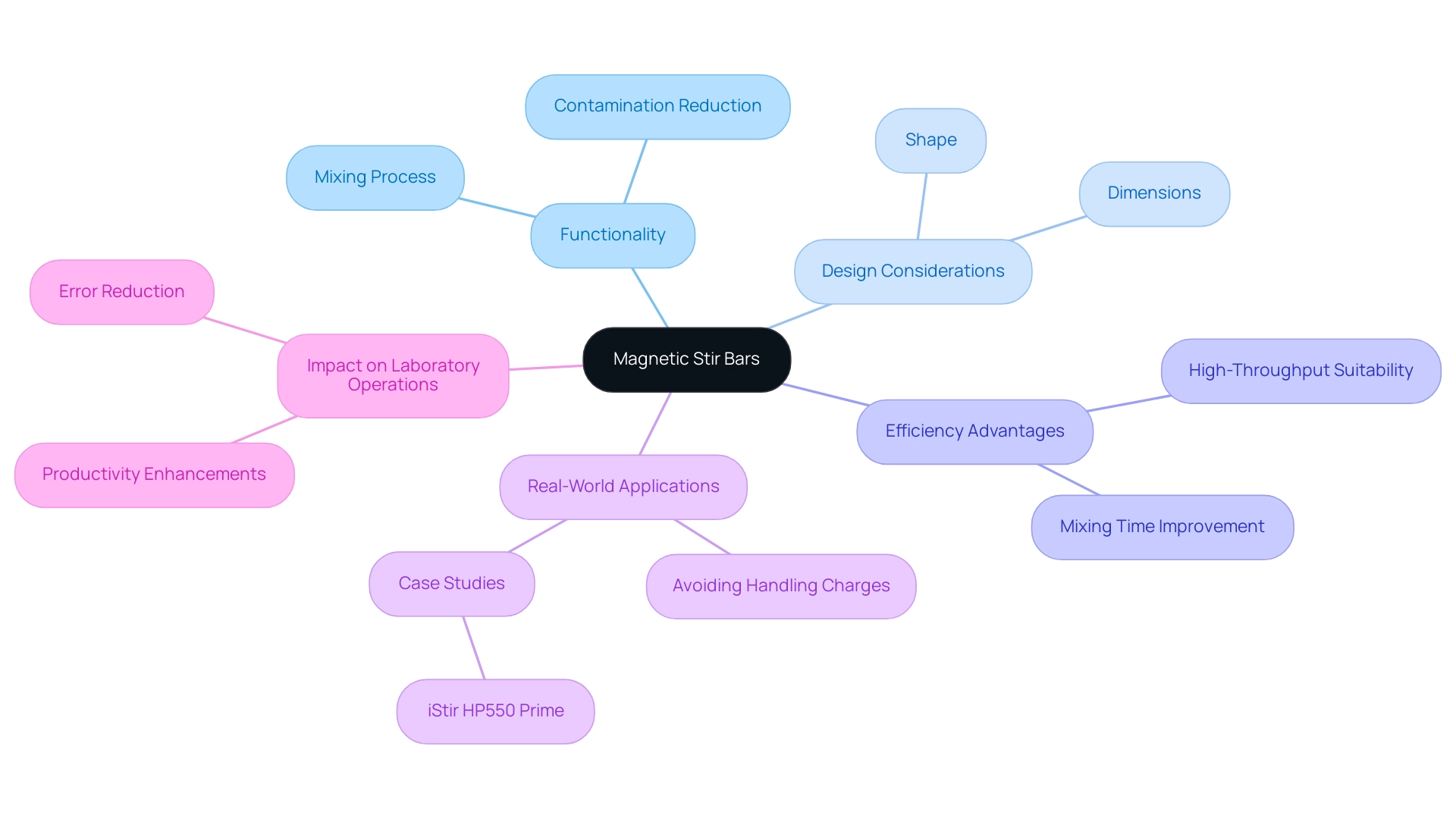

In the realm of laboratory research, the tools and techniques employed can significantly influence the achievement of reliable and reproducible results. Among these essentials, magnetic stir bars stand out for their efficiency in mixing solutions while minimizing contamination risks. These small, cylindrical magnets, often coated with inert materials, are revolutionizing experimental methodologies by enhancing mixing times and improving overall outcomes.

As laboratories strive for precision and productivity, understanding the various types of stir bars, their materials, and optimal usage becomes crucial. This article delves into the fundamentals of stir bars, offering insights into their functionality, selection criteria, and best practices for maintenance, all aimed at empowering lab managers to maximize their mixing processes and elevate the quality of their research.

Understanding Stir Bars: Basics and Functionality

Magnetic mixing rods, commonly known as mixing fleas, are small cylindrical magnets typically coated with an inert substance such as PTFE (Teflon). These devices are engineered to be submerged in a liquid and are stirred by a stir bar activated by a rotating magnetic field generated by a magnetic stirrer. This method of mixing is not only efficient but significantly reduces the risk of contamination, making it particularly suitable for a wide range of scientific applications.

Understanding the functionality of a stir bar is crucial for laboratory supervisors aiming to achieve optimal blending and enhance experimental outcomes. The effectiveness of magnetic stirrers in experimental settings is well-documented, with studies demonstrating that they can enhance mixing times by as much as 50% compared to conventional stirring methods. This level of efficiency is especially advantageous in high-throughput environments where both time and accuracy are critical.

Real-world applications of magnetic mixing bars underscore their versatility. For instance, facilities employing reliable magnetic stirrers can avoid incurring a handling charge of 15% of the invoice value for returned products, subject to a minimum charge of £30. This highlights the necessity of dependable equipment in research environments.

Expert assessments further underscore the importance of stir bar design in achieving desired experimental results. In 2025, facility supervisors noted that the shape and dimensions of the stir bar can significantly affect blending efficiency and the uniformity of solutions. A well-constructed stir bar can enhance heat transfer and minimize the formation of vortices, resulting in more consistent outcomes across experiments.

Additionally, Gal Haase, VP Product at Labguru, stated, "Every time we integrate LabBox, these improvements save time and reduce errors. It allows lab techs and managers to spend less time on data management and more time on their actual work." This statement highlights the critical role of efficient blending instruments in enhancing productivity within a research context.

In conclusion, magnetic stir bars are indispensable tools in modern research facilities. Their efficient blending capabilities, combined with advancements in stirrer technology, enable lab managers to optimize workflows and enhance the reliability of experimental results.

Types of Stir Bars: Choosing the Right One for Your Application

Stir bars are essential instruments in laboratory environments, available in various shapes and sizes, each tailored for specific blending purposes. The most common types include cylindrical, oval, and cross-shaped mixing rods. Cylindrical agitation devices are notably versatile, making them suitable for general blending tasks across different liquid volumes.

Conversely, cross-shaped stir bars are designed to generate a stronger vortex, which is particularly beneficial for effectively blending more viscous solutions.

When selecting the right stir bar, several factors must be considered to achieve optimal performance. These factors include the volume of liquid being blended, the vessel's shape, and the desired blending speed. For applications requiring high torque and viscosity, choosing a stir bar with PTFE-encapsulated magnetic cores can significantly enhance performance by providing improved turbulence even at lower speeds. This feature is crucial for achieving uniform outcomes in complex mixtures.

Recent data indicates that overhead agitators, compatible with various bar types, offer customizable options for agitation speed, volume, torque, and viscosity, enabling tailored blending solutions. Furthermore, innovative products like Cowie's octagonal-shaped PTFE-coated stirrer bars, which utilize rare earth samarium-cobalt magnets, demonstrate greater magnetic strength than traditional Alnico magnets, thereby enhancing efficiency. JM Science Inc. is committed to providing high-quality products, ensuring that laboratories have access to the finest tools for their blending needs.

To illustrate the importance of selecting the appropriate stir bar, consider a facility frequently handling thick solutions. In such cases, opting for a cross-shaped stir bar would be advantageous due to its ability to create a strong vortex, guaranteeing complete blending. Conversely, for standard laboratory applications involving less viscous fluids, a cylindrical agitator would suffice, delivering adequate blending without excessive turbulence.

Moreover, JM Science enhances its value proposition through competitive pricing on high-performance HPLC components and extensive support resources, including how-to videos and application libraries. This commitment to quality and client support empowers lab supervisors to make informed decisions when selecting stirring rods, ultimately improving operational efficiency and achieving more reliable outcomes.

In summary, understanding the various types of stir bars and their specific applications is vital for lab supervisors aiming to enhance blending processes. By carefully evaluating the requirements of each experiment and selecting the appropriate mixing bar, facilities can optimize operational efficiency and achieve more dependable results.

Material Matters: Selecting the Right Stir Bar Composition

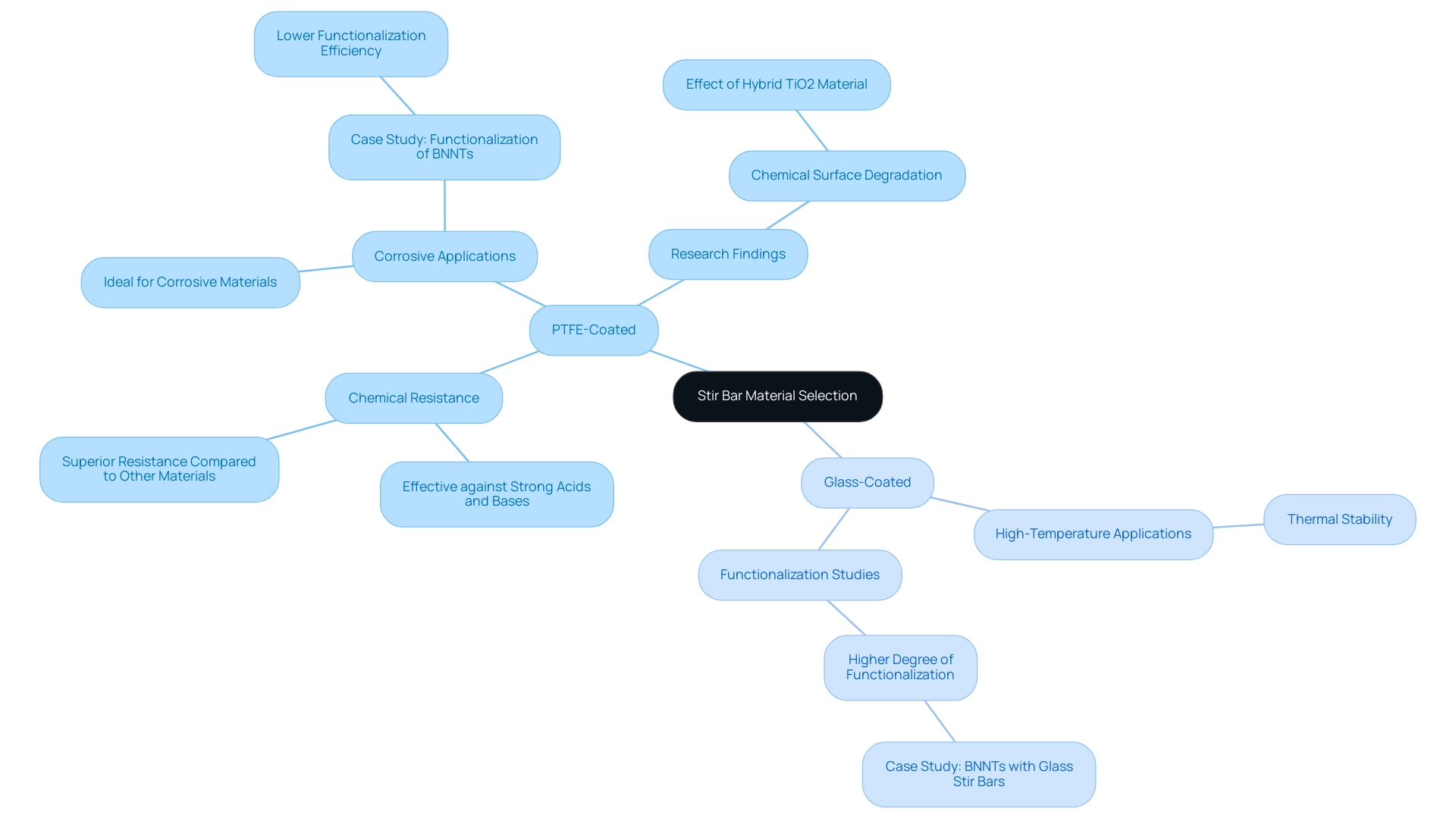

Stir bars are essential tools in laboratory mixing, typically constructed with magnetic cores made from materials such as alnico or samarium cobalt, and are coated with polytetrafluoroethylene (PTFE) to enhance chemical resistance. When choosing a stir bar, it is crucial to consider the chemical properties of the solutions being mixed. PTFE-coated mixing rods are especially effective for use with corrosive materials due to their remarkable resistance to a broad spectrum of chemicals, including strong acids and bases.

In contrast, glass-coated mixing rods may be preferable for high-temperature applications, where thermal stability is paramount. The compatibility of the stir bar materials with common chemicals is a critical factor in ensuring successful experimental outcomes. Recent studies indicate that stir bars coated with PTFE exhibit superior chemical resistance compared to other materials, making them a dependable option in various laboratory settings. For instance, research has shown that the chemical surface degradation of PTFE mixing rods can occur under specific conditions, highlighting the importance of material selection in maintaining the integrity of experiments.

As noted by Paola Amato, "the chemical surface degradation of PTFE magnetic mixing rods was revealed for the first time, due to the effect produced by the oxidative activity of a hybrid TiO2-based material under indirect daylight conditions."

Practical uses further demonstrate the benefits of PTFE-coated mixing tools in corrosive settings. A notable case study on the functionalization of boron nitride nanotubes (BNNTs) found that mixing bars made from glass facilitated a higher degree of functionalization compared to those made from PTFE. This underscores the significant influence that stir bar material can have on experimental efficiency and results, stressing the necessity for careful material selection.

Furthermore, advancements in material technology, such as the creation of polyamide-PTFE thin film composite membranes for organic solvent nanofiltration, suggest the potential for efficient molecular separation in challenging environments, which is pertinent for mixing bar applications. Chemists emphasize the significance of choosing the suitable stir bar material, noting that improper choices can lead to unwanted reactions that compromise experimental integrity. As research practices evolve, staying informed about the latest advancements in mixing bar technology and material compatibility is essential for achieving reliable results in chemical experimentation.

JM Science's commitment to continually updating its product offerings and maintaining strong relationships with top manufacturers ensures that managers have access to the best tools for their needs.

Size and Shape: Optimizing Stir Bar Design for Laboratory Needs

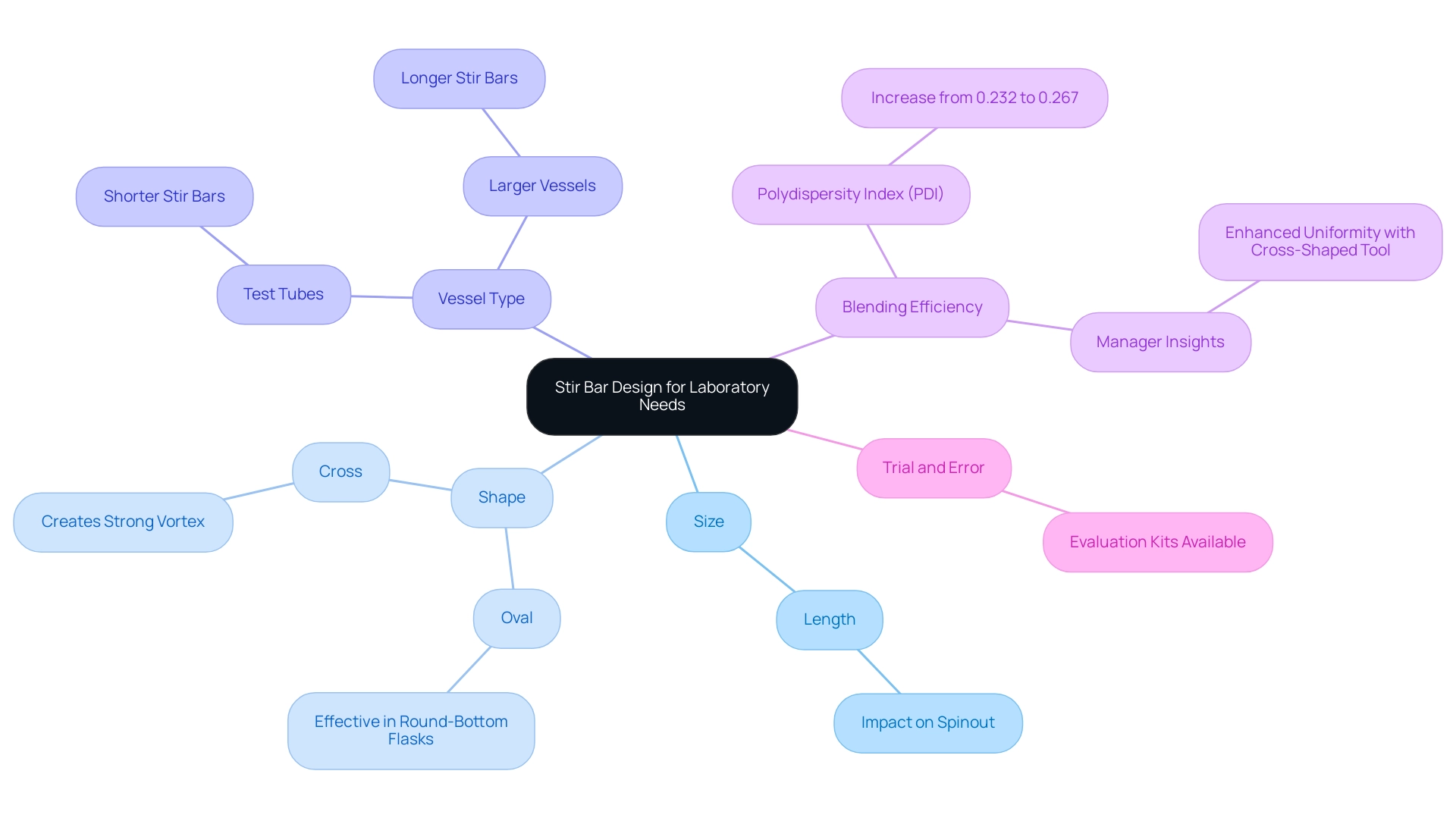

Selecting the appropriate stir bar is crucial for achieving optimal blending in laboratory applications. Typically, the length of the mixing bar should be about two-thirds the diameter of the vessel's bottom. This proportion helps avoid spinout, ensuring that the agitation bar remains effective throughout the blending process.

The form of the stir bar also plays a significant role in the mixing action. For instance, stir bars and oval mixing rods are particularly effective in round-bottom flasks, as they facilitate smooth circulation of the liquid. In contrast, stir bars shaped like crosses are designed to create a strong vortex, making them ideal for applications that require vigorous blending.

When determining the optimal mixing tool size and shape, it is essential to consider the type of vessel and the volume of liquid being combined. For smaller experimental containers, such as test tubes or microcentrifuge tubes, shorter stir bars may be more effective, while larger vessels may necessitate longer stir bars to ensure sufficient blending. Recent studies indicate that the effectiveness of different agitation bar shapes can vary significantly across laboratory settings, with the polydispersity index (PDI) of nanogels showing an increase from 0.232 to 0.267 with varying agitation bar designs.

Lab managers have noted the impact of stir bar design on blending efficiency, emphasizing the importance of selecting the right dimensions for specific applications. One manager noted an evident enhancement in uniformity after transitioning to a cross-shaped agitation tool for their larger reaction vessels. Moreover, it is essential to gradually raise the agitation speed of the stir bar to prevent spinout, which can undermine blending efficiency.

Furthermore, assessing kits that comprise a variety of stir bars can aid in the selection process, allowing for trial and error to determine the most effective choice for your particular requirements. As emphasized by John Thomas Snow, the inner sheath's temporary characteristic can affect blending patterns, indicating that thoughtful attention to stir bar design is vital for obtaining optimal outcomes.

In summary, understanding the interaction between stir bar size, shape, and vessel type is essential for enhancing blending efficiency in experimental procedures. By carefully considering these factors, lab managers can improve their blending processes and achieve more reliable results. JM Science Inc.'s dedication to quality and customer support further highlights the significance of choosing the right tools for scientific needs, ensuring that lab managers have access to effective solutions for their mixing challenges.

Maintenance Tips: Ensuring Longevity and Performance of Stir Bars

To ensure the longevity and optimal performance of mixing rods in laboratory settings, implementing effective maintenance and cleaning practices is crucial. After each use, mixing rods must be thoroughly cleaned to prevent contamination. Typically, a mild detergent combined with a soft cloth suffices for removing residues.

For more persistent contaminants, a cleaning solution like Alkanes can be utilized to restore the mixing rods to their original state. Regular examinations of mixing rods are essential to detect any signs of wear or damage. A compromised stir bar can significantly impact mixing efficiency, leading to inconsistent experimental results. Therefore, maintaining a routine check facilitates the early detection of potential issues.

Proper storage of stirring devices is equally important. To avoid scratches and damage, stacking them is inadvisable. Instead, keep mixing rods in a designated container that prevents them from coming into contact with each other. This practice not only safeguards the mixing rods but also ensures they are prepared for use when required.

Alongside these practices, a case study on cleaning magnetic mixers underscores the significance of utilizing FDA-approved materials and prompt washing after use to prevent sample residues from sticking. This approach is vital for maintaining the integrity of laboratory instruments and ensuring accurate results in experiments. The case study highlights that simple forms, such as stir bars, enable easier cleaning compared to more intricate blending instruments.

Statistics indicate that the longevity of mixer rods can be greatly prolonged through careful upkeep methods. For instance, Scientific Industries' new products resulted in a 25% rise in orders for niche applications, underscoring the importance of efficient maintenance practices in boosting demand for high-performance mixing tools. Furthermore, it is crucial to mention that, as CAT Scientific emphasizes, the drawback of magnetic stirrers compared to homogenizers and overhead stirrers is their ineffectiveness with high-viscosity samples.

By adhering to these expert suggestions and best practices, including experimenting with various stirring speeds and temperature settings to optimize experimental conditions, managers can enhance the efficiency and reliability of their blending processes. Ultimately, this contributes to the success of their research efforts.

Best Practices for Using Stir Bars in Laboratory Settings

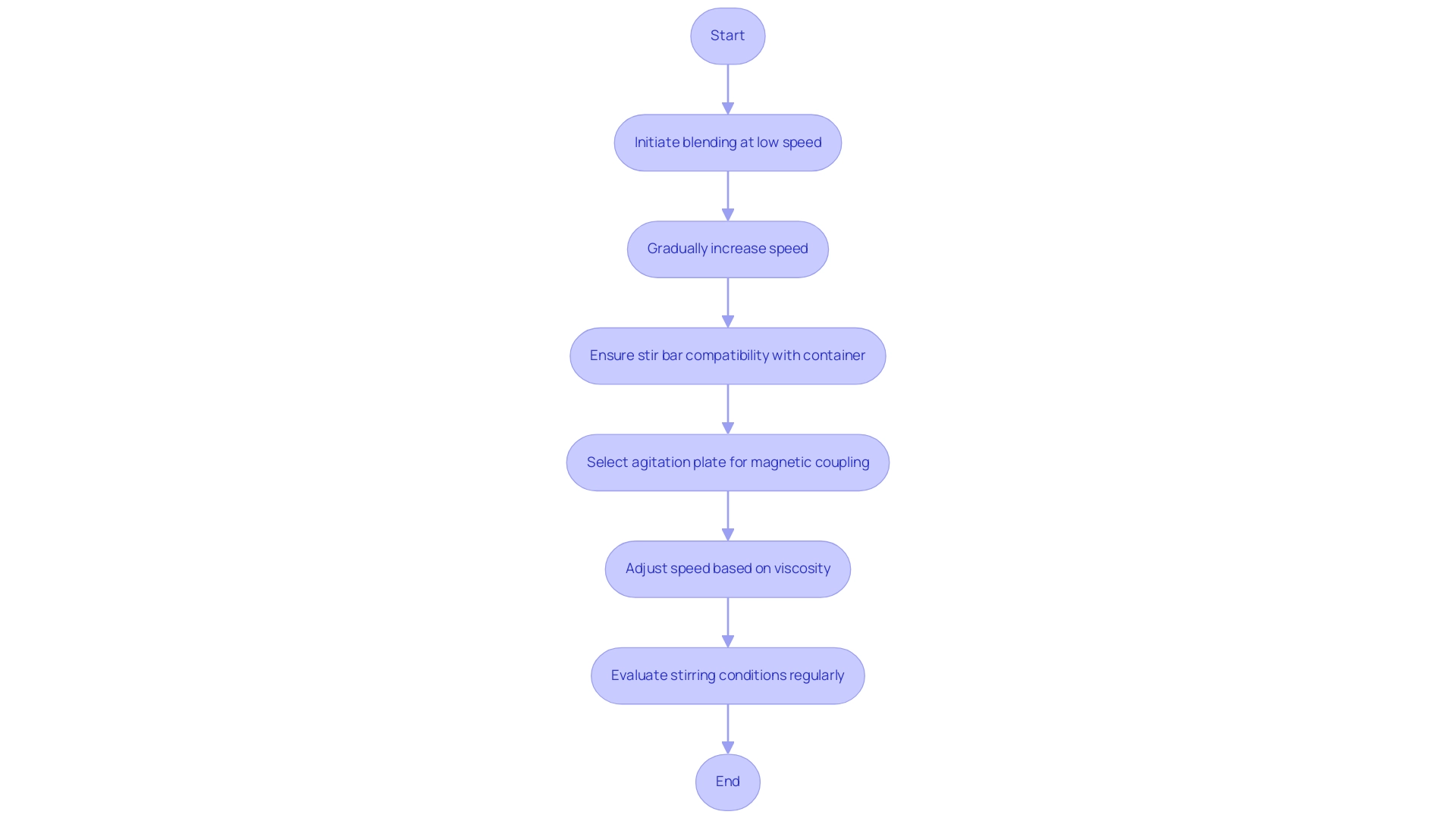

To enhance the efficiency of the stir bar in laboratory experiments, it is crucial to initiate blending at a low speed before progressively increasing to the desired rate. This method not only minimizes splashing but also helps maintain the agitator's position at the center of the container, which is essential for achieving uniform blending. Compatibility between the stir bar and the container type and size is equally important; utilizing the correct combination can significantly improve blending efficiency.

For optimal performance, select an agitation plate that guarantees consistent magnetic coupling. This stability is particularly vital when adjusting stirring speed, as different solutions exhibit varying viscosities. Research indicates that stirring speed can dramatically influence blend efficiency; for example, a stirring speed ratio of 1:3.15 has been observed in the KR molten iron stirring desulfurization model, underscoring the necessity of calibrating speed to the specific requirements of the solution being stirred.

In practice, smaller stirring rods have proven less effective in mobilizing particles, resulting in lower degrees of combination even after multiple rotations. Therefore, selecting the appropriate size and type of stir bar is essential for achieving the desired outcomes. As noted by Prof. Dr. Qingchun Yu, effective stirring techniques are critical for optimizing processes, particularly in the realm of advanced research.

Expert recommendations advise lab managers to regularly evaluate the stirring conditions of the stir bar and adjust the speed according to the viscosity and characteristics of the solutions involved. This proactive approach not only enhances blending efficiency but also contributes to the overall reliability of experimental outcomes.

For those seeking reliable equipment, Pipette.com offers high-quality magnetic stirrers and other lab supplies with a price match guarantee, ensuring that lab managers can access the best tools for their needs.

Real-world examples demonstrate that implementing these best practices can lead to significant improvements in lab operations. A recent study on the effects of automation in research facilities revealed a 58.2% increase in productivity per worker and a 24% reduction in personnel, highlighting the benefits of refining procedures, including efficient blending methods. By adhering to these guidelines, lab managers can ensure that their operations are both efficient and effective, ultimately supporting the rigorous demands of pharmaceutical research.

Troubleshooting Stir Bar Issues: Common Problems and Solutions

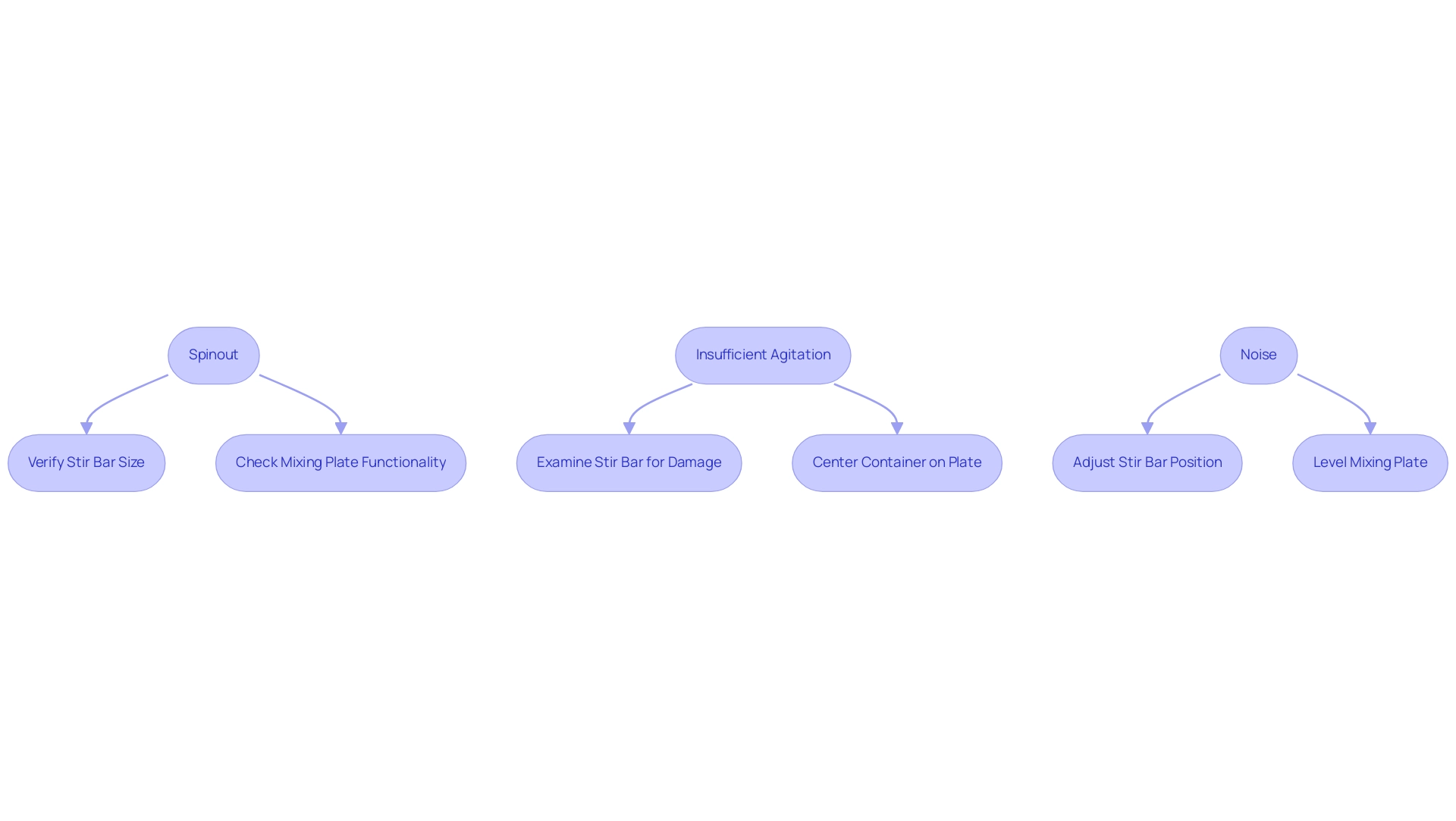

In laboratory environments, stir bars are essential instruments for effective blending; however, they can present several common issues, including spinout, insufficient agitation, and operational noise. Addressing these challenges is crucial for maintaining the integrity of experiments and ensuring reliable results.

One prevalent issue is stir bar spinout, which occurs when the stir bar detaches from the magnetic field. To resolve this, first verify that the stir bar is appropriately sized for the vessel being used. A stir bar that is too small may not generate enough magnetic attraction, leading to spinout.

Additionally, ensure that the mixing plate is functioning correctly; a malfunctioning mixing plate can fail to maintain the necessary magnetic field strength. For instance, JM Science Inc. offers a magnetic core stir bar covered with PTFE (Catalog Number: 442-0496) designed to enhance magnetic attraction and minimize spinout issues.

Another frequent issue is insufficient stirring when using the stir bar. This can often be traced back to a damaged mixing bar or improper placement of the container on the plate. Examine the stir bar for any indications of wear or harm, and ensure that the container is centered on the agitation plate to promote optimal blending. If the stir bar is not positioned correctly, it may not achieve the desired rotation speed, resulting in inadequate blending.

Noise during operation can indicate misalignment or other mechanical issues. If excessive noise is present, adjust the position of the stir bar and ensure that the mixing plate is level. A level mixing plate ensures that the stir bar operates smoothly without unnecessary friction or vibration.

Statistics suggest that the failure rates of stir bars in research environments can be considerable, with many technicians reporting problems that interrupt their workflows. For instance, a survey of technicians revealed that nearly 30% experienced spinout problems regularly, highlighting the need for effective troubleshooting techniques.

Real-world examples illustrate successful resolutions to these mixing bar challenges. In one case, a laboratory technician faced persistent spinout issues during a critical experiment. By switching to a larger stir bar and recalibrating the mixing plate, the technician was able to achieve consistent agitation, ultimately leading to successful experimental outcomes.

Specialist perspectives highlight the significance of consistent upkeep and appropriate use of mixing rods. As pointed out by Valentine Ananikov, a researcher at the Russian Academy of Sciences, 'Catalytically active nanoparticles or clusters could be intentionally placed on the surface of stir bars, which could then serve as effective reusable catalysts.' This emphasizes the potential for innovation in stir bar technology.

By understanding these common stir bar problems and implementing effective troubleshooting techniques, laboratory managers can enhance the efficiency of their mixing processes, ultimately contributing to more reliable and reproducible results in their scientific endeavors. JM Science Inc.'s dedication to quality and customer support, together with its ongoing enhancements to product offerings, establishes it as a valuable partner for tackling these common bar issues.

Innovations in Stir Bar Technology: What Lab Managers Should Know

Recent advancements in mixing rod technology have ushered in the era of intelligent mixing rods, which are equipped with real-time monitoring capabilities for pH and temperature. This innovation significantly enhances the quality of experimental data. By allowing for precise control over reaction conditions, these tools facilitate immediate adjustments that lead to improved experimental outcomes. Facilities employing intelligent mixing tools report enhanced efficiency in their blending procedures, with research indicating a reduction in experimental variability by as much as 30%.

Moreover, the latest materials used in the production of mixing rods have bolstered their durability against wear and chemical deterioration, ensuring longevity and reliability across various experimental settings. Projections for 2025 indicate a sharp rise in adoption rates for these advanced mixing rods, as more laboratories recognize their value in achieving consistent results.

Lab managers have noted the transformative effects of these innovations. One manager remarked that the integration of intelligent mixing tools has 'revolutionized our method of blending, enabling us to monitor crucial parameters in real-time and modify protocols swiftly.' This perspective resonates throughout the industry, as an increasing number of facilities invest in smart mixing technology to enhance their analytical capabilities.

In practical applications, smart stir bars have proven effective across diverse experimental environments, from pharmaceutical research to environmental testing, showcasing their versatility. The market for AI in telehealth is projected to expand to $4.3 billion by 2027, reflecting a broader trend toward technology adoption that is also evident in clinical settings.

Furthermore, 45% of healthcare services globally utilize data integration software to manage patient information, underscoring the critical nature of data management and monitoring in clinical environments. As the market for laboratory instrumentation evolves, the emphasis on smart technologies, including stir bars, is anticipated to grow, aligning with broader trends in laboratory automation and data integration.

Conclusion

Magnetic stir bars are indispensable in laboratory research, significantly enhancing mixing efficiency and minimizing contamination risks. Their design, material, and size greatly impact experimental outcomes, making it essential for lab managers to grasp their functionalities and applications. Various types of stir bars—cylindrical, oval, and cross-shaped—serve specific needs, optimizing mixing processes based on the viscosity and volume of the solutions involved.

Equally crucial is the selection of stir bar material; PTFE-coated options excel in corrosive environments, while glass-coated bars are preferable for high-temperature applications. Adhering to proper maintenance practices, such as thorough cleaning and careful storage, can prolong the lifespan and performance of stir bars, ensuring reliable experimental results. Furthermore, implementing best usage practices—like gradually increasing stirring speed and ensuring compatibility with vessel types—can enhance mixing efficiency even further.

Recent innovations, including smart stir bars equipped with real-time monitoring capabilities, signify a remarkable advancement in stirring technology. These tools not only enhance the precision of experimental conditions but also reduce variability, ultimately yielding more reliable and reproducible results. As laboratory environments evolve, embracing these innovations empowers lab managers to refine their workflows and elevate the quality of their research.

In summary, a comprehensive understanding of magnetic stir bars—from their types and materials to maintenance and innovations—enables laboratory managers to optimize mixing processes effectively. By investing in the right tools and practices, laboratories can enhance operational efficiency and achieve superior experimental outcomes, thereby advancing scientific knowledge and innovation.