Overview

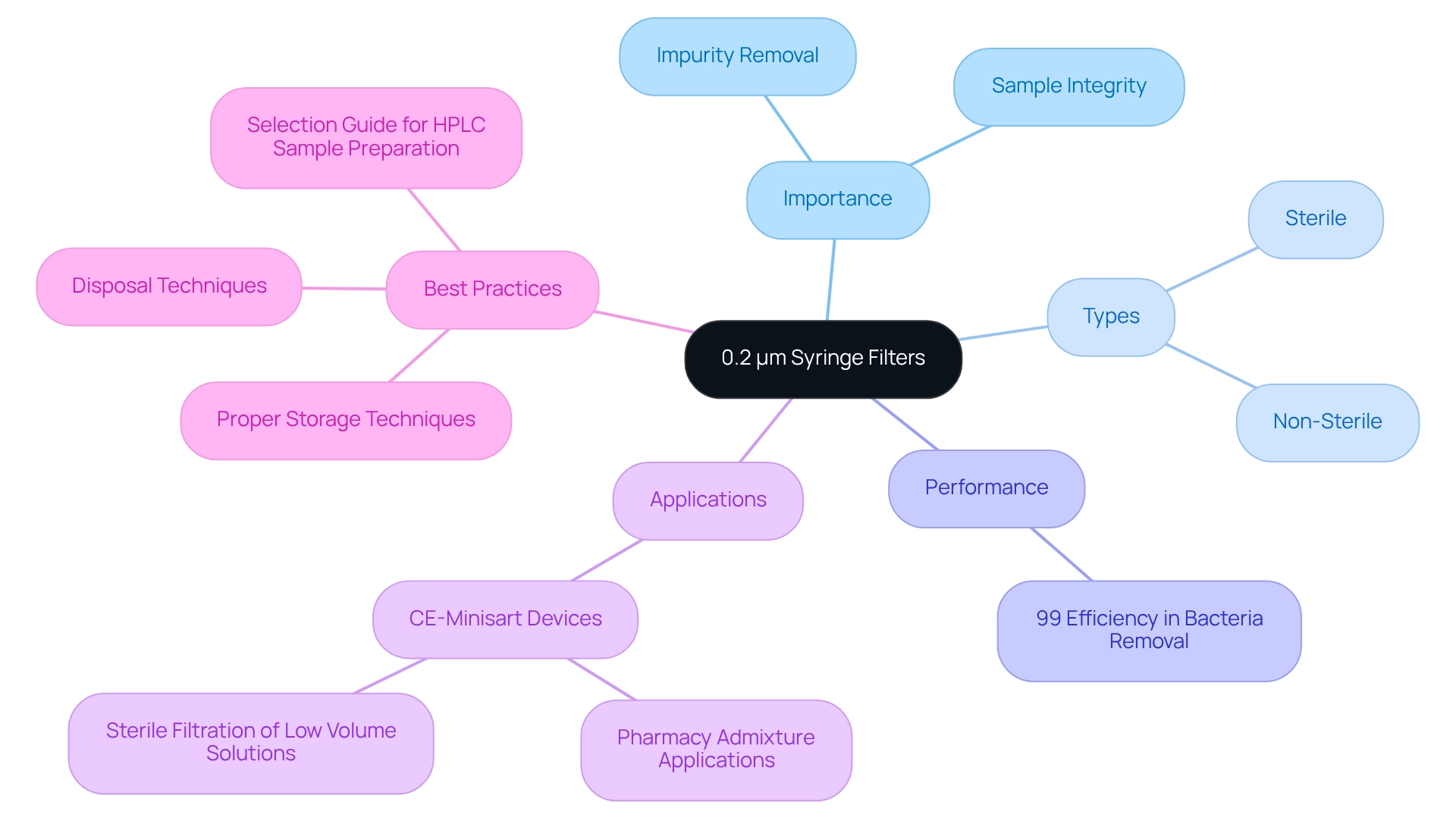

This article delves into the essential facts surrounding 0.2 µm syringe filters, underscoring their critical role in laboratory applications for the removal of impurities from liquid specimens. These filters are pivotal in enhancing the accuracy and reliability of analytical results by effectively eliminating particulates and microorganisms.

Furthermore, it is crucial to highlight the importance of proper usage, storage, and disposal practices. Such measures are vital for maintaining the filters' effectiveness and upholding laboratory standards, ensuring that scientific integrity is preserved in every analysis.

Introduction

In the realm of scientific research, precision is paramount, especially in sample preparation and analysis. JM Science's 0.2 µm syringe filters have emerged as essential tools for laboratories aiming to eliminate particulate impurities and ensure the accuracy of their results. As the demand for reliable filtration solutions continues to grow, these filters play a vital role in applications ranging from high-performance liquid chromatography (HPLC) to microbiological testing. By focusing on maintaining sample integrity, the use of these high-performance filters not only enhances workflow efficiency but also significantly contributes to the overall reliability of laboratory outcomes. This article delves into the significance of 0.2 µm syringe filters, exploring their applications, best practices for use, and the critical considerations for selecting the right filter to meet the evolving needs of the scientific community.

JM Science 0.2 µm Syringe Filters: Precision for Laboratory Applications

JM Science's 0.2 um syringe filters are engineered for precise separation across a range of scientific applications. These screens excel in eliminating particulate contaminants from liquid specimens, which is crucial for ensuring accurate and reliable analyses. Their high-performance design is particularly beneficial for sensitive applications, such as high-performance liquid chromatography (HPLC) and microbiological testing, where even the slightest contamination can jeopardize results. By employing these screens, research facilities can uphold the integrity of their specimens, significantly enhancing workflow efficiency.

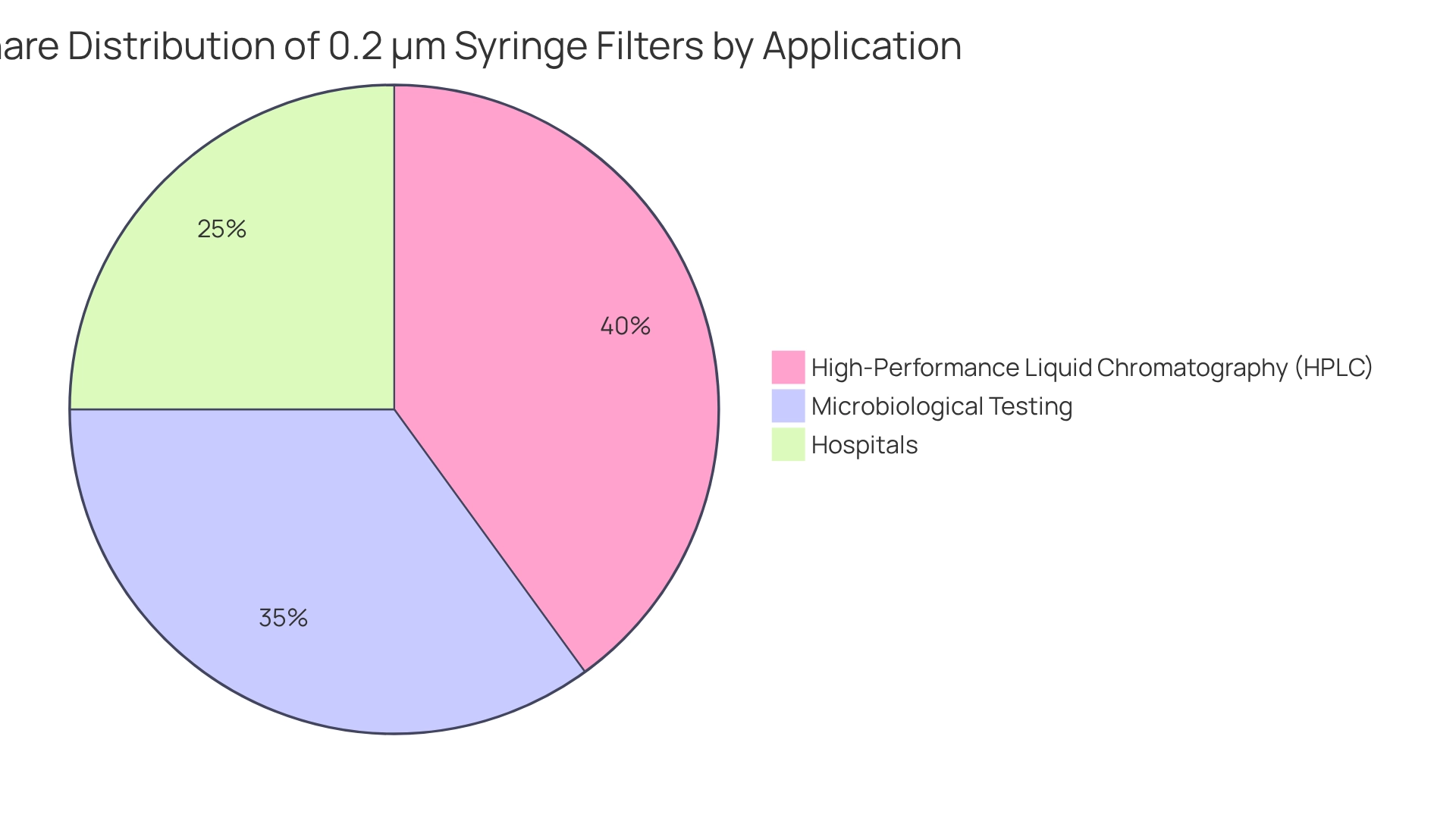

In line with JM Science's commitment to providing top-tier scientific instruments, recent statistics underscore a growing reliance on 0.2 um syringe filters within research environments, emphasizing their importance in maintaining high standards of precision filtration. According to a case study titled "Factors Driving Growth in Europe Medical Sterile Syringe Filters Market," the increasing demand for these devices in various applications, including hospitals and research facilities, highlights their effectiveness in improving the quality of analyses. Moreover, the market share of 0.2 um syringe filters in analytical applications continues to expand, underscoring their essential role in contemporary laboratory workflows. As the need for reliable purification solutions escalates, JM Science's 0.2 µm injection devices emerge as critical components, enabling researchers to achieve optimal outcomes in their scientific endeavors.

Understanding Syringe Filters: Purpose and Applications in Laboratories

Membrane-based devices are essential, disposable tools designed to connect to the end of a needle, primarily aimed at eliminating particulate matter from liquid specimens before analysis. Their applications are wide-ranging, including the preparation of specimens for high-performance liquid chromatography (HPLC), sterilization of culture media, and clarification of solutions across various scientific disciplines. By ensuring that specimens are free of impurities, needle strainers play a critical role in maintaining the precision and reliability of test outcomes.

Recent insights reveal an increasing reliance on filtration devices in laboratories, particularly for specimen preparation. Laboratory supervisors have expressed a preference for these devices due to their effectiveness in microbiological testing, where preserving sample integrity is paramount. The latest trends show a rising usage of injection device screens, especially those using 0.2 um syringe filters, which are favored for their ability to efficiently eliminate bacteria and other particulates.

In HPLC applications, injection device screens serve as a fundamental barrier against impurities that could compromise analytical results. Their significance in microbiological examinations is equally pronounced; for instance, utilizing autoclavable injection devices allows facilities to uphold stringent hygiene standards while minimizing waste and costs associated with single-use products. This dual functionality not only enhances operational efficiency but also contributes to more accurate and reliable analytical outcomes. As emphasized by GVS Malaysia, "GVS Malaysia's commitment to providing a wide range of high-quality needle cartridges assists laboratories in achieving more precise and reliable analytical outcomes, which ultimately results in improved data and safer practices."

Experts assert that the role of these filtration devices extends beyond mere filtering; they are vital for ensuring the safety and reliability of experimental processes. As research facilities evolve, the integration of 0.2 um syringe filters will remain a cornerstone of effective preparation and analysis.

Importance of 0.2 µm Pore Size: Ensuring Effective Filtration

The 0.2 um syringe filters, with their 0.2 µm pore size, are critical in research environments due to their effectiveness in eliminating bacteria and other microorganisms. This specific size is vital for applications requiring sterilization, such as the preparation of culture media or specimens for microbiological analysis, which often utilize 0.2 um syringe filters. By utilizing 0.2 µm needles from JM Science Inc., laboratories can ensure their specimens remain free from microbial contamination, significantly enhancing the reliability and accuracy of their experimental results.

To fully leverage the benefits of these instruments, it is recommended to select options that are compatible with the particular solvents and samples being used, thereby ensuring optimal performance in purification processes.

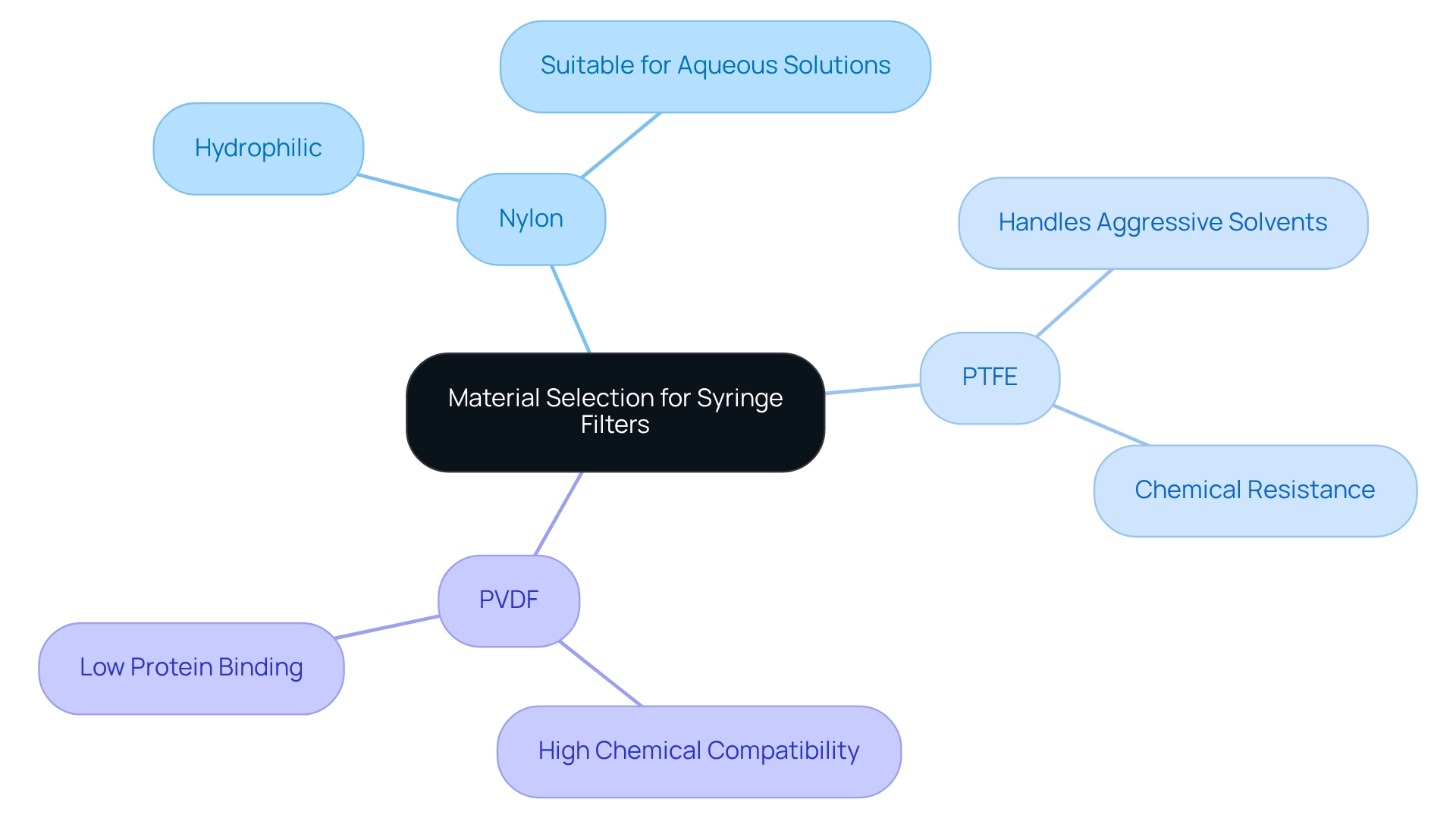

Material Selection for Syringe Filters: Impact on Chemical Compatibility

The composition of syringe membranes plays a crucial role in determining their chemical compatibility and overall performance. Common materials such as nylon, PTFE, and PVDF each possess distinct properties tailored for specific applications. For example:

- Nylon membranes are hydrophilic, making them well-suited for aqueous solutions.

- PTFE membranes excel in handling aggressive solvents.

Selecting the appropriate material is essential; it ensures that the device does not release impurities into the specimen, thereby preserving the integrity of the analysis. This careful consideration not only enhances the reliability of results but also underscores the importance of high-quality scientific instruments in laboratory settings.

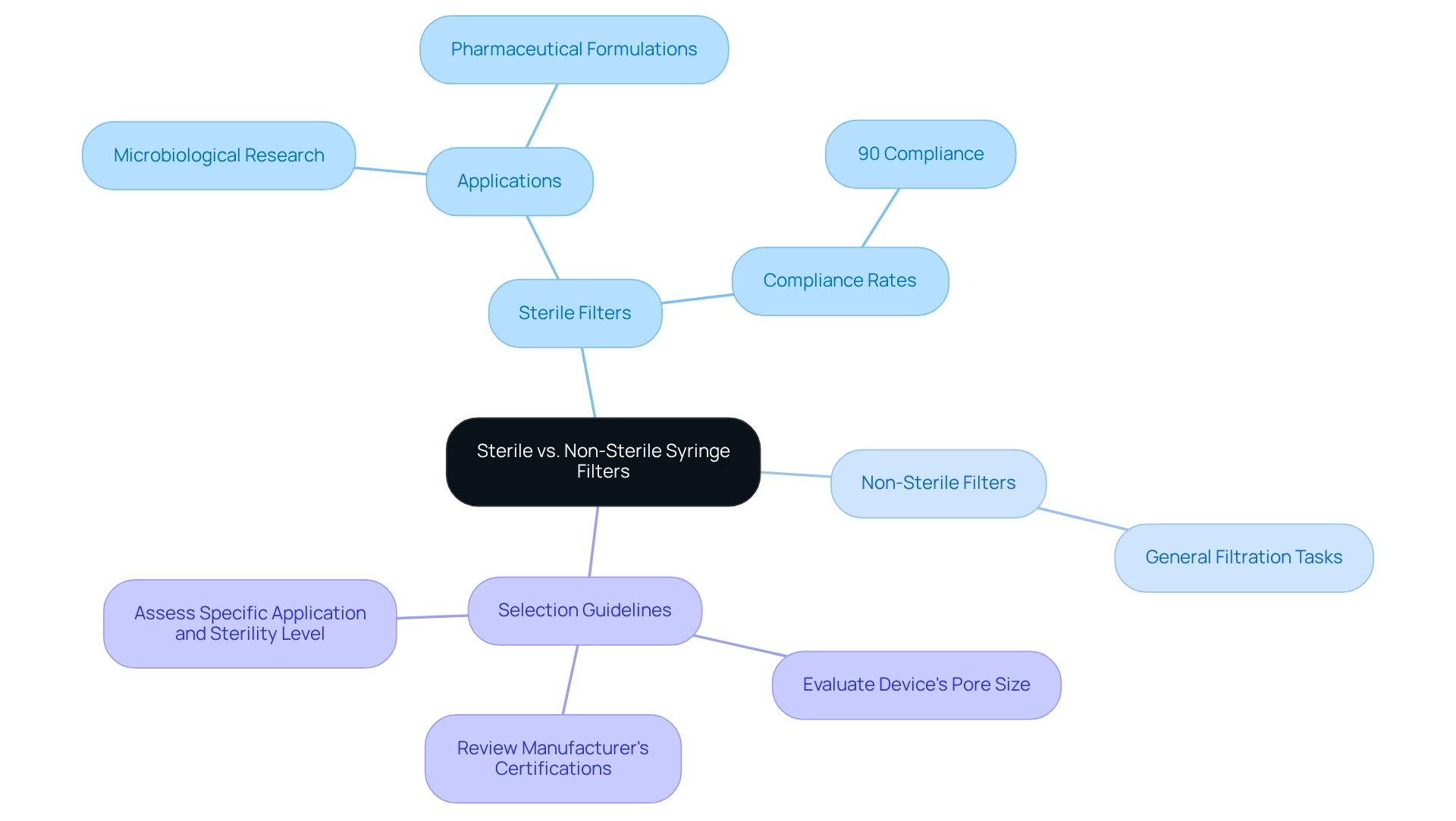

Sterile vs. Non-Sterile Syringe Filters: Choosing the Right Option

When selecting membrane filters, laboratories face the critical decision of choosing between sterile and non-sterile options. Sterile syringe membranes are indispensable for applications that demand contamination-free samples, particularly in microbiological research and pharmaceutical formulations. These devices are meticulously designed to eliminate any microbial presence, thereby safeguarding the integrity of sensitive analyses. Research indicates that facilities employing sterile sieves for microbiological investigations report compliance rates exceeding 90%, underscoring the vital role of sterility in maintaining quality standards. Conversely, non-sterile sieves may suffice for general filtration tasks, yet they must never be utilized in scenarios where sterility is paramount. Understanding these distinctions is essential for facilities aiming to uphold stringent safety and quality benchmarks, ultimately ensuring the reliability of their results.

In the realm of microbiological research, facility managers must consider several guidelines when selecting needle-based filtration devices:

- It is crucial to assess the specific application and the required level of sterility.

- Evaluating the device's pore size is necessary to confirm it meets the specifications for its intended use.

- Reviewing the manufacturer's certifications and compliance with industry standards is imperative.

By adhering to these guidelines, laboratories can enhance their filtration processes and guarantee the quality of their specimens, especially within the context of developing next-generation drugs in the biologics market, which poses unique challenges that demand innovative solutions.

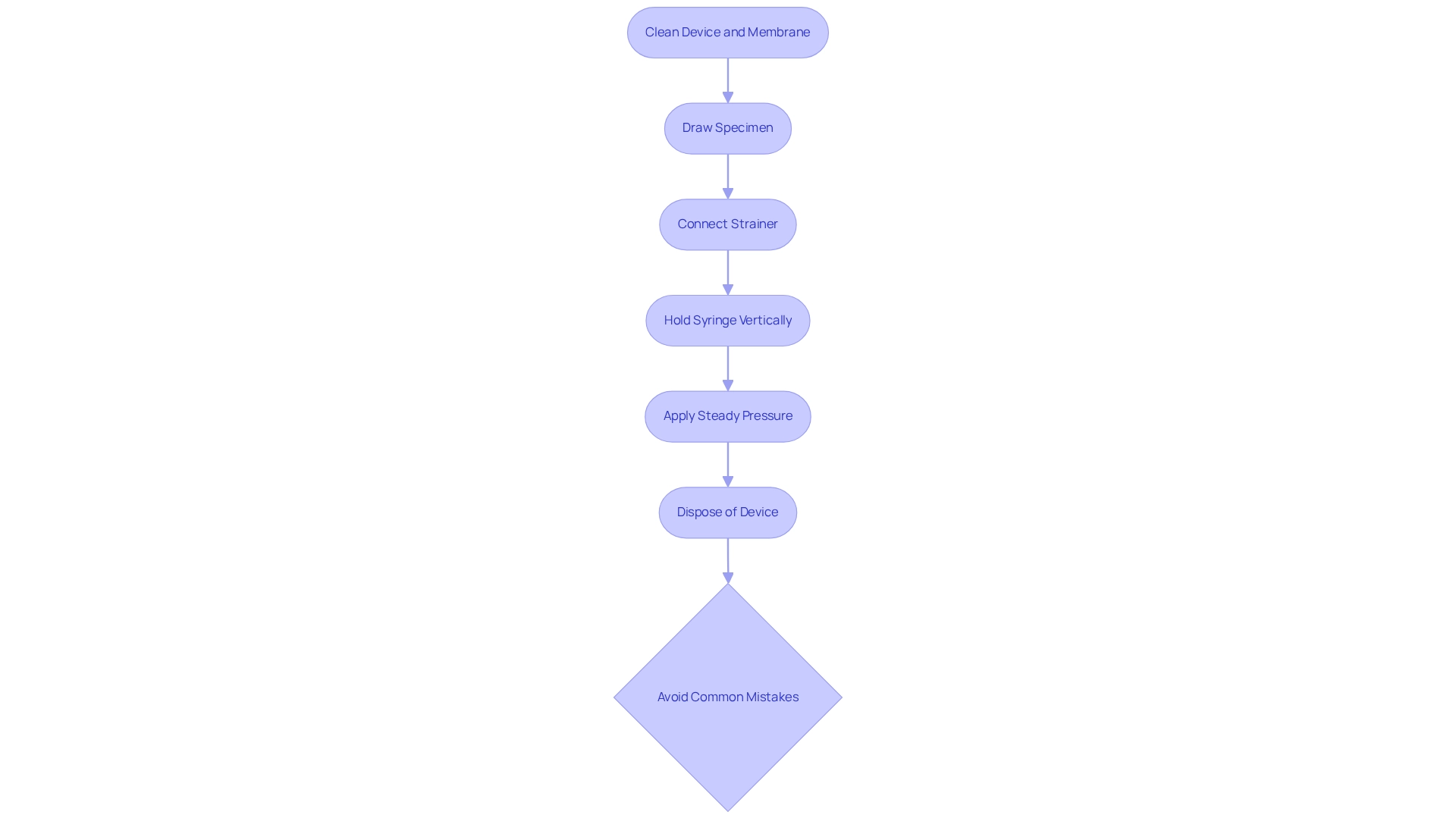

How to Use 0.2 µm Syringe Filters: Best Practices

To effectively utilize 0.2 um syringe filters, it is imperative to adhere to best practices that ensure optimal performance. Begin by ensuring that both the device and the membrane are meticulously cleaned and free from contaminants. Next, gently draw the specimen into the injection device, taking care to prevent air bubbles, and firmly connect the strainer. Remember, the capacity of the device ranges from 0.5 ml to 200 ml; thus, selecting the appropriate size based on your volume requirements is crucial. Hold the syringe in a vertical position and apply gentle, steady pressure to push the sample through the membrane. Avoid excessive force, as this can compromise the integrity of the membrane. After use, it is essential to discard the device in accordance with waste disposal procedures to ensure safety and compliance.

As highlighted in a case study on JM Science's adaptability to market needs, continually updating product offerings is vital for meeting the evolving demands of the scientific community. Additionally, as one experienced lab technician noted, 'Effective filtration techniques are vital for ensuring accurate results in any laboratory process.' This underscores the importance of employing proper methods in laboratory settings.

Lastly, be aware of common mistakes in membrane usage, such as neglecting to pre-wet the device or selecting the incorrect size. These oversights can significantly affect your outcomes, which underscores the importance of using 0.2 um syringe filters in laboratory practices.

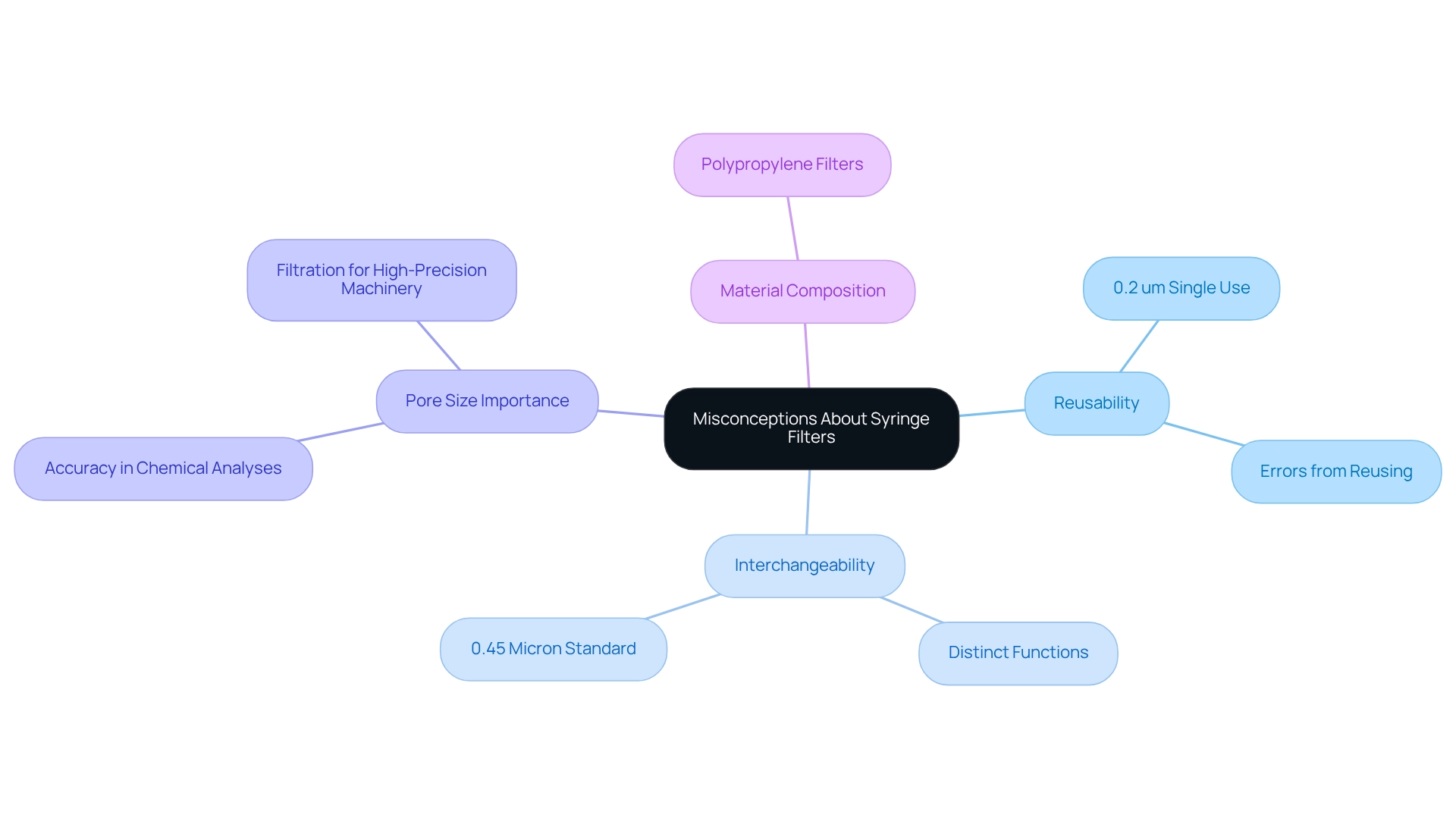

Debunking Myths: Common Misconceptions About Syringe Filters

Misunderstandings regarding injection device screens are prevalent, particularly the erroneous belief that they can be reused safely or that all screens are interchangeable. In reality, 0.2 um syringe filters are specifically designed for single use, making them a crucial choice that prevents contamination and preserves the integrity of samples.

Each type of strainer serves distinct functions, determined by its pore size and material composition. Notably, 0.45 micron is recognized as the standard size for bacterial filtration, underscoring the importance of selecting the appropriate medium for specific applications.

Polypropylene devices, valued for their cost-effectiveness, are commonly employed for general purification tasks in laboratories and industrial settings. Misconceptions about the reuse of sieves can lead to significant errors in test results, as evidenced by case studies in the chemical sector where 0.2 um syringe filters are essential for removing particulates from solutions prior to examination.

These devices ensure the accuracy of chemical analyses and the proper functioning of high-precision machinery. By grasping these critical facts, laboratory personnel can avoid costly errors and improve their filtration processes.

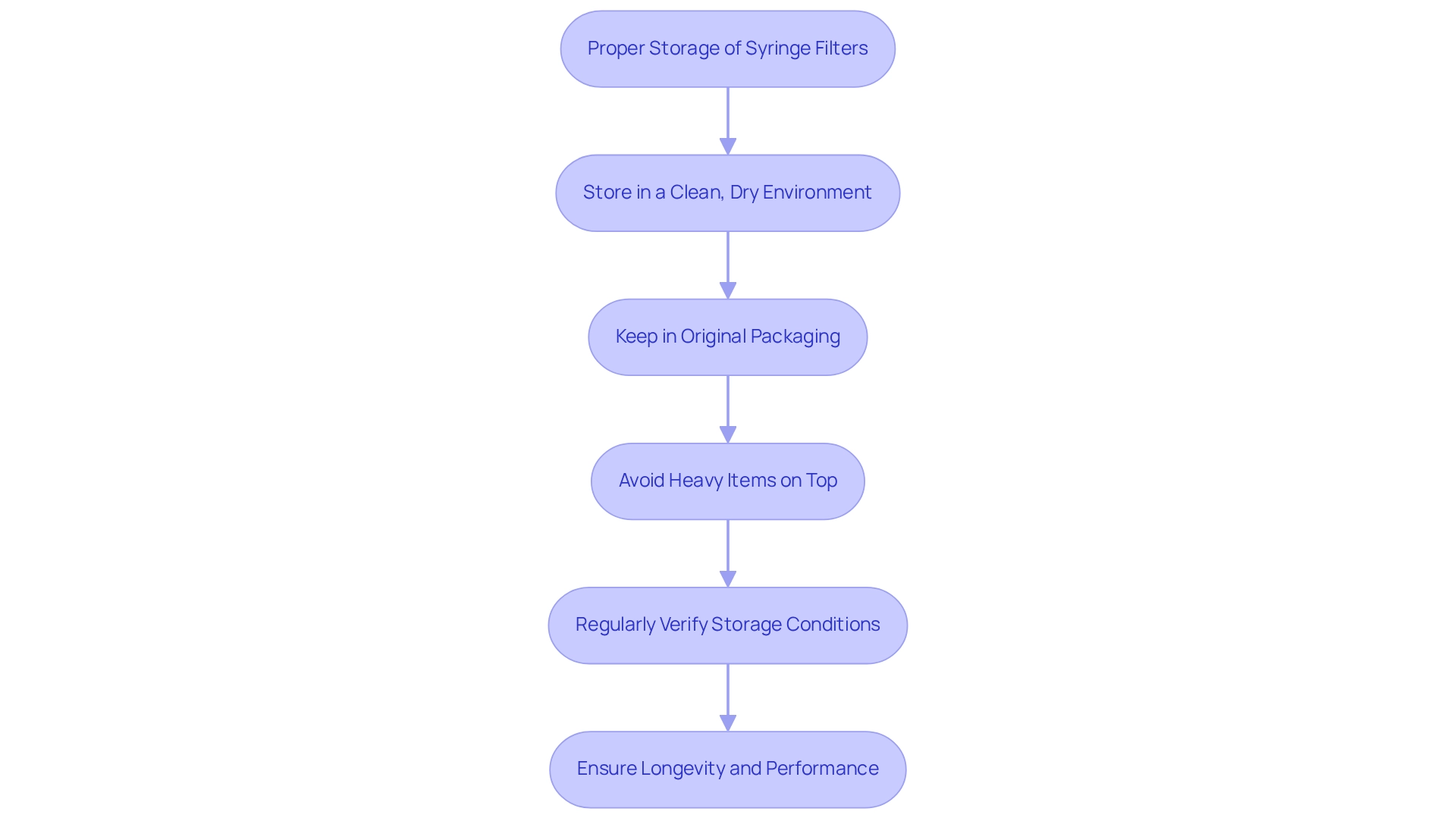

Storage and Handling of Syringe Filters: Ensuring Longevity and Performance

To enhance the longevity and performance of syringe devices, it is essential to store them in a clean, dry environment, shielded from direct sunlight and extreme temperatures. Maintaining the items in their original packaging until use is critical to prevent contamination. Additionally, avoid placing heavy items on top of the screens, as this can cause physical damage.

Adhering to these storage guidelines not only preserves the integrity of the devices but also guarantees reliable performance when they are needed. JM Science Inc. is dedicated to continually updating its product offerings, contributing to advancements in research and healthcare, and ensuring that users have access to the latest innovations in filtration technology.

To optimize your storage practices, consider creating a checklist to regularly verify that storage conditions remain ideal. Remember, improper storage can compromise the integrity of the system and lead to unreliable results, underscoring the importance of following these best practices.

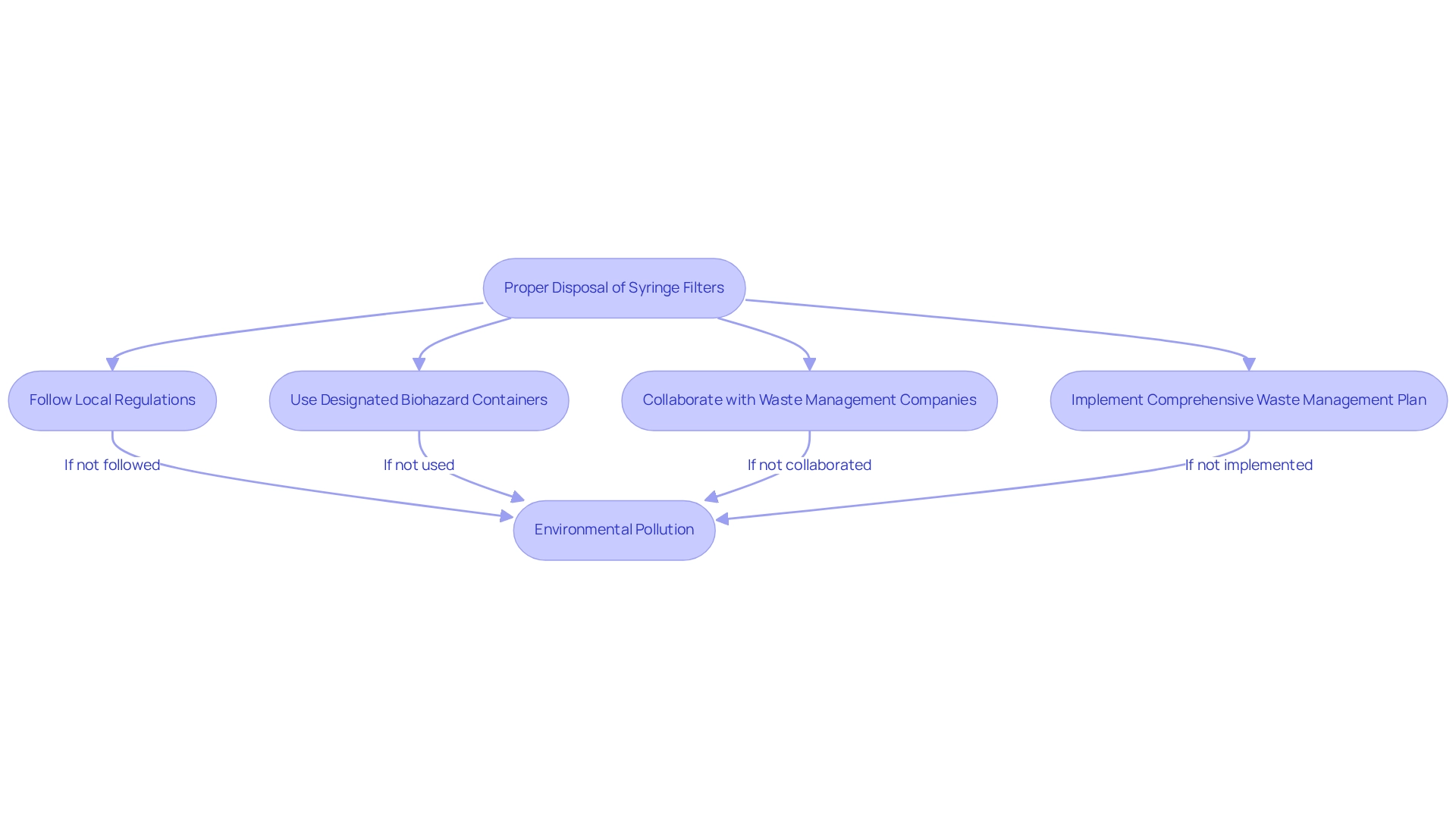

Environmental Considerations: Proper Disposal of Syringe Filters

Proper disposal of syringe membranes is essential for reducing environmental impact. Used filters must be disposed of in accordance with local regulations, typically in designated biohazard waste containers. The rise in medical waste by 40% since the onset of the Covid-19 outbreak underscores the necessity for efficient waste management approaches in research facilities. Implementing a comprehensive waste management plan that includes recycling options, where available, can significantly mitigate the ecological footprint of research operations.

Research facilities can adopt sustainable disposal practices by collaborating with waste management companies that specialize in hazardous waste, ensuring compliance with current regulations. Mark Chocola, a leading figure in hazardous waste disposal, emphasizes, "With over 25 years of experience in the hazardous waste disposal industry, we are committed to providing safe, compliant, and cost-effective hazardous waste solutions." This statement highlights the importance of partnering with experts in the field.

The inappropriate disposal of medical device components can lead to environmental pollution, making it crucial for research facilities to prioritize appropriate waste management to mitigate these hazards. Current guidelines mandate that facilities adhere to specific procedures for disposing of waste, including 0.2 um syringe filters, to prevent harmful substances from entering ecosystems. By following established protocols and exploring innovative recycling solutions, research facilities not only comply with health and safety regulations but also contribute to broader environmental sustainability efforts. This proactive approach is essential for fostering a responsible scientific community committed to protecting our planet.

Key Takeaways: Essential Facts About 0.2 µm Syringe Filters

0.2 um syringe filters are indispensable in laboratory environments, as they play a crucial role in the effective removal of impurities from fluid specimens. Their precision and compatibility with a range of materials are vital for preserving sample integrity and ensuring dependable analytical results. The implementation of these devices can significantly enhance the quality of experiments, as they are engineered to eliminate particulates and microorganisms that could jeopardize outcomes.

Understanding the differences between sterile and non-sterile options is essential for applications demanding aseptic conditions, representing best practices in their usage. Additionally, proper storage and disposal techniques further augment their effectiveness, ensuring these devices remain reliable throughout their lifecycle. For instance, CE-Minisart injection devices are specifically tailored for pharmacy admixture applications, demonstrating their suitability for sterile separation and clarification of low-volume solutions in research settings. These membranes are biocompatible according to ISO 10993-1 and can be subjected to gamma irradiation or sterilization with ethylene oxide, making them ideal for patient care applications while minimizing adsorption.

Statistics indicate that the use of 0.2 um syringe filters can achieve over 99% efficiency in the removal of bacteria and particulates, highlighting their significance in analytical processes. Practical examples illustrate how research facilities have optimized their purification workflows using these devices, leading to enhanced accuracy in results and increased operational efficiency. By adhering to established protocols and leveraging the features of 0.2 um syringe filters, laboratories can substantially improve high-quality analytical outcomes and advance their research objectives. Furthermore, Sartorius provides a selection guide for their Minisart syringe filters, assisting laboratories in selecting the appropriate filter for HPLC sample preparation, thereby enhancing the efficacy of their filtration processes.

Conclusion

The significance of JM Science's 0.2 µm syringe filters in laboratory settings is paramount. These filters are meticulously engineered to ensure precise filtration, effectively removing particulate impurities that can jeopardize the integrity of liquid samples. Their critical role in applications such as high-performance liquid chromatography (HPLC) and microbiological testing underscores their importance in achieving reliable and accurate analytical results. By employing these filters, laboratories not only enhance workflow efficiency but also uphold the highest standards of quality in their research.

Understanding the various aspects of syringe filters—including pore size, material compatibility, and the distinction between sterile and non-sterile options—is essential for laboratory personnel. Adherence to best practices in usage, storage, and disposal further optimizes the performance of these filters, ensuring they contribute effectively to the reliability of laboratory outcomes. As the demand for dependable filtration solutions continues to rise, the adoption of high-quality 0.2 µm syringe filters remains a cornerstone of effective sample preparation and analysis.

Ultimately, integrating 0.2 µm syringe filters into laboratory protocols not only enhances the accuracy of results but also supports the scientific community in achieving its research objectives. By prioritizing the use of these essential tools, laboratories can significantly improve their operational efficiency and contribute to advancements in various scientific fields. Embracing these filtration solutions is a vital step toward maintaining the integrity of experimental processes and ensuring the reliability of findings in an ever-evolving research landscape.