Overview

The article highlights the essential applications and benefits of 0.2 micron syringe filters within laboratory settings, particularly in the fields of pharmaceuticals and biotechnology. These filters play a critical role in ensuring sample integrity and precision in analytical results by effectively removing particulates and microorganisms. Supported by case studies and market trends, the article emphasizes the increasing demand for these filters and the advancements in filtration technology. Clearly, the significance of high-quality scientific instruments cannot be overstated, as they are vital for maintaining the accuracy and reliability of laboratory outcomes.

Introduction

In the realm of laboratory research, precision is paramount. JM Science's 0.2 micron syringe filters emerge as essential tools for achieving this accuracy. These filters are meticulously designed to eliminate particulates and ensure sample integrity, playing a critical role in various applications, particularly within the pharmaceutical and biotechnology sectors.

As the demand for reliable filtration solutions grows, it becomes increasingly important to understand the significance of pore size, material composition, and sterilization standards. This article delves into the multifaceted advantages of 0.2 micron syringe filters, exploring their construction, applications, and the latest innovations that enhance their effectiveness in laboratory settings.

From debunking common myths to providing practical usage guidelines, readers will gain valuable insights into how these filters contribute to the accuracy and reliability of analytical results.

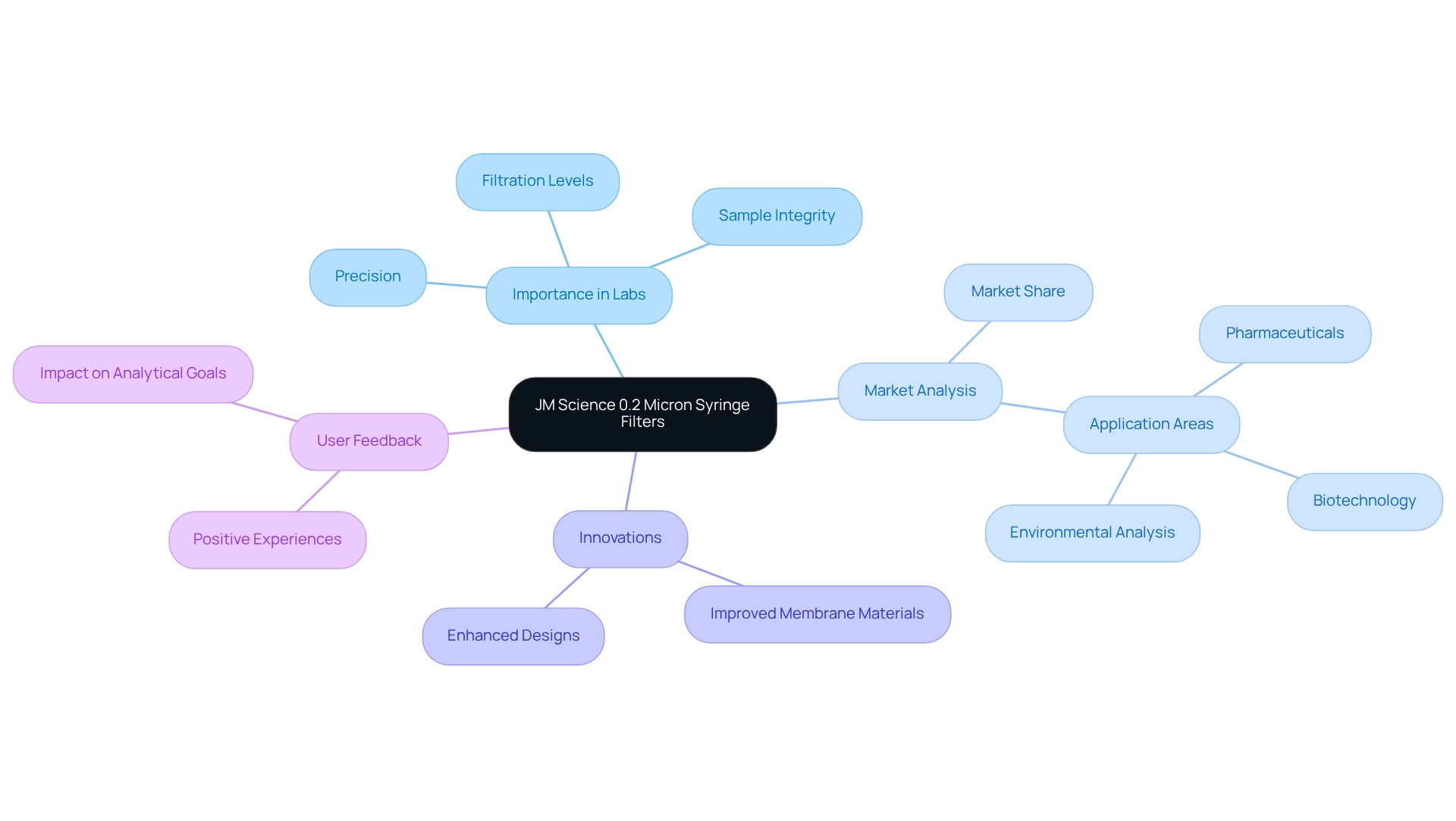

JM Science 0.2 Micron Syringe Filters: Precision for Laboratory Applications

JM Science's 0.2 micron syringe filter screens are engineered to deliver unparalleled accuracy in scientific tasks, making them indispensable for ensuring that samples are devoid of particulates. This level of filtration is essential for achieving precise analytical results, especially in sensitive environments such as pharmaceuticals and biotechnology.

While the 0.45 micron pore size is recognized as the standard for bacterial filtration, the 0.2 micron syringe filter is recommended for scenarios requiring the removal of smaller particles, underscoring its critical role in maintaining sample integrity. Recent market analysis indicates that 0.2 micron syringe filters command a significant share in analytical applications, driven by their efficacy in eliminating smaller particles.

This trend is supported by case studies that demonstrate their effectiveness across various research settings, where scientists have observed enhanced precision in their results when utilizing these tools. For instance, the market segmentation analysis highlights that the needle-type membrane market is specifically designed to fulfill industry requirements, such as those in pharmaceuticals and biotechnology, further emphasizing the importance of the 0.2 micron syringe filter in these sectors.

The design of JM Science's needle-type membranes ensures reliability and durability, making them a favored choice among professionals in research environments. Innovations in syringe strainer technology are continuously emerging, featuring advancements like improved membrane materials and designs aimed at boosting purification efficiency and user-friendliness.

These developments not only enhance the effectiveness of the devices but also facilitate efficient workflows in laboratories. Moreover, JM Science's commitment to excellence is reflected in the positive feedback from users who have experienced the benefits of these devices firsthand. By providing exceptional filtration solutions, JM Science supports research facilities in achieving their analytical goals, solidifying its role as a trusted partner in the scientific community.

For lab supervisors, selecting the appropriate syringe strainer based on specific lab requirements—such as sample type and necessary filtration level—can significantly impact the precision and reliability of analytical results.

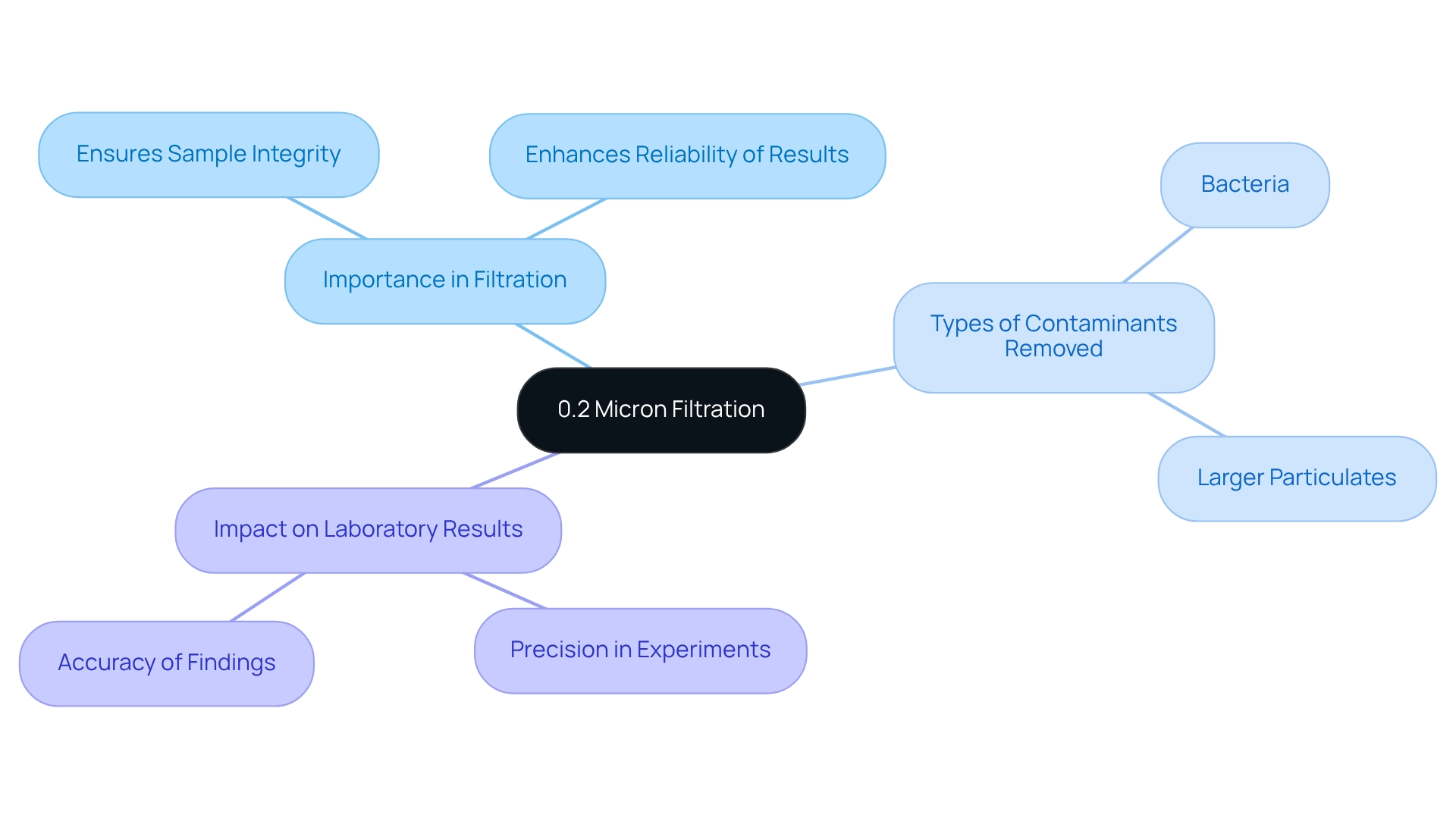

Understanding Pore Size: The Role of 0.2 Micron in Effective Filtration

The use of a 0.2 micron syringe filter is crucial for achieving efficient filtration, particularly in environments that require the removal of bacteria and larger particulates. Filters, such as the 0.2 micron syringe filter, effectively capture contaminants while permitting the desired liquid to flow through. This capability not only ensures the integrity of samples but also enhances the reliability of results. Understanding the importance of this filtration standard is essential for anyone involved in laboratory settings, where precision and accuracy are paramount.

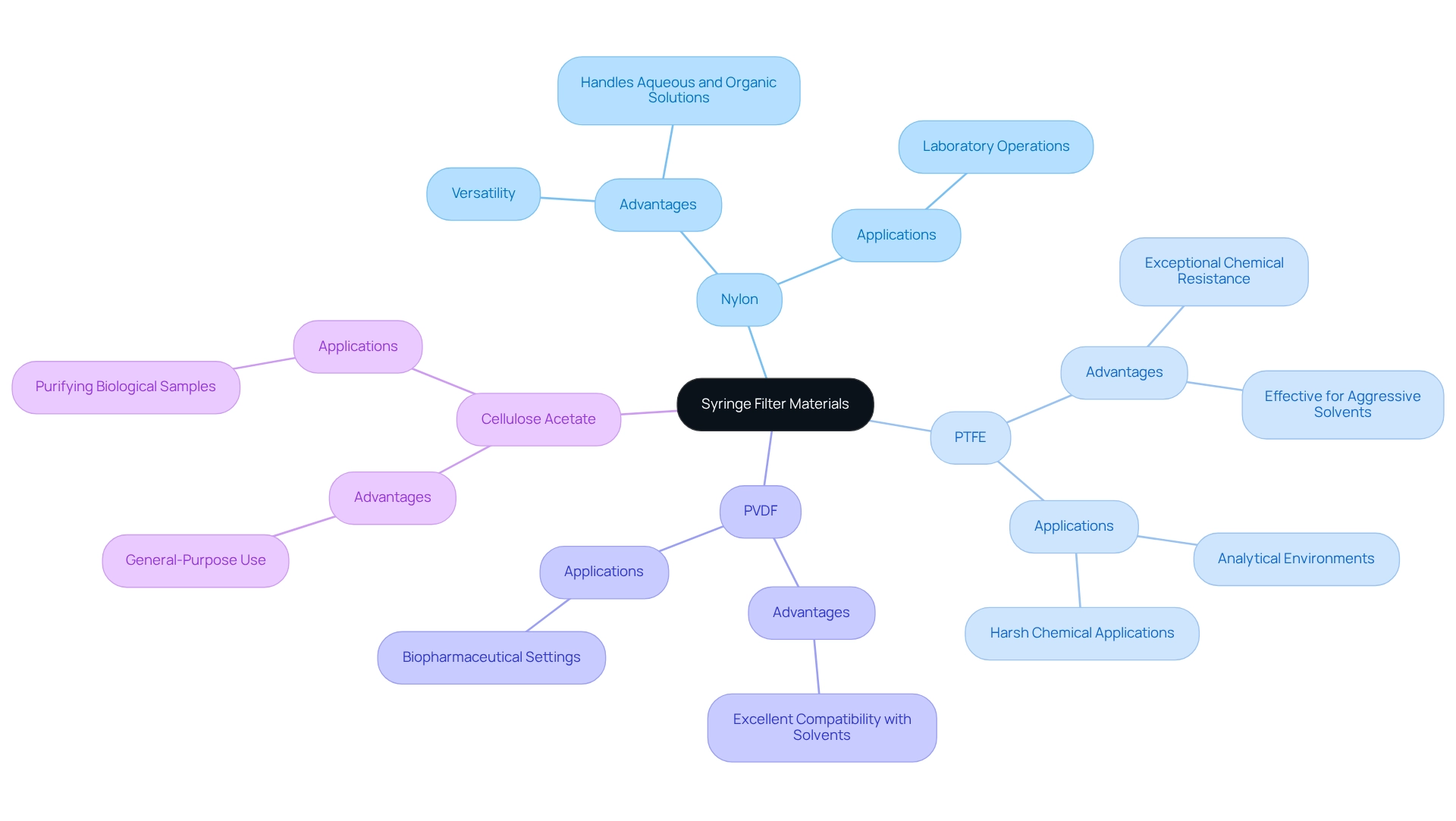

Syringe Filter Materials: Choosing the Right Composition for Your Needs

Syringe membranes are available in a variety of substances, including nylon, PTFE, PVDF, and cellulose acetate, each offering distinct advantages tailored to specific research applications. PTFE, for instance, is particularly effective for filtering aggressive solvents due to its exceptional chemical resistance, making it a preferred choice in numerous analytical environments. Conversely, nylon membranes are recognized for their versatility, efficiently handling both aqueous and organic solutions, which is vital for a wide range of laboratory operations.

Understanding the differences among these materials is essential for selecting the appropriate device. PTFE membranes excel in applications involving harsh chemicals, while PVDF demonstrates excellent compatibility with various solvents and is frequently favored in biopharmaceutical settings. In contrast, cellulose acetate membranes are suitable for general-purpose applications and are particularly effective in purifying biological samples.

Recent trends in the filtration market reveal a significant increase in investment by biopharmaceutical companies in research and development, anticipated to boost demand for high-quality filtration solutions. This trend underscores the importance of choosing the right material for the appropriate filtration device, as it can profoundly impact the effectiveness and precision of laboratory analyses. For instance, the diameter of needle barriers typically measures 33 mm, a detail that influences the selection of the screen based on the specific requirements of the application.

Expert opinions highlight that the most effective materials for 0.2 micron syringe filters often include PTFE and nylon, especially when dealing with various solvents. Practical applications illustrate the reliability of PTFE and nylon screens across different solvents, emphasizing their dependability in critical scientific processes. As noted by Sartorius, "the introduction of our new Grade 175 paper for analytical applications demonstrates the continuous advancement in filtration technology." By staying informed about the latest advancements and market trends in filtration materials, research facilities can enhance their separation strategies and ensure optimal outcomes in their analytical endeavors.

Sterilization Standards: Ensuring Safety with 0.2 Micron Syringe Filters

In clinical environments, the use of 0.2 micron syringe filters is indispensable, requiring strict adherence to rigorous sterilization standards to ensure safety and reliability. Common sterilization methods, such as gamma irradiation and ethylene oxide treatment, effectively eliminate microbial contamination. Additionally, ultrasonication employs high-frequency sound waves to disrupt microbes, although it does not achieve complete sterilization. Compliance with these standards is paramount, as it directly influences the integrity of experimental results and patient safety.

Recent studies reveal that facilities utilizing these sterilization techniques report high compliance rates with established safety protocols. For instance, gamma irradiation not only ensures thorough sterilization but also leaves no chemical residues, making it the preferred choice for sensitive applications. Conversely, while ethylene oxide treatment is effective, it necessitates careful handling due to its toxic nature, highlighting the need for stringent safety measures during the sterilization process. As noted by an expert, "These techniques are commonly utilized due to their effectiveness and usually leave no chemical residuals."

In clinical settings, case studies underscore the importance of maintaining sterile environments, particularly in facilities handling hazardous biological materials. For example, the decontamination of Bio Safety Cabinets (BSC) often employs methods such as hydrogen peroxide and chlorine dioxide, recognized for their efficacy in ensuring a sterile workspace. These procedures are critical for facilities striving to uphold the highest safety standards, especially concerning the sterilization of injection apparatus.

Safety protocol specialists assert that the selection of sterilization technique must align with the specific requirements of using a 0.2 micron syringe filter for the filtration application. As laboratory practices evolve, it is crucial to remain informed about the latest sterilization techniques and compliance standards to ensure the effectiveness of the 0.2 micron syringe filter in preventing contamination and safeguarding experimental integrity.

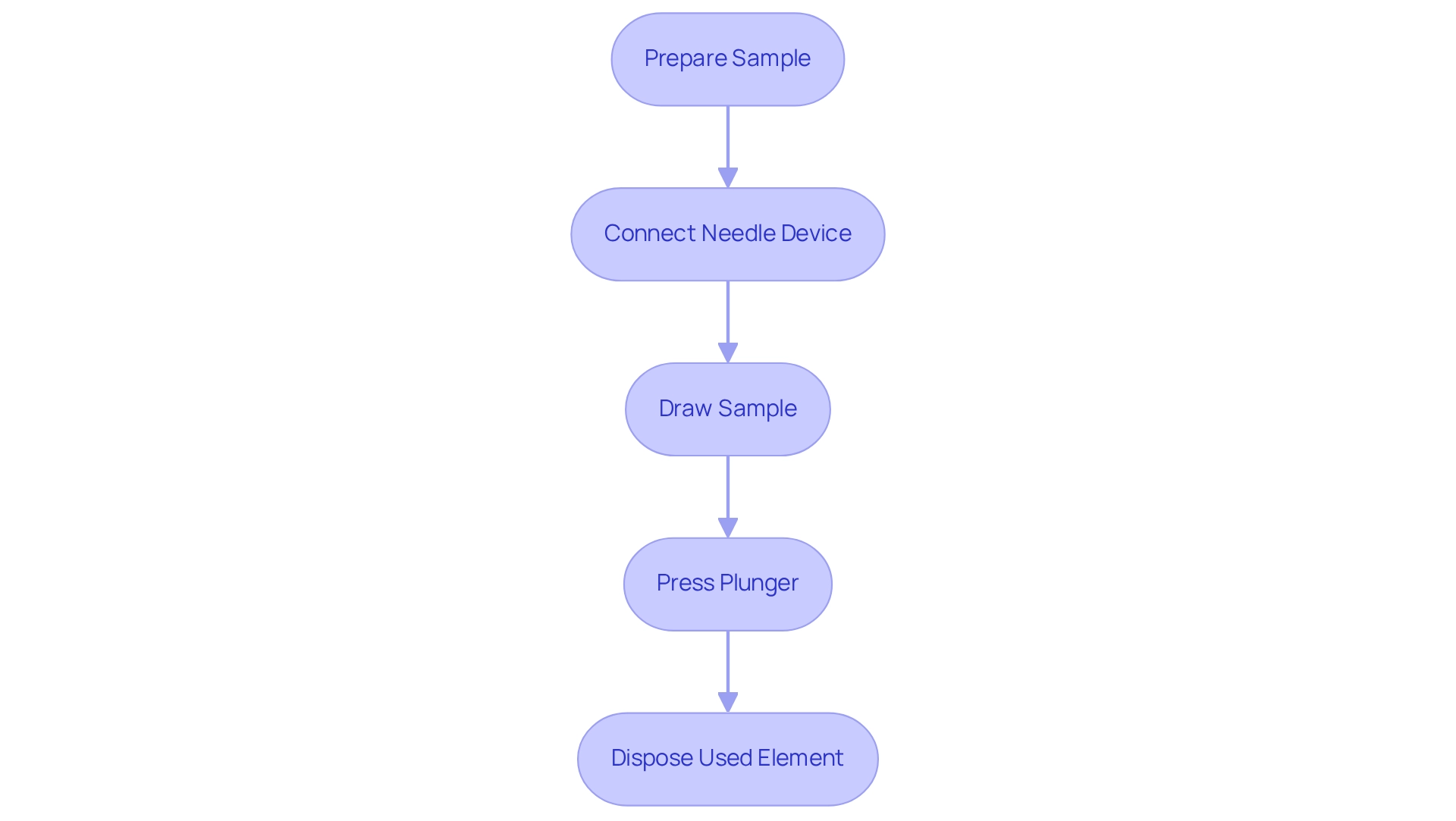

How to Use 0.2 Micron Syringe Filters: Step-by-Step Instructions

To effectively utilize a 0.2 micron syringe filter, it is crucial to follow these essential steps:

- Prepare your sample, ensuring it is devoid of large particulates that could compromise the integrity of your results.

- Securely connect the needle device to the injection apparatus, ensuring a firm attachment to prevent any leakage.

- Proceed to draw the sample into the injection device, taking care to maintain a steady hand for accuracy.

- Gently press the plunger to strain the sample through a 0.2 micron syringe filter and the needle assembly, directing it into a clean container to avoid contamination.

- Finally, dispose of the used element in accordance with your laboratory's waste disposal guidelines, ensuring compliance with safety protocols.

Following these steps meticulously will enhance the quality of your laboratory work.

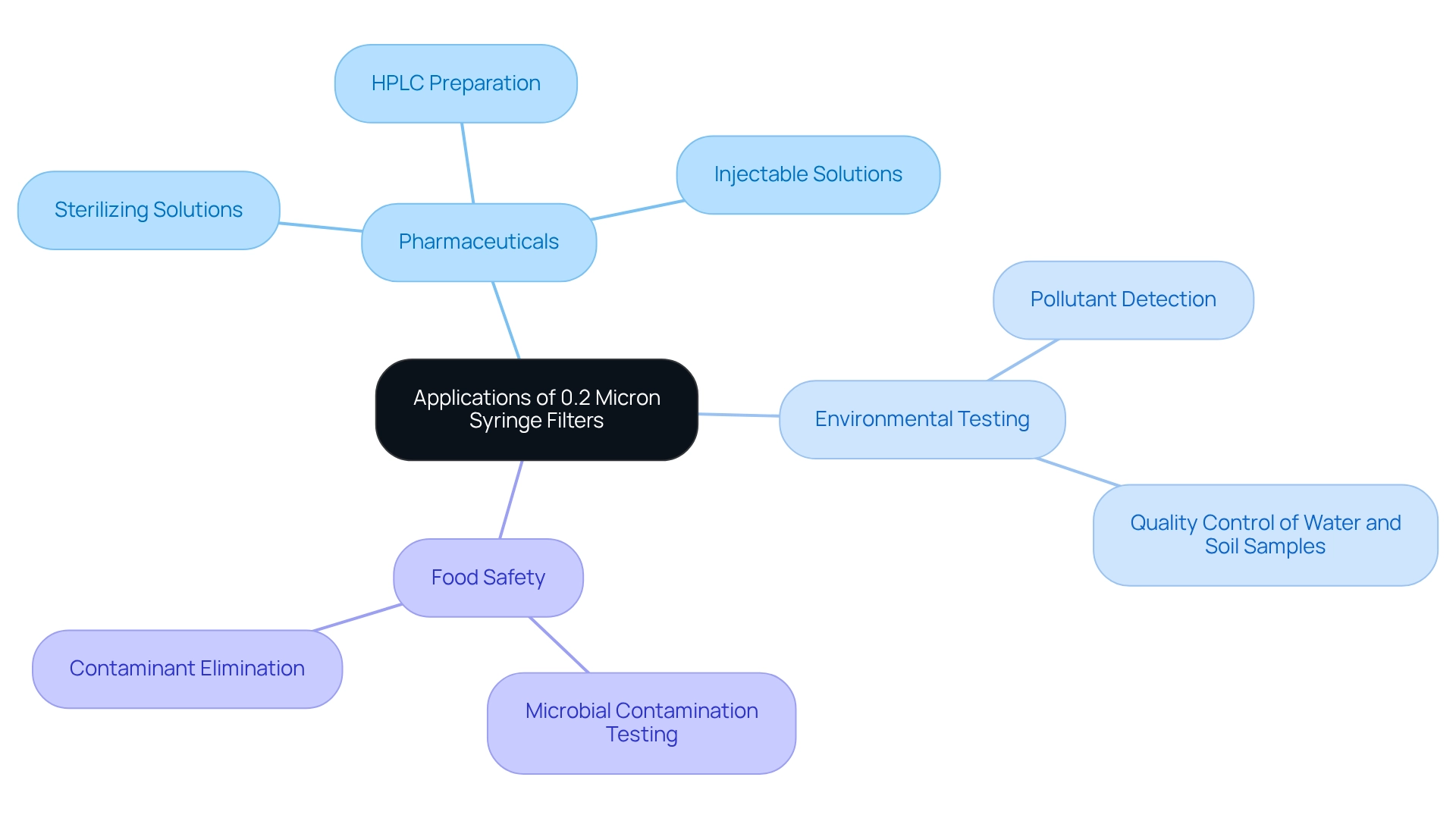

Applications of 0.2 Micron Syringe Filters: From Pharmaceuticals to Research

0.2 micron needle membranes play a crucial role in the pharmaceutical sector, primarily for sterilizing solutions, preparing samples for high-performance liquid chromatography (HPLC), and ensuring the purity of biological specimens. Their high chemical resistance and low extractables render them ideal for reliable sample preparation, which is vital for accurate analytical results. Researchers emphasize that these devices are instrumental in minimizing contamination, thereby enhancing the reliability of experimental outcomes.

The environmental testing sector has witnessed significant growth in the use of 0.2 micron medical devices, driven by an increasing demand for stringent quality control measures. These devices are essential for ensuring that water and soil samples are free from particulates that could interfere with analysis. A recent study underscored their effectiveness in detecting pollutants in water samples, highlighting their indispensable role in environmental monitoring. Projections indicate that the adoption rate of 0.2 micron membranes in environmental testing is expected to rise substantially, underscoring the industry's commitment to quality assurance.

In the pharmaceutical industry, the utilization of 0.2 micron syringe filters has surged, particularly in the formulation of injectable solutions. Their capability to eliminate bacteria and particulates with a 0.2 micron syringe filter ensures that products comply with safety standards, which is crucial for patient care. Case studies reveal that pharmaceutical companies employing these devices have improved product quality and regulatory compliance. JM Science's commitment to quality and customer support, including resources such as instructional videos and usage libraries, further enhances the value of these products in achieving high standards.

Expert insights highlight the versatility of 0.2 micron medical devices across various applications, including food and beverage analysis. They are utilized to eliminate contaminants in samples, ensuring product safety for consumers. Real-world examples demonstrate their application in testing for microbial contamination in food products, further emphasizing their significance in safeguarding public health.

As technological advancements continue to influence the filtration landscape, the market for medical devices is projected to expand, driven by environmental demands and innovations in research methodologies. Industry leaders reflect this trend, stating, "For example, we can now help our customers take a new therapeutic from idea to injection, starting with discovery, through process development, to large-scale manufacturing." The unwavering dedication to quality and customer support from companies like JM Science enhances the value proposition of these essential tools, ensuring that facilities have access to reliable filtration solutions.

Advantages of 0.2 Micron Syringe Filters: Why They Are Essential

The 0.2 micron syringe filter is an essential instrument in research environments, known for its ability to efficiently remove bacteria and particulates, thereby safeguarding sample integrity. Their single-use design significantly mitigates the risk of cross-contamination between samples, chemicals, or biological substances, which is crucial for maintaining the accuracy of analytical results. Not only are these devices easy to use, but they are also economical, making them a favored option for facilities operating under budget constraints.

In terms of compatibility, 0.2 micron devices integrate seamlessly with a diverse array of solvents, enhancing their versatility across various applications. Their reliability is underscored by numerous studies indicating that they consistently produce reproducible results, which is essential for high-performance liquid chromatography (HPLC) sample preparation. An organized ordering procedure for filtration devices ensures that research facilities select the appropriate specifications tailored to their specific filtration needs, ultimately resulting in enhanced operational efficiency. This process is highlighted in the case study titled "Ordering Syringe Filters," which emphasizes the importance of adhering to a structured approach.

Cost-effectiveness statistics reveal that employing 0.2 micron syringe filters can yield significant savings in laboratory expenses, particularly when considering the potential costs associated with equipment damage from blocked HPLC columns. Laboratory supervisors have noted that these devices not only enhance the reliability of their analyses but also contribute to overall workflow efficiency. Expert insights stress that the elimination of microorganisms and impurities through these devices is vital for obtaining precise and reproducible measurements, underscoring their crucial role in research and diagnostics. Furthermore, injection device membranes can be packaged separately and gamma-irradiated for sterility, further ensuring sample integrity. When placing an order for needle cartridges, it is essential to confirm all specifications and quantities to facilitate proper procurement.

Selecting the Right Syringe Filter: Key Considerations for Users

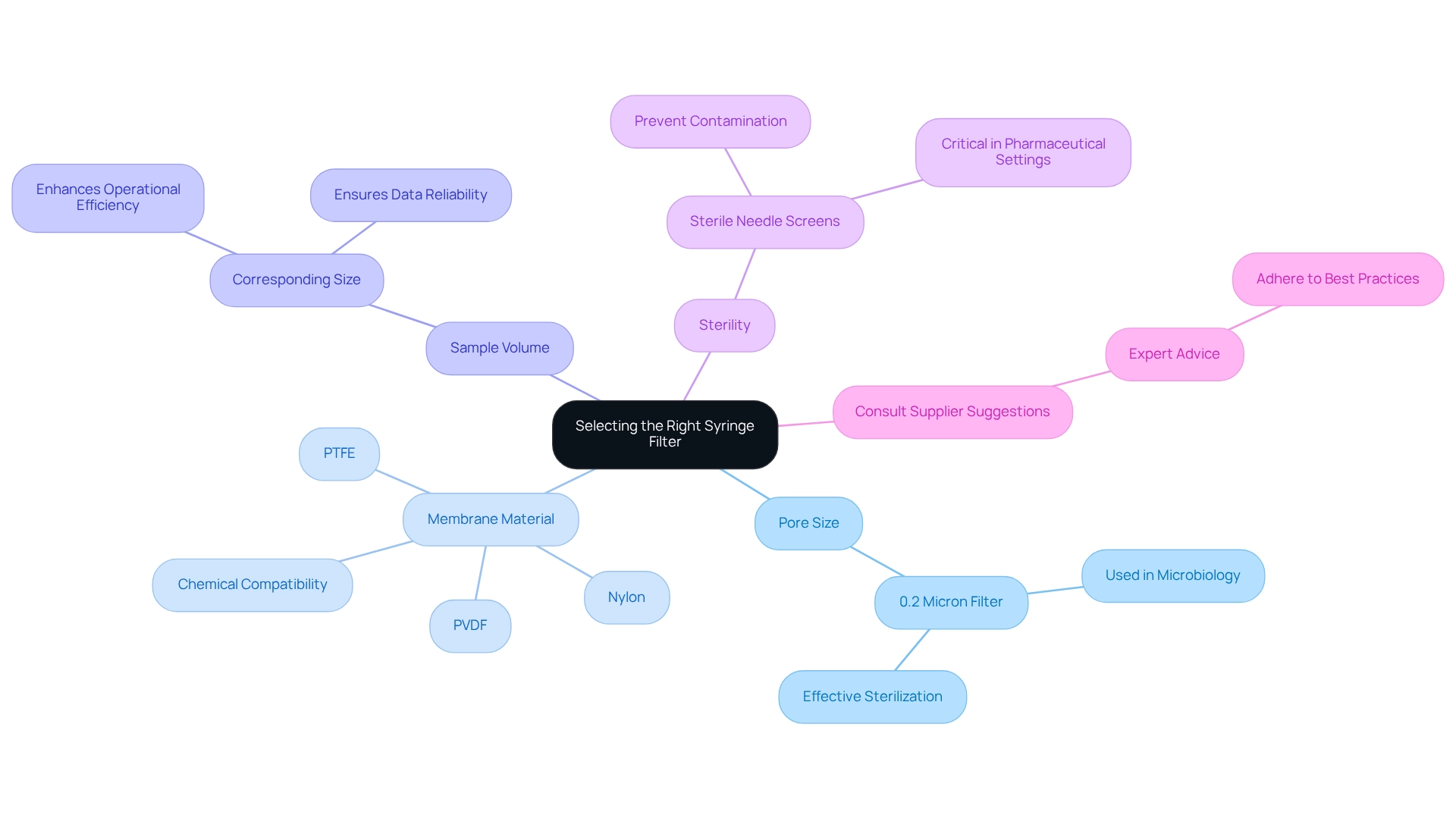

Selecting the appropriate syringe membrane is crucial for achieving reliable results in laboratory applications. To ensure optimal outcomes, consider the following key factors:

- Pore Size: The membrane's pore size must align with your specific application requirements. For example, the 0.2 micron syringe filter is widely utilized in microbiology and cell culture to guarantee effective sterilization and eliminate contaminants. In these contexts, sterile syringe membranes are vital to prevent contamination that could compromise experimental results.

- Membrane Material: Opt for a membrane material that exhibits chemical compatibility with your samples. Various materials, including nylon, PTFE, and PVDF, provide differing levels of resistance to solvents and acids, which can significantly influence filtration efficiency.

- Sample Volume: Ensure that the size of the membrane corresponds to your sample volume. Selecting the right membrane size can greatly enhance operational efficiency and ensure the reliability of data, ultimately improving the quality of your experiments.

- Sterility: Assess whether your application requires sterile membranes. Sterile needle screens are imperative in scenarios where contamination could endanger outcomes, particularly in pharmaceutical and clinical settings.

- Consult Supplier Suggestions: It is wise to refer to supplier recommendations and seek expert advice when selecting injection devices for research purposes. This approach can aid in choosing membranes that adhere to best practices in filtration.

By prioritizing these considerations, laboratories can select needle pass-throughs that meet their unique needs while contributing to precise and reliable outcomes. The findings from the case study titled "Evaluating Syringe Filters for Laboratory Applications" underscore the significance of evaluating membrane material, pore size, sample compatibility, and sterility during the selection process. By focusing on these critical factors, you can enhance the quality of your experiments and ensure dependable results.

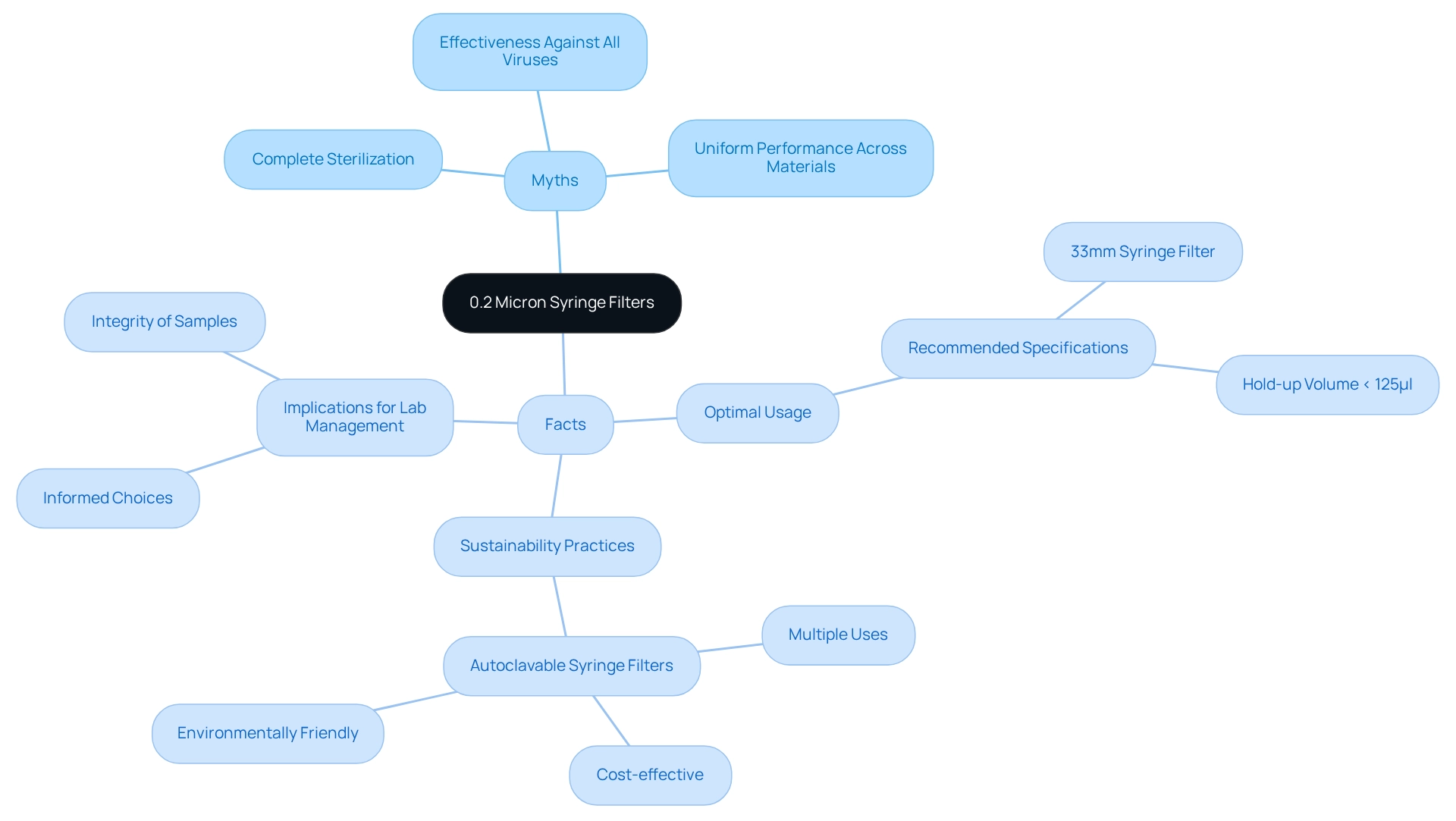

Debunking Myths: What You Should Know About 0.2 Micron Syringe Filters

Misconceptions abound regarding 0.2 micron syringe filters, particularly the notion that they can achieve complete sterilization of all solutions. While these devices effectively remove bacteria, they do not guarantee the elimination of all viruses or smaller particles, which may still pass through. This limitation is crucial for lab managers to understand; relying solely on these filters for thorough sterilization can lead to inadequate results in critical applications. Moreover, the effectiveness of the 0.2 micron syringe filter can vary significantly depending on the material and construction used. Studies indicate that for sample volumes between 10-200ml, a 33mm syringe strainer with a hold-up volume of less than 125μl is optimal for precise filtration tasks.

A case study on autoclavable syringe devices highlights their ability to be sterilized for multiple uses, promoting both economical and sustainable practices in laboratories. This feature enhances usability while simultaneously encouraging environmentally friendly practices by reducing waste associated with single-use items. Understanding the distinct capabilities of various types of filters is therefore essential. Additionally, distinguishing between myths and facts regarding the sterilization capabilities of injection devices is vital. By addressing these prevalent misconceptions, lab managers can make more informed choices about filtration methods, ultimately ensuring the integrity of their samples.

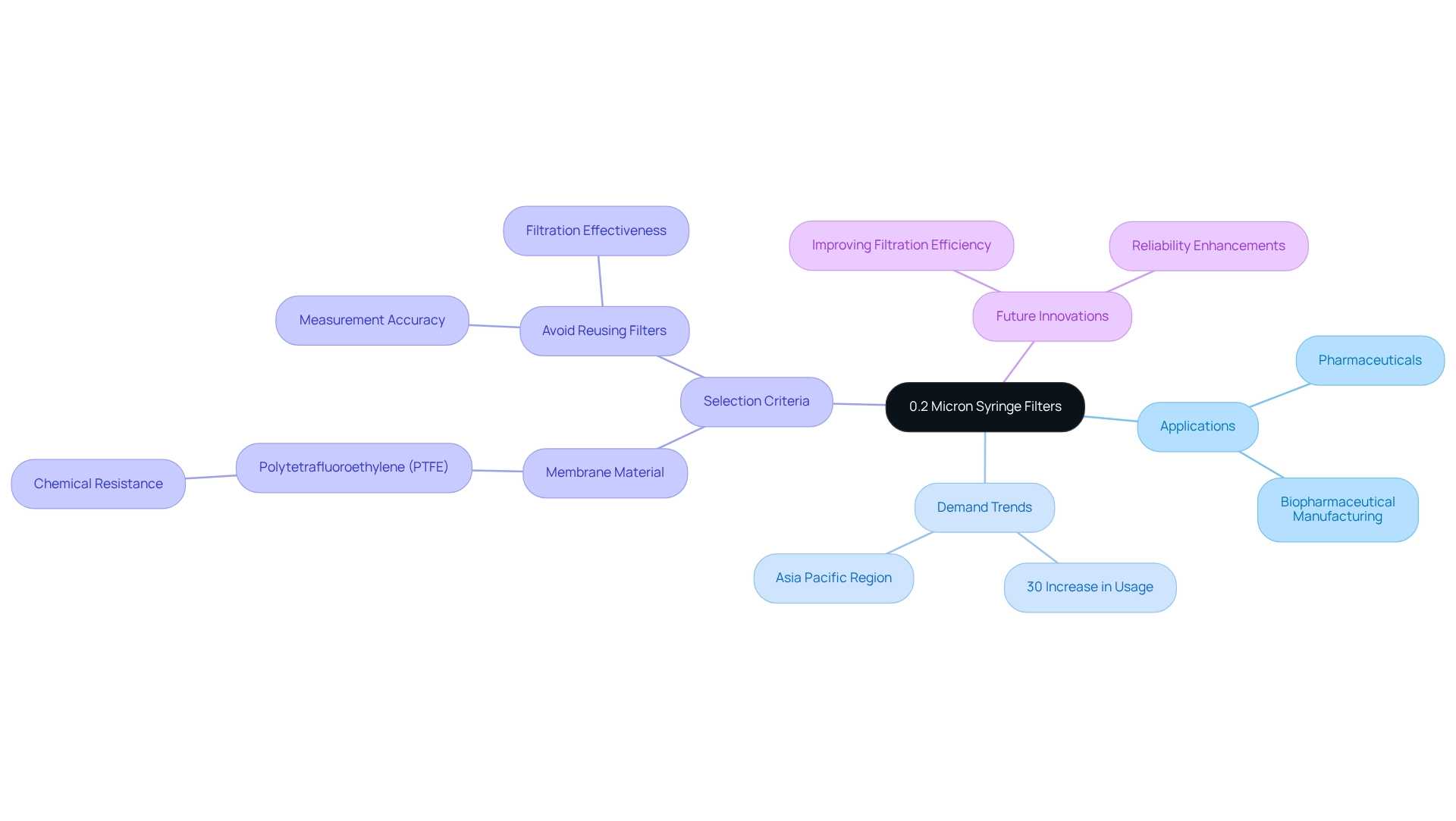

Key Takeaways: Essential Insights on 0.2 Micron Syringe Filters

0.2 micron syringe filters are indispensable in laboratory environments, providing unmatched accuracy and reliability in sample preparation. Their applications extend across various sectors, particularly in pharmaceuticals and biopharmaceutical manufacturing, where preserving sample integrity is of utmost importance. These devices excel in their ability to eliminate particulates and microorganisms, ensuring analyses yield precise results.

Recent trends indicate a significant increase in the demand for syringe membranes, particularly in the Asia Pacific region, where biopharmaceutical production is on the rise. This surge is anticipated to result in a 30% increase in usage, fueled by investments in local biologics manufacturing. As highlighted in the case study titled "Opportunities in Biopharmaceutical Manufacturing," this demand is essential for both upstream and downstream processes, underscoring the growing dependence on high-quality filtration solutions in contemporary laboratories.

Laboratory professionals emphasize the importance of selecting the appropriate membrane based on pore size, material, and specific application requirements. For instance, polytetrafluoroethylene (PTFE) membranes are preferred for their superior chemical resistance, making them suitable for aggressive solvents. However, it is crucial to avoid reusing needle screens, as this practice can compromise measurement accuracy and filtration efficiency. Ursula Koslik, Director of Marketing & PR, states, "The future of needle technology is promising, with ongoing innovations aimed at improving filtration efficiency and reliability."

To optimize the use of 0.2 micron syringe filters, consistent training for personnel on proper usage techniques is essential, alongside maintaining an inventory of 0.2 micron syringe filters tailored for various applications. By adhering to these guidelines, facilities can enhance their analytical capabilities and ensure the reliability of their results. As filtration technology continues to advance, industry leaders anticipate developments that will further enhance the efficiency and effectiveness of syringe filters in laboratory settings. JM Science's dedication to updating product offerings and fostering strong partnerships with leading manufacturers positions them as a pivotal player in addressing these evolving demands.

Conclusion

The multifaceted advantages of 0.2 micron syringe filters highlight their essential role in laboratory research, particularly within the pharmaceutical and biotechnology sectors. Their capacity to effectively eliminate bacteria and particulates ensures sample integrity, which is crucial for reliable analytical results. As the demand for precise filtration solutions continues to escalate, it becomes increasingly vital to understand the significance of pore size, material composition, and sterilization standards.

From their robust construction to their adaptability across various applications, these filters not only enhance workflow efficiency but also contribute to the accuracy of experiments. Innovations in filter technology, combined with rigorous adherence to sterilization standards, further reinforce their reliability in critical laboratory processes.

In conclusion, 0.2 micron syringe filters are indispensable tools that empower laboratories to achieve their analytical goals. By selecting the appropriate filter based on specific needs and adhering to best practices, laboratories can significantly enhance their results while upholding the highest safety standards. As the landscape of laboratory practices evolves, the commitment of manufacturers like JM Science to quality and innovation will be crucial in meeting the increasing demands for effective filtration solutions.