Overview

Effectively choosing and utilizing a 250 ml beaker requires a comprehensive understanding of its features, types, and maintenance practices, which are crucial for optimal performance in laboratory settings. Selecting the appropriate beaker type based on specific application needs is paramount. Key features such as graduation marks and spout design play a critical role in ensuring accuracy during experiments.

Furthermore, adhering to best practices for maintenance and compliance with safety standards promotes reliability and safety in all laboratory activities. By prioritizing these elements, laboratory professionals can enhance the effectiveness of their work.

Introduction

In the realm of laboratory equipment, the 250 ml beaker emerges as an indispensable tool, fundamental to a wide array of scientific tasks. This cylindrical container excels in mixing, heating, and precise measurements, designed meticulously to meet the rigorous demands of modern research. Equipped with graduated markings for accuracy, a spout for effortless pouring, and a robust construction that withstands thermal shock and chemical exposure, the 250 ml beaker proves to be a reliable companion in both chemistry labs and medical diagnostics.

As laboratories evolve, it becomes crucial to understand the various types and materials of beakers, alongside best practices for their use and maintenance, ensuring safety and efficiency in experimental outcomes. This article delves into the essential aspects of 250 ml beakers, offering insights that empower laboratory professionals to make informed decisions in their scientific endeavors.

Understanding the Basics of 250 ml Beakers

The 250 ml beaker stands as an indispensable tool in laboratories, serving a multitude of functions such as mixing, heating, and holding liquids. Defined by its flat bottom, spout for effortless pouring, and graduated markings for precise volume measurement, this container is meticulously crafted to meet the stringent demands of scientific research. Its robust construction enables it to withstand thermal shock and resist chemical exposure, rendering it a versatile asset in both chemistry labs and medical diagnostics.

Significantly, the coefficient of linear expansion of the glass is 3.3, which enhances its capacity to endure temperature fluctuations without compromising structural integrity.

As we look to 2025, expert perspectives underscore the critical role of container characteristics in research environments. The autoclavable feature of the 250 ml beaker enhances its functionality, allowing for repeated sterilization and compliance with stringent standards. This adaptability is vital, as numerous laboratories report that a substantial percentage—over 70%—utilize containers for both mixing and heating processes, underscoring their essential role in experimental protocols.

Laboratory professionals consistently commend the 250 ml beaker for its reliability and functionality. User feedback highlights that the container's design promotes accurate measurements and efficient liquid handling, which are imperative for successful experimental outcomes. A case study titled "Commitment to Quality and Innovation" exemplifies how JM Science's commitment to quality elevates the functionality of their products, including the 250 ml beaker.

Moreover, a quote from Robert S. reinforces this sentiment: "I don't think I've ever experienced that level of customer service before, and taking it into consideration along with the quality of their products, I would absolutely recommend Geyer to fellow teachers."

Furthermore, the importance of container design cannot be overstated. Features such as the spout and graduated markings not only enhance usability but also contribute significantly to the precision of experiments. As research facilities continue to evolve, the demand for high-quality containers that fulfill these specifications remains critical, ensuring that scientists can rely on their instruments for consistent and reproducible outcomes.

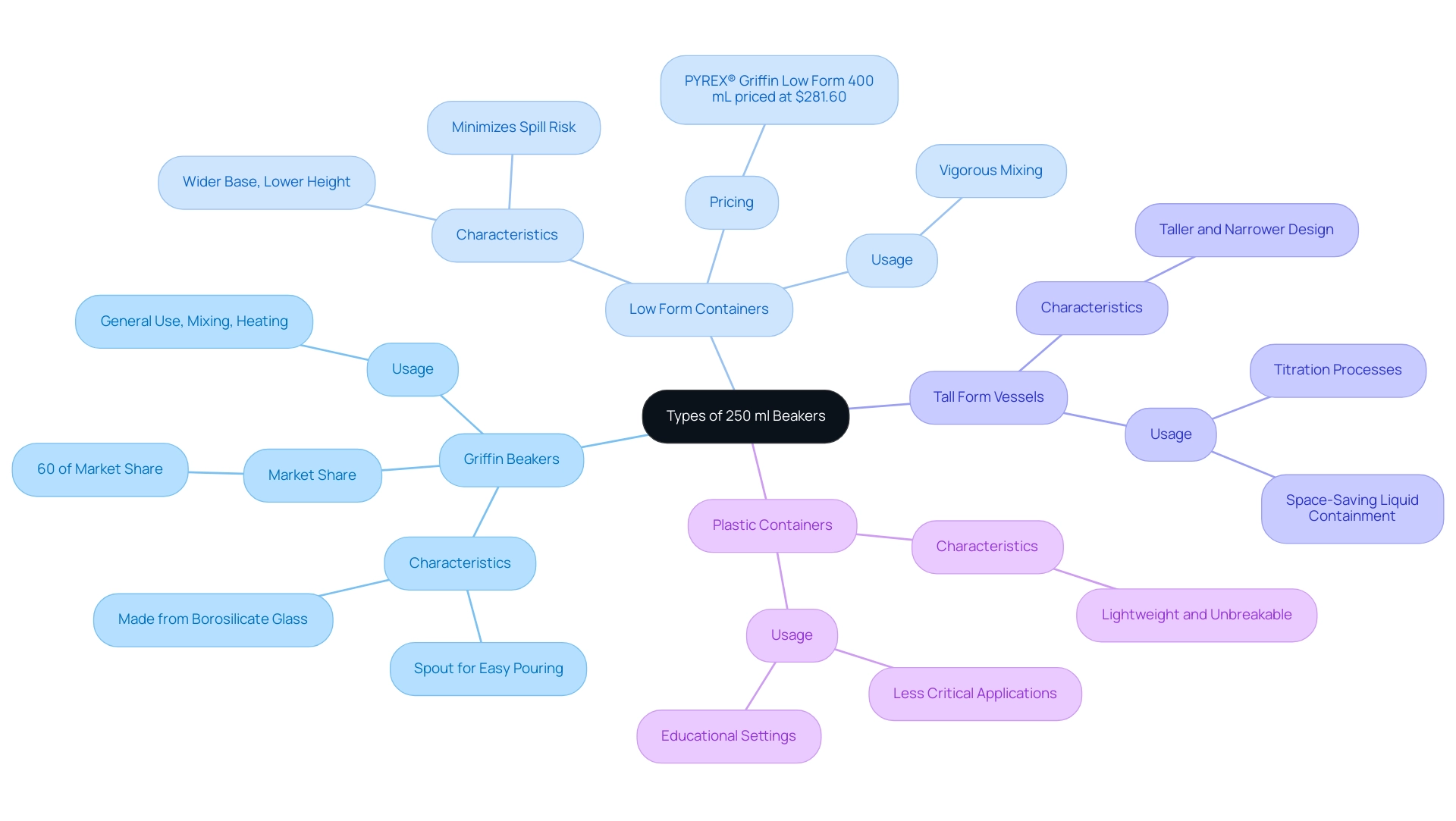

Exploring Different Types of 250 ml Beakers

When selecting a 250 ml beaker, understanding the various types available is essential, as each is designed for specific laboratory applications.

- Griffin Beakers are the most widely used beakers, characterized by their spout, which facilitates easy pouring. Typically made from borosilicate glass, they are ideal for general use, including mixing and heating solutions. Their versatility underscores their popularity, making them a staple in many labs. Notably, Griffin containers represent approximately 60% of the market share among 250 ml beakers, indicating their widespread acceptance and dependability in research environments.

- Low Form Containers are specifically designed for mixing and heating, featuring a wider base and lower height that minimize the risk of spills. This design allows for better stability during use, making them particularly useful in experiments requiring vigorous mixing. For instance, the PYREX® Griffin Low Form 400 mL container is priced at $281.60, illustrating the cost of quality vessels for laboratory managers.

- Tall Form Vessels, being taller and narrower than their counterparts, are suitable for applications that require a smaller footprint. They are often employed in titration processes or when a larger volume of liquid needs containment without occupying much space on the lab bench.

- Plastic Containers are lightweight and unbreakable, making them perfect for educational settings or environments where breakage poses a significant risk. Available in various sizes, they are often utilized for less critical applications where precision is not paramount.

Understanding these options is crucial for laboratory managers when selecting the appropriate container for specific tasks. Expert opinions emphasize the importance of choosing the right container type according to the intended application. Laboratory managers have noted that while Griffin containers excel in general use, low form vessels are preferred for tasks involving vigorous mixing due to their stability.

As one lab supervisor articulated, "Selecting the appropriate container can greatly affect the effectiveness and safety of our experiments." Additionally, customer feedback reinforces this sentiment, with one Amazon customer noting that these containers are 'thick and sturdy, fun for drinking glasses and accurate for measuring!'

By comprehending the unique traits and uses of each type of container, professionals in the field can make informed choices that enhance operational efficiency and ensure precise outcomes. Furthermore, JM Science Inc.'s commitment to quality and customer support, along with the availability of quality certificates for Corning products, underscores the significance of compliance and quality assurance in testing environments.

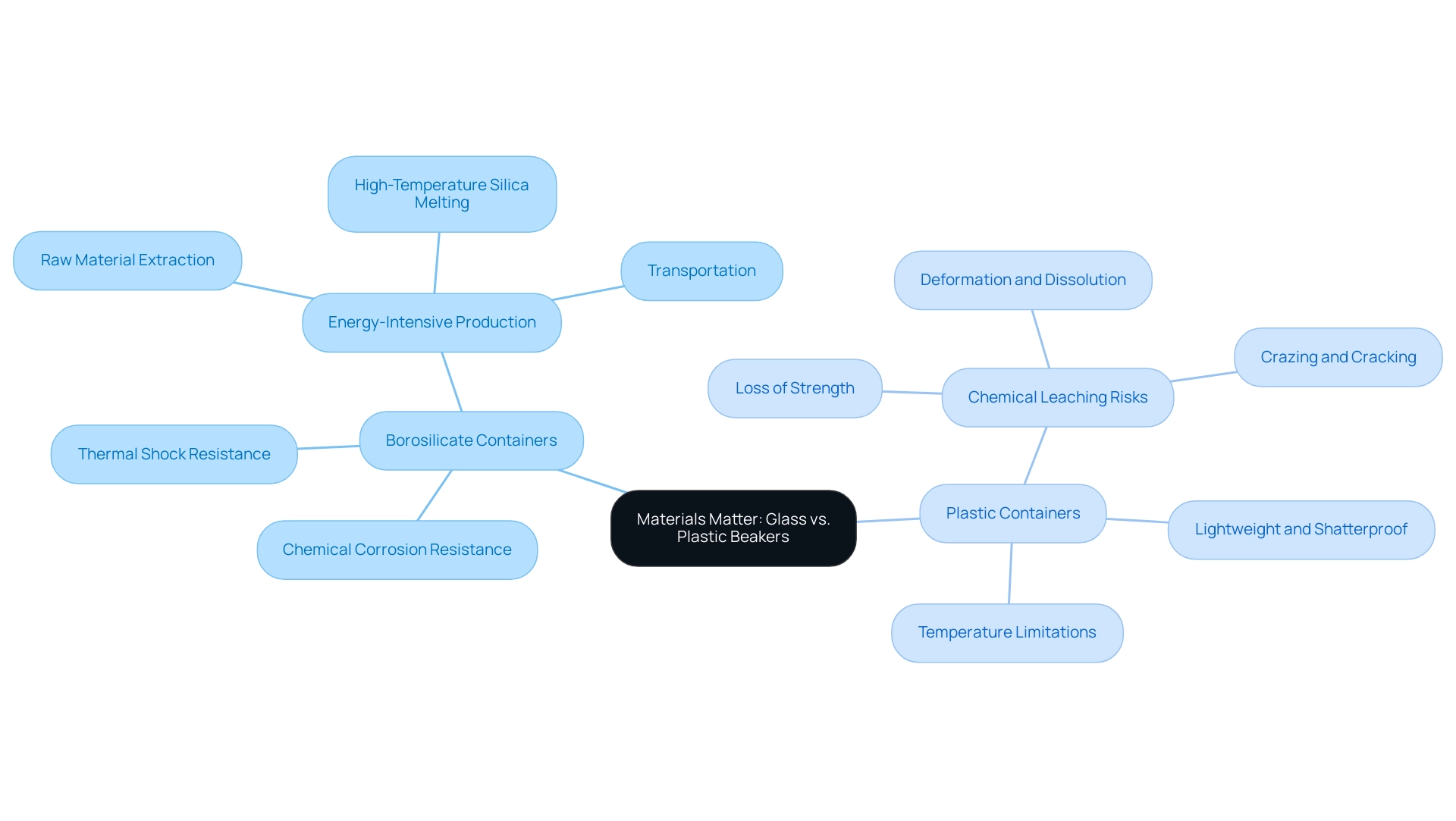

Materials Matter: Glass vs. Plastic Beakers

When selecting a 250 ml container, the choice of material is vital for ensuring optimal performance in laboratory environments.

Borosilicate Containers: Typically composed of borosilicate material, these vessels exhibit exceptional resistance to thermal shock and chemical corrosion. This characteristic renders them particularly suitable for high-temperature applications and experiments involving reactive substances. Their durability and stability under varying temperatures facilitate precise measurements and reliable results, especially in critical processes such as evaporation and crystallization. However, it is crucial to recognize that the manufacturing of transparent materials is energy-intensive, as discussed in a study published in the 'Journal of Cleaner Production,' which addresses the environmental considerations associated with its production.

Plastic Containers: Generally made from polypropylene or polystyrene, plastic containers are lightweight and shatterproof, making them ideal for handling less hazardous materials. However, they do have limitations; they may not withstand high temperatures and can be prone to chemical leaching, potentially compromising sample integrity. Immediate damage can occur depending on the type of plastic used, leading to issues such as crazing, cracking, or loss of strength. For instance, using a plastic container for a high-temperature reaction could result in deformation or dissolution, impacting the experiment's outcomes.

The decision between ceramic and plastic vessels should be guided by the specific needs of your experiments, including factors such as temperature resistance, chemical compatibility, and safety considerations. For example, while borosilicate containers are favored for their durability in high-temperature applications, a 250 ml beaker may be more appropriate for routine tasks involving non-reactive solutions. Recent insights from experts underscore the significance of material selection in experimental settings.

In 2025, it is widely acknowledged that borosilicate vessels offer superior thermal shock resistance compared to their plastic counterparts, establishing them as the preferred choice for rigorous scientific applications. Furthermore, studies indicate that glass containers maintain chemical compatibility across a broader range of substances, further solidifying their role in precise scientific work.

Real-world examples highlight the effectiveness of borosilicate glass vessels in high-temperature applications, demonstrating their capacity to endure extreme conditions without compromising sample quality. Conversely, plastic containers have proven beneficial in various chemical experiments where protection and ease of use are paramount, particularly in educational environments or initial testing phases. Additionally, flat-form containers are frequently utilized for evaporation and crystallization, while low-shaped vessels are preferred for mixing and heating liquids in research settings.

Ultimately, understanding the advantages and limitations of each material will empower managers to make informed decisions that enhance the precision and safety of their scientific endeavors. As 91% of life sciences companies plan to increase their investment in R&D innovation, the importance of high-quality research equipment cannot be overstated, as it fosters advancements in research and development.

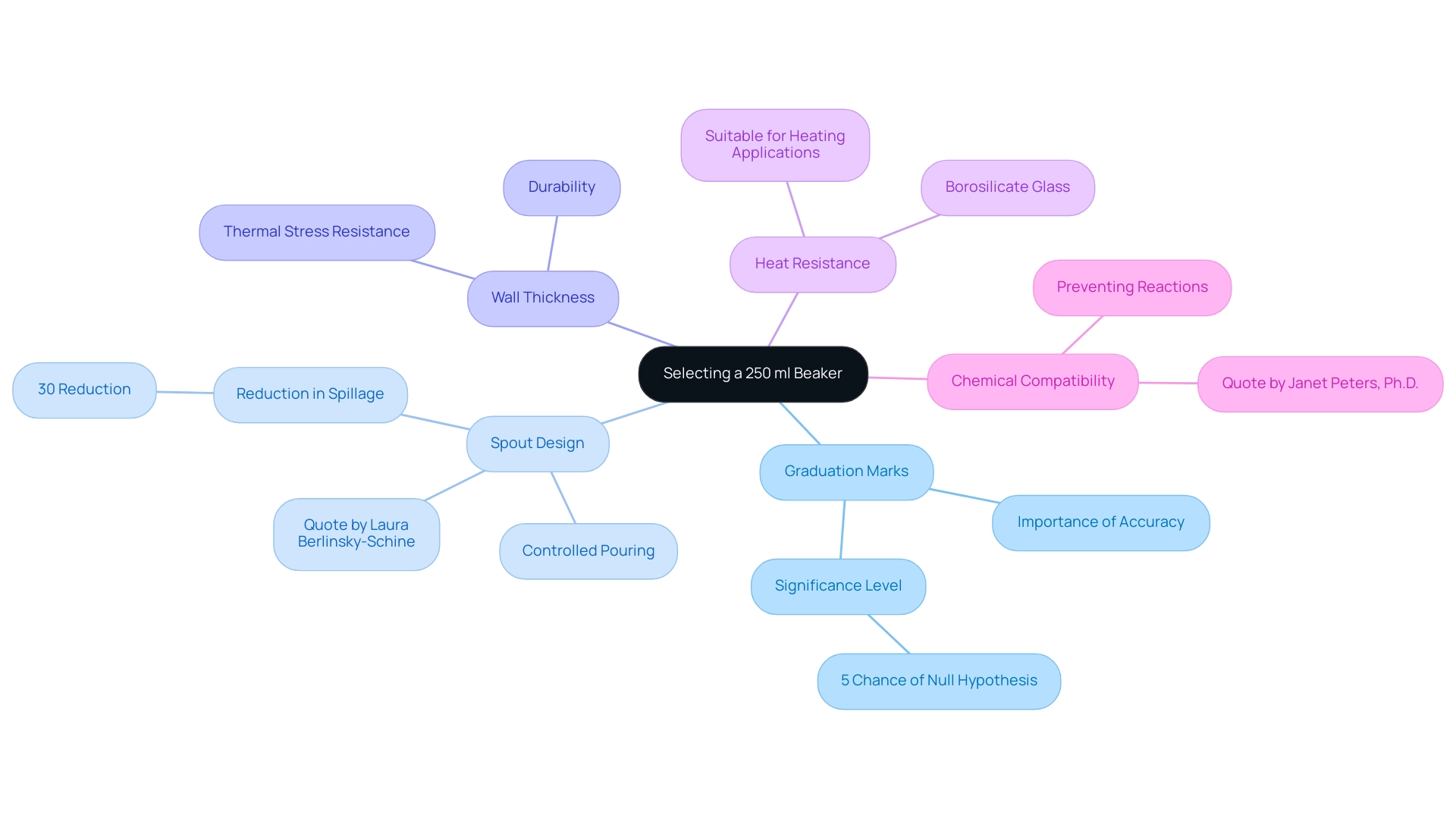

Key Features to Consider When Selecting a 250 ml Beaker

When selecting a 250 ml beaker, several key features must be prioritized to ensure optimal performance and safety in laboratory settings:

- Graduation Marks: Clear and accurate graduation marks are essential for precise measurements. Studies indicate that containers with well-defined graduation marks significantly improve measurement accuracy, reducing the likelihood of errors in experimental procedures. A significance level of 5% is typically set for studies, indicating a less than 5% chance of findings occurring under the null hypothesis, underscoring the critical nature of accuracy in measurements.

- Spout Design: A thoughtfully designed spout on the 250 ml beaker is crucial for controlled pouring, minimizing spills and enhancing efficiency. Research indicates that containers with optimized spout designs can reduce spillage by up to 30%, making them a preferred choice in busy laboratory environments. As noted by Laura Berlinsky-Schine, "This statistic just shouldn’t necessarily be a making or breaking point for students in the admissions process," highlighting the importance of practical design features in educational settings.

- Wall Thickness: The durability of a 250 ml beaker is often determined by the thickness of its walls. Thicker walls not only offer greater resistance to breakage but also improve the container's ability to endure thermal stress, especially in vessels used for heating applications.

- Heat Resistance: For experiments involving heating, it is vital to select a 250 ml beaker that can endure high temperatures without deforming. Beakers made from borosilicate glass, for instance, are known for their excellent heat resistance, making them suitable for a variety of laboratory applications.

- Chemical Compatibility: Ensure that the material of the 250 ml beaker is compatible with the chemicals being used. This is especially crucial in preventing reactions that could jeopardize both the integrity of the container and the accuracy of the results. Janet Peters, Ph.D., emphasizes that "the good news is that it’s also incredibly fun – statistics unites all areas of psychology and is present in everyday life," which parallels the significance of statistical accuracy in experimental measurements.

By concentrating on these characteristics, you can choose a container that not only fulfills functional needs but also enhances safety and efficiency in your operational processes. JM Science Inc. distinguishes itself through its commitment to quality, customer support, and a strategic emphasis on innovation in scientific instrumentation, ensuring that you have access to the best products for your research needs.

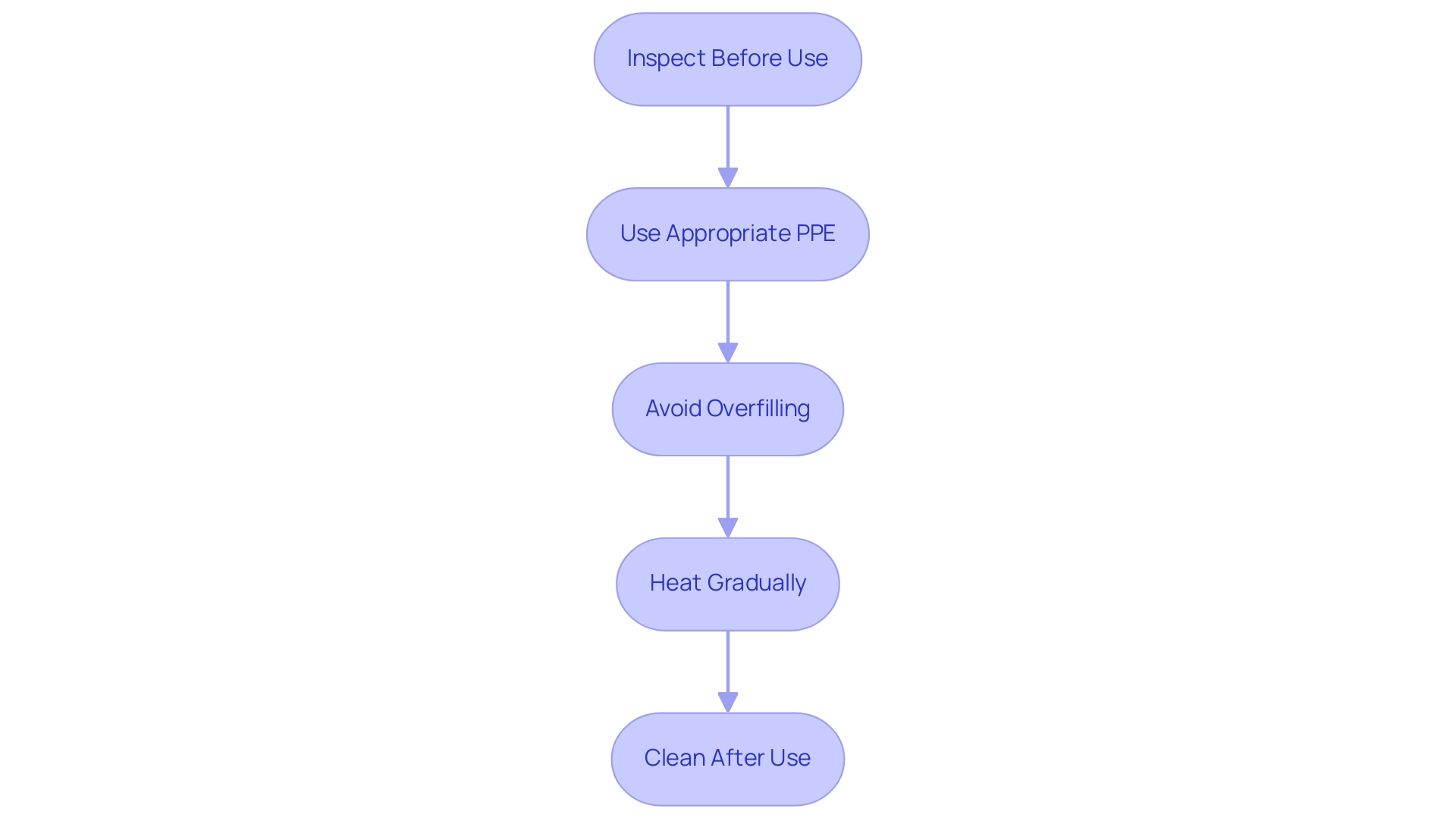

Best Practices for Using a 250 ml Beaker Safely and Effectively

To ensure the safe and effective use of a 250 ml container, it is imperative to adhere to the following best practices:

- Inspect Before Use: Always examine glass vessels for any cracks or chips prior to use. Such imperfections can compromise the integrity of the container, leading to breakage during experiments, which is a common cause of laboratory accidents.

- Use Appropriate PPE: Equip yourself with gloves and protective goggles when handling chemicals. This protective equipment is crucial to shield against spills and splashes, greatly diminishing the risk of injury.

- Avoid Overfilling: Refrain from filling the 250 ml beaker to the brim. Leaving adequate space is crucial to prevent overflow when adding substances, which can lead to hazardous situations.

- Heat Gradually: When heating liquids, apply gradual heat to avoid thermal shock. Rapid temperature fluctuations can lead to glass containers breaking, creating hazards in the laboratory.

- Clean After Use: Rinse the vessel promptly after use to remove residue accumulation. This method not only preserves the container's state but also guarantees the precision of upcoming experiments.

Implementing these approaches encourages a culture of security and creativity in the workspace, ultimately boosting employee involvement and aiding in cost reductions. As emphasized by officers, following established protocols is crucial for reducing risks related to laboratory work involving a 250 ml beaker. The tragic incident involving Sheharbano Sangji serves as a stark reminder of the consequences of overlooking precautionary measures. Furthermore, the University of California, Los Angeles (UCLA) revamped its security procedures after a lab accident in 2008, resulting in a 25-fold increase in lab personnel attending online training. This highlights the significance of thorough training and protocols in promoting a more secure research environment. As Alberto Galasso pointed out, the publication rates of wet labs performing experiments did not vary considerably after the shock, underscoring the necessity for continued dedication to security in laboratory environments. Promoting sustainability in labs also plays a crucial role in fostering a culture of safety and innovation.

Caring for Your 250 ml Beaker: Maintenance Tips

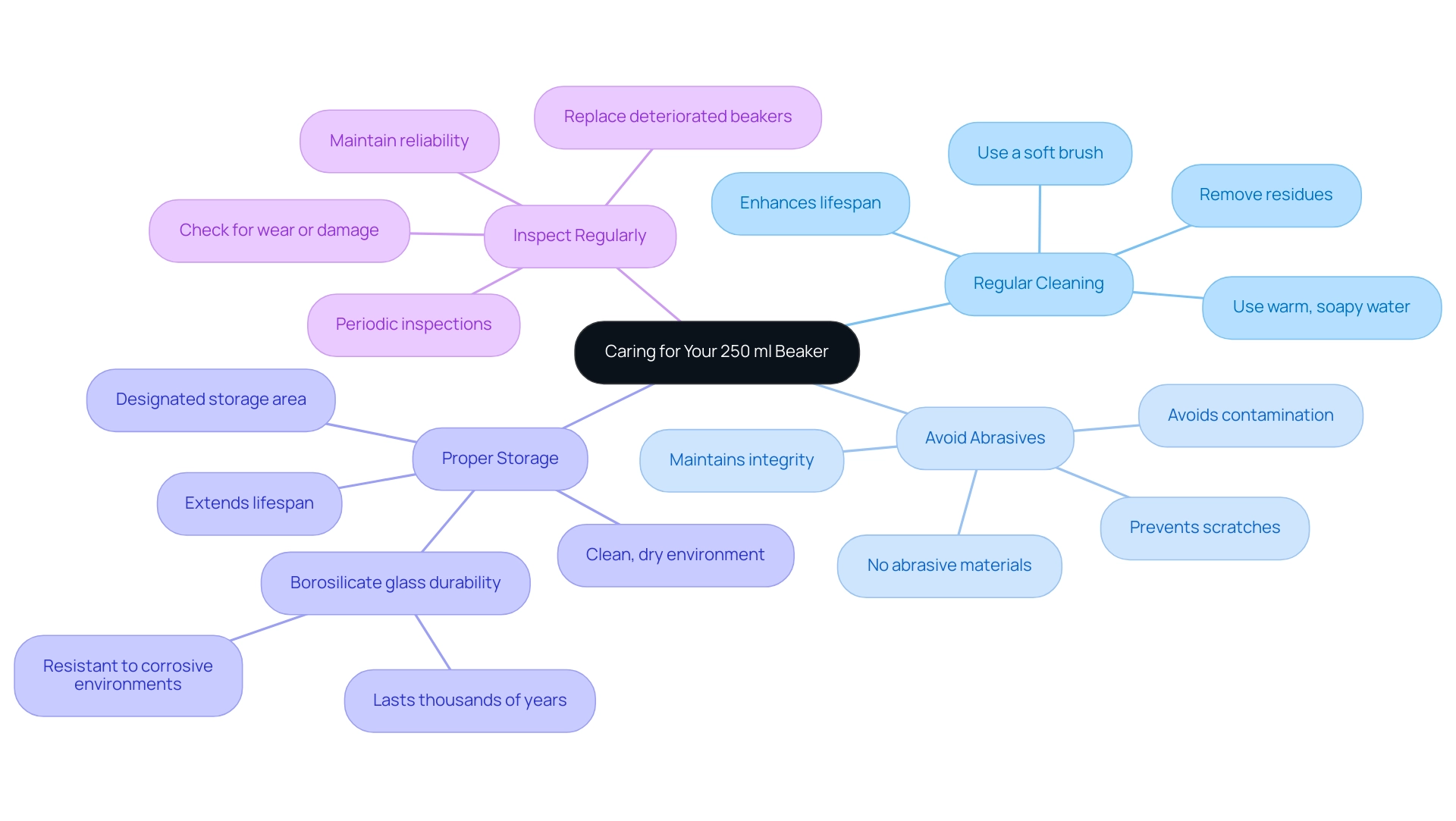

To ensure the longevity and accuracy of your 250 ml beaker, it is imperative to implement essential maintenance practices:

- Regular Cleaning: After each use, thoroughly clean the beaker with warm, soapy water and a soft brush to effectively remove any residues. This practice is crucial, as studies indicate that regular maintenance significantly enhances the lifespan of laboratory glassware.

- Avoid Abrasives: Steer clear of abrasive materials that can scratch the glass or plastic surfaces. Scratches not only compromise the integrity of the container but can also lead to contamination, affecting experimental results.

- Proper Storage: Keep containers in a clean, dry environment, ideally in a designated area to minimize the risk of accidental damage. Proper storage conditions can extend the average lifespan of glass containers, which varies based on material—borosilicate glass, for instance, is known for its durability and resistance to corrosive environments, potentially lasting thousands or even millions of years with appropriate care due to vitrification technology.

- Inspect Regularly: Conduct periodic inspections for any signs of wear or damage. Beakers that show deterioration should be replaced quickly to maintain the reliability of your tools.

By adhering to these maintenance tips, you can significantly prolong the life of your 250 ml beaker, ensuring it remains a reliable tool in your workspace. Laboratory managers have noted that implementing these best practices not only enhances equipment longevity but also contributes to overall operational efficiency. As one satisfied customer, Axl, remarked, "When my professor of organic chemistry saw this, she was so happy," reflecting the positive impact of quality scientific equipment.

Additionally, JM Science Inc.'s commitment to quality and customer support underscores the importance of maintaining glassware, as evidenced by the satisfaction expressed by international customers regarding product quality and swift shipping.

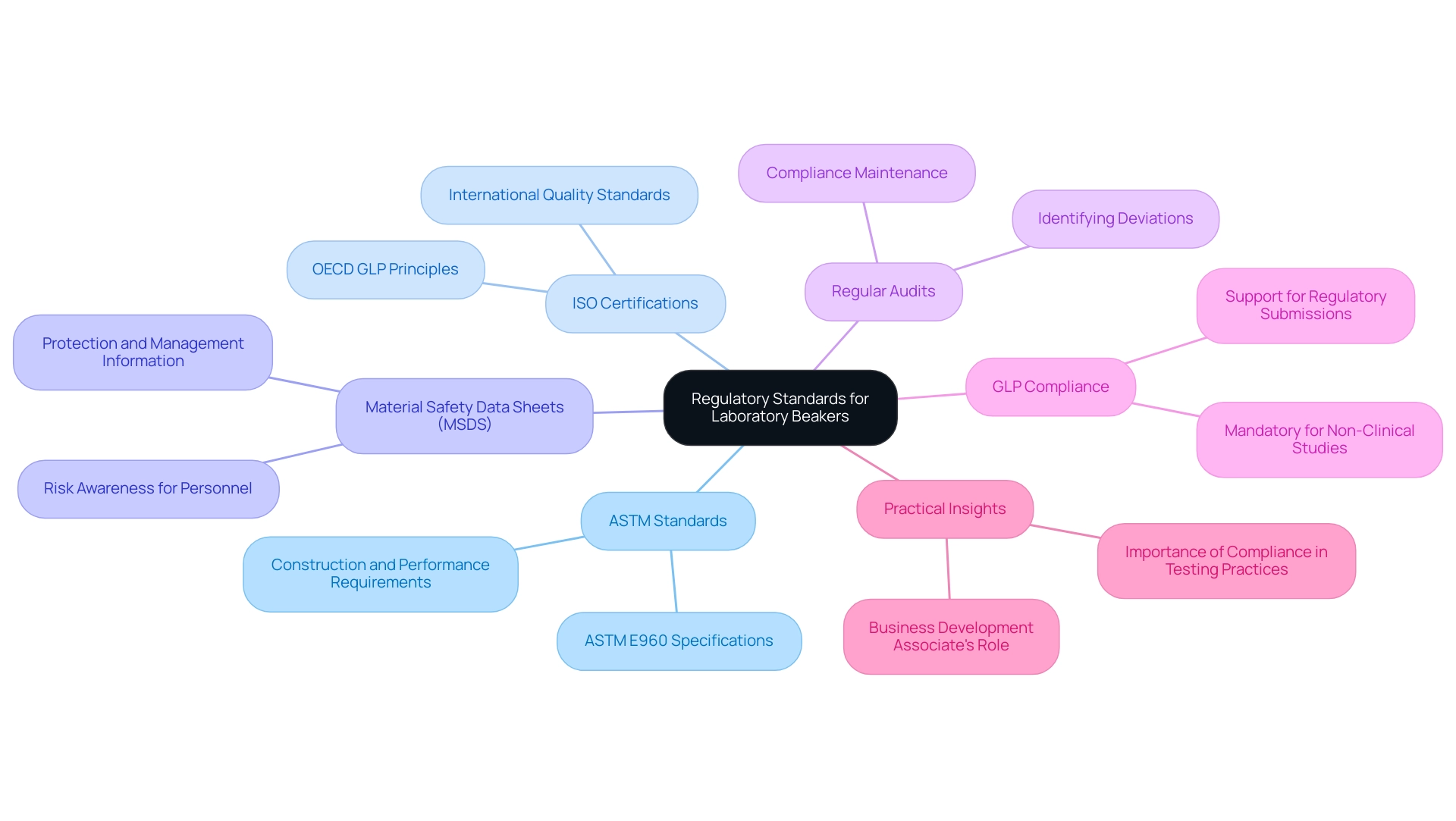

Ensuring Compliance: Regulatory Standards for Laboratory Beakers

Laboratory beakers must adhere to a variety of regulatory standards to ensure both safety and effectiveness in scientific applications.

- ASTM Standards: Beakers should comply with ASTM E960 specifications, which detail essential requirements for construction, accuracy, and performance. These standards are crucial for guaranteeing that containers can endure the demands of scientific use while delivering accurate measurements.

- ISO Certifications: Choosing containers with ISO certifications is vital, as these certifications signify that the products meet internationally recognized quality standards. Adherence to ISO standards not only enhances the reliability of results but also promotes mutual acceptance of data across borders, as outlined by OECD GLP Principles.

- Material Safety Data Sheets (MSDS): It is imperative to consult the MSDS for the materials used in your beakers. These documents provide crucial information concerning protection, management, and potential dangers related to the materials, ensuring that personnel are well-informed about the risks involved.

- Regular Audits: Conducting regular audits of equipment is essential for maintaining compliance with safety regulations and standards. This practice helps identify any deviations from established protocols and ensures that all equipment, including the 250 ml beaker, is functioning correctly and safely.

- GLP Compliance: It is important to note that GLP compliance is mandatory for non-clinical studies that support regulatory submissions. This underscores the critical importance of adhering to established standards in experimental environments.

- Practical Insights: As a Business Development Associate noted, "My main roles and responsibilities are to generate/qualify leads, create proposals, follow up with clients and develop our partnership program," highlighting the importance of compliance and standards in testing practices.

By adhering to these standards, managers can foster a safe working environment and uphold the integrity of their research, ultimately contributing to advancements in the scientific community. Recent statistics indicate that approximately 85% of facilities are now meeting ASTM and ISO standards, reflecting a growing commitment to compliance and security in practices. Additionally, the case study named "Safety and Equipment Requirements" details precautions for managing hazardous chemicals and specifies the essential tools for performing analyses, underscoring the significance of utilizing suitable equipment in research settings.

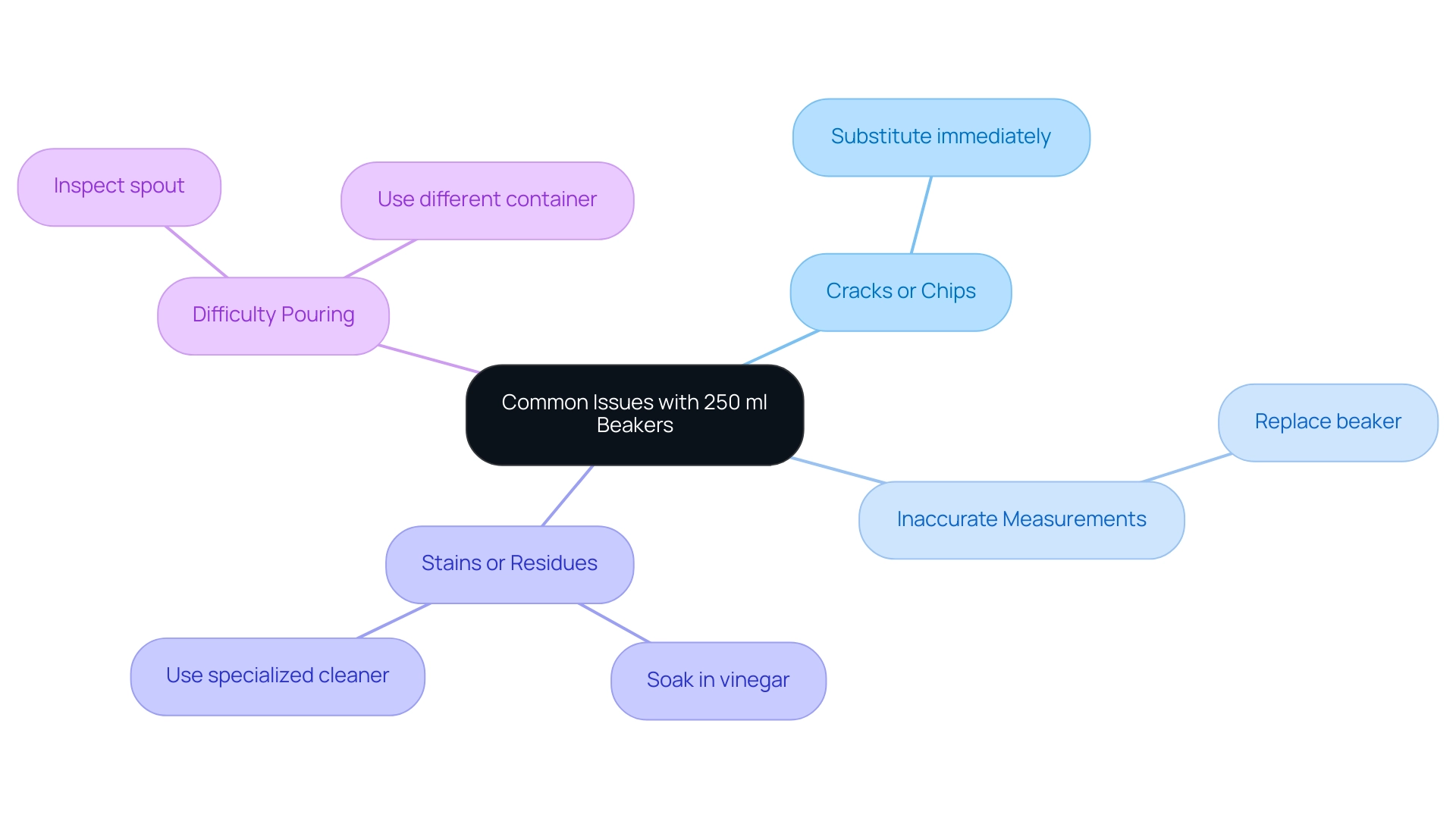

Troubleshooting Common Issues with 250 ml Beakers

Common issues with 250 ml beakers and their solutions include:

- Cracks or Chips: Any visible cracks or chips necessitate immediate discontinuation of use to prevent potential breakage and injury. Substituting the container quickly is essential to guarantee security in the laboratory setting. As lab safety consultant Dan Scungio states, "Lab safety begins the moment you step into the lab," underscoring the importance of addressing these issues proactively.

- Inaccurate Measurements: Worn or unclear graduation marks can lead to significant measurement errors. If accuracy is compromised, replacing the 250 ml beaker is essential to ensure the integrity of experimental results. Statistics indicate that a significant percentage of 250 ml beakers are replaced due to cracks or inaccuracies, highlighting the necessity of regular maintenance.

- Stains or Residues: Stubborn stains can affect both the appearance and functionality of glassware. Soaking the container in a solution of warm water and vinegar or utilizing a specialized glassware cleaner can effectively restore clarity and cleanliness.

- Difficulty Pouring: A malfunctioning spout can hinder the pouring process. Inspect the spout for any blockages, and if issues persist, consider using a different container designed for optimal pouring.

Addressing these common issues promptly not only enhances the functionality of equipment but also upholds safety standards. Laboratory technicians emphasize that maintaining the integrity of a 250 ml beaker is vital for accurate results, with one technician stating, "Regular checks for cracks and clarity of the 250 ml beaker are essential for reliable measurements in our experiments." Furthermore, it is crucial to follow proper disposal procedures for damaged glassware as outlined in the EHS Waste Management Manual – Appendix XI – Sharps Management Chart.

By implementing these solutions, laboratories can ensure that their glassware remains a dependable tool in their scientific endeavors.

Conclusion

The 250 ml beaker stands as an essential instrument in laboratory environments, celebrated for its adaptability in mixing, heating, and measuring liquids. Its meticulous design, which includes graduated markings and a spout for precise pouring, guarantees accuracy and reliability in scientific endeavors. By understanding the different types of beakers—such as Griffin, low form, tall form, and plastic—laboratory professionals can make informed decisions that enhance both safety and efficiency.

Material choice is pivotal; borosilicate glass beakers are esteemed for their resistance to thermal shock and chemical exposure, rendering them suitable for rigorous applications. In contrast, plastic beakers provide lightweight, shatterproof alternatives that are perfect for educational settings and less critical tasks. Essential features such as graduation marks and wall thickness further impact the effectiveness of liquid handling.

To extend the lifespan and accuracy of 250 ml beakers, adherence to best practices is crucial. Regular inspections, thorough cleaning, and compliance with regulatory standards are vital for maintaining the integrity of these indispensable instruments.

In conclusion, the 250 ml beaker is vital for achieving precise measurements and dependable results in laboratory work. By recognizing its features and adhering to best practices, laboratory professionals can optimize its use, ultimately leading to successful and safe experimental outcomes.