Overview

Selecting the appropriate filter syringe is crucial for achieving accurate laboratory results, particularly in high-performance liquid chromatography (HPLC) applications. Key factors to consider include:

- Sample type

- Pore size

- Membrane material

The right choice and proper usage significantly influence the integrity of analytical outcomes, helping to prevent issues such as clogging and contamination. Understanding these elements not only enhances the reliability of your results but also underscores the importance of utilizing high-quality scientific instruments in laboratory settings.

Introduction

In the realm of laboratory analysis, syringe filters emerge as indispensable tools, meticulously engineered to guarantee the purity of liquid samples prior to critical evaluations. Their significance is particularly pronounced in high-performance liquid chromatography (HPLC), where even the slightest contaminants can distort results and compromise equipment integrity. As laboratories pursue accuracy and reliability in their analyses, grasping the intricacies of syringe filters—from their types and technical specifications to best practices for usage—becomes essential. This article examines the vital aspects of syringe filters, highlighting:

- Their importance

- The factors to consider when selecting one

- Practical troubleshooting tips to enhance filtration processes

Understanding Syringe Filters: Definition and Importance

Syringe membranes serve as essential, single-use devices meticulously crafted to eliminate particulate impurities from liquid samples prior to analysis. Their importance in laboratory environments is paramount, particularly in high-performance liquid chromatography (HPLC) applications, where even the minutest contaminants can distort results and damage equipment. The integrity of laboratory analysis hinges on the effective use of medical devices, which not only safeguard delicate instruments but also enhance the precision of analytical outcomes.

The influence of injection mesh on HPLC results is substantial. Research indicates that inadequate removal of particles from the mobile phase can lead to heightened back pressure in ultra-high-performance liquid chromatography (UHPLC) columns, potentially jeopardizing the entire analytical process. This underscores the necessity of selecting the appropriate device to ensure optimal performance and avert complications such as increased back pressure, which can hinder analysis.

In laboratory analysis, employing a filter syringe is critical for preparing specimens for chromatography. Their design facilitates the efficient removal of contaminants, which is vital for preserving the integrity of results. For example, a recent study underscored the importance of pre-rinsing in the analysis of pharmaceuticals and personal care products (PPCPs).

It was discovered that discarding the first 1 mL of pre-rinsing samples significantly mitigated mass losses for certain PPCPs, illustrating the efficacy of utilizing a 0.22 μm hydrophobic-PTFE membrane in conjunction with pre-rinsing. This study highlights the essential nature of appropriate usage in attaining .

The practical applications of needle-based membranes in HPLC are extensive. In the analysis of ecological specimens, for instance, the choice of membrane material and pore size can profoundly influence the identification of micropollutants. Expert evaluations have revealed that the suitability of needle screens for PPCP analysis depends on various factors, including the screen material and the solvents employed.

As noted by Wenjing Dong, "The appropriateness of injection device membranes for PPCP analysis in aqueous samples was assessed considering the material of injection device membranes, the pore size of injection device membranes, solvents, and pre-rinsing," which emphasizes the critical nature of careful selection to ensure accurate results.

Recent advancements in needle technology have further augmented their utility in laboratory settings. Innovations in materials and designs have bolstered their efficiency and reliability, establishing them as indispensable tools for researchers. As laboratories increasingly encounter challenges in detecting contaminants at environmentally significant concentration levels, the role of injection device screens becomes progressively vital.

In conclusion, the importance of needle strainers in laboratory analysis is undeniable. They are crucial for ensuring the accuracy and reliability of HPLC results, and their proper use is essential for upholding the integrity of laboratory operations. By grasping the intricacies of syringe selection and application, laboratory managers can significantly enhance their analytical capabilities.

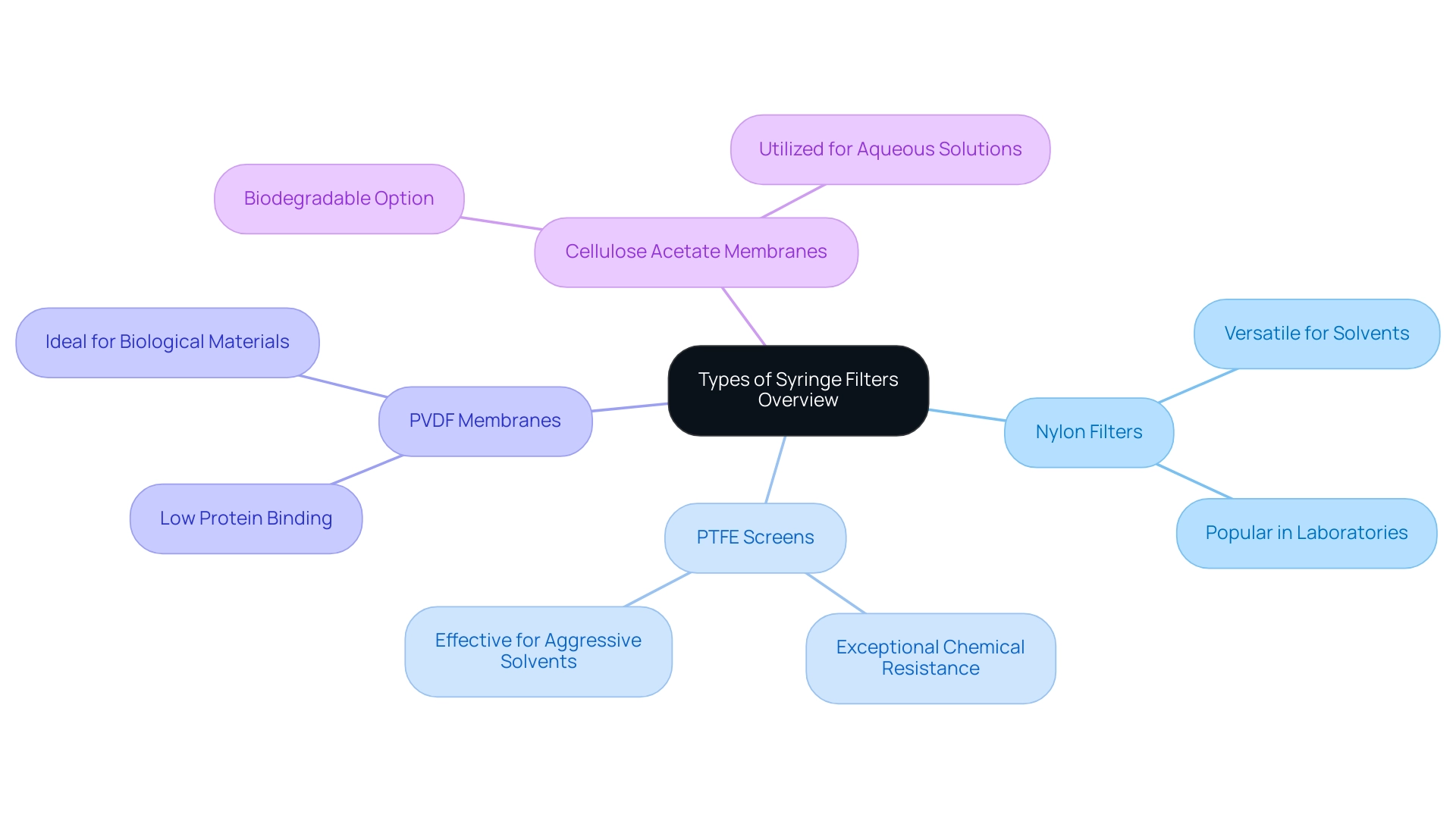

Types of Syringe Filters: A Comprehensive Overview

Filter syringes serve as essential tools in laboratory settings, available in various types tailored for specific applications. The most common types include:

- Nylon Filters: Highly versatile, these filters accommodate a broad spectrum of solvents, including both aqueous and organic solutions. Their adaptability makes them a popular choice in many laboratories.

- PTFE Screens: Renowned for exceptional chemical resistance, PTFE screens are particularly effective for separating aggressive solvents and gases. This quality renders them indispensable in environments where harsh chemicals are handled.

- PVDF Membranes: Known for low protein binding, PVDF membranes are ideal for applications involving biological materials. Their distinctive characteristics ensure the integrity of the material is preserved during the filtering process.

- Cellulose Acetate Membranes: Often utilized for aqueous solutions, these membranes are biodegradable, providing an environmentally friendly option for laboratories.

Understanding the unique features of these membranes is crucial for selecting the suitable device based on specific sample attributes and the required filter syringe specifications. For example, nylon membranes are frequently employed in pharmaceutical labs for their versatility, while PTFE membranes are favored in chemical analysis due to their robustness against aggressive solvents.

In terms of market dynamics, the medical device market is projected to experience significant growth from 2025 to 2033, driven by increasing demand in emerging markets such as China and India. This growth is further supported by the rise of e-commerce sales channels, facilitating easier access to these essential laboratory tools. Prominent firms in the filtration market, such as Sartorius AG and , are concentrating on innovation and product advancement to maintain their competitive advantage.

Ongoing advancements in purification technology are essential for addressing the evolving requirements of laboratories, ensuring that researchers have access to reliable and effective filtration solutions. As noted by a Senior Analyst at Cognitive Market Research, "I fulfill data requirements with thorough research and analytics," underscoring the importance of informed decision-making in this dynamic market.

Key Factors to Consider When Selecting a Syringe Filter

Selecting the appropriate syringe strainer is crucial for achieving reliable outcomes in laboratory applications. To ensure optimal performance, consider the following key factors:

- Sample Type: Understanding the chemical properties of your specimen is vital for ensuring compatibility with the filtration material. For instance, the presence of organic solvents can affect the partitioning of pharmaceuticals and personal care products (PPCPs) in the solution phase, as highlighted by Wenjing Dong, potentially influencing separation results.

- Capacity: The volume of the specimen dictates the dimensions of the strainer. Larger sample volumes typically necessitate larger diameter membranes to facilitate effective processing without compromising sample integrity.

- Pore Size: The selection of pore size is critical for efficient separation. A pore size of 0.2 µm is commonly used for bacteria removal, while 0.45 µm membranes are suitable for general separation of larger particles. A case study titled "Syringe Filter Pore Size Selection" illustrates that the pore size choice is contingent upon the particle size to be purified, with 0.2 µm membranes employed for particles larger than 0.2 microns and 0.45 µm membranes for those larger than 3 microns. Furthermore, research shows that mass losses of QL antibiotics significantly decreased from 100% to 11% as the pore size increased, underscoring the importance of this choice.

- Membrane Material: The selection of membrane material must align with your application to prevent extractables or contamination. before sampling has been demonstrated to reduce mass losses for target PPCPs, although some compounds still displayed considerable losses.

By meticulously assessing these factors, including the specific needs of your samples and the intended analytical techniques, you can select the most effective syringe for your application. This method not only enhances the reliability of your laboratory results but also ensures compliance with best practices in purification and sterilization.

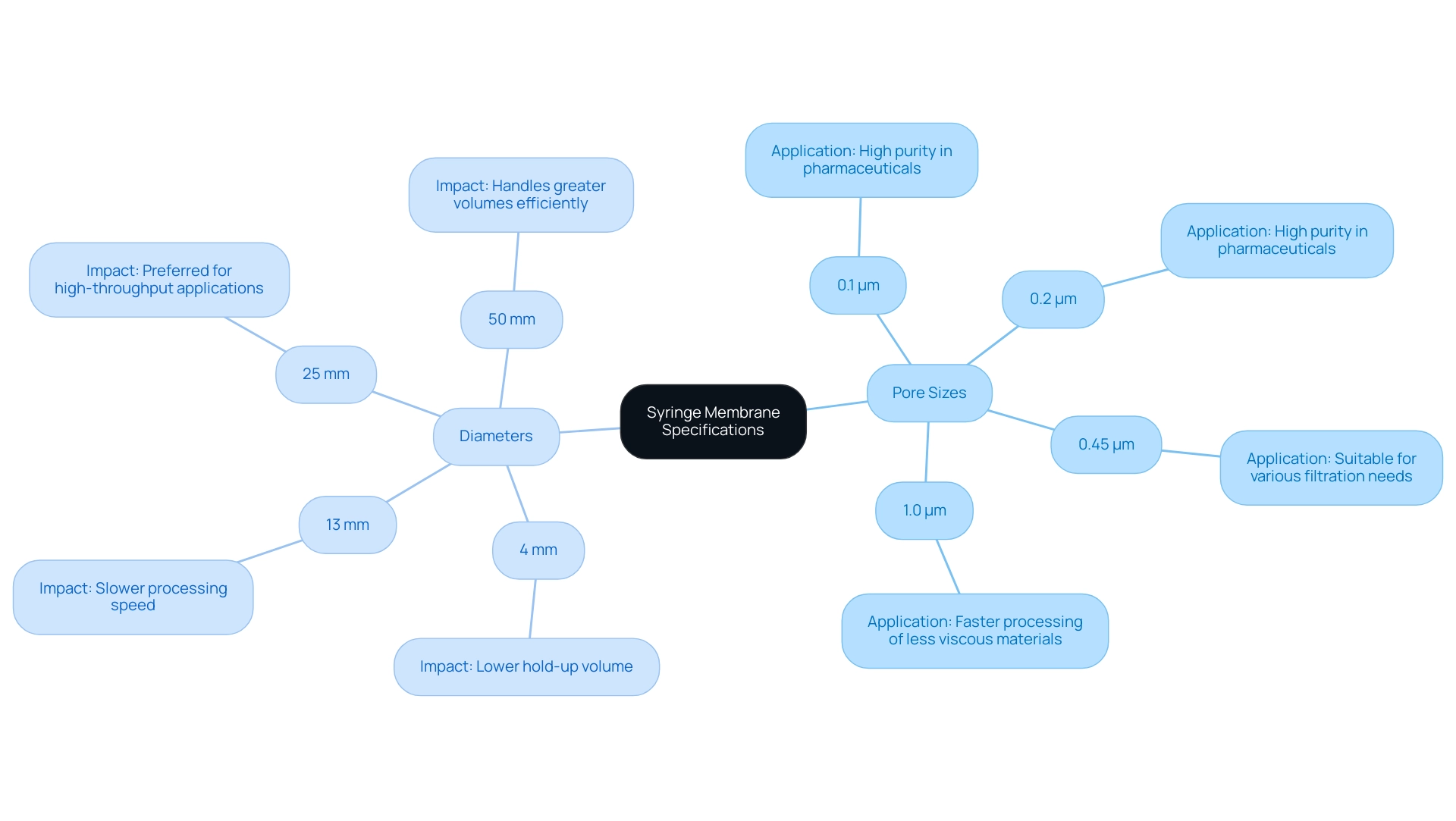

Technical Specifications: Pore Sizes and Diameters Explained

Syringe membranes come in a variety of pore dimensions and diameters, both of which critically influence their separation efficiency.

Pore Dimensions: Common pore sizes include 0.1 µm, 0.2 µm, 0.45 µm, and 1.0 µm. Smaller pore sizes are optimal for filtering out finer particles, rendering them suitable for applications that demand high purity, particularly in pharmaceutical settings where adherence to stringent regulatory standards is non-negotiable. This high purity is essential for compliance in pharmaceutical applications. Conversely, larger pore sizes facilitate quicker processing of less viscous materials, thereby enhancing workflow efficiency.

Diameters: Syringe filters typically range from 4 mm to 50 mm in diameter. The diameter significantly affects both hold-up volume and filtration speed. Larger diameters can handle greater volumes, promoting more efficient processing. For instance, a 25 mm device processes samples more swiftly than a 13 mm one, making it a preferred option for high-throughput applications. Separation speed data indicate that larger diameters contribute to the overall efficiency of the separation process.

Understanding the interplay between pore size and diameter is crucial for achieving optimal separation results. For example, PES (Polyethersulfone) membranes, used in filter syringes, are noted for their naturally hydrophilic properties, making them particularly effective for aqueous solutions and alcohols. They do not require wetting agents and possess mechanical strength, enabling high-temperature liquid separation.

These devices demonstrate exceptional performance for biological specimens and media culture, characterized by low protein binding and excellent flow rates across a wide pH range. A case analysis of PES injectors highlights their specific advantages, underscoring their suitability for critical applications.

In summary, selecting and diameter is essential for optimizing separation efficiency and preserving the integrity of the samples being processed. By choosing filter syringes from a reputable supplier like JM Science, which prioritizes quality and customer support, laboratories can enhance their filtration processes while ensuring compliance with regulatory standards.

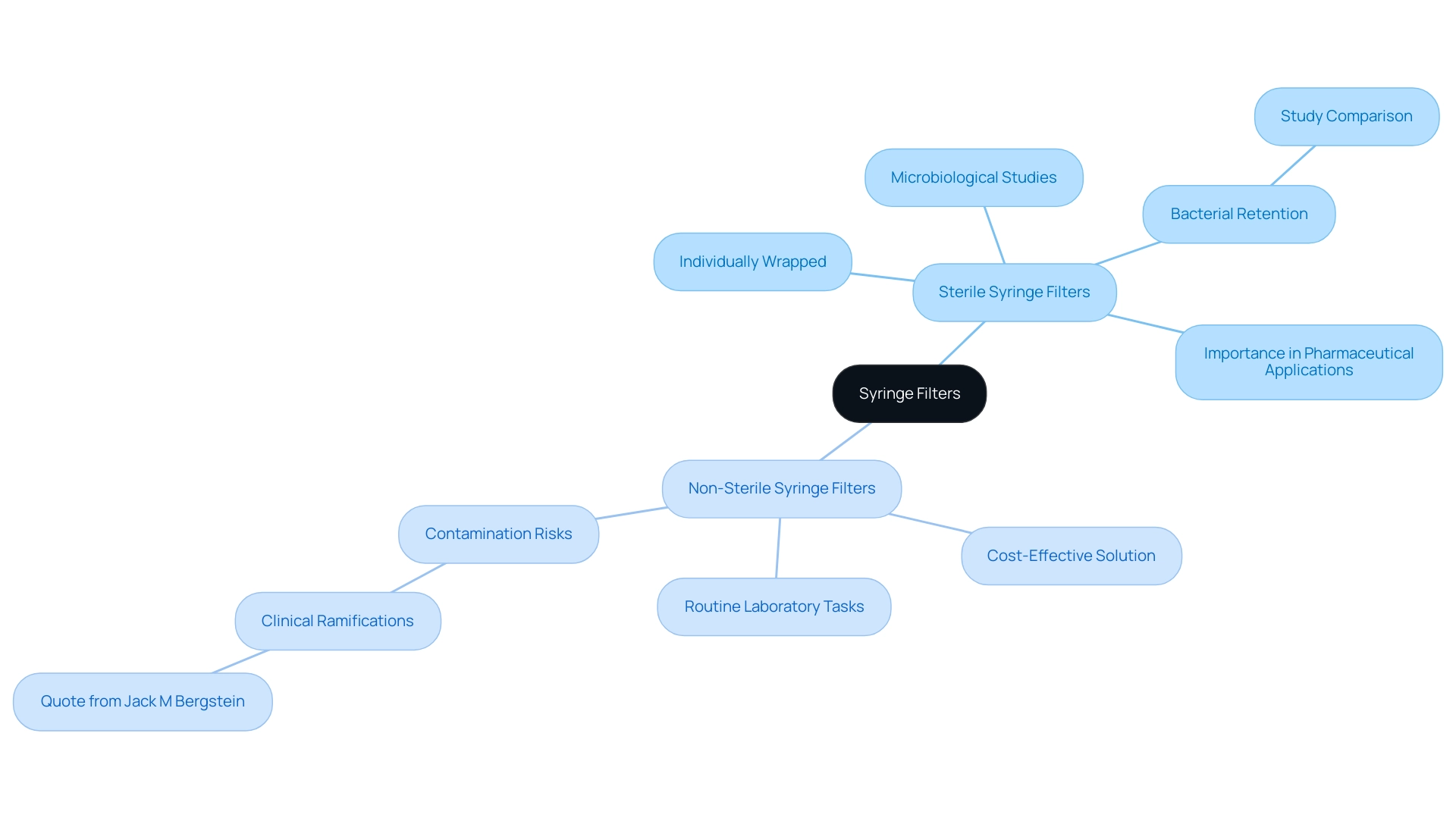

Sterile vs. Non-Sterile Syringe Filters: What You Need to Know

Syringe membranes, such as those utilized in filter syringes, are classified into two primary types: sterile and non-sterile, each fulfilling distinct roles in laboratory applications.

- Sterile Syringe Strainers: These devices are individually wrapped to maintain sterility and are essential for applications necessitating contamination-free specimens. Their importance is particularly pronounced in microbiological studies and pharmaceutical preparations, where sample integrity is critical. Recent findings underscore the necessity for healthcare professionals to comprehend specifications, especially in contexts where bacterial retention is vital. A study comparing a commercialized needle device with of 0.2-micron unit demonstrated that the latter achieved total bacterial retention, highlighting the imperative for effective filtration in sensitive applications.

- Non-Sterile Syringe Screens: These devices are generally employed for routine laboratory tasks where sterility is not a primary concern. They offer a cost-effective solution for everyday applications, making them a favored choice in various laboratory environments. However, it is crucial to acknowledge that utilizing a filter syringe or other non-sterile devices in sensitive applications may lead to contamination, potentially compromising results. As Jack M Bergstein, an AM Surgeon, noted, "Abscess formation at the site of drug injection is the commonest infectious complication in drug addicts," emphasizing the clinical ramifications of contamination.

The market demand for sterile injection devices is on the rise, particularly for filter syringes, driven by an increased focus on contamination prevention in pharmaceutical applications. The global market for online sales of laboratory consumables is projected to reach USD 1 billion in 2023, with a growth rate of 15%. This trend reflects a growing awareness of the critical role that sterility, especially through the use of a filter syringe, plays in ensuring reliable laboratory results.

Real-world examples illustrate the effectiveness of filter syringes in preventing contamination during sterile injections. Ongoing research on HIV and viral hepatitis infections among injecting drug users in the EU indicates that, while harm reduction strategies are implemented, they have not fully curtailed the transmission of these infections. This underscores the necessity for effective interventions, including the use of a filter syringe as a sterile barrier to mitigate contamination risks.

When choosing between sterile and non-sterile options, it is imperative to consider the specific needs of your application, particularly if a filter syringe is required. Sterile membranes should be employed in scenarios where microbiological integrity is essential, while non-sterile membranes may suffice for less sensitive tasks. Expert opinions consistently emphasize the importance of sterility in laboratory applications, reinforcing the notion that the selection of a filter syringe can significantly influence the reliability of experimental outcomes.

By understanding the distinctions between these two types of mechanisms, laboratory managers can make informed decisions that enhance the quality and accuracy of their work.

Step-by-Step Instructions for Using Syringe Filters

To utilize effectively, follow these detailed steps:

- Prepare the Injection Device: Ensure that the injection device is thoroughly cleaned and free from contaminants. Carefully draw the sample into the injection device, avoiding air bubbles that could compromise the integrity of the sample.

- Attach the Device: Securely fasten the needle holder to the apparatus. A twisting motion is essential to create a tight seal, preventing leaks and ensuring optimal performance.

- Strain the Sample: Position the syringe vertically and gently depress the plunger to push the sample through the strainer. It is crucial to apply pressure gradually; excessive force can damage the membrane, leading to compromised filtration results.

- Collect the Filtrate: Direct the outlet of the sieve into a clean collection container. This step is vital for ensuring that the filtered sample is collected without contamination, thereby maintaining the quality of the analysis.

- Dispose of the Syringe: After completing the separation process, discard the syringe component properly. These devices are intended for one-time use only, and appropriate disposal is essential for upholding laboratory safety and compliance.

Incorporating these best practices not only protects (U)HPLC columns from premature clogging but also ensures high-quality data. As Piyawan Phansi from the Department of Chemistry at Thepsatri Rajabhat University emphasizes, "Proper separation techniques are crucial for obtaining reliable analytical results." A recent case study demonstrated the effectiveness of a fully automated method using in-syringe magnetic stirring-assisted DLLME coupled to HPLC for determining UV substances in water samples.

This method achieved detection limits between 0.08 and 12 mg/L, underscoring the significance of employing suitable separation techniques to enhance analytical performance.

Common mistakes in using a filter syringe include failing to pre-wet the filter membrane or using the incorrect pore size for specific applications. For general filtering tasks, a filter syringe with a pore size of 0.45 µm is typically recommended to effectively remove larger particles, thereby improving the reliability of subsequent analyses. By following these guidelines, laboratory professionals can optimize their filtration processes and achieve more accurate results.

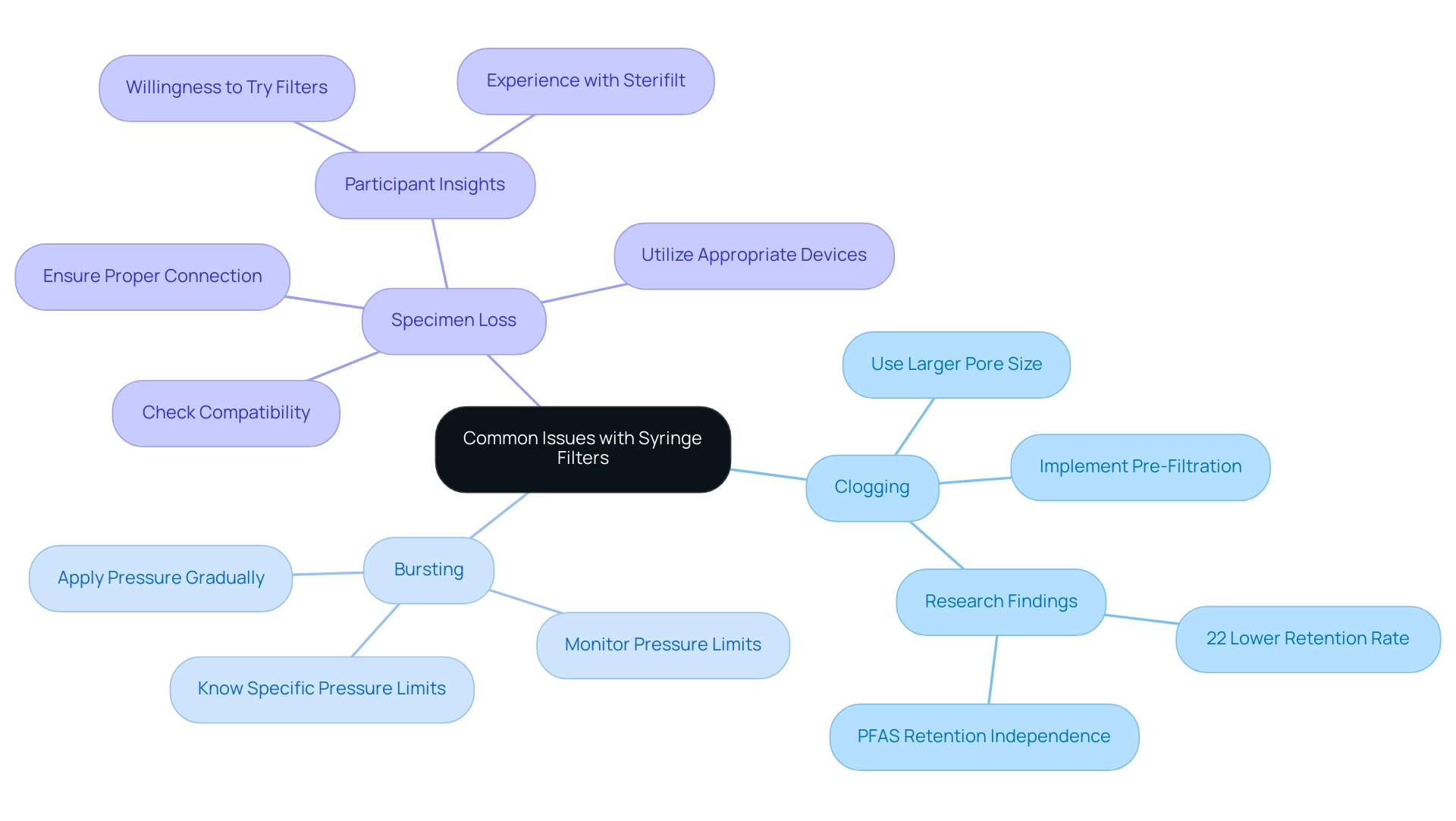

Troubleshooting Common Issues with Syringe Filters

Common issues encountered with syringe filters include:

- Clogging: This problem frequently arises when the filter becomes overloaded with particulates. To reduce clogging, consider selecting a strainer with a larger pore size or implementing a pre-filtration step to eliminate larger particles from the sample. Research indicates that clogging rates can vary significantly among different types of media, with some demonstrating a 22% lower retention rate in solutions containing 20 mg of SRNOM compared to deionized water. Furthermore, a study titled "" reveals that PFAS retention remains largely independent of concentration for the tested conditions, although minor variations were noted, emphasizing the significance of selecting the appropriate type based on water quality parameters.

- Bursting: Excessive pressure applied during filtration can lead to the rupture of the membrane. To prevent this, always apply pressure gradually and ensure that it remains within the manufacturer’s recommended limits. Expert guidance recommends closely monitoring the pressure, particularly when filtering thick solutions, to prevent sudden bursts that can jeopardize the integrity of the system. It is crucial to be aware of the specific pressure limits for various types of strainers to ensure optimal performance.

- Specimen Loss: Proper connection of the strainer to the syringe is essential to avoid leaks that can lead to specimen loss. If you encounter material loss, check the compatibility between the screen and the type of substance, as certain materials may not bond effectively. A participant shared their experience, stating, "I always used the Sterifilt solely for Subutex (buprenorphine)... For heroin and cocaine, I had that old 'craze' to use a cotton and keep it..." This emphasizes the significance of utilizing devices specifically designed for the sample matrix to significantly reduce the risk of loss. Furthermore, qualitative data indicates a growing willingness among participants to try filter syringes, suggesting an evolving acceptance of these tools in various applications.

By understanding these common issues and implementing the suggested solutions, you can enhance the reliability and efficiency of your filtration processes, ultimately leading to more accurate and reproducible results.

Conclusion

Syringe filters are indispensable components in laboratory analysis, particularly in high-performance liquid chromatography (HPLC), where the integrity of results relies heavily on the removal of contaminants. This article has examined the various types of syringe filters, underscoring their critical roles in ensuring the purity of liquid samples. By understanding the unique characteristics of each filter type—such as nylon, PTFE, PVDF, and cellulose acetate—laboratory professionals are empowered to make informed decisions that cater to their specific filtration needs.

Selecting the appropriate syringe filter transcends mere choice; it necessitates a careful consideration of key factors such as sample type, volume, pore size, and membrane material. This meticulous approach not only enhances the reliability of analytical outcomes but also aligns with best practices in laboratory operations. Moreover, the technical specifications regarding pore sizes and diameters are pivotal to filtration efficiency, emphasizing the necessity of matching these features to the intended application.

The distinction between sterile and non-sterile syringe filters further highlights the importance of understanding the requirements of specific applications. Sterile filters are crucial in contexts where contamination could jeopardize results, while non-sterile filters are well-suited for routine procedures. By adhering to the outlined best practices for usage and troubleshooting common issues, laboratories can significantly enhance their filtration processes.

In summary, the effective utilization of syringe filters is essential for achieving accurate and reliable analytical results in laboratory settings. By prioritizing the right filter selection and implementing best practices, laboratory professionals can safeguard the integrity of their analyses, ultimately contributing to the advancement of scientific research and quality control across various industries.