Overview

Centrifuge tubes are vital laboratory instruments that facilitate sample separation during centrifugation, playing a crucial role in the accuracy of various scientific applications, including blood analysis and molecular biology. Selecting the appropriate centrifuge tubes is paramount; factors such as material compatibility, size, and closure type significantly impact sample integrity and experimental outcomes.

Lab managers must remain vigilant about advancements in tube technology and adhere to best practices to ensure optimal results in their research endeavors. Staying informed not only enhances the quality of experiments but also reinforces the credibility of the laboratory's work.

Introduction

In the realm of laboratory science, centrifuge tubes serve as indispensable tools, facilitating a myriad of essential processes, from blood analysis to molecular biology. These specialized vessels are not simply containers; they are meticulously engineered to endure the intense forces of centrifugation, all while preserving the integrity of samples. As the demand for precise diagnostics and innovative research escalates, a comprehensive understanding of centrifuge tubes—including their materials, sizes, and compatibility with various laboratory equipment—becomes paramount.

Projections indicate significant growth in the centrifuge tube market, propelled by technological advancements and evolving laboratory practices. This article explores the vital roles these tubes play, addresses the challenges in selecting the appropriate type, and outlines best practices for their effective use in modern laboratories.

Understanding Centrifuge Tubes: Definition and Purpose

Centrifuge tubes are specialized vessels meticulously designed to hold samples during the centrifugation process, which separates components based on their density. These containers are engineered to withstand the high forces produced during centrifugation, making them essential for various scientific applications, including blood analysis, cell separation, and biochemical assays. By 2025, the utilization of spinning containers in research facilities is projected to be substantial, driven by advancements in medical diagnostics and studies.

The market for spinning containers is part of a larger sector valued at approximately 0.25 billion USD in 2023, underscoring the critical role these items play in research environments.

The definition and purpose of these containers extend beyond mere containment; they are vital in ensuring the integrity and accuracy of laboratory results. For instance, in blood analysis, spinning containers facilitate the separation of plasma from cellular elements, which is crucial for precise diagnostic testing. Laboratory supervisors emphasize the importance of selecting high-quality test containers, as their performance directly impacts the reliability of test results.

As remarked, 'The appropriate vial can significantly impact obtaining accurate results, particularly in essential uses such as blood analysis.'

Recent advancements in centrifuge tube technology have led to the development of tailored, high-quality sterile products that address the evolving needs of research facilities. The market has witnessed substantial innovations, including designs that minimize sample contamination and enhance separation efficiency. Insights from the case study titled "Recent Developments in the Centrifuge Tube Market" reveal that these trends are shaping market dynamics, emphasizing customized solutions and increased investment in research and development, reflecting a broader trend towards enhancing efficiency and accuracy in scientific settings.

In summary, spinning containers are not merely vessels; they are crucial instruments that enhance the success of experimental applications. Their importance in ensuring precise sample separation cannot be overstated, especially within contemporary scientific practices. As Rahul, an Assistant Manager, emphasizes, staying informed about market trends and advancements is essential for lab managers aiming to optimize their operations.

As the landscape of research technology continues to evolve, remaining updated on the latest improvements in spinning vessel design and functionality will be indispensable.

Key Applications of Centrifuge Tubes in Laboratory Settings

Centrifuge tubes are indispensable in a variety of applications, particularly within clinical environments. Their versatility is evident in several critical areas:

- Blood Component Separation: In clinical settings, centrifuge tubes are essential for effectively isolating plasma and serum from whole blood, a process vital for accurate diagnostics and patient monitoring.

- Cell Culture: These tubes play a crucial role in extracting cells from growth media, thereby advancing research in cell biology and regenerative medicine.

- DNA/RNA Extraction: In molecular biology, centrifuge tubes are employed to purify nucleic acids, facilitating genetic analysis and research.

- Protein Purification: In the field of biochemistry, these tubes assist in isolating proteins from complex mixtures, which is fundamental for various applications, including drug development and therapeutic research.

Recent insights reveal that approximately 75% of research facilities utilize centrifuge tubes for blood separation, underscoring their significance in clinical diagnostics. By 2025, the market for these spinning containers is expected to expand considerably, driven by technological innovations and the integration of automated systems, with a compound annual growth rate of 6.6% projected through 2029. The scientific analysis equipment sector is anticipated to reach a market value of USD 1.67 billion in 2025, increasing to USD 2.16 billion by 2029, indicating a robust demand for reliable and effective instruments.

Moreover, expert insights highlight the evolving applications of centrifuge tubes, particularly in DNA extraction processes. Biochemists emphasize their contribution to protein purification, asserting that the accuracy and reliability of centrifuge tubes are crucial for achieving optimal outcomes in experimental settings. This growing reliance on centrifuge tubes exemplifies their essential role in contemporary research practices, making it imperative for laboratory supervisors to select tailored to their specific experimental needs.

Furthermore, end users of medical devices, including hospitals, clinics, homecare, and diagnostic centers, are increasingly recognizing the importance of these containers in their operations. As noted by Deloitte, partnerships with market analysis firms such as MarkWide Research provide valuable insights into trends and advancements in testing equipment, further underscoring the critical role of centrifuge tubes in the evolving landscape of clinical facilities.

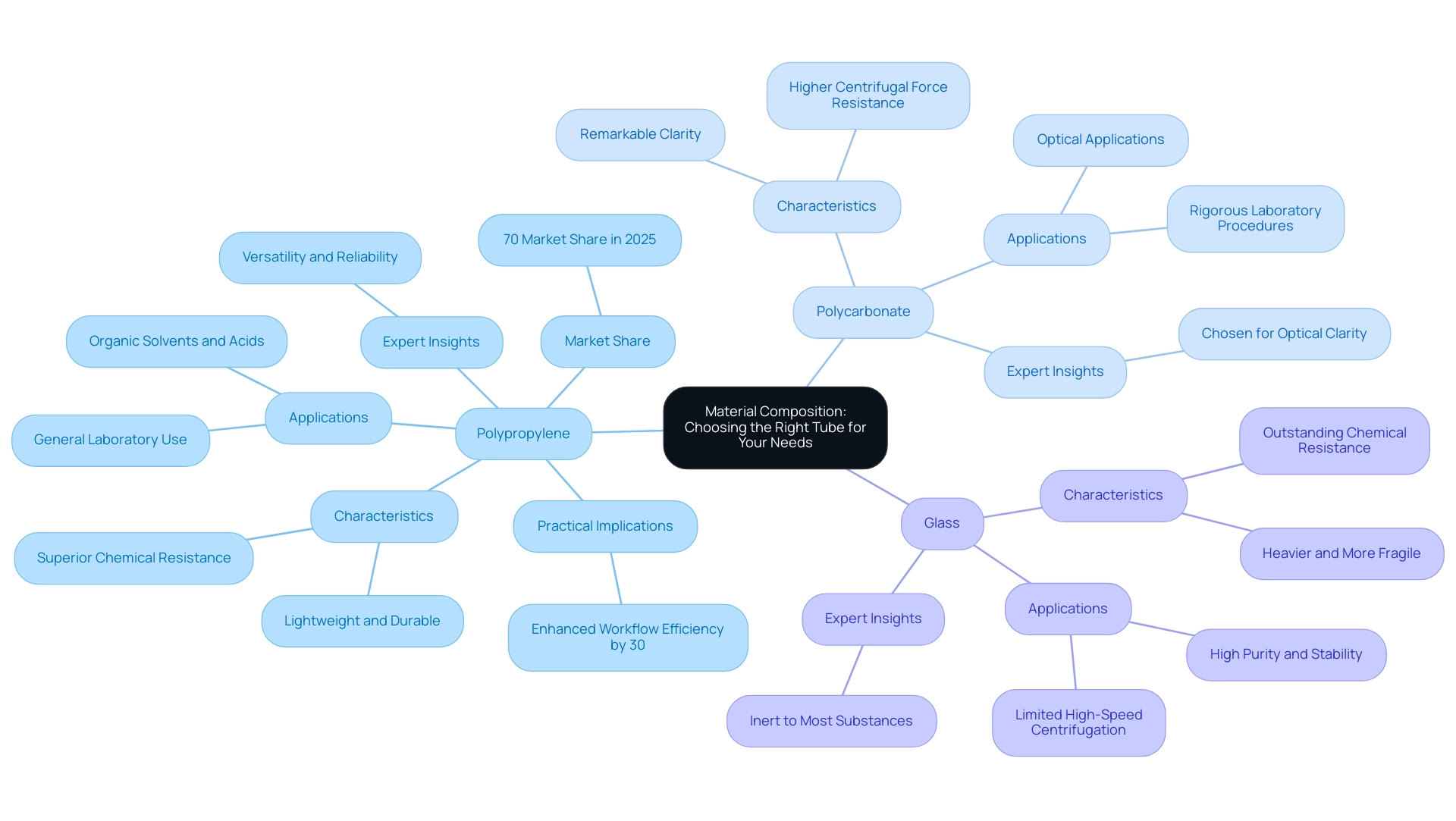

Material Composition: Choosing the Right Tube for Your Needs

Centrifuge tubes are essential instruments in research environments, typically constructed from materials such as polypropylene, polycarbonate, and glass, each offering unique benefits tailored to specific applications.

- Polypropylene: This lightweight material is celebrated for its superior chemical resistance, making it ideal for a broad spectrum of applications, including those involving organic solvents and acids. Its durability and cost-effectiveness make polypropylene tubes a preferred choice in many research facilities, commanding approximately 70% of the market share in 2025. This statistic underscores its versatility and reliability across diverse scientific endeavors.

- Polycarbonate: Known for its remarkable clarity and durability, polycarbonate containers excel in optical applications where sample visibility is crucial. They can endure higher centrifugal forces than polypropylene, rendering them suitable for more rigorous laboratory procedures.

- Glass: While glass centrifuge containers provide outstanding chemical resistance and are inert to most substances, they are heavier and more fragile than their plastic counterparts. This characteristic limits their suitability for high-speed centrifugation but makes them advantageous for applications demanding high purity and stability.

When selecting a centrifuge tube, it is imperative to evaluate the chemical compatibility with your samples and the specific conditions under which they will be centrifuged. For example, polypropylene tubes are often favored for their versatility, while polycarbonate tubes are chosen for applications requiring optical clarity.

Recent expert insights highlight the significance of material composition in achieving optimal results in laboratory processes. Equipment specialists recommend assessing the intended application of the separation containers, as material selection can profoundly influence sample integrity and the effectiveness of the separation procedure. One expert remarked, "Choosing the right material for centrifuge tubes is crucial; it can dictate your experimental outcomes."

Real-world scenarios further illustrate the practical implications of material selection. In a study focused on the separation of cellular components, facilities reported that polypropylene centrifuge tubes consistently surpassed glass containers in terms of weight and ease of handling, while polycarbonate vessels provided the necessary clarity for visual assessments. A case study from a prominent pharmaceutical lab revealed that transitioning to polypropylene containers enhanced workflow efficiency by 30%, attributed to reduced breakage and handling challenges.

In summary, understanding the distinct characteristics and applications of polypropylene, polycarbonate, and glass centrifuge tubes is vital for managers aiming to optimize their workflows and ensure the accuracy of their results. Staying informed about the , as JM Science does through collaborations with leading manufacturers, is essential for making informed decisions in research environments.

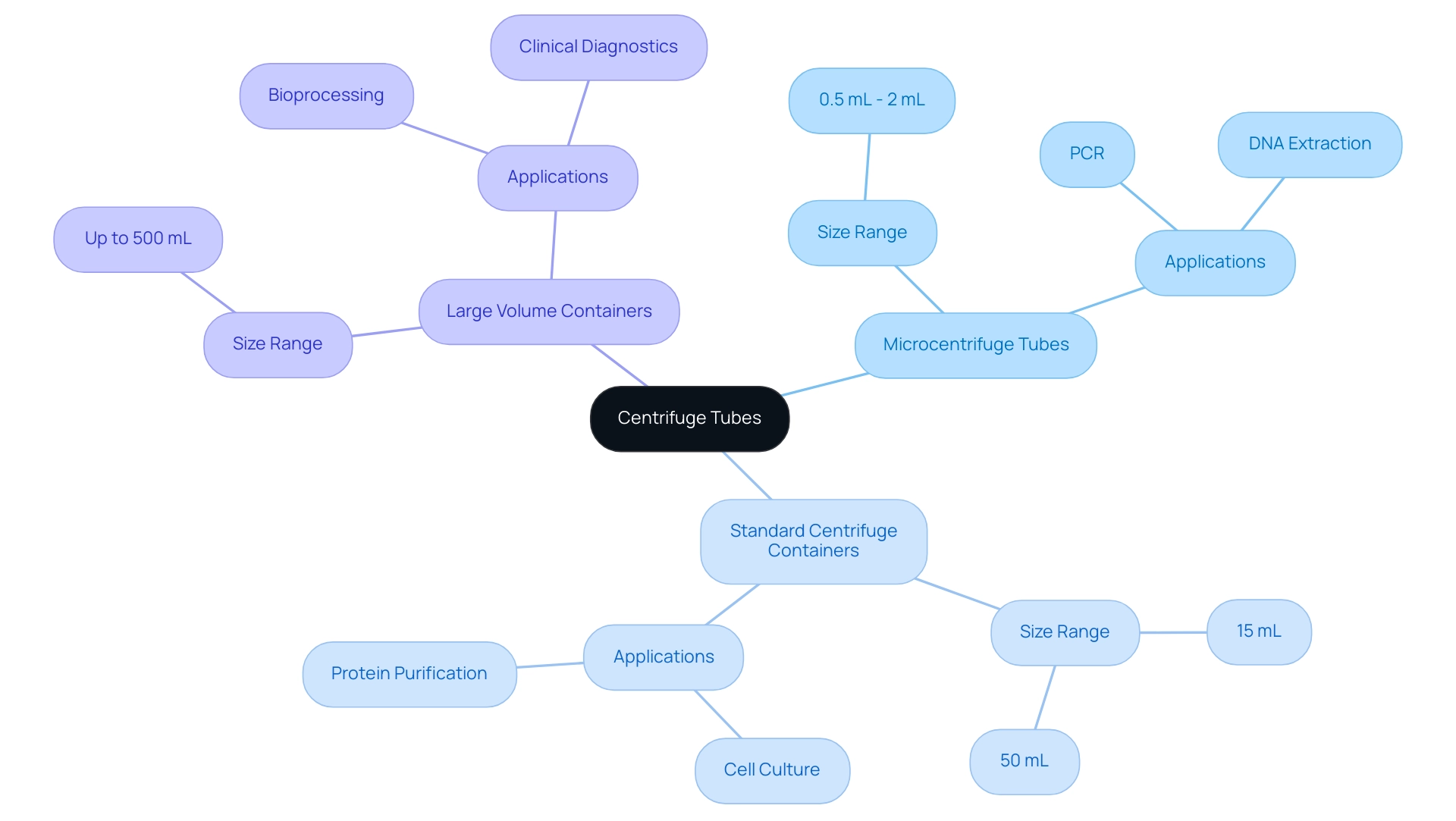

Capacity and Size Considerations for Centrifuge Tubes

Centrifuge tubes are available in a diverse range of sizes, typically from 0.2 mL to over 500 mL, catering to various research needs. The most common sizes include:

- Microcentrifuge Tubes: Ranging from 0.5 mL to 2 mL, these tubes are essential for managing small sample volumes, particularly in molecular biology applications such as PCR and DNA extraction.

- Standard Centrifuge Containers: Offered in 15 mL and , these containers are versatile, suitable for a wide array of laboratory applications, including cell culture and protein purification.

- Large Volume Containers: With a capacity of up to 500 mL, these vessels are designed for processing larger specimens, frequently utilized in bioprocessing and clinical diagnostics.

When selecting a spinning vessel, it is crucial to ensure that the chosen size can accommodate your volume while providing sufficient headspace to prevent overflow during spinning. For instance, a 15 mL container should ideally hold no more than 12 mL to maintain optimal performance.

In 2025, the average dimensions of spinning containers used in research facilities indicate a growing trend towards larger capacities, driven by increasing sample volumes in scientific and medical contexts. Statistics reveal a particularly high demand for 50 mL containers, as they are commonly employed in applications such as cell harvesting and protein analysis. Moreover, the laboratory spinning machine market is projected to see significant capacity additions through 2027, reflecting a robust growth trajectory in response to escalating research demands.

Expert insights underscore the importance of considering both capacity and dimensions when selecting laboratory containers. Lab managers frequently assert that choosing the appropriate size can greatly influence processing efficiency. Anushka Gore, a Research Associate, notes, "The appropriate size of the container can streamline workflows and enhance reproducibility in experiments," highlighting the critical nature of this decision.

Centrifuge tubes, particularly microcentrifuge tubes, have extensive applications in research, such as isolating nucleic acids and proteins, where precision and minimal sample loss are crucial. As the market for spinning devices evolves, manufacturers are investing in innovative designs and sustainable practices to meet the industry's growing demands, especially in the Asia-Pacific region, which is currently the fastest-growing market due to expanding healthcare infrastructure and increasing investments in biotechnology and pharmaceuticals. Key players in the scientific equipment market, such as Thermo Fisher Scientific and Eppendorf AG, are strategically positioned to capitalize on this demand, facilitating advancements in biotechnology, clinical diagnostics, and pharmaceuticals.

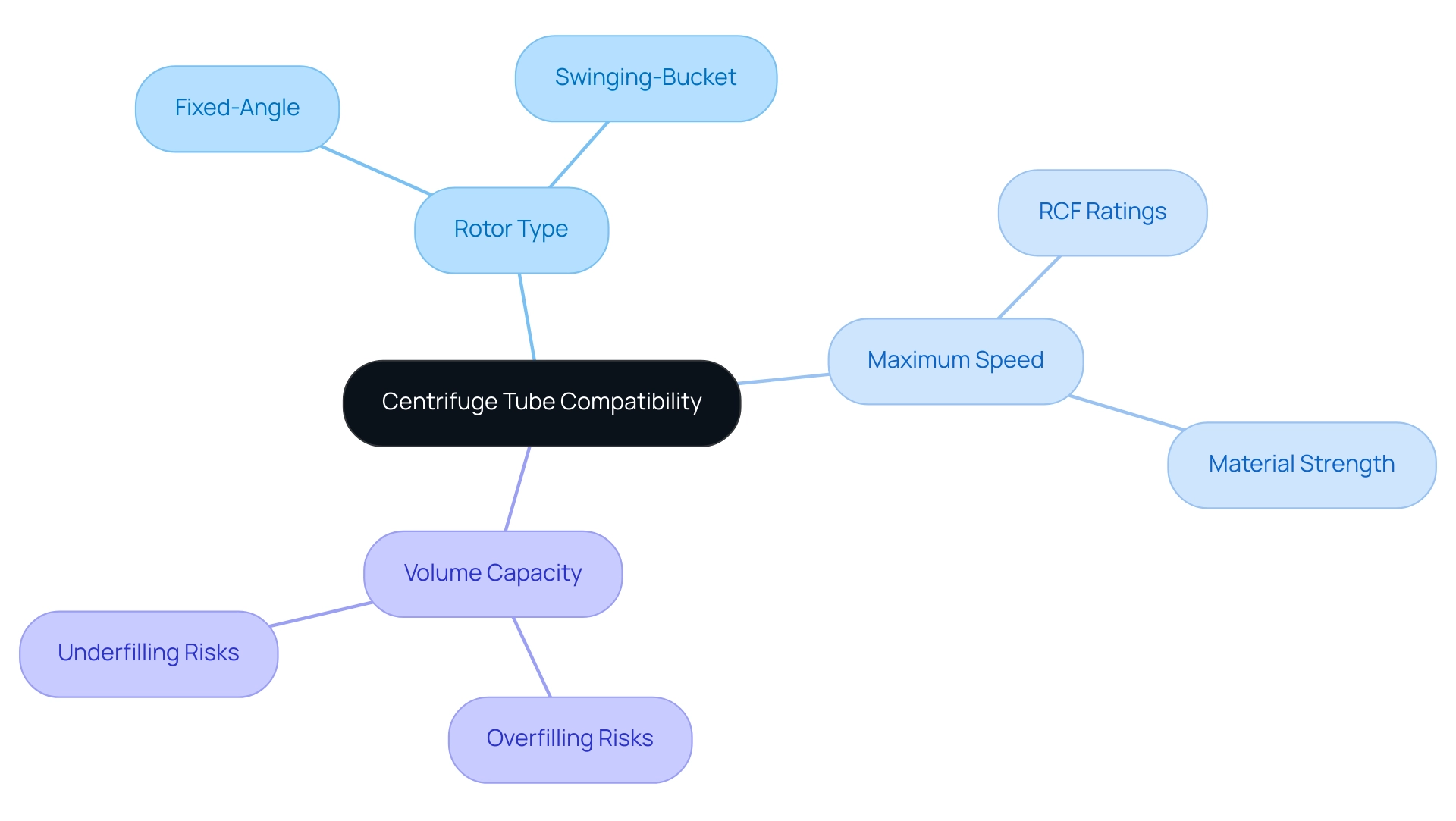

Ensuring Compatibility: Centrifuge Tubes and Equipment

Choosing the suitable centrifuge tube is crucial for optimal performance and safety in laboratory operations. Compatibility with the specific centrifuge model is paramount, and several key factors must be considered:

- Rotor Type: Each rotor design may necessitate specific tube shapes and sizes. For instance, fixed-angle rotors typically require conical containers, while swinging-bucket rotors can accommodate a wider variety of shapes. Comprehending the rotor type is essential for ensuring that the containers can be securely held during centrifugation.

- Maximum Speed: It is essential to confirm that the spinning containers can withstand the highest relative centrifugal force (RCF) produced by the device. Centrifuge tubes that are not rated for the required RCF may deform or break, which can lead to sample loss and potential damage to the centrifuge.

- Volume Capacity: The volume capacity of the containers must align with the rotor's specifications. Overfilling containers can lead to spillage, while underfilling may result in inadequate separation. Ensuring that the cylinders fit comfortably within the rotor without exceeding its capacity is essential for maintaining the integrity of both the samples and the equipment.

Recent compatibility statistics show that as of 2025, a significant percentage of spinning vessel containers are engineered to be compatible with a wide range of spinning machine models, reflecting advancements in manufacturing and design. Furthermore, the Application Segment Analysis of the Disposable Centrifuge Vessel Market highlights trends in diagnostics, therapy, and monitoring, underscoring the critical role of compatibility across various applications.

Expert opinions highlight the significance of following the most recent guidelines for choosing separation containers according to rotor type, which can greatly affect the effectiveness of cell and volume separation processes. Anushka Gore, a Research Associate at Cognitive Market Research, observes that "ensuring compatibility between centrifuge containers and rotor types is essential for optimizing workflows and achieving reliable outcomes."

Real-world examples demonstrate how rotor types affect the selection of conduits. For example, a laboratory using a high-speed microcentrifuge with a fixed-angle rotor may choose 1.5 mL microcentrifuge containers specifically designed to endure high RCFs, ensuring dependable results in processing.

Manufacturers consistently highlight the necessity of ensuring compatibility between different types of centrifuge tubes and rotor types. This focus on compatibility not only enhances operational efficiency but also minimizes the risk of equipment failure and sample contamination. By staying informed about the latest developments in centrifuge technology and adhering to best practices, lab managers can optimize their workflows and ensure the reliability of their results.

JM Science's commitment to continually and maintaining strong relationships with top manufacturers further supports the importance of ensuring compatibility and reliability in scientific operations.

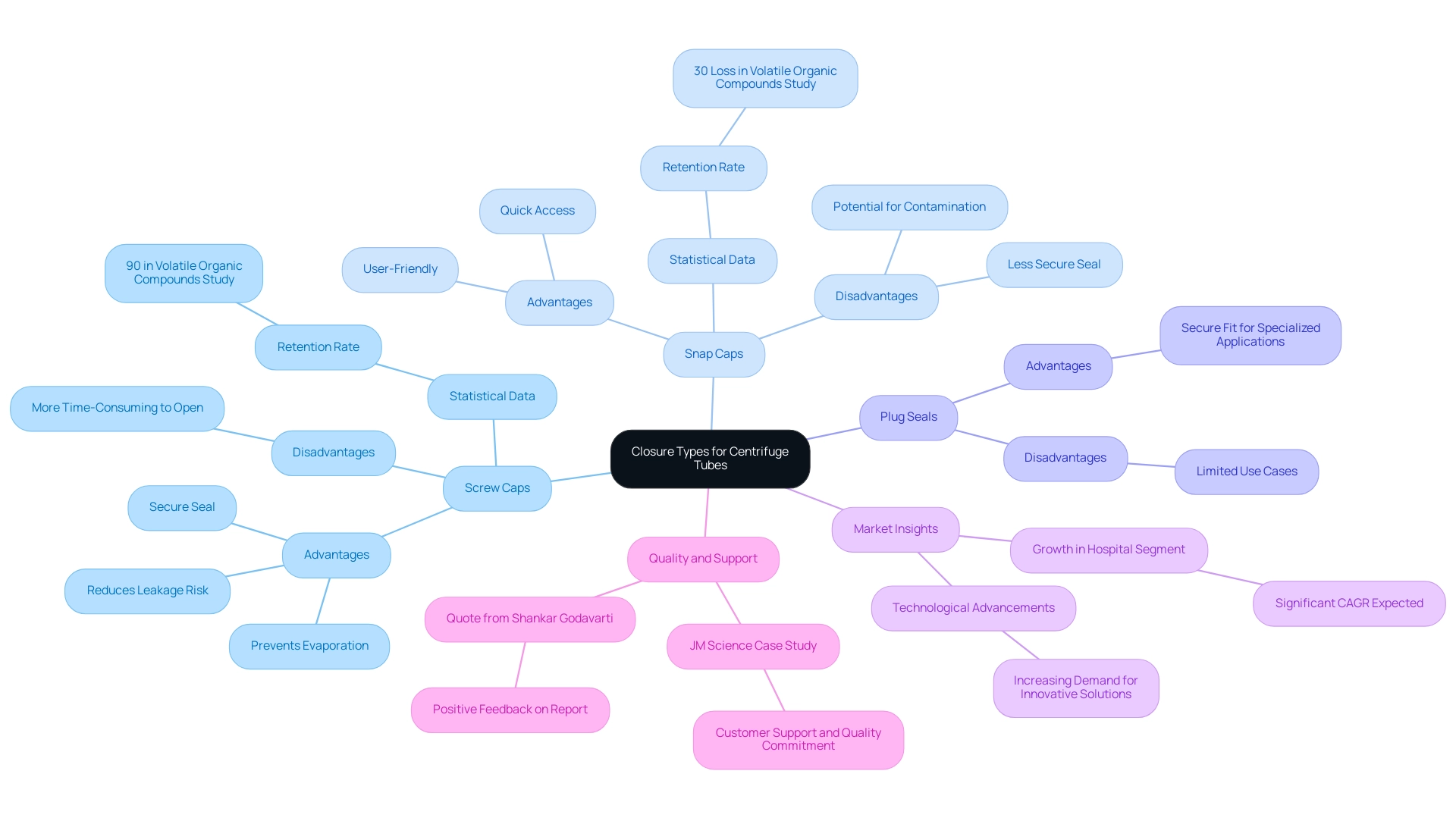

Closure Types: Ensuring Sample Integrity and Safety

Centrifuge tubes are equipped with a variety of closure types, each meticulously crafted to fulfill laboratory requirements and safeguard specimen integrity during centrifugation. The primary closure types include:

- Screw Caps: These closures provide a secure seal, making them optimal for volatile samples that necessitate protection from evaporation or contamination. Their robust design significantly reduces the risk of leakage, which is vital for upholding specimen integrity.

- Snap Caps: Although user-friendly and facilitating quick access, these caps may not deliver as tight a seal as screw caps. This could lead to potential loss or contamination, particularly in sensitive applications.

- Plug Seals: Frequently utilized for specialized applications, plug seals accommodate specific types and conditions. Their design ensures a secure fit, which is crucial for maintaining the integrity of the contents.

In 2025, statistics indicate that screw caps are favored in approximately 65% of testing environments due to their reliability in preserving specimen quality. Expert insights underscore that the selection of closure type profoundly influences sample integrity, with numerous laboratory professionals advocating for secure seals to avert contamination and guarantee accurate results.

Recent advancements in sealing mechanisms for containers have introduced innovative materials and designs that enhance closure effectiveness. For example, some manufacturers now provide hybrid closures that merge the advantages of screw and snap caps, offering both ease of use and a secure seal.

Real-world examples elucidate the disparities between screw cap and snap cap centrifuge tubes. In a study involving volatile organic compounds, specimens sealed with screw caps exhibited a 90% retention rate, whereas those with snap caps showed a 30% loss due to evaporation. Such findings accentuate the importance of selecting the appropriate closure type based on the specific requirements of the materials being processed.

Laboratories must remain vigilant regarding integrity concerns associated with spinning vessel closures. Insufficient sealing can lead to contamination, undermining the reliability of analytical results. Case studies have illustrated that improper closure selection can result in significant discrepancies in experimental outcomes, emphasizing the critical nature of this decision.

As the pharmaceutical and healthcare sectors continue to evolve, with the hospital segment anticipated to expand at a substantial CAGR throughout the forecast period, the demand for innovative solutions in laboratory practices will increase. Ensuring the correct closure types are utilized for centrifuge tubes is a fundamental step in maintaining specimen integrity and achieving reliable results.

Furthermore, JM Science's dedication to , as highlighted in the case study titled "Customer Support and Quality Commitment," reinforces the significance of selecting appropriate closure types for safeguarding sample integrity. As Shankar Godavarti, Global Product, Quality & Strategy Executive at Donaldson, remarked, "The response was good, and I got what I was looking for as far as the report. Thank you for that."

This underscores the necessity of dependable products and support in research environments.

Additionally, it is crucial to consider the various types of glass containers available, such as round bottom and conical bottom, to provide a more comprehensive overview of the options accessible to managers in research settings.

Best Practices for Using Centrifuge Tubes Effectively

To enhance the efficiency of laboratory containers, following various best practices is crucial:

- Label Containers: Each container must be distinctly marked with relevant information, such as the specimen type, date, and technician's initials. This practice is vital for preventing mix-ups and ensuring precise tracking. A recent study emphasized that appropriate labeling significantly improves sample management, decreasing mistakes in sample identification by as much as 30%.

- Balance Containers: Always ensure that the spinning device is balanced by placing containers of equal weight directly opposite each other. This action not only prevents mechanical damage to the device but also ensures optimal performance during operation. An unbalanced load can result in vibrations that jeopardize the integrity of the samples.

- Inspect Containers: Before use, examine each spinning container for any cracks or defects. Utilizing compromised centrifuge tubes can lead to failures during centrifugation, potentially resulting in sample loss or contamination. Frequent evaluations are a best practice that can reduce pre-analytical errors, as highlighted in a recent case study that created a survey scale for assessing rotor operation competency.

In addition to these practices, seasoned lab managers emphasize the significance of continuous training for technicians. As noted by Alper Gümüş from the University of Health Sciences, incorporating training on rotational device operation into educational curricula is essential for ensuring that technicians are well-versed in both theoretical and practical aspects of its use. This focused training is crucial for reducing pre-analytical errors in clinical environments.

Moreover, the introduction of DynaSpin technology, which minimizes the requirement for depth filtration cartridges and boosts efficiency by 70%, illustrates progress in spinning technology that can enhance practices in testing facilities.

By adopting , facilities can improve the safety and effectiveness of their spinning processes, ultimately resulting in more dependable outcomes in their analyses. Notably, North America and Europe represented the largest portion of the global laboratory spinning machine market in 2016, underscoring the significance of efficient technology in the sector. However, it is important to acknowledge the limitations of studies in this field, including reliance on self-reported data, which may affect the generalizability of findings.

The Importance of Balancing Centrifuge Tubes

Balancing spinning containers is essential for guaranteeing safe and effective operation. Key considerations must be kept in mind:

- Equal Weight Distribution: Position tubes symmetrically within the rotor. This practice is vital, as an unbalanced load can lead to excessive vibrations, potentially damaging the centrifuge and compromising sample integrity.

- Use Dummy Centrifuge Tubes: When faced with an odd number of tubes, fill dummy centrifuge tubes with water to achieve balance. This straightforward step can prevent accidents related to imbalance, which have been associated with higher accident rates in experimental environments.

- Regular Inspections: Conduct routine checks of the rotor for any signs of wear or damage that may arise from improper balancing. Regular maintenance not only enhances the reliability of the device but also extends its operational lifespan. A recent case study emphasizes that adherence to maintenance protocols and adequate training for users improves the reliability and lifespan of spinning devices in research environments.

Recent studies indicate that 71% of research staff reported not receiving formal training on spinning machine operation, highlighting a significant gap in knowledge that can lead to unsafe practices. As Kübra Nur Köyüstü noted, "No material from other sources was reproduced in this study," underscoring the importance of following established protocols and procedures.

Expert insights emphasize that even minor imbalances can result in catastrophic failures, underscoring the necessity of proper training and adherence to balancing protocols. Real-world examples illustrate the consequences of neglecting these practices; accidents caused by have led to equipment damage and compromised research results, highlighting the necessity of maintaining balance in research operations.

By prioritizing these guidelines, lab managers can significantly reduce risks and enhance the overall safety and efficiency of their equipment use. JM Science Inc. is dedicated to offering quality resources and customer support to help personnel achieve these goals.

Challenges and Considerations in Selecting Centrifuge Tubes

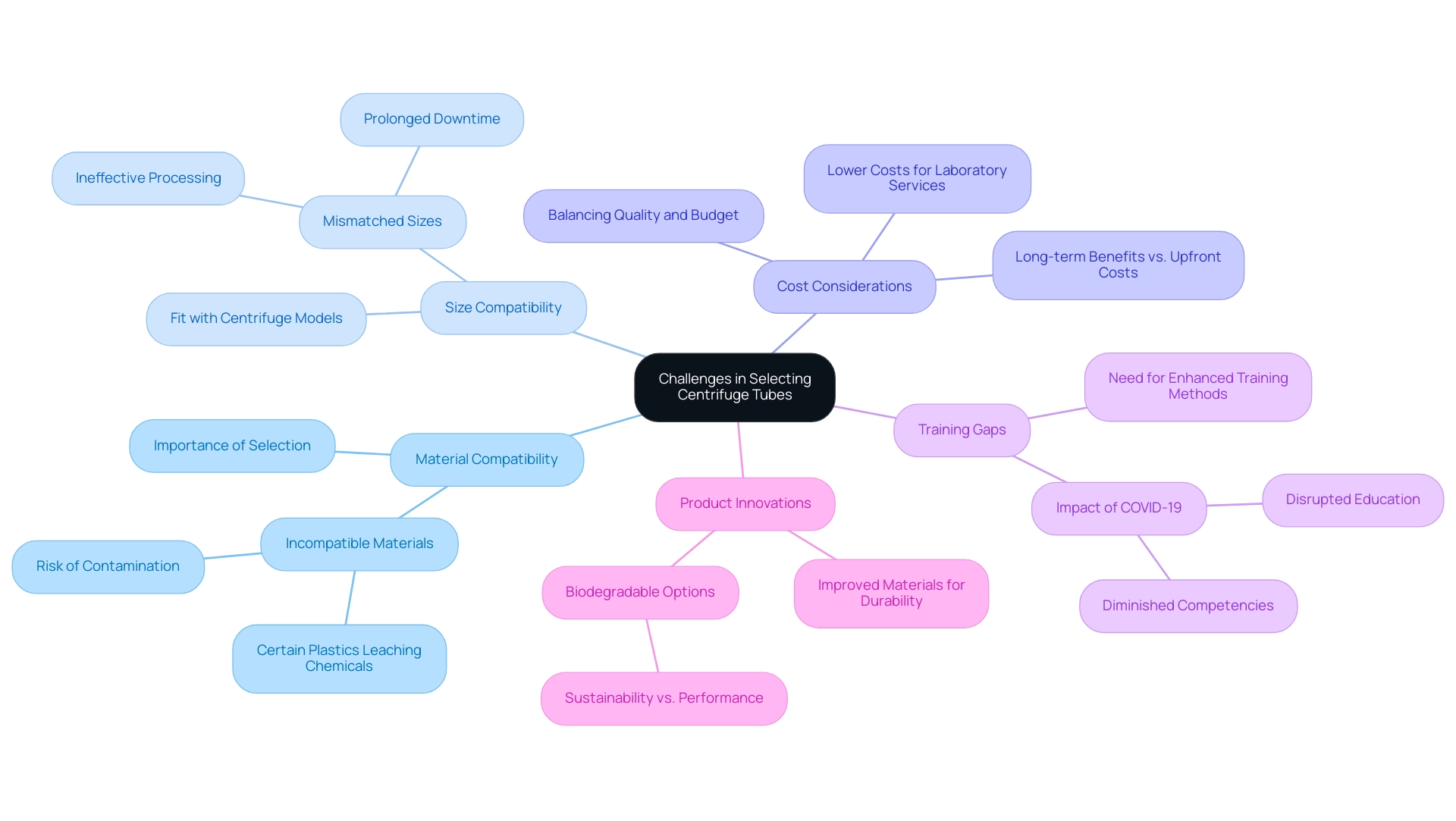

Choosing the appropriate centrifuge tube presents several challenges for laboratory supervisors, each of which can significantly impact operational efficiency and specimen integrity.

- Material compatibility stands as a primary concern, necessitating that the tube material aligns with the substances being processed. Incompatible materials risk contamination or degradation of specimens, potentially compromising experimental outcomes. For example, certain plastics may leach chemicals into sensitive biological samples, underscoring the need for careful selection based on the specific requirements of the analysis.

- Another challenge involves the size of the containers relative to specific centrifuge models. Not all tubes are universally compatible, leading to difficulties in achieving the right fit. This issue is particularly evident in facilities utilizing a variety of spinning device models, where mismatched sizes can result in ineffective processing and prolonged downtime.

- Cost considerations further complicate the decision-making process in research environments. Balancing quality with budget constraints is a persistent challenge. While high-quality centrifuge tubes often deliver superior performance and reliability, they typically come at a higher price point. Lab managers must evaluate the long-term benefits of investing in premium products against immediate budgetary limitations. Recent statistics reveal that costs for testing services per unit are significantly lower than those for visits to other departments, highlighting the importance of cost-effective operations. This emphasizes the necessity for lab managers to make informed decisions that consider not only upfront costs but also the overall value and efficiency of processes.

- These challenges are exacerbated by the evolving landscape of testing practices. A recent case study examining the impact of COVID-19 on training within research facilities revealed that many young technicians faced interruptions in their education, particularly regarding hands-on skills related to centrifuge operation. The study found that these disruptions have resulted in diminished competencies among technical staff, emphasizing the need for enhanced training methods to address these educational gaps.

- This training gap underscores the importance of ensuring that laboratory personnel are adequately prepared to make informed choices regarding centrifuge tube selection. Expert opinions from lab managers highlight the critical nature of material compatibility and cost considerations. Many have observed that while biodegradable options are increasingly available, the balance between sustainability and performance remains a significant concern. As articulated, "Selecting the appropriate container is not merely a matter of expense; it is about ensuring the integrity of our samples and the reliability of our results."

- Moreover, product innovations, such as improved materials for durability and the introduction of biodegradable centrifuge tubes, are transforming the market. These advancements not only enhance the sustainability of laboratory practices but also meet the growing demand for reliable and efficient equipment.

In summary, understanding these challenges empowers laboratory managers to make more informed decisions, ultimately leading to enhanced operational efficiency and improved outcomes in laboratory analyses.

Conclusion

Centrifuge tubes are indispensable tools in laboratory science, playing a pivotal role in essential processes ranging from blood analysis to molecular biology. Their robust design is engineered to withstand the forces of centrifugation while ensuring the integrity of samples is preserved. As the demand for accurate diagnostics and innovative research escalates, it becomes increasingly vital to comprehend the diverse materials, sizes, and compatibility of centrifuge tubes.

This article underscores the versatility of centrifuge tubes across critical applications, including blood component separation, cell culture, and DNA/RNA extraction. The selection of materials is paramount; options such as polypropylene, polycarbonate, and glass each present distinct advantages tailored to specific laboratory requirements. Notably, the trend towards larger tube capacities mirrors the rising volume of samples encountered in research environments.

Moreover, compatibility with centrifuge equipment and the appropriate closure types are essential for safeguarding sample integrity and ensuring safety. Adhering to best practices, such as balancing tubes and meticulous labeling, significantly enhances workflow efficiency and minimizes errors. Laboratory managers encounter challenges in choosing suitable centrifuge tubes, grappling with considerations of material compatibility, size constraints, and cost factors.

In summary, the significance of centrifuge tubes in contemporary laboratories is irrefutable. As laboratory practices advance, remaining informed about innovations and best practices is crucial for optimizing operations. Making educated choices regarding centrifuge tubes can lead to enhanced efficiency, precise results, and substantial contributions to scientific research and diagnostics.